TAGGED: 2D, convergence, mesh-convergence, mesh-generation, structural-mechanics

-

-

August 11, 2020 at 4:19 pm

aimeri42

SubscriberDear community,

Before I share my problem, I want to say that I have seen similar posts like mine, but I could not figure the solution from them.

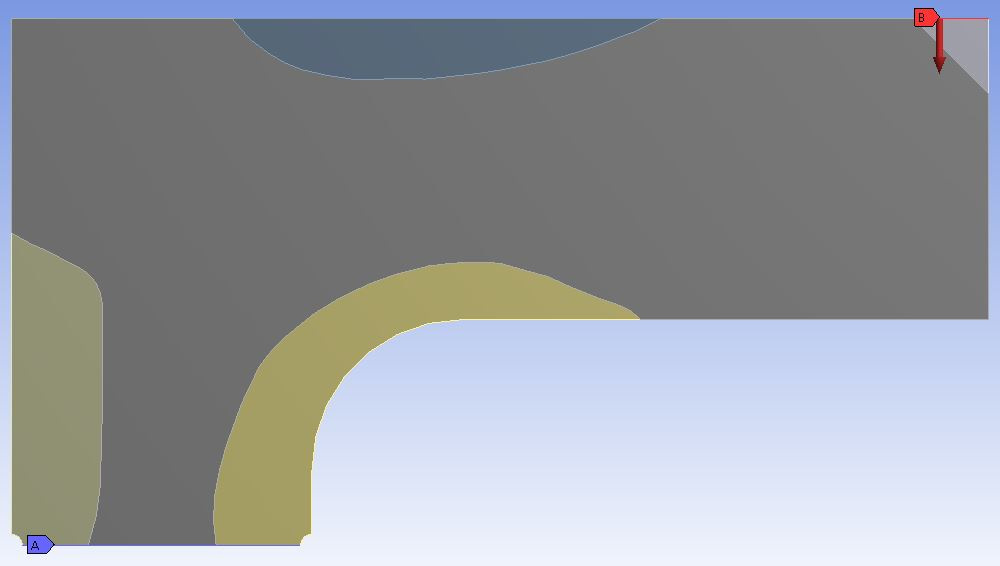

I am doing 2D analysis on a curved beam by applying a load ( fig1) then based on the analysis I am separating the regions with higher strain ( with the idea of using different material in there). However, every time I change mesh size, the results (strain energy) change by one magnitude of order. The geometry is simple, but the results are not converging. Could you please give me some tips or help on how to make the study mesh independent and have the results converge? Attached you will find the figures and the table of data. The material is ABS plastic.

August 12, 2020 at 3:15 ampeteroznewman

SubscriberAugust 13, 2020 at 7:17 pmaimeri42

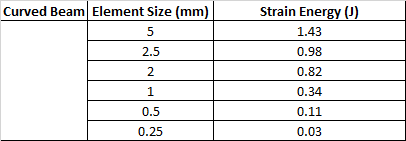

SubscriberHello peteroznewman, thanks for your reply!To avoid that, I went and changed geometry to the figure below. n However, whenever I reduce the element size, the results are always changing by an order. The table shows the result:n

