-

-

October 18, 2019 at 5:14 am

sravank

SubscriberHai

I have a code for simulation of double ellipsoidal heat source model. But getting parallel(two) directional flows.

Am attaching the code of it. Can any one resolve the error in the code. Kindly help me to slove the problem.

Thank you

Kindly find the attachment.

-

October 18, 2019 at 8:13 am

Rob

Forum ModeratorPlease provide more details, and include images within the text: staff are not permitted to open/download attachments.

-

October 18, 2019 at 10:49 am

sravank

SubscriberCMSEL,ALL

*GET,EMAX,ELEM,,NUM,MAX

*GET,EMIN,ELEM,,NUM,MIN

ALLSEL

AUTOTS,ON

TIME_WELD=200

DT=1

A=0.003

B=0.004

C1=0.004

C2=0.016 !A, B AND C ARE JUST THE HEAT SOURCE DIMENSIONS

TAU=0 !TIME DELAY

FF=0.4 !FRACTION OF HEAT ON THE FRONT PART OF THE HEAT SOURCE

FR=1.6 !FRACTION OF HEAT ON THE REAR PART OF THE HEAT SOURCE

Q=3840 !WELDING ENERGY J/S (W)

VEL=0.002 !WELDING SPEED

EE=2.71 !I HAD TO DEFINE THE EULER NUMBER AS 2.71 INSTEAD OF USING exp() DUE TO UNSTABILITIES ON MY RESULTS

NPT=TIME_WELD/DT

a

*DO,ii,1,NPT,1 !TIME INCREMENT

WTIME=(ii/2)

TIME,WTIME

HCENTER=VEL*WTIME !HEAT SOURCE CENTER

*DO,jj,EMIN,EMAX,1 !SELECTS THE CENTROID OF EVERY ELEMENT

X=CENTRX(jj)

Y=CENTRY(jj)

Z=CENTRZ(jj)

CSI=Y+(VEL*(TAU-WTIME)) !MOVING COORDINATE (IT MOVES THROUGH Z AS TIME PASSES

*IF,Y,GT,HCENTER,THEN !DEFINES WHETHER IT'S THE FRONT PART OF THE HEAT SOURCE OR THE REAR PART

C=C1

F=FF

*ELSE

C=C2

F=FR

*ENDIF

PART1=(6*(3**0.5)*Q*F)/(A*B*C*3.14*(3.14**0.5))

PART2=(EE**(-3*(Z/A)**2))*(EE**(-3*(X/

**2))*(EE**(-3*((CSI/C)**2)))

**2))*(EE**(-3*((CSI/C)**2)))

QF=PART1*PART2 !HEAT SOURCE EQUATION

BFE,jj,HGEN,,QF

*ENDDO

SOLVE

*ENDDO

CMSEL,ALL

BFEDELE,ALL,ALL

ALLSEL

Here in the 3rd image the flow is parallel and two flows are getting. But i need only one flow on the middle of the part..

Thank you

-

November 11, 2019 at 7:08 pm

Sandeep Medikonda

Ansys EmployeeIt is not clear, what you are trying to do here? can you explain? What are the 2 flows you are referring to?

-

November 13, 2019 at 6:46 am

sravank

SubscriberTwo flows are referring the directional heat flux. It should be in unidirection along the weldzone. After chaning the orientation in the Details of directional heat flux am getting the directional heat flux in unidirection. Directional problem is sloved. But i need help with UDF.

Am working on simulation of the moving heat source of double ellisopidal heat source model (In ansys ACT extension Gaussian moving heat source is only available)..To find out the temperature distribution along the weldzone. Giving convection and moving heat source (UDF) as input. In the code the mathemtical equation of double ellipsoidal is given. But am not getting the temperature distribution reference to the double ellipsoidal graph.

Code is attached. Can you please check the code..

