-

-

October 16, 2019 at 5:00 pm

Behzad127

SubscriberHello,

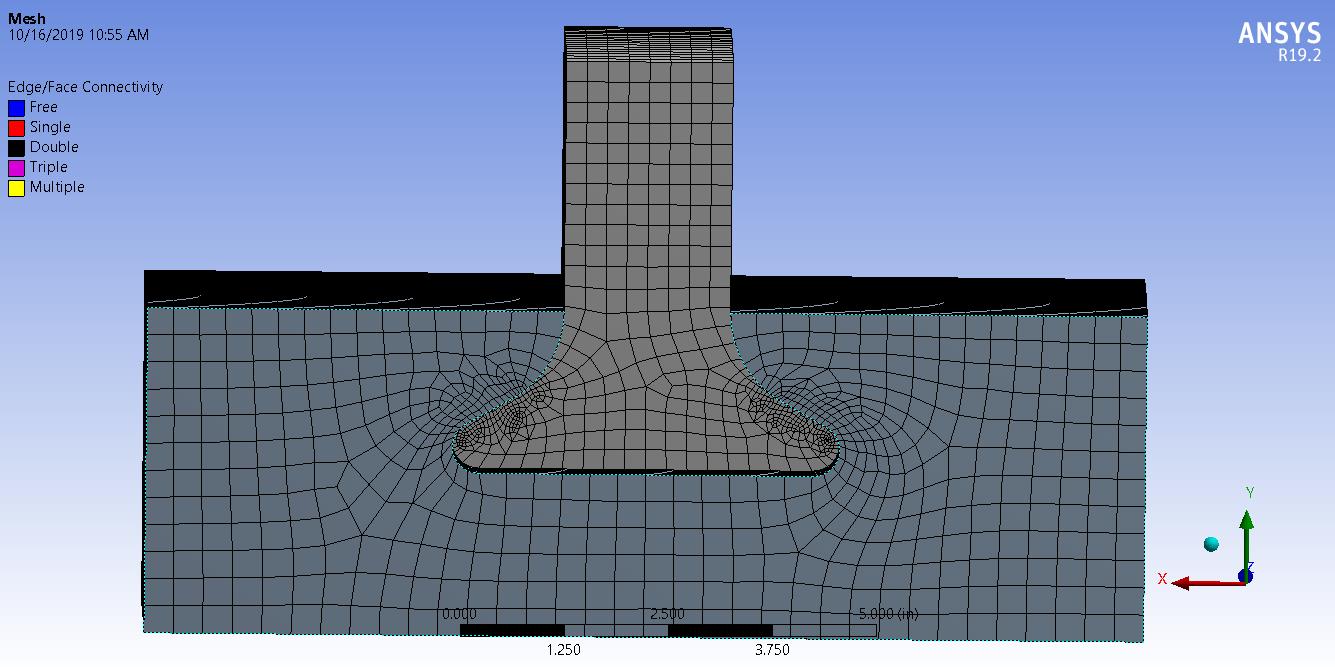

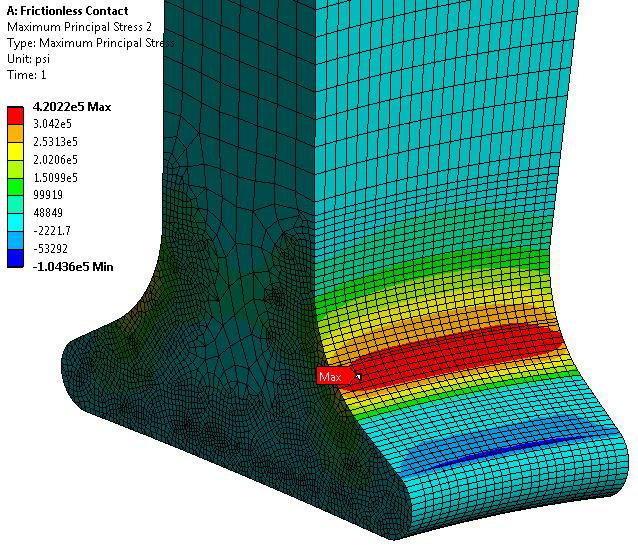

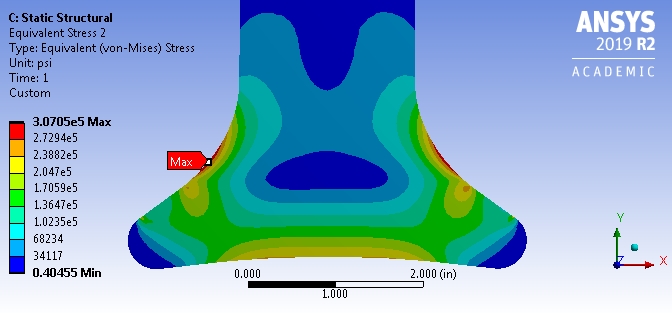

I have an issue with a singularity point that cannot be ignored. The singularity happens in a corner of a dovetail blade attachment, but it is very close to the high tensile stress region of the fillet. I have performed mesh refinement up to .005" size elements and the minimum principle stress keeps rising (i.e. up to 1.8 Mpsi). I suspect the tangency between the flat and circular geometry plays a role here.

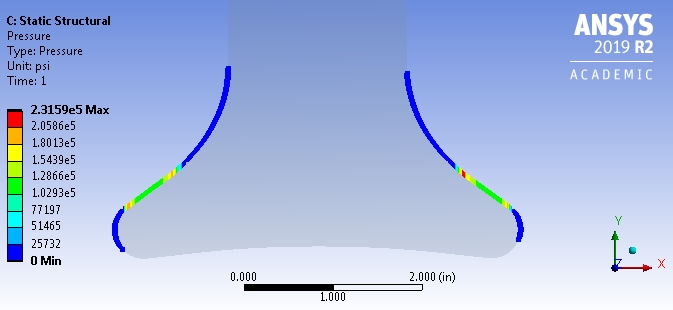

I have been able to simplify the problem into a simple geometry. In the attached example the singularity does not really affect the max principle stress, but the actual blade is asymmetric and therefore the high stress is very close to the singularity corner. The high stress points coincidentally have high penetration. I have tried the following with no success:

- Different combinations of contacts and their options

- Adding chamfer/fillet on the corner. The high stress point just shifts to the starting point of the chamfer/fillet.

- Including plasticity from this discussion.

- Changing the contact regions

Please let me know if there is anyway to eliminate this singularity. The Archive file is attached and is in 19.2 version.

