TAGGED: membrane-elements, shell-elements

-

-

July 1, 2025 at 2:10 pm

cardiac.scripter

SubscriberHi,

I am using normal shell elements for modelling a pressure application on anatomical valve leaflets. The pressure is applied on the underside of the leaflets and closes them and the leaflets interact with contact. I noticed that the leaflets are struggling to fold tightly. This indicates a high bending stiffness. Therefore, I would like to transition from shell to membrane elements.

However, other papers use membrane elements to model the leaflets. I assumed this is so they can fold in tightly on each other.

I am struggling to transition from normal shells to membrane shells.

This is my current card for normal shells:

*PART_COMPOSITE_CONTACT$# title

Leaflet

$# pid elform shrf nloc marea hgid adpopt thshel

1 2 0.833 0.0 0.0 0 0 0

$# fs fd dc vc optt sft ssf cparm8

$# mid1 thick1 b1 tmid1 mid2 thick2 b2 tmid2

4 0.45

$# mid2 thick2

1 0.1

$# mid3 thick3

4 0.45

and this is my card for membrane shells:

*PART_COMPOSITE_CONTACT$# title

Leaflet

$# pid elform shrf nloc marea hgid adpopt thshel

1 5 0.833 0.0 0.0 0 0 0

$# fs fd dc vc optt sft ssf cparm8

$# mid1 thick1 b1 tmid1 mid2 thick2 b2 tmid2

4 0.45

$# mid2 thick2

1 0.1

$# mid3 thick3

4 0.45

Changing the elform from 2 to 5.

