-

-

July 17, 2020 at 2:33 pm

Sundra

SubscriberHello,

I am simulating a multiphase system (gas-solid using Eulerian Granular, Model: Realizable k-e, Standard Wall Function) with a air inlet velocity of 13 m/s. I want to simulate it as a fluidized packed bed reactor (without inlet and outlet flow of plastic pellets) and with "Adapt" - "Patch" I fill the reactor with plastic pellets (see image).

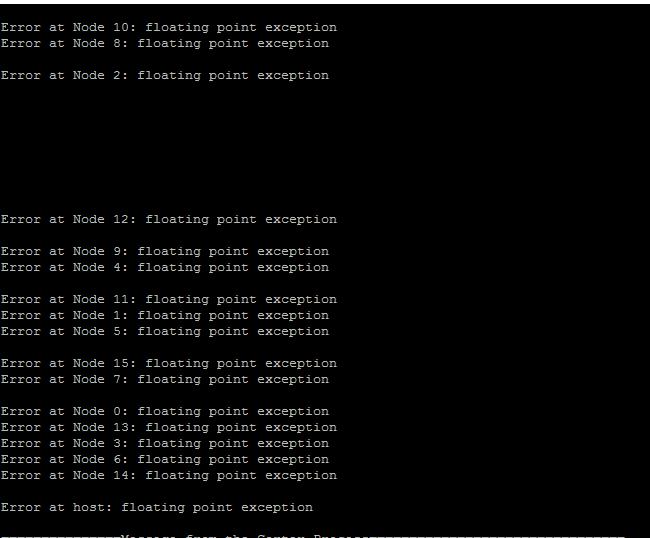

I have a problem during the calculation. I get a floating point exception error (turbulent viscosity limited to viscosity ratio of 1.000000e+05). I refined my mesh looking at skewness and orthogonal quality and it was really fine. I looked at some other forums and it seems that the k-epsilon model is probably calculating erroneously or my solver/controls setup is not right for my simulation.

Is there anyone who could help me with this problem? If you need more information I will immediately share it with you.

Thanks,

Sundra

-

July 20, 2020 at 11:01 am

Rob

Forum ModeratorViscosity ratio is a warning, but you may then see the solver fail because of whatever is triggering this.

How are you adding the particles?

-

July 20, 2020 at 11:24 am

Sundra

SubscriberIt´s seems to be that the viscosity ratio exceeds in every cell (800k) + it shows "reversed flow pressure outlet ".

I am following this tutorial 1:1 and just change my parameters.

https://www.youtube.com/watch?v=W2y9rKXapds

Basically I am creating a secondary "fluid" (plastic with its density, I don´t change the viscosity), adjust the secondary phase with "Granular", add the diameter and use syamlal-obrien for granular viscosity. After initializing I use the function "Refine/Coarse" and mark the cells where the plastic pellets should be. Than I patch the marked cells with volume fraction of plastic pellets, change my interaction phase with drag coefficient syamlal-obrien-para and then I start to simulate.

-

July 20, 2020 at 3:48 pm

Rob

Forum ModeratorWhat volume fraction did you use? If you patched at the packing limit it'll do interesting things: try 0.01 less than the packing limit.

-

July 20, 2020 at 6:15 pm

Sundra

SubscriberI used a volume fraction of 0.578 and void of 0.422. The packing limit is 0.63

-

July 20, 2020 at 6:45 pm

-

July 20, 2020 at 6:49 pm

Sundra

SubscriberI also reduced the time step size to 0.001s (tried 1s, 0.1s, 0.01s) and at the end I will get the same error but way later

-

July 20, 2020 at 8:11 pm

Sundra

SubscriberI did some research and probably my dt was to big. With 0.001s I had the best "results" yet but in my case I might need to reduce dt even more. The minimum cell size is 2x10-5m and the maximal cell size is 0.065m. So I am trying to simulate with the "Adaptive Time Stepping" method and I am getting a physical dt varying between 1x10-5s to 5x10-5s (inlet velocity of air is 12.6m/s). At the end I will have a solution with a flow time of maybe 1s if I iterate 20 000 times... Not good not terrible

-

July 20, 2020 at 8:47 pm

Sundra

SubscriberI tried to make my cells bigger so that I can increase my dt without changing the inlet velocity (which should stay constant). The smallest cells I get are from the inflation layers at the walls of the vessel and pipe (approximately 0.004m). With these cell sizes I can "increase" my dt to 0.0003s which is anyway really small.

-

July 21, 2020 at 3:17 pm

Rob

Forum ModeratorWelcome to CFD multiphase. You've already started down one of the better paths. Depending on the size of the domain, how critical do you think the near wall flow is?

-

July 21, 2020 at 4:27 pm

Sundra

SubscriberThe whole vessel has a height of 10m and a diameter of 2.3m. The pipe has a diameter of 0.4m. The most critical parts is the air coming out of the pipe and colliding to the conical diffusor plates. My goal is to see how big does the pellets influence the velocity of the air close to the diffusor and lower vessel (4m height). I have done a lot of simulations without the pellets before just to see how the air behaves inside the vessel. My next step is to compare the 1phase and 2phase system without inflation layers.

-

July 22, 2020 at 10:32 am

Rob

Forum ModeratorIf you remove the inflation how does it look? Very simply the finer the mesh the smaller the timestep and the more accurate the solution. Coarsening the mesh will speed things up, but reduce accuracy. You need to decide which you want.

-

July 22, 2020 at 10:54 am

Sundra

SubscriberWithout inflation layer I got to the end of my simulation without any mayor troubles, just some cells where the turbulent ratio limit exceeded. I used a dt of 0.001s.

That´s the question... I might need to try both (coarse/fine) and see how big the differences are. Do you have any tips for multiphase in general? What are the most critical parameters/controls/methods as a rule of thumb?

Thanks for helping me out

-

July 23, 2020 at 10:56 am

Rob

Forum ModeratorI need to be careful here as giving detailed advice or using "my engineering knowledge" to any extent is beyond what we're allowed to cover on here.

For multiphase you need to work out roughly what will happen (ie understand what you're modelling) before you start. You then choose the model(s) to do this before going away and getting the geometry & creating the mesh. The planning stage is also used to work out expected speeds, residence times etc to help with cell size and accuracy

-

- The topic ‘Solid-Gas Multiphase System ERROR: Turbulent viscosity limited to viscosity ratio of 1.000000e+05’ is closed to new replies.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Centrifugal Fan Analysis for Determination of Characteristic Curve

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- Issue to compile a UDF in ANSYS Fluent

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

-

4062

-

1487

-

1308

-

1156

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.