TAGGED: Spark-ignition

-

-

September 11, 2023 at 6:31 am

pavol.tarbajovsky

Subscriber -

September 19, 2023 at 3:03 pm

pavol.tarbajovsky

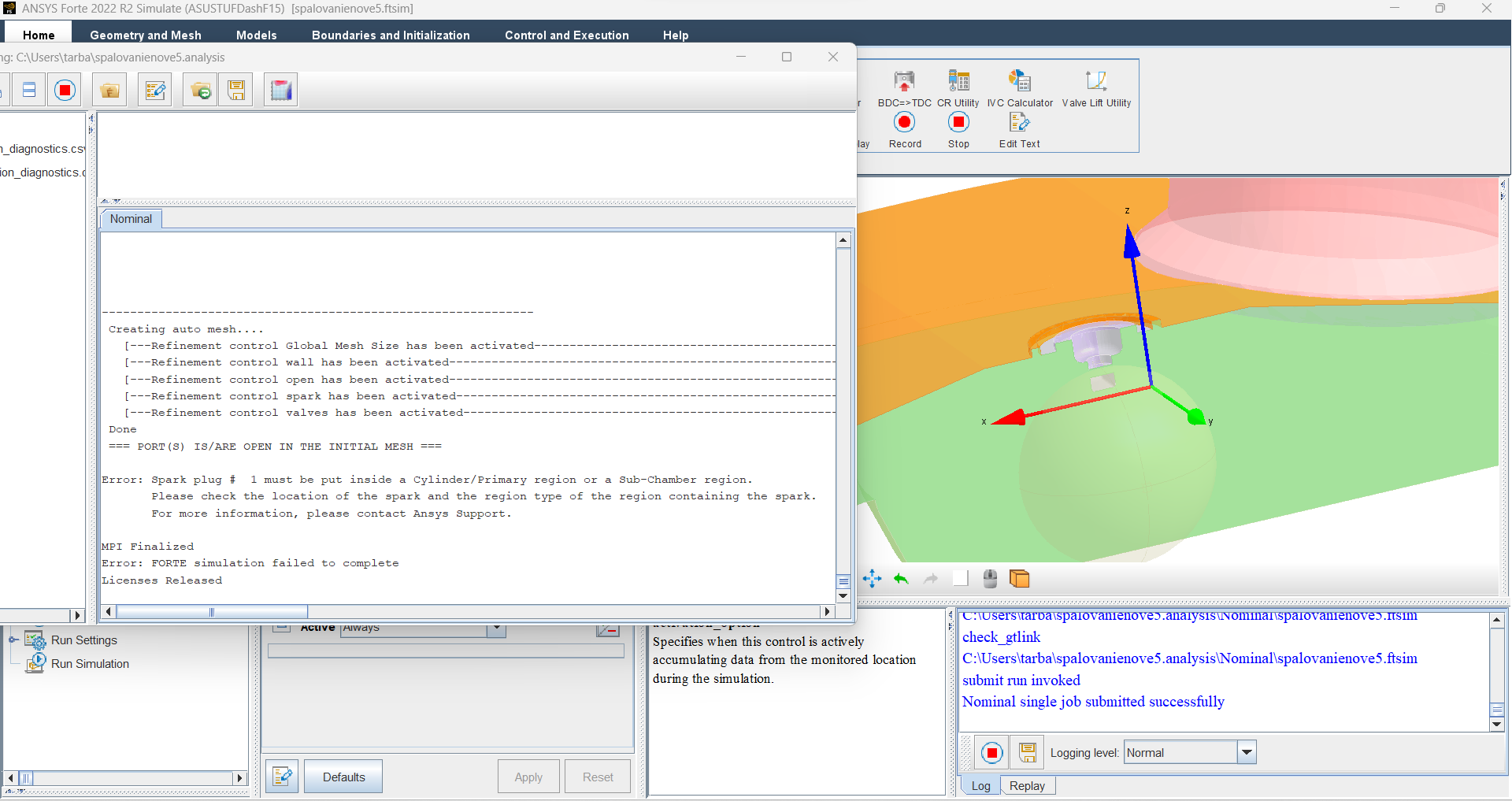

SubscriberHello, does somebody know how to fix that error ? I would really appreciate help since it is important for my thesis. Thank you in advance.

-

September 21, 2023 at 3:18 pm

Ren

Ansys EmployeeHello, Pavol,

Please check the setting for the spark Location input under Spark Ignition->Spark task page. Make sure the spark location is correct.

-

September 21, 2023 at 6:43 pm

pavol.tarbajovsky

SubscriberLocation of spark should be set insede the sub-chamber. The spehere, which represents the sprak is also shown in the area where it should be. Can be this error linked with somethink else?

