-

-

August 30, 2020 at 2:44 am

Autonewbie

SubscriberHello~

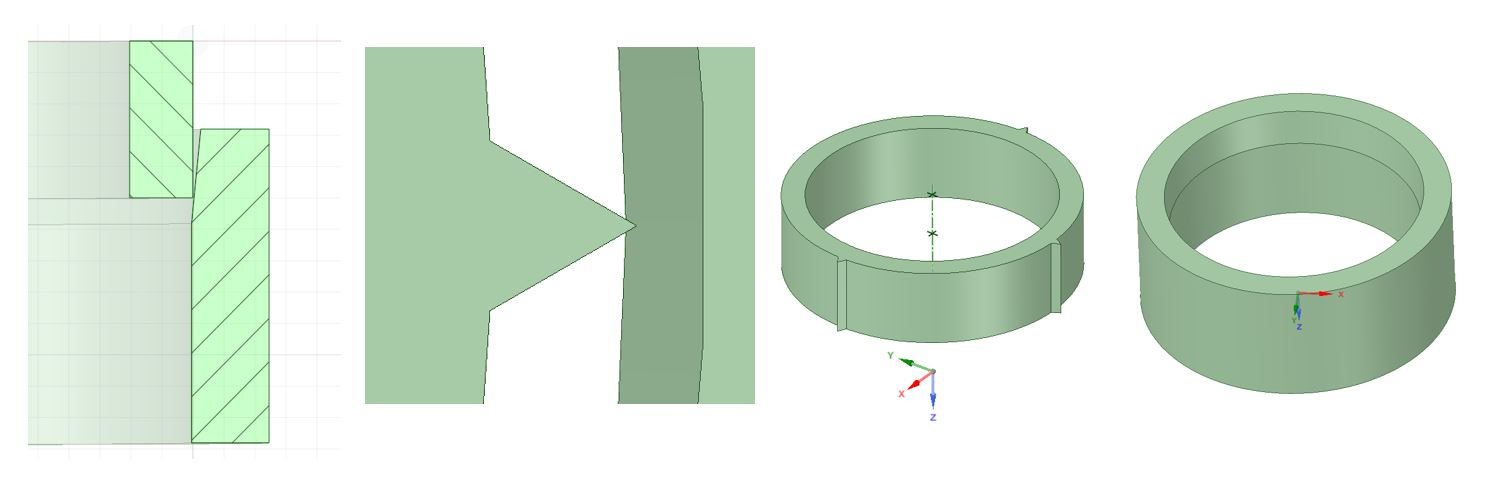

I am simulating a sharp rib with very small interference fit of 0.04mm. It is injection molding.

But I am having convergence issue when I try to press the part into another part. Any tips? Thanks!

August 30, 2020 at 4:12 ampeteroznewman

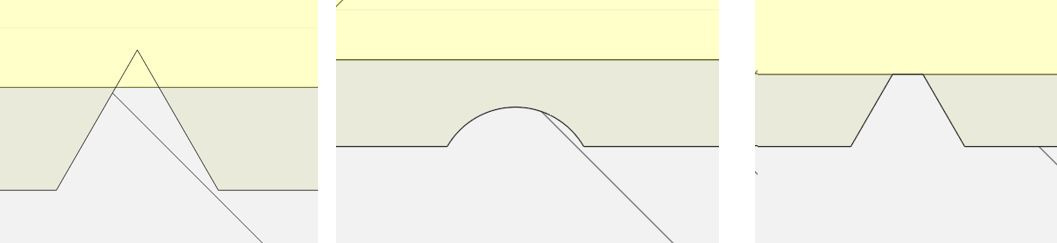

SubscriberPut a small radius on the tip of the rib and put 10 elements around the radius. Make equally small elements on the part making contact with the rib.nUse plasticity in the material model.nDo you need to simulate the axial insertion or can you just simulate the parts already in place and just let contact resolve the interference? It will be easier not to slide the parts together.nIf you don't need to slide the parts together, then you can use a 2D plane strain model instead of a 3D model.nUse Symmetry.nAugust 30, 2020 at 8:23 amAutonewbie

SubscriberHi Peter,nIn fact, I need to simulate the pull out force and if I make the tip rounded, the interference fit will not be captured. nI did once by using rounded tip but the result did not correlate to test result... Test result is much smaller.nAugust 30, 2020 at 1:19 pmpeteroznewman