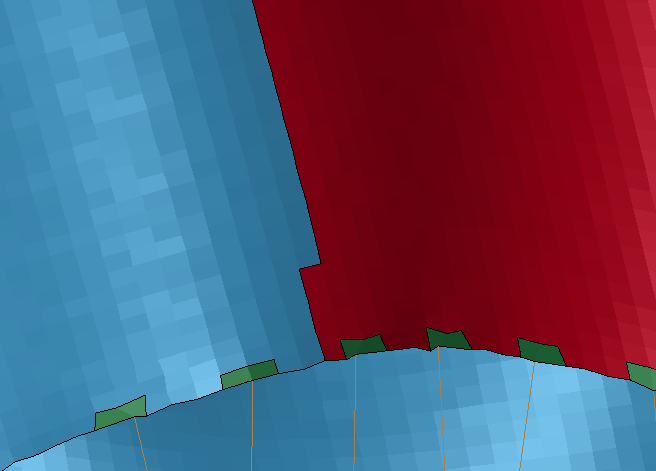

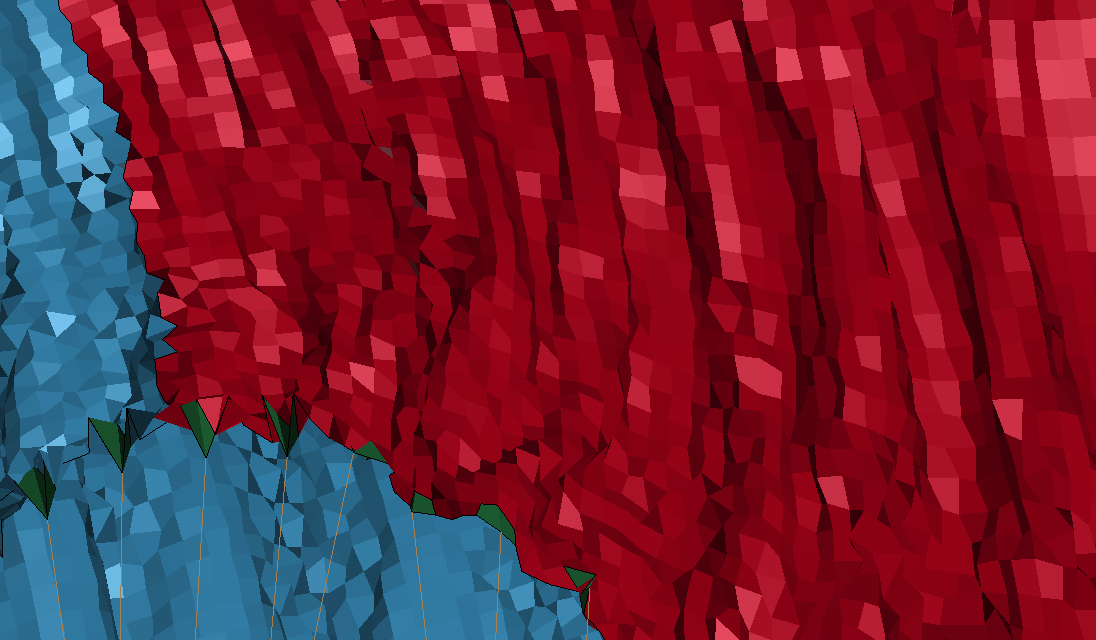

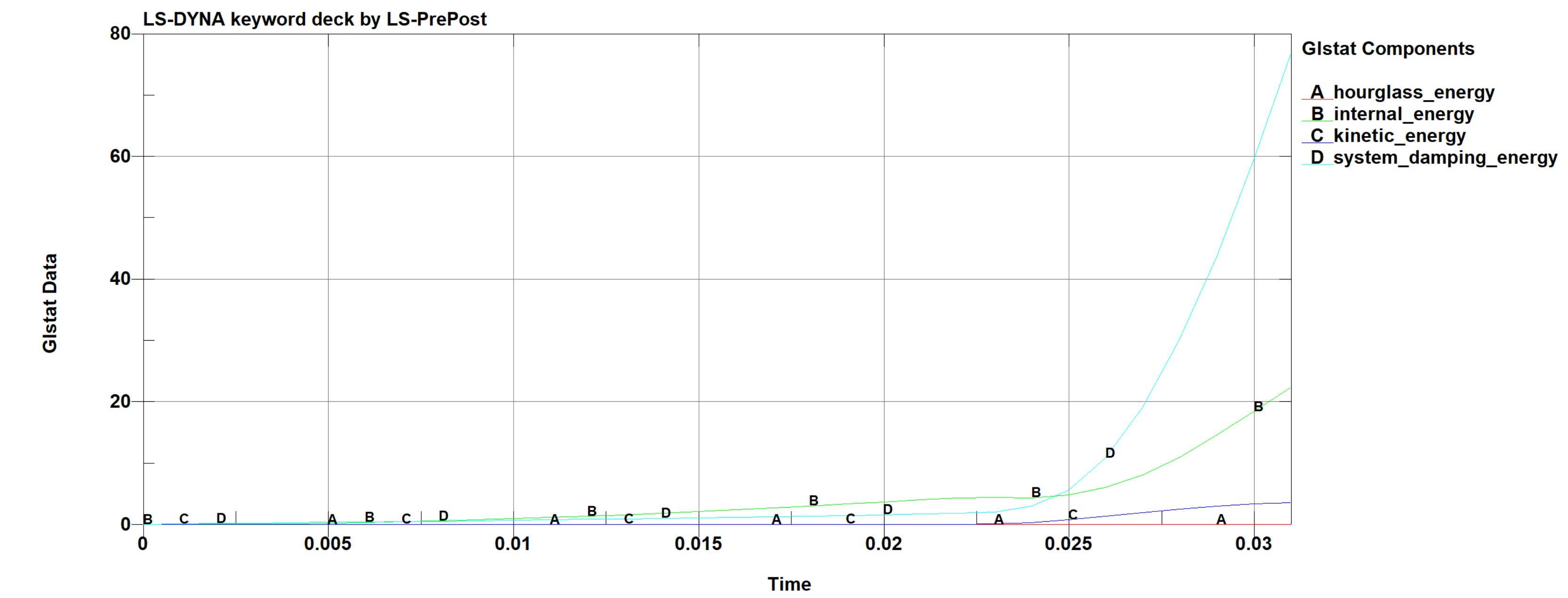

However, I get loads of hourglassing and the simulation fails. See example of two simulations below: à

