-

-

October 18, 2023 at 5:45 am

shubc

SubscriberHi,

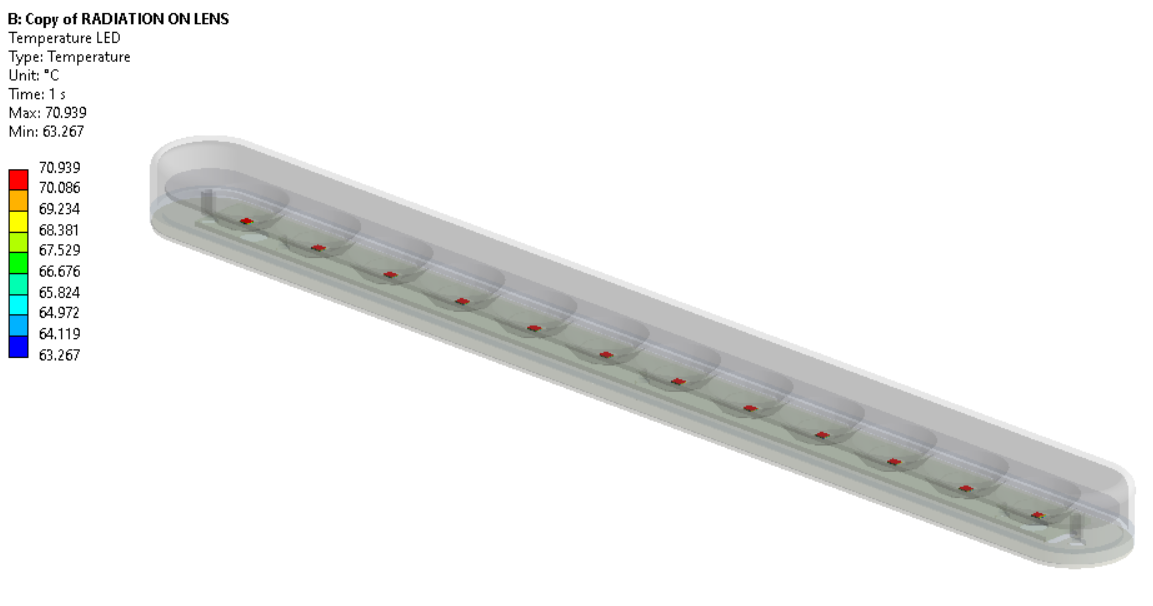

I am performing the simulation of Steady state thermal for A lamp which is illuminated by number of LED's.

Providing voluemtric heat generation rate in ANSYS workbench, with Radiation boundary condition to LENS of 0.85 Emissivity.

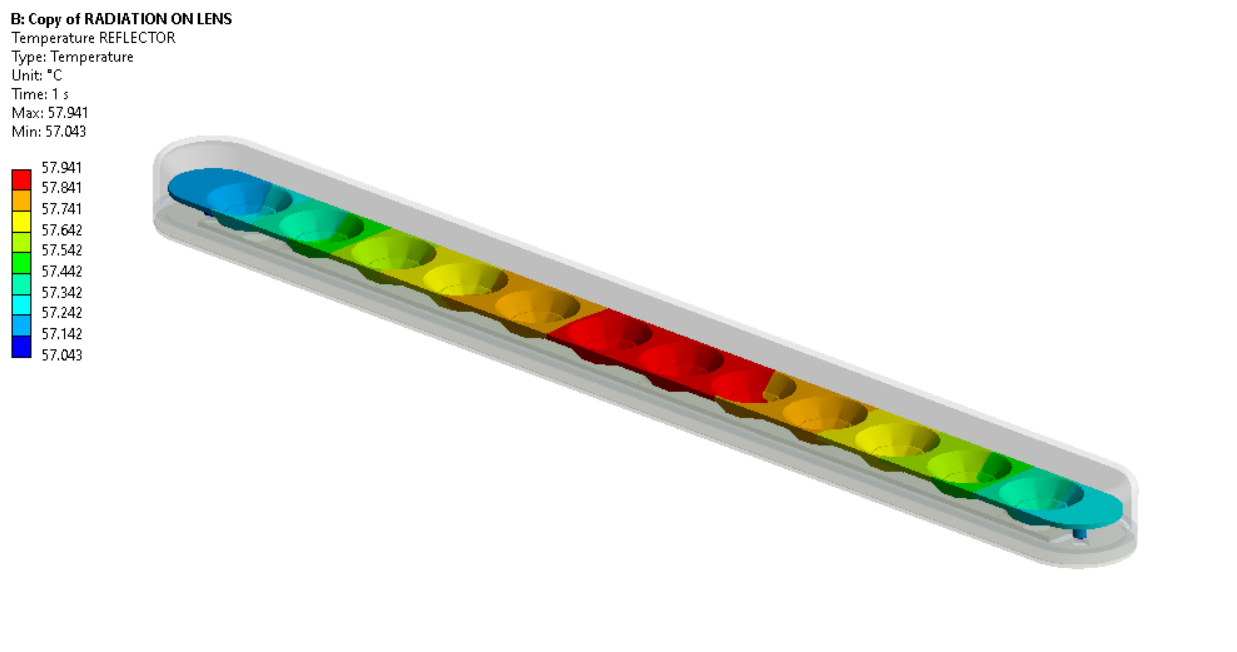

What i Found is, the temperature are higher at the middle and then get lowered as they move from center.

This is quite not understanding as all the LED of same dimensions, volumetric heat flux is same for all the LED.

Then why temperature contour showing maximum temperature at center and lower temperature at end of domain.

As it is steady state simulation the Temperature generated by the LED and heat flow should be constant at every instant of geometry. Attached are the images for reference.

As we can see in above image that, LED are generating equal temperature distribution along the thickness.

In above image which on the reflectors, the Temperature rise at middle is at 57.9 and at end its 57.04. Why?

-

November 17, 2023 at 9:43 am

C N

Ansys EmployeeHello Shubham,

The difference in temperature is very small. I would recommend you to check the boundary condition and what type of radiation model you have used. To improve your accuracy I recommend you to follow the user guide link for setting up appropriate radiation model for your application. Kindly check this.

15.3. Modeling Radiation (ansys.com)

I hope this helps you in your simulation.

Thanks,

-

- The topic ‘Steady state thermal analysis Simulation of LED’ is closed to new replies.

-

4708

-

1565

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.