Thank you,

Behzad

-

October 16, 2019 at 8:18 pm

-

October 16, 2019 at 9:21 pm

Behzad127

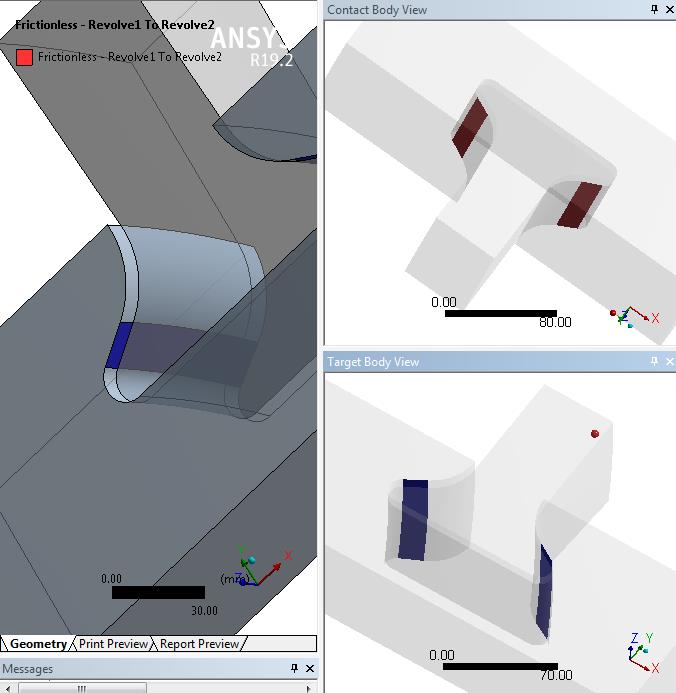

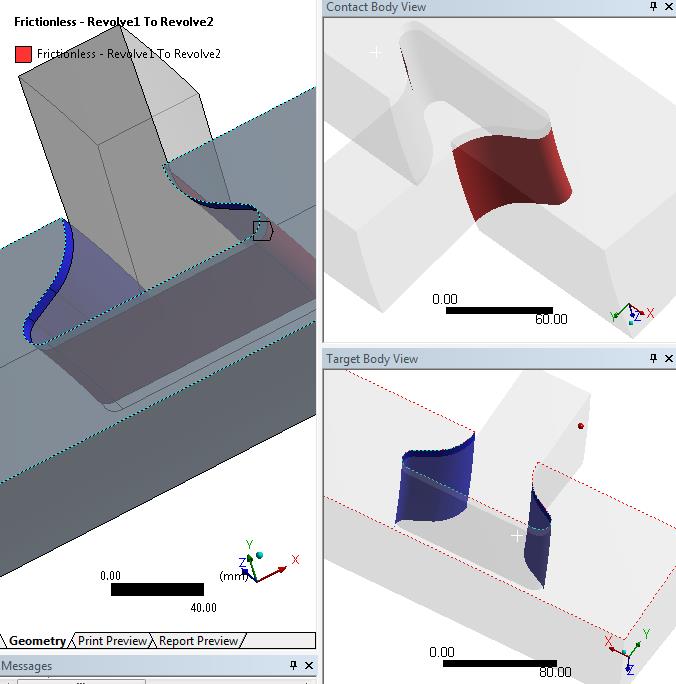

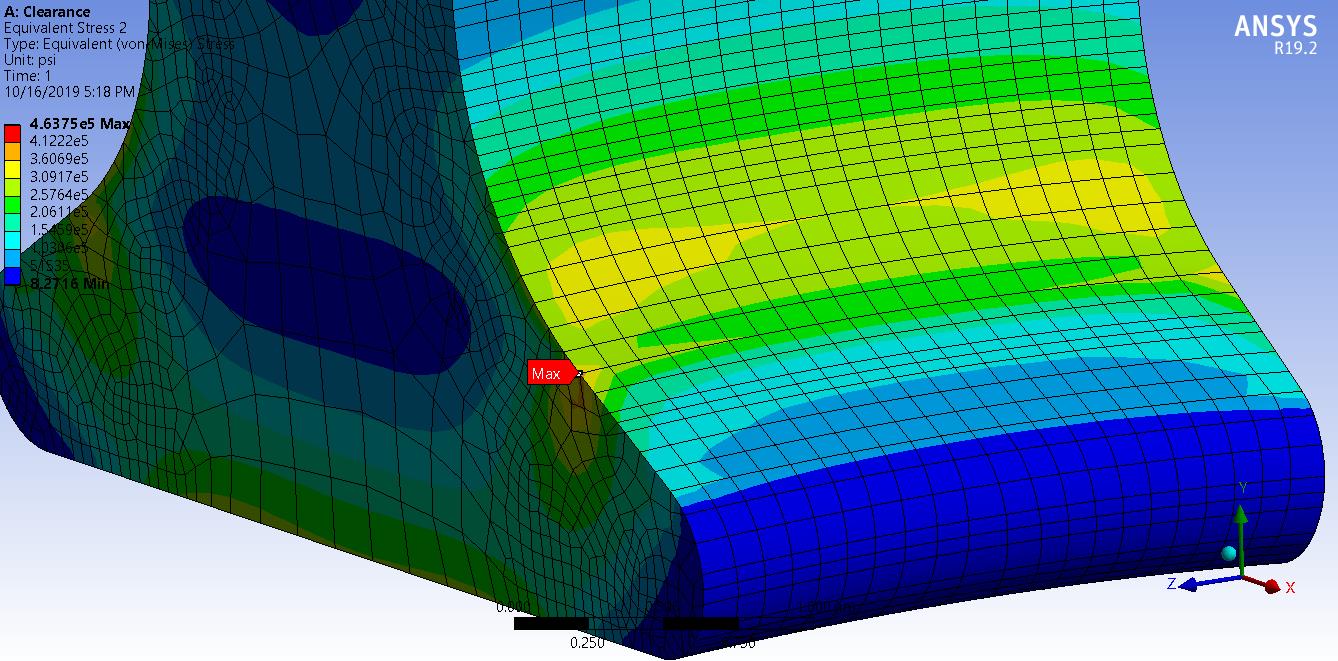

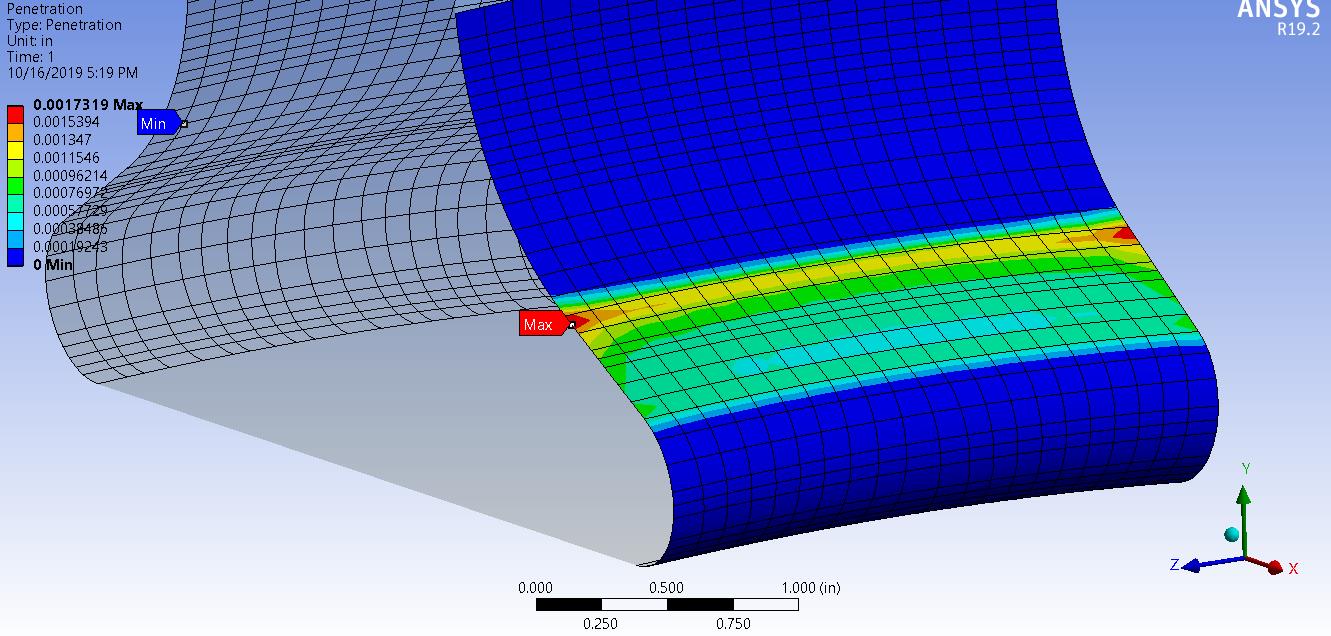

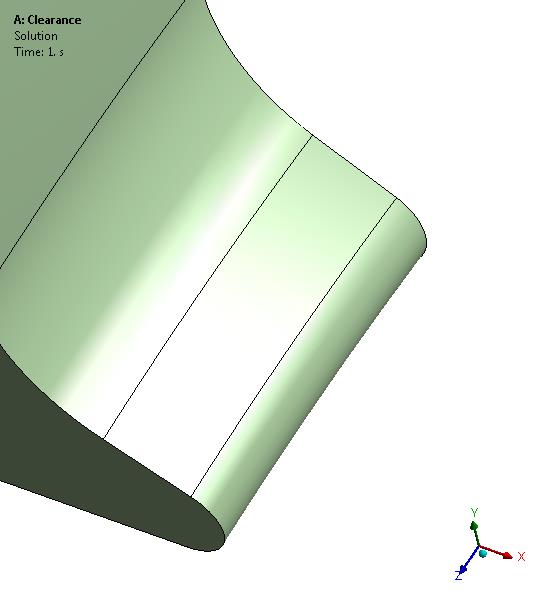

SubscriberThank you for the feedback Peter. But in reality only the original face will have contact and the circular faces are clearance regions. I modified my model to include the clearance and changed the contact to all the adjacent faces, but I still get a high stress point. The high stress point also has a relatively high penetration.