CMSEL,ALL

*GET,EMAX,ELEM,,NUM,MAX

*GET,EMIN,ELEM,,NUM,MIN

ALLSEL

AUTOTS,ON

TIME_WELD=100

DT=1 ! Time step

A=0.003

B=0.004

C1=0.004

C2=0.016 !A, B AND C ARE JUST THE HEAT SOURCE DIMENSIONS

TAU=0 !TIME DELAY

FF=0.6 !FRACTION OF HEAT ON THE FRONT PART OF THE HEAT SOURCE

FR=1.4 !FRACTION OF HEAT ON THE REAR PART OF THE HEAT SOURCE

Q=3840 !WELDING ENERGY J/S (W)

VEL=1.73e-3 !WELDING SPEED

!!EE=2.71 !I HAD TO DEFINE THE EULER NUMBER AS 2.71 INSTEAD OF USING exp() DUE TO UNSTABILITIES ON MY RESULTS

NPT=TIME_WELD/DT

NROPT, FULL

*DO,i,1,NPT,1 !TIME INCREMENT

WTIME=(i/2)

TIME,WTIME

HCENTER=VEL*WTIME !HEAT SOURCE CENTER

*DO,jj,EMIN,EMAX,1 !SELECTS THE CENTROID OF EVERY ELEMENT

X=CENTRX(jj)

Y=CENTRY(jj)

Z=CENTRZ(jj)

CSI=Z+(VEL*(TAU-WTIME)) !MOVING COORDINATE (IT MOVES THROUGH Z AS TIME PASSES

*IF,Z,GT,HCENTER,THEN !DEFINES WHETHER IT'S THE FRONT PART OF THE HEAT SOURCE OR THE REAR PART

C=C1

F=FF

*ELSE

C=C2

F=FR

*ENDIF

PART1=(6*(3**0.5)*Q*F)/(A*B*C*3.14*(3.14**0.5))

PART2=(Exp(-3*(X/A)**2))*(Exp(-3*(Y/

**2))*(Exp(-3*((CSI/C)**2)))

**2))*(Exp(-3*((CSI/C)**2)))

QF=PART1*PART2 !HEAT SOURCE EQUATION

BFE,jj,HGEN,,QF

*ENDDO

SOLVE

*ENDDO

CMSEL,ALL

BFEDELE,ALL,ALL

ALLSEL

-

November 14, 2019 at 11:07 pm

Sandeep Medikonda

Ansys EmployeeHi,

Here is what I would suggest you do.

You are looping over 100 timesteps; at every time step you are applying a BFE load for each element. Then solving. The problem is that you are only looking at the postprocessor results. To debug this I would recommend simplifying.

1) remove the outer DO loop. Just set NPT = 50.

You should know what heat generation load each element should get. Or at least you can choose a few elements and check.

2) I would remove the SOLVE.

You do not need to solve to check if the load is applied correctly

3) So if you set NPT=50 and apply load on all elements you can then either do BFELIST to list the loads and check them. You can also do /PBF command to plot the elements with the heat gen loads shown.

So, my suggestion is to review the loads at time=50 before doing any solution

-

November 15, 2019 at 4:42 pm

sravank

Subscriberhai

What i got understand from your points i changed the code and sloved. Results are attached. Once check it please..

CMSEL,ALL

*GET,EMAX,ELEM,,NUM,MAX

*GET,EMIN,ELEM,,NUM,MIN

ALLSEL

TIME_WELD=100

DT=1

A=0.002

B=0.002

C1=0.004

C2=0.015

TAU=0.6

FF=0.6

FR=1.4

Q=1500

VEL=1.73e-3

NPT=50

NROPT, FULL

*DO,jj,EMIN,EMAX,1

X=CENTRX(jj)

Y=CENTRY(jj)

Z=CENTRZ(jj)

CSI=-Z+VEL*(TAU)

*IF,Z,GT,0,THEN

C=C1

F=FF

*ELSE

C=C2

F=FR

*ENDIF

PART1=(6*(3**0.5)*F*Q)/(A*B*C*3.14*(3.14**0.5))

PART2=(exp(-3*(X/A)**2))*(exp(-3*(Y/

**2))*(exp(-3*(CSI/C)**2))

**2))*(exp(-3*(CSI/C)**2))

QF=PART1*PART2

BFE,jj,HGEN,,QF

*ENDDO

SOLVE

CMSEL,ALL

BFEDELE,ALL,ALL

ALLSEL

There is no moving action. At one place the temperature is distributing. But we need moving heat source across the weldzone.

If I remove solve, am getting error.

Thank you. Awaiting for your reply.

-

November 15, 2019 at 7:19 pm

Sandeep Medikonda

Ansys EmployeeIf you are using the moving heat source ACT, the index number is the number of heat sources. You can have as many as you want. Why script it?

