-

-

October 3, 2024 at 8:18 am

ahmet.yildirim

SubscriberDear Recipient,

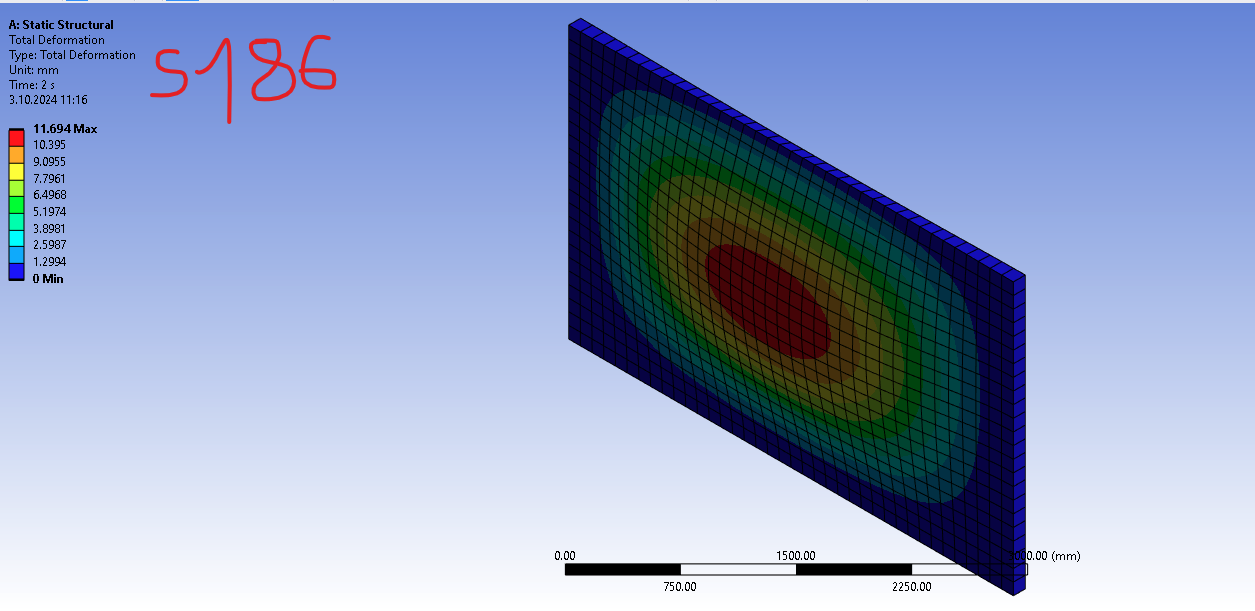

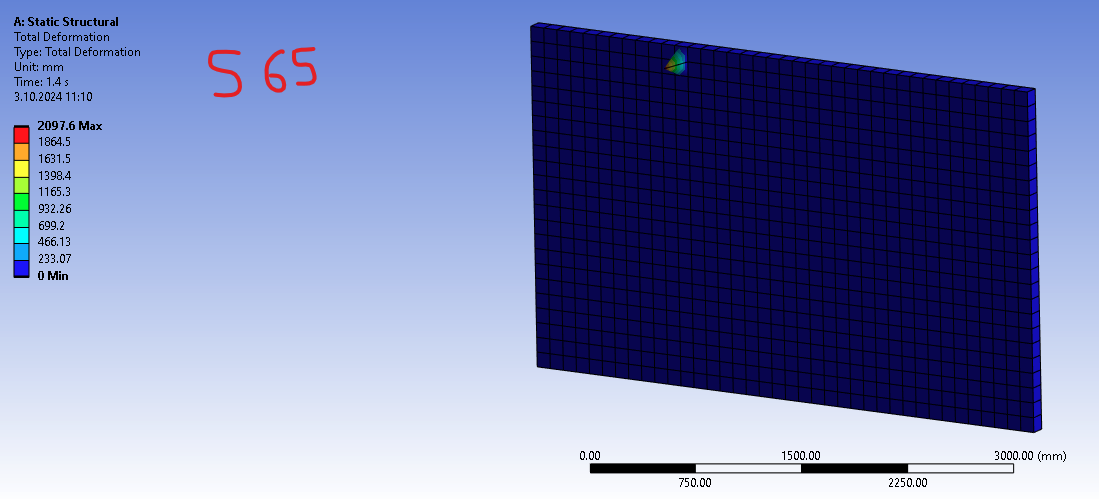

The model given in the picture results differently for solid 65 and solid 186. It can be understood that these elements are different behaviours but why this results are obtained I did not figure out?

Just description of the model: Pressure (0.1 MPa) at the top, fixed at the bottom and simply supported at each side and at top except y-dir to apply pressure effect. Then remote-disp (4 mm) at the face in the direction out-of-plane let's say normal to the surface.

Also, material data: Just Elastic Modulus, Density and Poisson ratio.

The results is OK with Solid 186 element but it was not the same with Solid 65 (or Solid 185 I tried).

Pictures can be found below (First Solid 186 and then Solid 65 element result):

Looking forward to your response,

Regards,

Ahmet YILDIRIM

-

October 7, 2024 at 3:26 pm

Tasos Zacharakis

Ansys EmployeeHello Ahmet,

Take a look at the assumptions and restrictions of solid65 at : SOLID65 (ansys.com).

Hope that helps.

Thank you,

Tasos

-

- You must be logged in to reply to this topic.

-

4673

-

1565

-

1386

-

1236

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.