-

October 17, 2019 at 11:00 am

peteroznewman

SubscriberHave you considered using a 2D Plane Stress model? You can get results much faster and can more easily perform a mesh refinement study. Plane stress will automatically give you results from the center of the part without any end effects. I understand it is not the exact same model because in 3D, the 8 degree slice puts a little more mass at the top than the bottom of the insert. This makes me wonder if you should put a distributed mass at the top of the insert to represent mass that has been cut off in the geometry. That may move the point of high stress away from the tangent point.

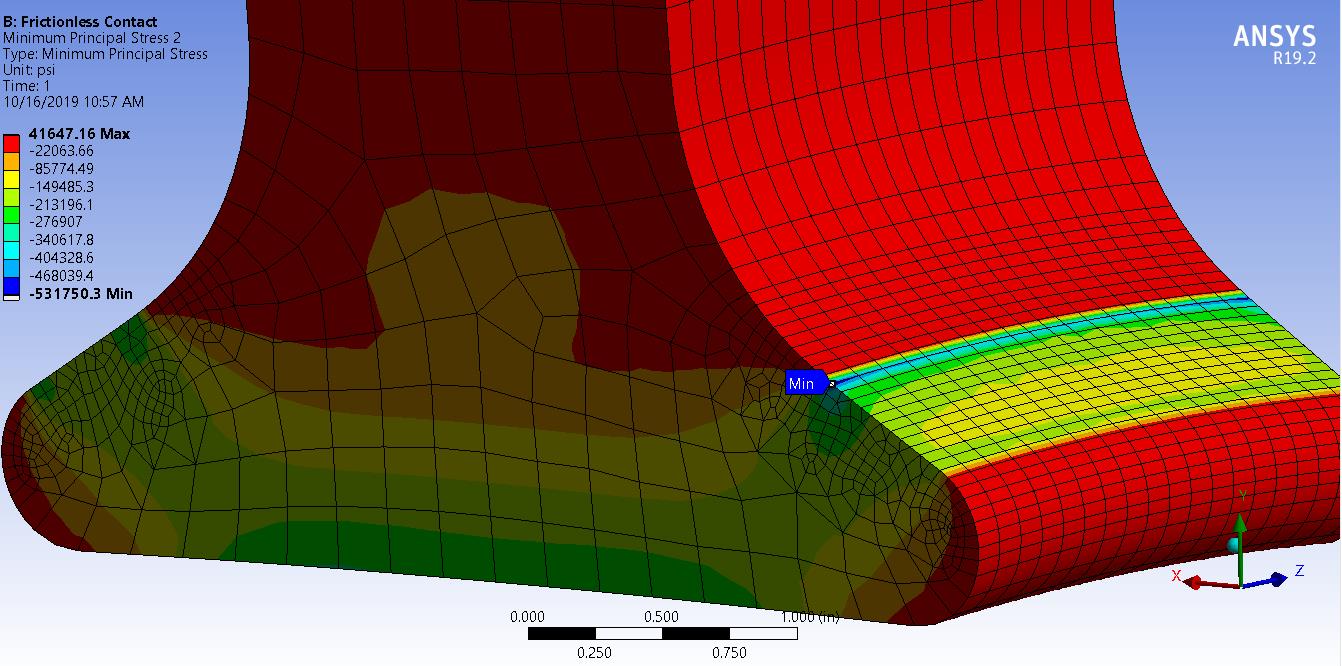

The maximum stress on the insert is not even at the contact point.

-

October 17, 2019 at 12:15 pm

Behzad127

SubscriberThanks Peter. This is a simplified model of a more complicated cyclic symmetric geometry with airfoils and spacers. As you correctly point out, the max stress is in the fillet region (second picture), and that is the stress I am interested in. The problem is, the corner high stress points are mesh dependent and I cannot get a converging max fillet stress as I increase the mesh density. I there any way to minimize the effect of the corner points on the max fillet stress (max principal)?