-

November 16, 2019 at 7:13 am

sravank

SubscriberAnsys providing the moving heat source extension for only Gaussian model. Adding extension and giving parameters produce the simulation of it with correct results.

But my requirement is finding the moving heat source for double ellipsodial model instead of gaussian model.

Thank You

-

February 11, 2020 at 6:25 pm

opencdr

Subscriberhi,

Have you solved the problem?I'm doing the same job as you. Do you have a good solution?

Thank You

-

February 12, 2020 at 2:16 pm

sravank

SubscriberHai

Still working on it..

Same job means..?? Can i know the project title /domain ...??

Thank you

-

April 30, 2020 at 1:16 pm

sunil.voleti

SubscriberHi sandeep,

could you please explain me about how we can calculate and input laser absorption rate in moving heatflux extension.

thanks in advance.

with regards,

sunil.voleti

-

May 10, 2020 at 10:29 am

Shekhar

SubscriberHi sravank

I need some help to understand your code.

1) U have used velocity as 1.73 mm/s. Is it not a very small value as the welding speed?

2) Why you opt TIME_WELD = 100? Is it the 100 seconds?

3) What is DT?

-

May 15, 2020 at 7:01 am

sravank

SubscriberHai

1. Yes. welding speed is the velocity.

2. Duration of welding time with cooling cycle. In above case welding time is 80sec am giving 20sec cooling.

3. DT - Time steps in the analysis.

Can i know whats you project/research..?? Which domain..?? my contact - ksravank27@gmail.com

Thank you

-

June 25, 2020 at 7:06 am

Hassaan123

SubscriberDear Sandeep,

I want to simulate 2 moving heat sources using moving heat source act. Can I have a tutorial or how can I achieve it?

Regards,

Muhammad Hassaan Bin Tariq

-

July 1, 2020 at 11:45 am

sunil.voleti

SubscriberHai Hassaan,

you can move two or more heatsources by index number,first patch and last patch settings. If there is only one moving heat load then 'first patch' and 'last patch' are both yes,if you have two or more heatsources you can set first patch yes for the first heatsource but last patch as no.set last patch as yes for the last heatsource.

-

July 2, 2020 at 9:39 am

Hassaan123

SubscriberDear sunil.voleti,

Thank you for your response,

It is working. However, when I attach structural analysis, deformation is only shown for the first second. Deformation is not being shown for the whole analysis which is of 12 seconds. Due to which deformation is only shown in the start of the thin sheets. Picture is attached herewith.

Thanks in advance.

Regards,

Muhammad Hassaan Bin Tariq

-

July 3, 2020 at 8:22 am

sunil.voleti

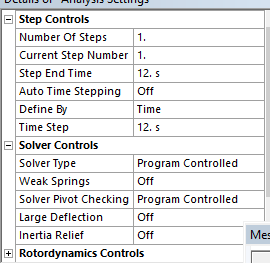

SubscriberIn your "Analyze settings" you have the possibility to define the simulation time. Standard is 1 s. You can define any time you like. Usually the time stepping is default. You set "Auto Time Stepping" to "Off" and "Defined By" to "Time". Then you can define a minimun, a maximum and a start value do define the resolution of your load function. -

July 3, 2020 at 4:02 pm

-

July 4, 2020 at 4:01 am

sravank

SubscriberHi

TIME_WELD (In Command) = No. of steps (Analysis Settings). Change no. of steps not step End time. Try this once

Thank you.

-

July 7, 2020 at 7:22 pm

Hassaan123

SubscriberShould I write this in command section?

Regards

-

July 8, 2020 at 2:25 pm

sunil.voleti

SubscriberIf you defined Apdl code write command in that but I think you are using Moving heatsource extension so please try once changing no. of steps.I think you used no. of steps as 1, so change it with some other no of steps and try

-

July 9, 2020 at 10:50 am

Hassaan123

SubscriberHi Sunil,

Thanks for your response.

I figured out another thing. The problem is with the imported load I suppose. Body temperature is only being imported for 1 sec, therefore stresses are for 1 sec only. Can you help me out in this?

Regards

-

July 4, 2023 at 12:07 pm

DHARMISTA BANALA

Subscriberwhere can i find the extension for goldak heat source model?

-

- The topic ‘SIMULATION | DOUBLE ELLIPSOIDAL HEAT SOURCE MODEL ||’ is closed to new replies.

-

5014

-

1682

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.