-

-

September 11, 2020 at 3:40 pm

Rizwan_ul_Haq

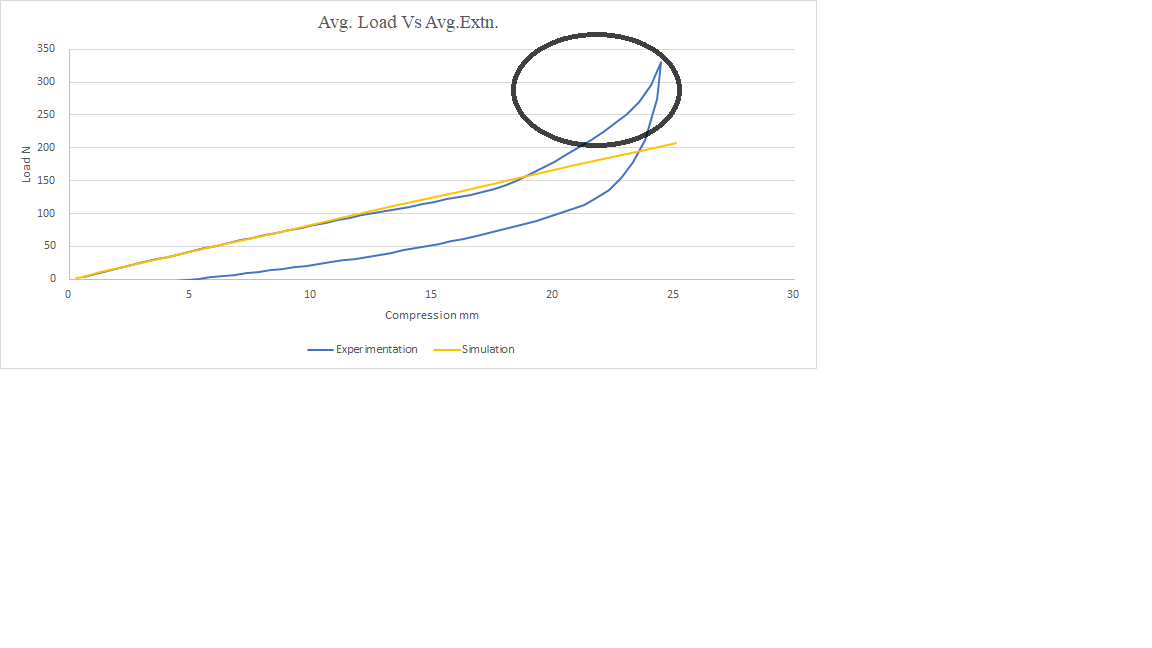

SubscriberHi. I am doing simulation of compression testing of a spring.My experimental and simulation results are same in the linear region. I have tried the simulation with all types of contact behavior even with pin ball at different radius with linear and non linear material properties with large deflection on/off. The graph is different when all helix are in contact with each other.The following graph shows my results. I will be grateful if anyone can suggest any solution to simulate the encircled curve.