à

Even with using hourglassing:

*CONTROL_HOURGLASS$# ihq qh

4 0.1

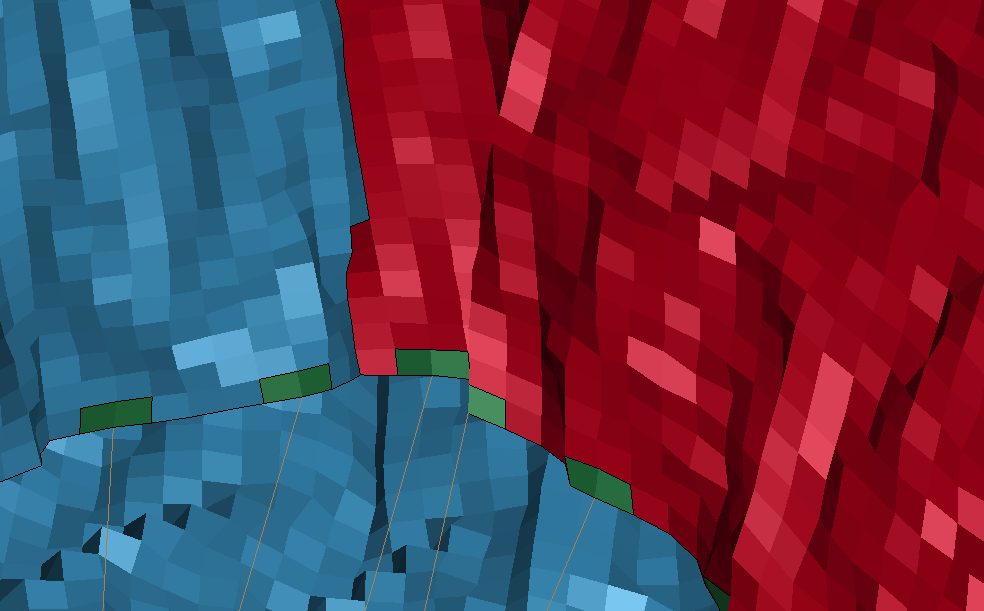

Or even with fully-integrated membrane elements (elform=9) we get failure but without hourglassing:

These are my control keywords:

*CONTROL_TERMINATION

$# endtim endcyc dtmin endeng endmas nosol

0.099 0 0.0 0.0 1e+08 0

*CONTROL_ENERGY

$# hgen rwen slnten rylen irgen maten drlen disen

2 2 2 1 2 1 1 1

*CONTROL_OUTPUT

$# npopt neecho nrefup iaccop opifs ipnint ikedit iflush

1 3 0 0 0.0 0 100 5000

$# iprtf ierode tet10s8 msgmax ipcurv gmdt ip1dblt eocs

0 0 2 50 0 0.0 0 0

$# tolev newleg frfreq minfo solsig msgflg cdetol

2 0 1 0 0 0 10.0

$# phschng demden icrfile spc2bnd penout shlsig hisnout engout

0 0 0 0 0 0 0

$# insf isolsf ibsf issf mlkbag

0 0 0 0 0

*CONTROL_TIMESTEP

$# dtinit tssfac isdo tslimt dt2ms lctm erode ms1st

0.0 0.1 0 0.0 0.0 0 0 0

$# dt2msf dt2mslc imscl unused unused rmscl emscl ihdo

0.0 0.0 0

*CONTROL_HOURGLASS

$# ihq qh

4 0.1

*CONTROL_ACCURACY

$# osu inn pidosu iacc exacc

1 2

*CONTROL_BULK_VISCOSITY

$# q1 q2 type btype tstype

1.5 0.06 -2 0 0

*CONTROL_SHELL

$# wrpang esort irnxx istupd theory bwc miter proj

20.0 0 -2 0 2 1 1 1

$# rotascl intgrd lamsht cstyp6 thshel

1.0 0 0 1 0

$# psstupd sidt4tu cntco itsflg irquad w-mode stretch icrq

0 0 0 0 3 0

$# nfail1 nfail4 psnfail keepcs delfr drcpsid drcprm intperr

0 0 0 0 1.0 0

$# drcmth lispsid nlocdt

0 0 0

Here are my material keywords:

*MAT_001

$# mid ro e pr da db unused

1 1.25e-09 32.0 0.45

*MAT_001

$# mid ro e pr da db unused

4 1.25e-09 0.55 0.45

If you could provide some guidance that would be amazing.

Thanks in advance, -

July 2, 2025 at 11:58 am

Ram Gopisetti

Ansys EmployeeHi,

Hi,

I noticed in your information that the

TSSFACvalue is set quite low—at 0.1. Is this intended for a hypersonic model? Typically,TSSFACis a scale factor for the computed time step and is set to 0.9 by default. While it can be reduced for high-energy simulations, such as explosions, it's generally best to keep it at 0.9 for most cases. Could you try adjusting it back to 0.9 and see if the model performs as expected?Also, have you considered using

ELFORM 9withIHQ=8? This configuration provides some warping stiffness and could potentially improve the performance of your model.Cheers,Ram

-

July 2, 2025 at 2:55 pm

cardiac.scripter

SubscriberHi Ram,

I moved to TSSFAC of 0.9.

ELFORM 9 with IHQ=8 looks like it works well. But the shells fail24084 t 2.6000E-02 dt 1.07E-06 write d3plot file 07/02/25 15:51:3025000 t 2.6985E-02 dt 1.07E-06 flush i/o buffers 07/02/25 15:51:3225014 t 2.7000E-02 dt 1.07E-06 write d3plot file 07/02/25 15:51:3225952 t 2.8000E-02 dt 1.06E-06 write d3plot file 07/02/25 15:51:3426911 t 2.9000E-02 dt 1.04E-06 write d3plot file 07/02/25 15:51:3627894 t 2.9999E-02 dt 9.79E-07 write d3plot file 07/02/25 15:51:3928910 t 3.0999E-02 dt 1.02E-06 write d3plot file 07/02/25 15:51:42*** Error 40500 (SOL+500)node # 7828 has out-of-range velocitiesx-velocity= -1.3640E+30y-velocity= -3.9775E+28z-velocity= 3.2981E+29*** Error 40500 (SOL+500)node # 7829 has out-of-range velocitiesx-velocity= -1.3688E+30y-velocity= -3.9997E+28z-velocity= 3.2999E+29*** Error 40500 (SOL+500)node # 7936 has out-of-range velocitiesx-velocity= 1.6540E+30y-velocity= 9.2023E+29z-velocity= 4.4860E+28Here is my contact keyword:

*CONTACT_AUTOMATIC_SINGLE_SURFACE

$# cid title

$# surfa surfb surfatyp surfbtyp saboxid sbboxid sapr sbpr

3 0 2 0 0 0 0 0

$# fs fd dc vc vdc penchk bt dt

0.0 0.0 0.0 0.0 60.0 0 0.0 0.0

$# sfsa sfsb sast sbst sfsat sfsbt fsf vsf

1.0 1.0 0.0 0.0 1.0 1.0 1.0 1.0

$# soft sofscl lcidab maxpar sbopt depth bsort frcfrq

2 0.1 0 1.025 2 2 0 1

I noticed also the damping is very high:

*DAMPING_GLOBAL

$# lcid valdmp stx sty stz srx sry srz

0 2500.0 0.0 0.0 0.0 0.0 0.0 0.0

Cheers,

Ben -

July 2, 2025 at 3:40 pm

cardiac.scripter

SubscriberHi Ram,

I have simplified my parts so that they are no longer composites. Material model is *MAT_ELASTIC.