-

October 18, 2019 at 10:04 pm

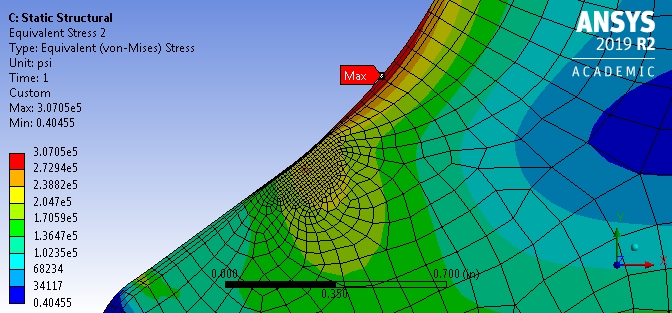

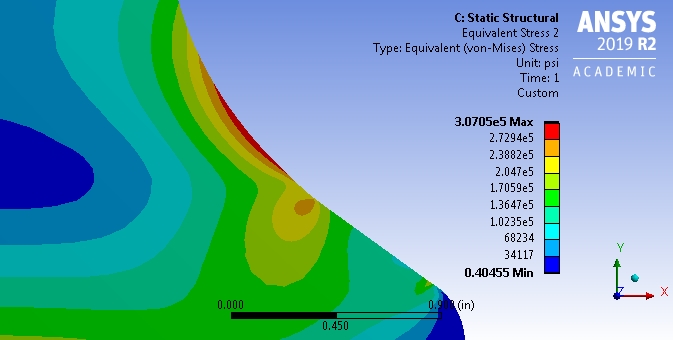

peteroznewman

SubscriberThis is not a singularity, it is the contact model misbehaving. It should deliver smooth results as the elements get smaller, but it is not. I used a very fine mesh and the stress has a hot spot that wasn't there before. The fact that the hot spot moves around is why I would not categorize this as a singularity. A singularity has a fixed location and the stress consistently increases as the element gets smaller. This is not happening here.

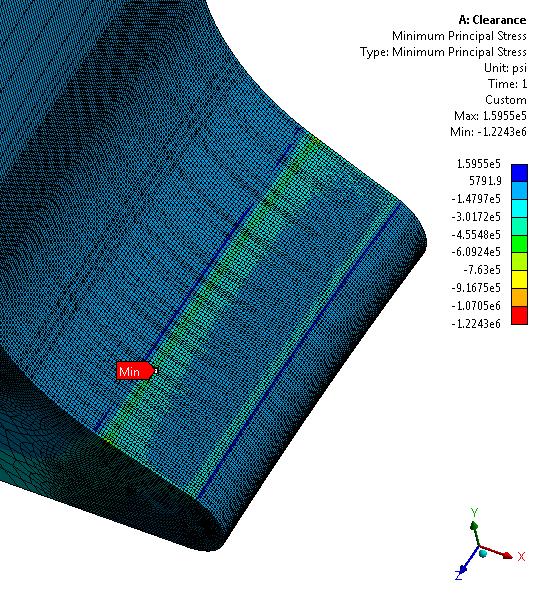

Geometry

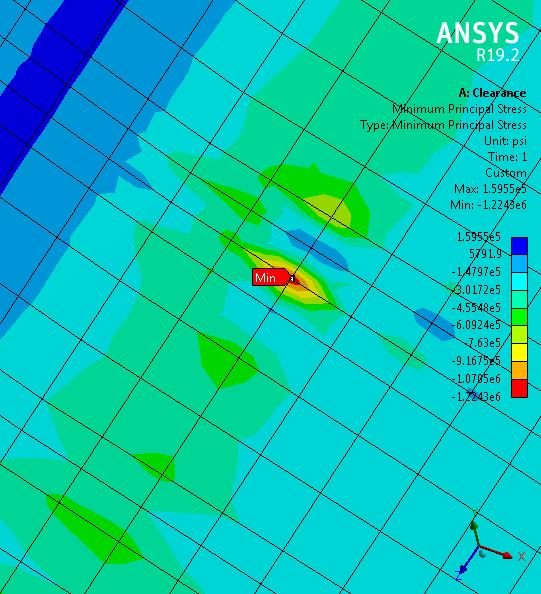

Hot Spot on Fine Mesh

Detail of Hot Spot on Fine Mesh

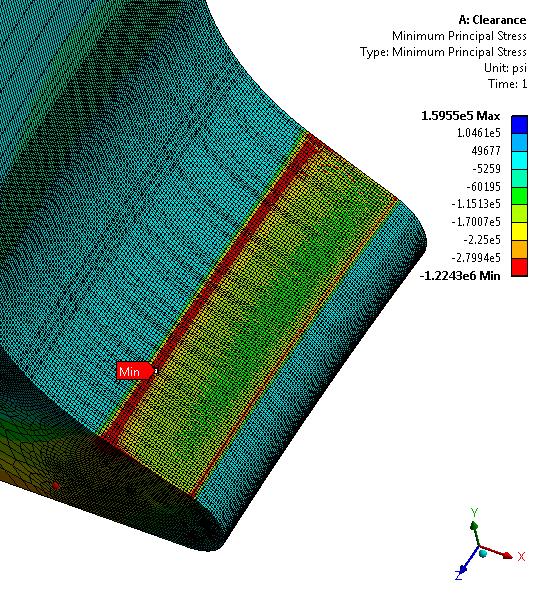

Fine Mesh with red color threshold value set to the average stress along tangent line.