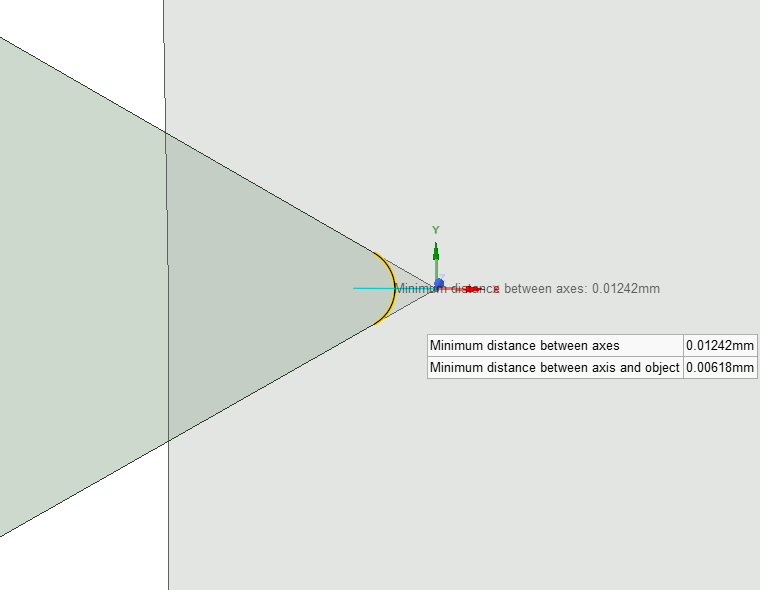

SubscriberSo you are saying that my advice worked, putting a radius on the tip helped the simulation to converge. That was your original question. You can simply offset the face of the other part to regain the missing interference. In this example, offset the contact by 0.00618 mm and you will still have 0.04 mm of interference.n nNow you want to tune a simulation to agree with an experimental result. That is a new and different question. You say the pull out force gave a lower value than the force in the model, but the model looks like it was setup to insert the pipe. Did you have a two-step simulation where you first did the insertion and then did the pull-out? I expect the pull-out forces to be lower than the insertion forces due to the plastic work that goes into deforming the two parts during insertion. Did you have plasticity in the model? One way to match the pull-out force is to lower the coefficient of friction in the contact between the rib and the pipe.nIn the experiment, how much time elapsed between insertion and pull-out? Did the material model include creep properties and was the elapsed time included in the simulation?n

August 30, 2020 at 3:18 pm

nNow you want to tune a simulation to agree with an experimental result. That is a new and different question. You say the pull out force gave a lower value than the force in the model, but the model looks like it was setup to insert the pipe. Did you have a two-step simulation where you first did the insertion and then did the pull-out? I expect the pull-out forces to be lower than the insertion forces due to the plastic work that goes into deforming the two parts during insertion. Did you have plasticity in the model? One way to match the pull-out force is to lower the coefficient of friction in the contact between the rib and the pipe.nIn the experiment, how much time elapsed between insertion and pull-out? Did the material model include creep properties and was the elapsed time included in the simulation?n

August 30, 2020 at 3:18 pmAutonewbie

Subscriber nActually the model not exactly rounded tip as the interference fit is below 0.1mm. If I make it round, there is a gap appears, so I make it flat by touching and input a offset to simulate the interference fit.nI did not run two steps simulation like insert and pull out but just simulating the contact pressure due to the fit. The simulation was considering plasticity but it is just getting the contact pressure (not insertion and pull out) and calculate the friction force for predicting pull out force.nI need to find out the elapsed time from the test guy but good tip!n

August 31, 2020 at 1:29 pm

nActually the model not exactly rounded tip as the interference fit is below 0.1mm. If I make it round, there is a gap appears, so I make it flat by touching and input a offset to simulate the interference fit.nI did not run two steps simulation like insert and pull out but just simulating the contact pressure due to the fit. The simulation was considering plasticity but it is just getting the contact pressure (not insertion and pull out) and calculate the friction force for predicting pull out force.nI need to find out the elapsed time from the test guy but good tip!n

August 31, 2020 at 1:29 pmAutonewbie

SubscriberHi Peter,nIs that possible to run the simulation with sharp tip?nAugust 31, 2020 at 3:45 pmpeteroznewman

SubscriberA sharp tip has an infinite stress, so it tends to have problems convergingnViewing 6 reply threads- The topic ‘Sharp Rib Contact’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4999

-

1675

-

1386

-

1248

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.