-

September 25, 2023 at 8:52 am

Ren

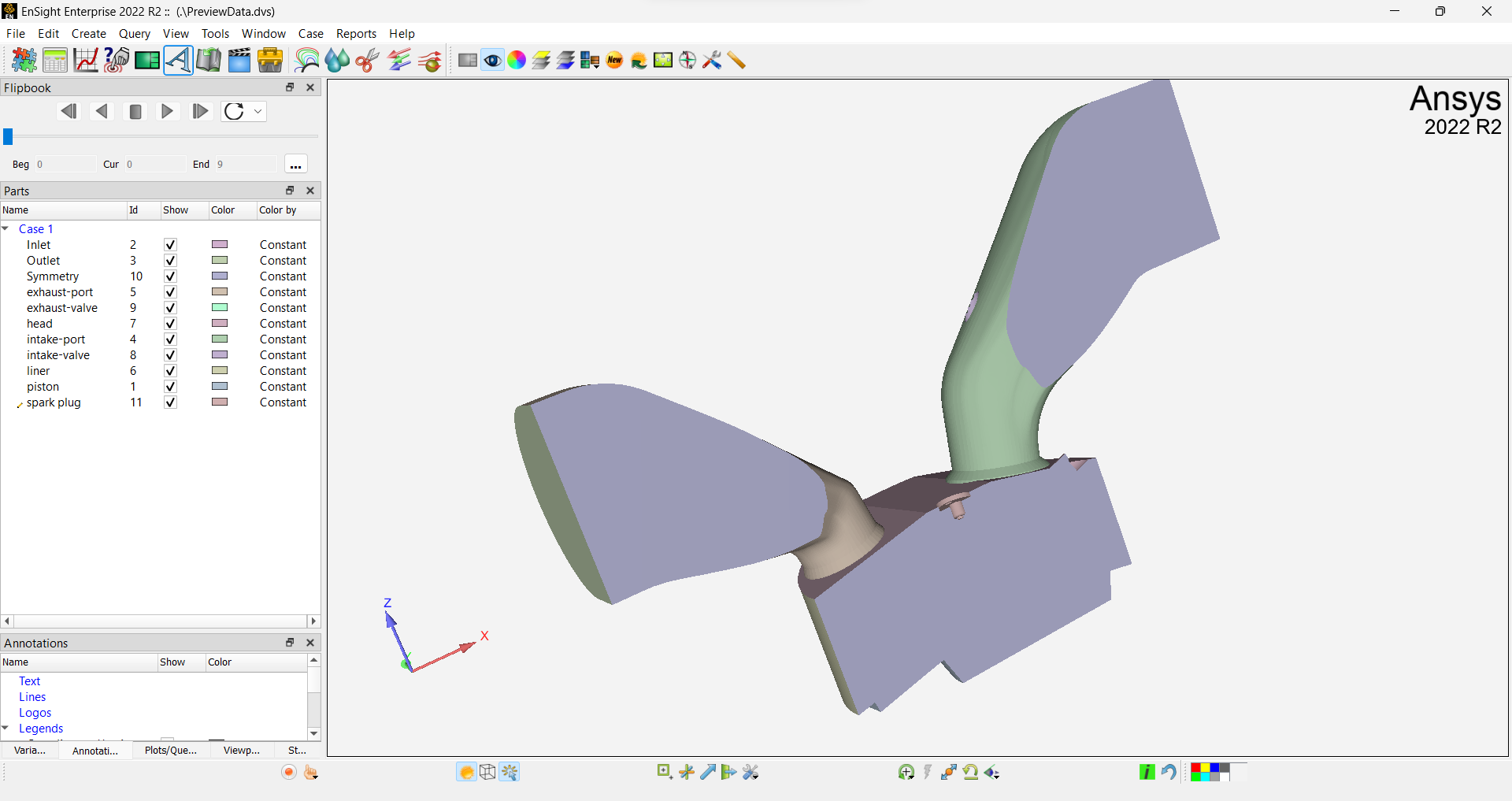

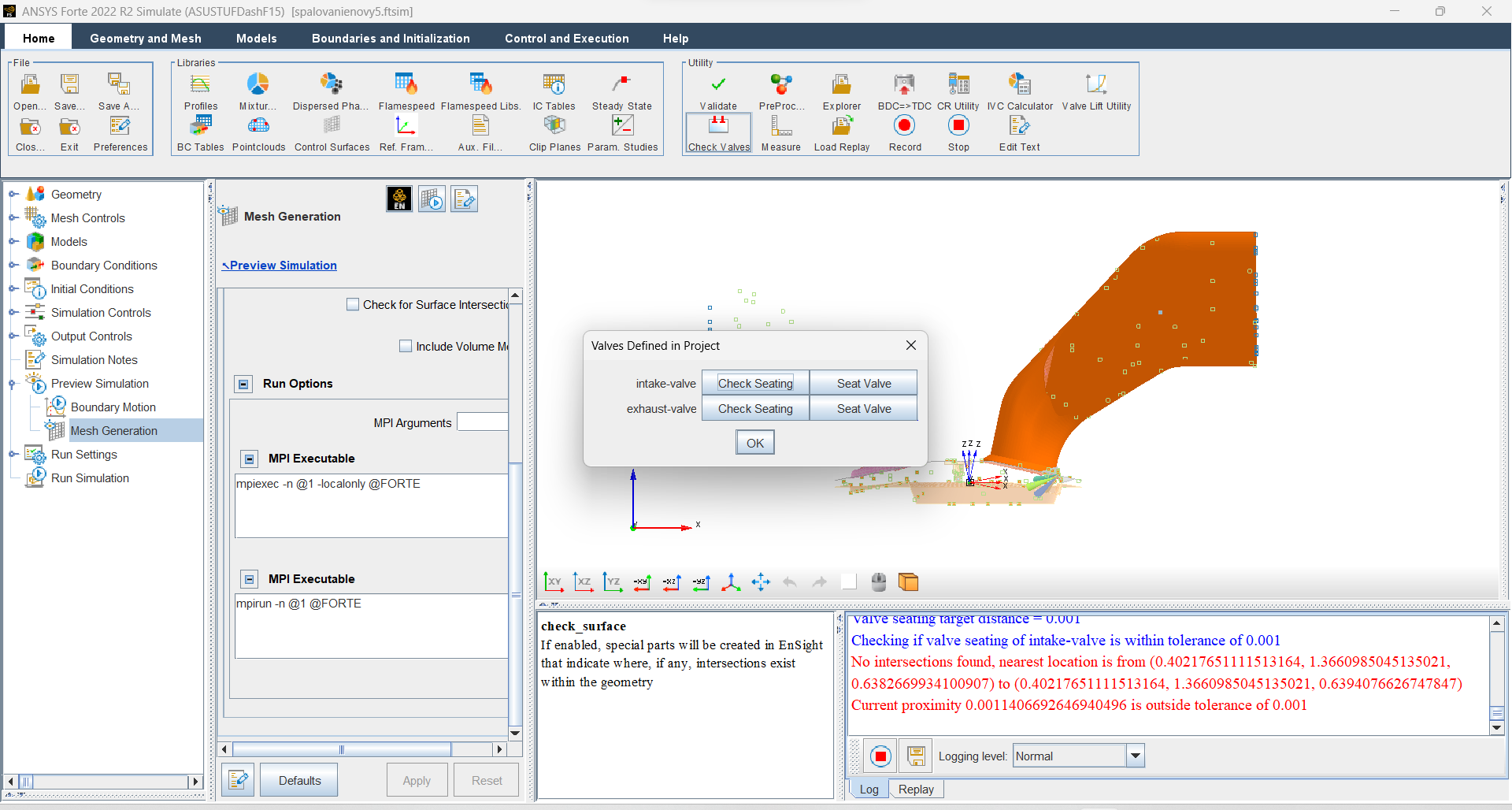

Ansys EmployeeAssuming the location of the spark location has been double-checked, this error that complains the spark location not being inside a cylinder/sub-chamber region must be caused by incorrect region IDs in the mesh. What typically happens is that the cylinder/sub-chamber region containing the spark plug is not given the correct region ID and initial conditions due to some topology issues in the surface mesh. The valves not being tightly seated is the most frequently encountered cause for such an error. To confirm, you can do a test run by turning off the spark ignition model and selecting region ID as a spatially-resolved output variable. Turning off the spark ignition model will allow this error message to be bypassed and hence allow the initial spatially-resolved solution to be saved. You can then check the region IDs and initial conditions in the initial solution using Ensight. If the valves indeed contain non-trivial gaps in the surface mesh, you can use the "Check Valves" utility within the "Utility" ribbon group to seat the valves to a specified tolerance.

-

September 29, 2023 at 7:05 am

-

September 29, 2023 at 8:39 am

-

September 29, 2023 at 9:54 am

Ren

Ansys EmployeeThe previous idea is to check if there are three separagte regions: intake port, cylinder chamber, exhaust port. In EnSight, you can verify it by displaying only the "Symmetry" part and color it by Region ID.

In addition, you can also visually check the mesh to see if there are any gaps between the valves and the valve seats.