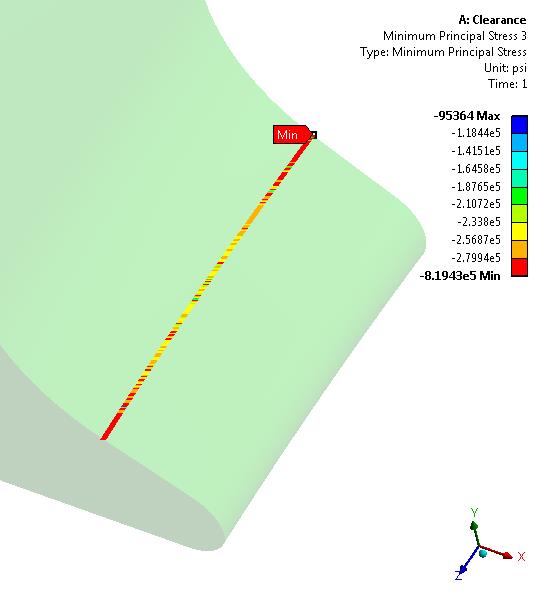

Stress along Tangent Line

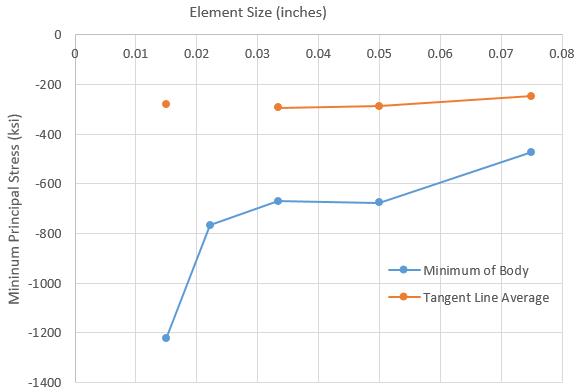

The Minimum value of the Minimum Principal Stress on that body is subject to the variation caused by the appearance of a Hot Spot. One way to determine a good value for the Minimum Principal stress in the material is to use the Average value of stress on the line, which is much less affected by the hot spot than just using the Minimum value.

-

October 21, 2019 at 2:39 pm

Behzad127

SubscriberPeter,

I appreciate you looking at this in detail. Do you know why the contact model is misbehaving? Is it due to the abrupt status changes of contact elements from no-contact to contact (as the small clearance is closed due to load)? Or does it have something to do with the tangent line that separates the fillet region from the flat region?

-

October 21, 2019 at 3:26 pm

peteroznewman

SubscriberSince the contact faces include the adjacent faces that are tangent to the contact faces, with small enough elements and enough force, the contact can extend onto the adjacent face smoothly, so there is no hard edge like there was with just a single face.

I don't know why the hotspot appears. I wonder if a different contact setting would make that go away, but each experiment takes hours of run time to find out. I would try things like making the contact Symmetric, and try some other Detection settings.

-

October 19, 2022 at 5:43 pm

vkm120991

SubscriberHi Peter! Really appreciate your active responses!

I've seen hotspots occuring in contact region even for a simple system like a small cylindrical pin (convex, let say) pressing onto a concave (more than thrice the size of the pin) slot.

I've experimented with multiple detection methods, formulation, controlling penetration in addition to sphere of influence refinement upto element size of 0.001" but couldnt get away with the singularity. It rather was too odd where the maximum tensile principal stress in the model would be half the yield for the metal. But compressive stresses around hotspot would be almost 6 times the yield!

Any suggestions for getting around such systems?

Thanks in advance!

-

-

- The topic ‘Singularity in Contact Region’ is closed to new replies.

-

4763

-

1565

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.