September 12, 2020 at 3:58 pmpeteroznewman

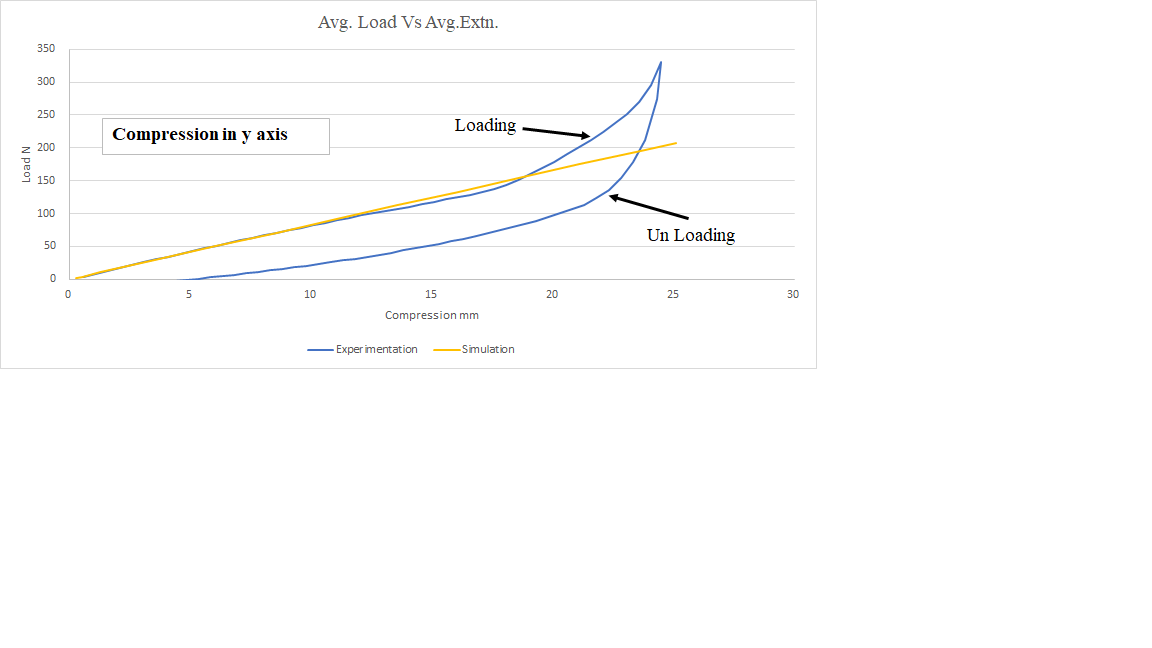

SubscriberArray nYou are showing compression as a positive value.nIf compression is along the X axis, that means the right end of the spring is fixed, while the left end of the spring moves to the right along the positive X axis.nPlease mark the blue curves with arrows or a legend to show compression and release. For example, use an arrow pointing to the right on the branch of the blue curve that was traced when the left end of the spring was moving to the right and the spring was being compressed. Use an arrow pointing to the left on the branch of the blue curve that was traced when the left end of the spring was moving to the left and the spring was being released.nDoes your material include plasticity? I expect you will need that to get a large nonlinear behavior.nYou say The graph is different when all helix are in contact with each other. Please show that graph.nPlease reply with images of the geometry and the mesh.nSeptember 13, 2020 at 1:52 pmSeptember 13, 2020 at 2:51 pmpeteroznewman

SubscriberMake sure Large Deflection is On,.nYou need the contact to be present to increase the slope as the coils begin to collapse on each other.nYou need to get this behavior first. Attach a zip file with your project archive and I will take a look.nYou need Plasticity to have the slope change when the unloading occurs.nGo to the Engineering Data cell in Workbench, and from the Toolbox, expand the Plasticity category.nDrag and Drop Bilinear Kinematic Hardening onto your material. On the Yield Strength cell, pay attention to the units when enter a value. Type a 0 into the Tangent Modulus.nNow rerun your model.nnSeptember 16, 2020 at 7:12 amRizwan_ul_Haq