-

October 5, 2023 at 7:02 am

pavol.tarbajovsky

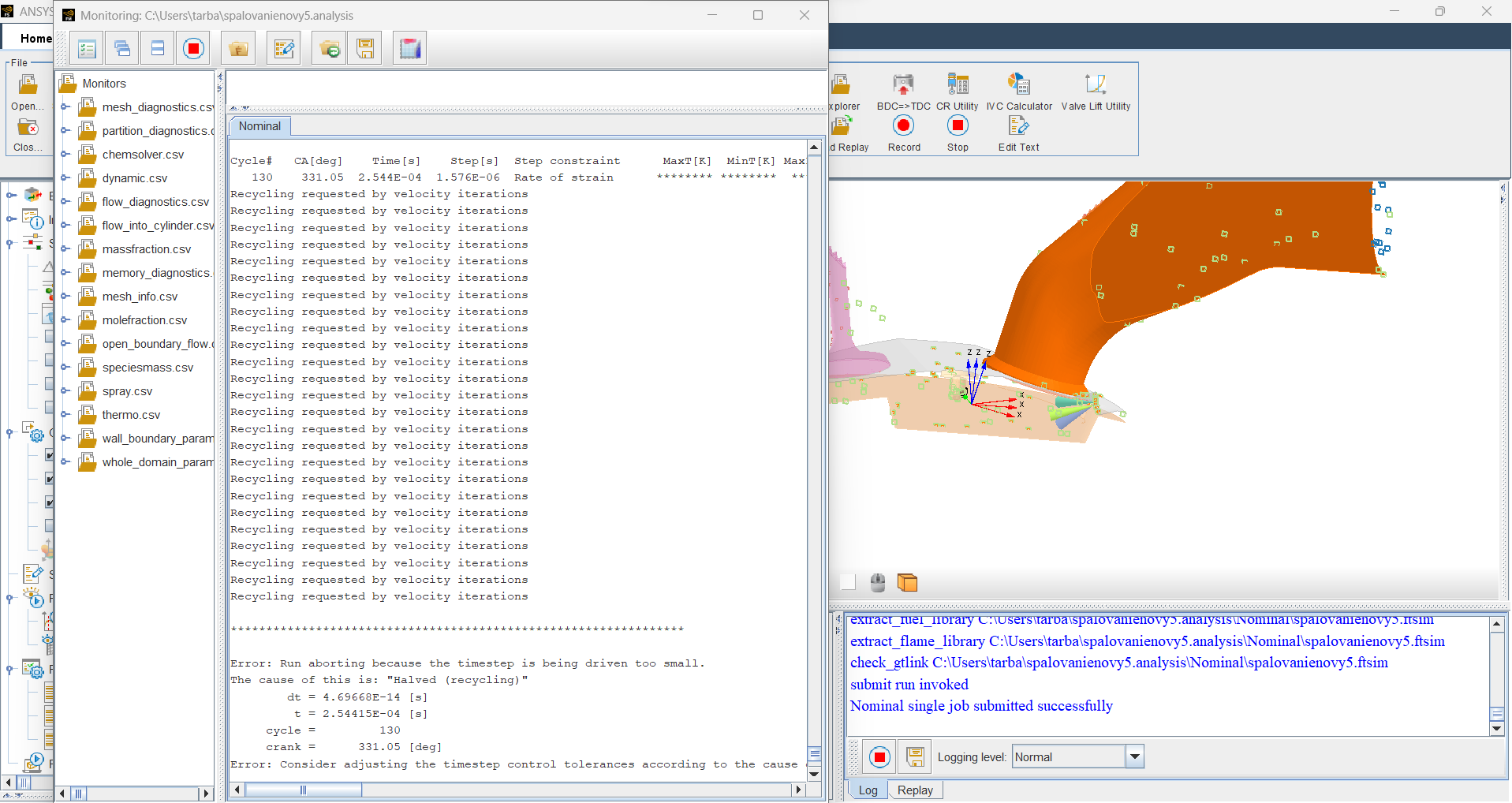

SubscriberI sorted out the spark plug error. The intake valve was not seated right (geometry problem). After I fixed it, it started to calculate the solution, but at around 394 degrees it failed due to timesteps being to small. How should I set time steps?

-

October 6, 2023 at 10:24 am

Ren

Ansys EmployeeThis is commonly caused by some issues in the geometry such that the local velocity becomes very large resulting in the need for exessively small time steps. Please examine the solution and mesh just before the crash to see if you can find anything.

-

- The topic ‘Spark plug location error’ is closed to new replies.

-

5579

-

1885

-

1403

-

1298

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.