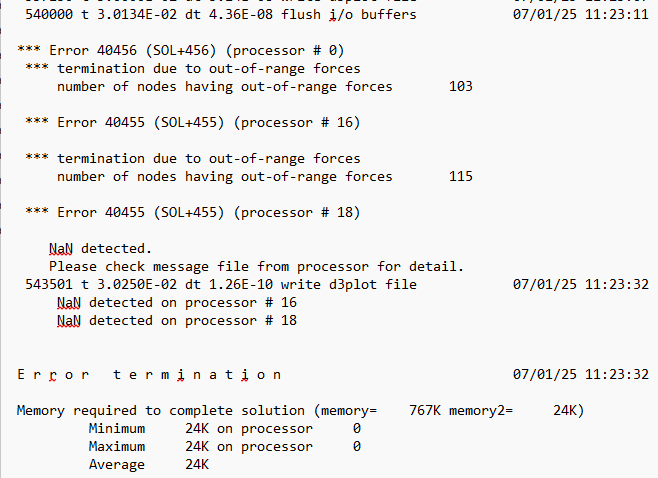

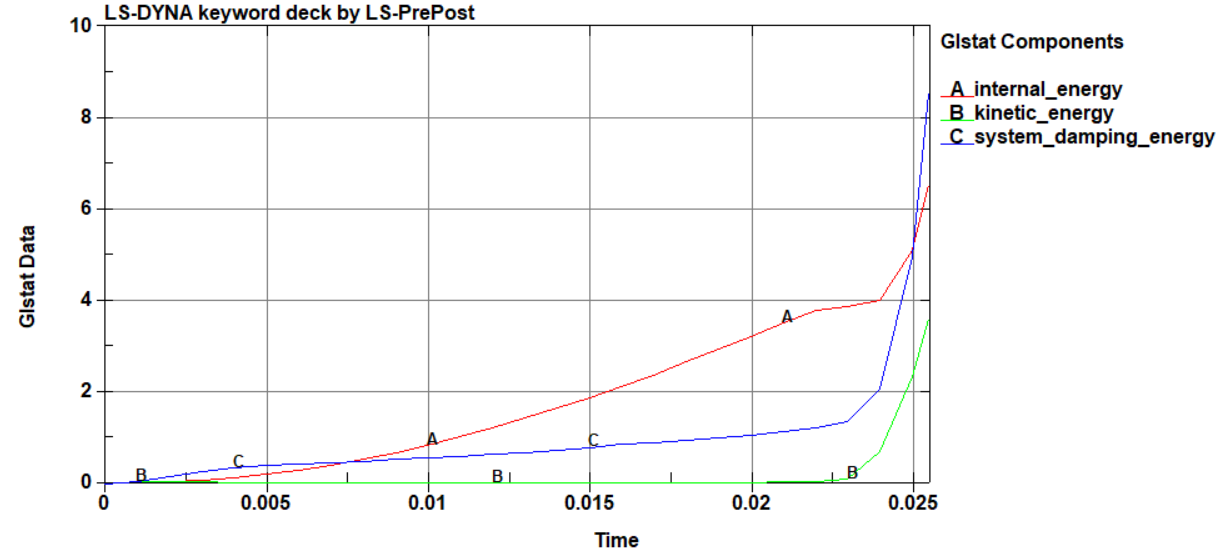

Now I get failure at 26% through simulation. With these failure messages:

43800 t 2.0000E-02 dt 4.53E-07 write d3plot file 07/02/25 16:35:11

45000 t 2.0543E-02 dt 4.53E-07 flush i/o buffers 07/02/25 16:35:17

46008 t 2.1000E-02 dt 4.53E-07 write d3plot file 07/02/25 16:35:23

48215 t 2.2000E-02 dt 4.53E-07 write d3plot file 07/02/25 16:35:29

50000 t 2.2807E-02 dt 4.53E-07 flush i/o buffers 07/02/25 16:35:34

50426 t 2.3000E-02 dt 4.53E-07 write d3plot file 07/02/25 16:35:36

52630 t 2.4000E-02 dt 4.67E-07 write d3plot file 07/02/25 16:35:43

54793 t 2.5000E-02 dt 4.53E-07 write d3plot file 07/02/25 16:35:50

55000 t 2.5094E-02 dt 4.55E-07 flush i/o buffers 07/02/25 16:35:51

57041 t 2.6000E-02 dt 4.26E-07 write d3plot file 07/02/25 16:35:58

beam element 40 failed at time 2.6465E-02

beam element 56 failed at time 2.6465E-02

beam element 38 failed at time 2.6465E-02

beam element 39 failed at time 2.6465E-02

beam element 55 failed at time 2.6465E-02

beam element 57 failed at time 2.6465E-02

shell element 15871 failed at time 2.6465E-02

shell element 16328 failed at time 2.6465E-02

shell element 19092 failed at time 2.6465E-02

shell element 19093 failed at time 2.6465E-02

shell element 19094 failed at time 2.6465E-02

shell element 19095 failed at time 2.6465E-02

shell element 20939 failed at time 2.6465E-02

shell element 21398 failed at time 2.6465E-02

shell element 21857 failed at time 2.6465E-02

shell element 21862 failed at time 2.6465E-02

shell element 23234 failed at time 2.6465E-02

shell element 19109 failed at time 2.6465E-02

shell element 21861 failed at time 2.6465E-02

These are my energies just before failure:

These are my control cards:

*CONTROL_ACCURACY

$# osu inn pidosu iacc exacc

1 2 0 0 0.0

*CONTROL_BULK_VISCOSITY

$# q1 q2 type btype tstype

1.5 0.06 -2 0 0

*CONTROL_ENERGY

$# hgen rwen slnten rylen irgen maten drlen disen

2 2 2 1 2 1 1 1

*CONTROL_HOURGLASS

$# ihq qh

8 0.1

*CONTROL_OUTPUT

$# npopt neecho nrefup iaccop opifs ipnint ikedit iflush

1 3 0 0 0.0 0 100 5000

$# iprtf ierode tet10s8 msgmax ipcurv gmdt ip1dblt eocs

0 0 2 50 0 0.0 0 0

$# tolev newleg frfreq minfo solsig msgflg cdetol igeom

2 0 1 0 0 0 10.0 1

$# phschng demden icrfile spc2bnd penout shlsig hisnout engout

0 0 0 0 0 0 0 0

$# insf isolsf ibsf issf mlkbag kineng isfcnt

0 0 0 0 0 0 1

*CONTROL_SHELL

$# wrpang esort irnxx istupd theory bwc miter proj

20.0 0 -2 0 2 1 1 1

$# rotascl intgrd lamsht cstyp6 thshel

1.0 0 0 1 0

$# psstupd sidt4tu cntco itsflg irquad w-mode stretch icrq

0 0 0 0 3 0.0 0.0 0

$# nfail1 nfail4 psnfail keepcs delfr drcpsid drcprm intperr

0 0 0 0 0 0 1.0 0

$# drcmth lispsid nlocdt iswshl

0 0 0 0

*CONTROL_TERMINATION

$# endtim endcyc dtmin endeng endmas nosol

0.1 0 0.0 0.01.000000E8 0

*CONTROL_TIMESTEP

$# dtinit tssfac isdo tslimt dt2ms lctm erode ms1st

0.0 0.9 0 0.0 0.0 0 0 0

$# dt2msf dt2mslc imscl unused unused rmscl emscl ihdo

0.0 0 0 0.0 0.0 0

-

- You must be logged in to reply to this topic.

-

3402

-

1052

-

1050

-

896

-

872

© 2025 Copyright ANSYS, Inc. All rights reserved.