-

-

September 1, 2025 at 2:44 am

powerrep3

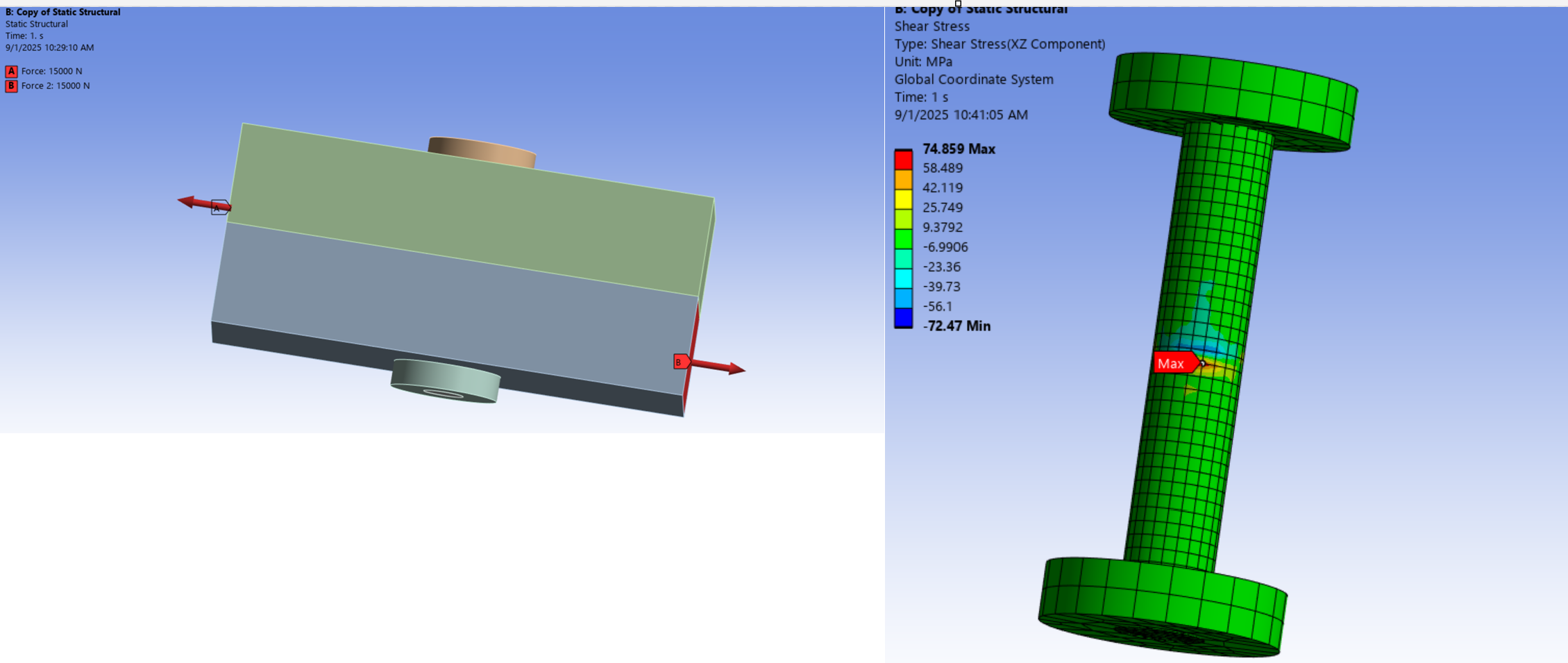

SubscriberHello, I'm trying to compare the analytical result with the simulation result for the shear stress of a bolt.The bolt has a diameter of 16 mm. It is located at the center between two sliding plates. One end of the top plate (left side) is subjected to a 15 kN force, while the opposite end of the bottom plate (right side) is also subjected to a 15 kN force. The calculated analytical result for shear stress is 74.6 MPa.I ran the simulation in Ansys. The contacts were set to frictionless for the sliding parts only and bonded for the other parts. The results I obtained with different mesh sizes are:20 mm mesh size → 50 MPa10 mm mesh size → 60 MPa5 mm mesh size → 66 MPa2.5 mm mesh size → 74.8 MPa1.25 mm mesh size → 119 MPaI thought I was on the right track since the 2.5 mm mesh gave a result very close to the analytical value. However, I expected the 1.25 mm mesh to give an even closer result t0 74MPA , but instead, it gave a much higher stress.Is there something wrong with my setup? Thanks -

September 1, 2025 at 4:42 pm

peteroznewman

SubscriberHow is this structure connected to ground? A better set of loads and supports would be a fixed support on the bottom plate face where the force is applied, and that force deleted. The reaction force of the fixed support will be 15 kN in the normal direction.

Are the bonded faces only the annular ring of the nut and bolt head to the bottom and top faces of the plates?

Is there frictionless contact between the shaft and the two holes?

-

Viewing 1 reply thread

- You must be logged in to reply to this topic.

Ansys Innovation Space

Trending discussions

Top Contributors

-

3832

-

1394

-

1188

-

1100

-

1015

Top Rated Tags

© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.