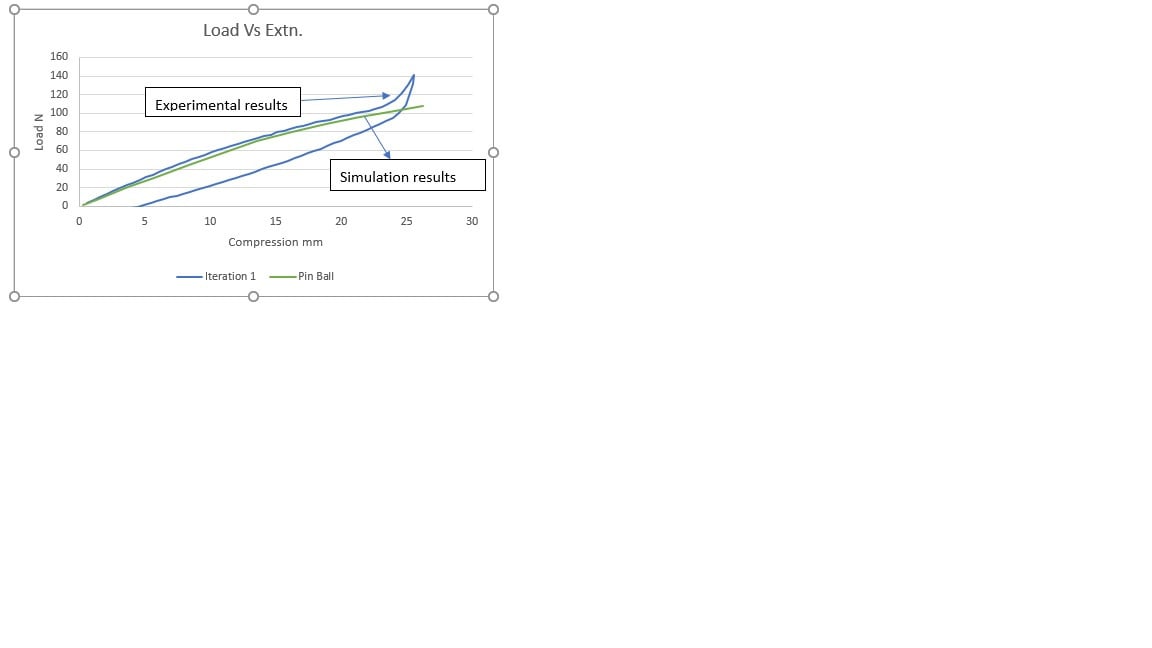

SubscriberI have tried the recommendations but still struggling to get the required results. Please find the attached Archive file of my structure for further recommendations. I would like to mention that the non linear data is actually extracted by using extensometer and used in this simulation.I have to delete the results and solution data from the attached file due to size of the file. I ave used 0.5-1 mm mesh size with 26 mm displacement. So your valuable recommendations will be highly appreciated.n n

September 16, 2020 at 1:19 pm

n

September 16, 2020 at 1:19 pmpeteroznewman

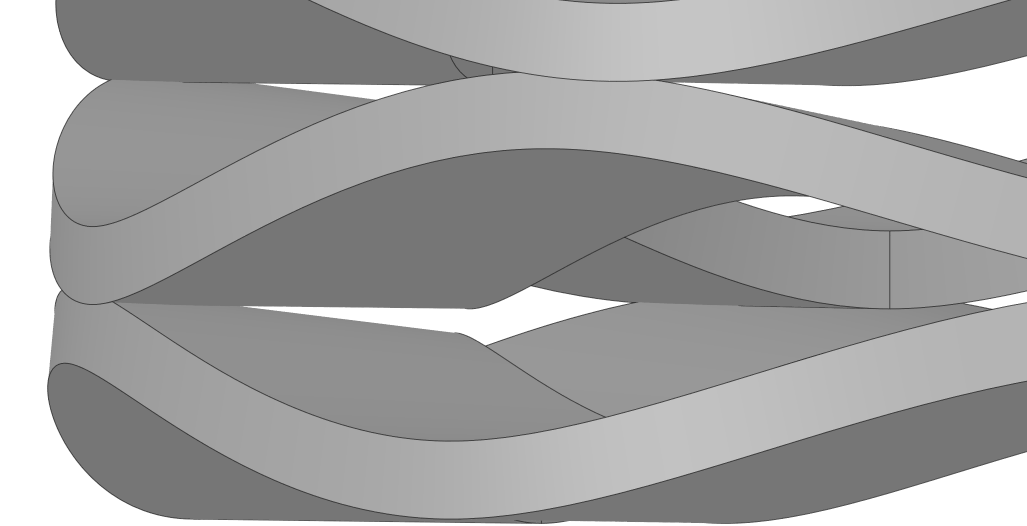

SubscriberWhen I said Contact, I should have been more specific and said Frictional Contact. Your model is using Bonded Contact, which doesn't pick up new contact as the structure deforms.nYou will have some trouble with frictional contact because your stack of washers is not precisely assembled. There is significant interference. Fix that before you start.n There are five waves in each washer. Make two planes, and cut through the washers where they touch, then apply symmetry on those planes and the model that will solve much faster.n

Viewing 5 reply threads

There are five waves in each washer. Make two planes, and cut through the washers where they touch, then apply symmetry on those planes and the model that will solve much faster.n

Viewing 5 reply threads- The topic ‘Simulation of compression testing of spring.’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4893

-

1587

-

1386

-

1242

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.