-

-

February 22, 2023 at 6:09 pm

javat33489

SubscriberHi all.

Please tell me this is the problem.

I have a task with an interference fit.

- First, I plant a part on another part through the ekill.

- Then I move the stretched part. If I use a stiffness factor of 0.02 in contacts.

The problem is solved faster, there are no stress concentrators at the points in the solution. But when using the stiffness factor, the resulting stress is less than without it. How to understand what is more correct, with or without the stiffness factor?

-

February 23, 2023 at 7:14 am

Rahul Kumbhar

Ansys EmployeeI assume you are referring to contact normal stiffness factor. 0.02 is very less value. You should get more accurate results with higher stiffness factor. But again it can increase the convergence difficulty.

-

February 24, 2023 at 1:54 pm

Akshay Maniyar

Ansys EmployeeHi javat33489,

Contact normal stiffness affects both accuracy and convergence behavior. A large value of stiffness gives better accuracy and less penetration, but the problem may become more difficult to converge. If the contact stiffness is too large, the model may oscillate, with contacting surfaces bouncing off each other. With large normal stiffness, the normal contact force will be high, and because of which contact was unstable. We generally need to find a balance between allowable penetration and accuracy needed to decide the normal stiffness factor. You can also check below Ansys How to video on interference fit.

https://www.youtube.com/watch?v=5jH2Ox6-YkU

Thank you,

Akshay Maniyar

How to access Ansys help links

Guidelines for Posting on Ansys Learning Forum

-

February 24, 2023 at 7:45 pm

javat33489

SubscriberThanks for the info. There is no information on stiffnes in the video.

-

February 28, 2023 at 5:08 pm

javat33489

SubscriberThank you I saw this video. Then tell me, when can the Stifness factor be applied so that it does not introduce an error into the calculation? HE helps to make convergence better, but makes a strong error, the problem can be solved incorrectly.

-

March 5, 2023 at 7:33 pm

javat33489

Subscriber???

-

-

-

March 6, 2023 at 5:11 am

Akshay Maniyar

Ansys EmployeeHi javat33489,

Normal Stiffness Factor property appears when the Normal Stiffness property is set to Factor. It enables you to specify the Normal Stiffness Factor. Only non-zero positive values are supported. The usual factor range is from 0.01 – 10. The default value is selected by the application. A smaller value provides for easier convergence but with more penetration.

Determining a good stiffness value may require some experimentation on your part. To arrive at a good stiffness value, you can try the following procedure as a "trial run":

- Use a low value for the contact stiffness to start. In general, it is better to underestimate this value rather than overestimate it. Penetration problems resulting from a low stiffness are easier to fix than convergence difficulties that arise from a high stiffness.

- Run the analysis up to a fraction of the final load (just enough to get the contact fully established).

- Check the penetration and the number of equilibrium iterations used in each substep. If the global convergence difficulty is caused by too much penetration (rather than by residual forces and displacement increments), FKN (Normal penalty stiffness factor) may be underestimated or FTOLN(Penetration tolerance factor) may be too small. If the global convergence requires many equilibrium iterations for achieving convergence tolerances of residual forces and displacements rather than the resulting penetration, FKN may be overestimated.

- Adjust FKN, FTOLN, or SLTO (Allowable elastic slip) as necessary and run the full analysis. If the penetration control becomes dominant in the global equilibrium iterations (that is, if more iterations were used to converge the problem to within the penetration tolerance than to converge the residual forces), you may increase FTOLN to permit more allowable penetration or increase FKN.

Below Ansys video might help you in understanding the contact penetration.

Thank you,

Akshay Maniyar

How to access Ansys help links

Guidelines for Posting on Ansys Learning Forum

-

March 8, 2023 at 5:42 pm

javat33489

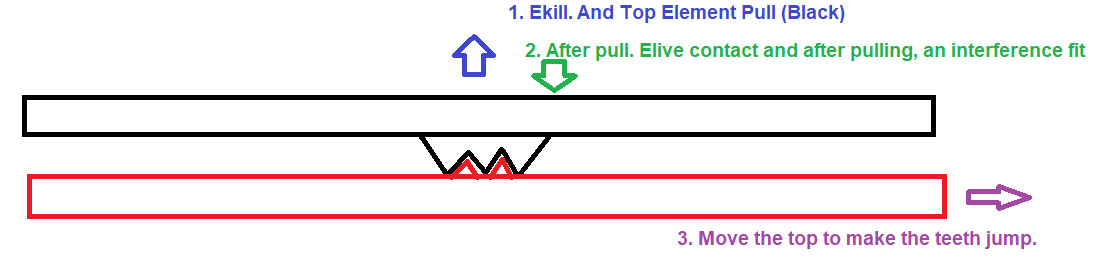

SubscriberThanks for the answer. Now I am solving the problem of teeth interference fit and their failure.

Now I'm solving the problem of engagement. And it is important to me with what force the teeth will jump. For this I use force reaction. I use metal ductility, bilinear isotropic hardening and large diflection. I have a constant error with the grid DISTORTED 9999999. If I set the stiffness factor to 0.01, then the problem is sometimes solved, but this gives a strong error in the calculation, refining the grid does not help, I tried different triangular and square grids. I also tried using NORMAL LAGRANGE. I use friction contact 0.1. Augmented Lagrange, Axysymmetric, Nodal Normal to target, Add Offset ramped effects.

All teeth are rounded.

Please give me advice on how to solve this problem.

-

March 8, 2023 at 5:57 pm

Akshay Maniyar

Ansys EmployeeHi javat33489,

Thank you for the update. Can you start a new forum thread as it is a new question? It will be useful for other users as well for reference.

Thank you,

Akshay Maniyar

-

March 8, 2023 at 7:35 pm

javat33489

Subscriber

-

-

- The topic ‘Stiffness factor’ is closed to new replies.

-

4613

-

1530

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.