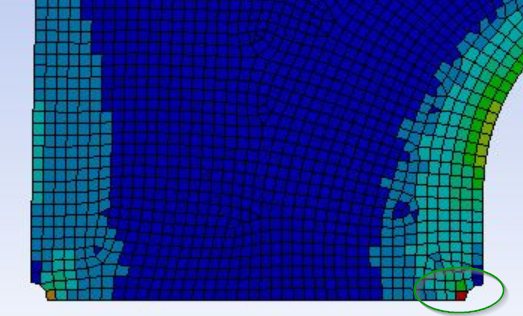

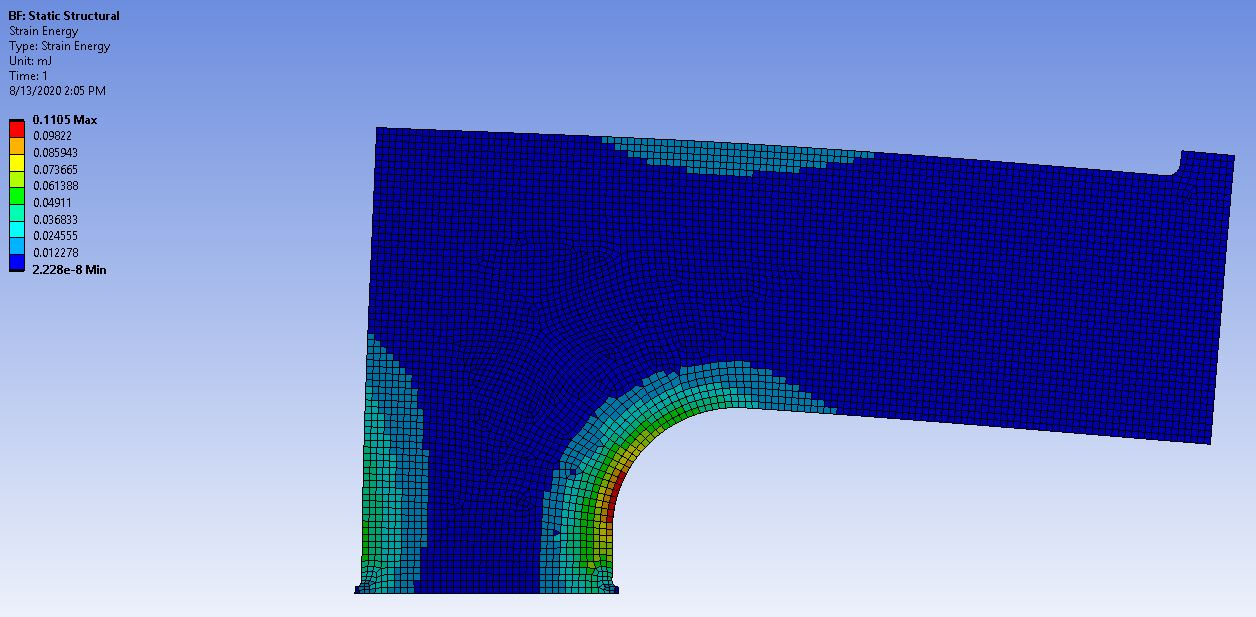

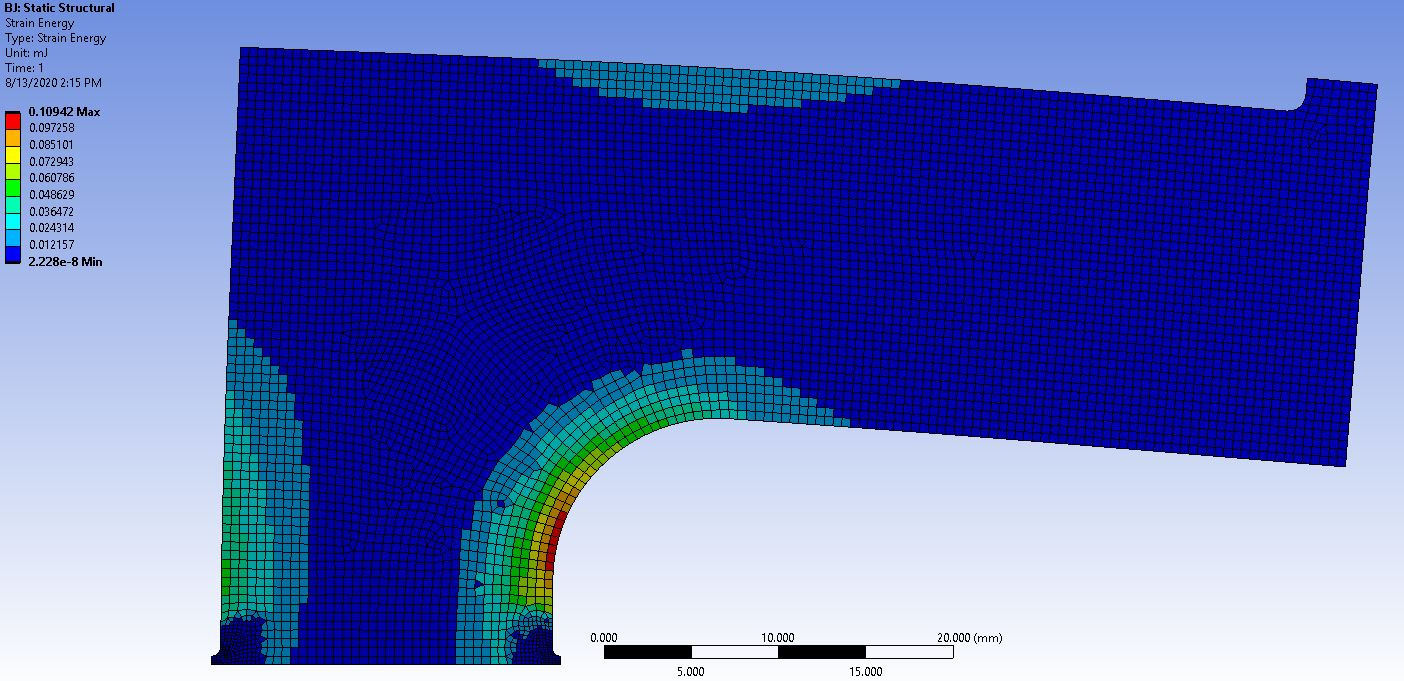

However, whenever I reduce the element size, the results are always changing by an order. The table shows the result:n Further, for the cases of 5, 2.5, and 0.5 mm, I added convergence, which give 0.1221, 0.561, and 0.109, respectively. The convegence is set up to 2% maximum change and it goes to 5 max refinement loops with 3 refinement depth. nPicture of the 0.5mm converged results is shown in the figure belown

Further, for the cases of 5, 2.5, and 0.5 mm, I added convergence, which give 0.1221, 0.561, and 0.109, respectively. The convegence is set up to 2% maximum change and it goes to 5 max refinement loops with 3 refinement depth. nPicture of the 0.5mm converged results is shown in the figure belown nI mean what could be the reason now? How can I make sure that any of these results are the ones that I need, when they are always changing? Your input is greatly appreciated. n

August 14, 2020 at 9:49 am

nI mean what could be the reason now? How can I make sure that any of these results are the ones that I need, when they are always changing? Your input is greatly appreciated. n

August 14, 2020 at 9:49 ampeteroznewman

SubscriberI see that the mesh refinement is happening at the lip at the bottom and not at the point of maximum strain energy. If you turn on the Maximum flag, does it show up in the red area? I recommend you not have any geometry change at that lower corner. Try a simple right angle corner. Delete the Convergence Tool from the Result and perform the Mesh Sizing manually.nApply a Sizing mesh control to the large curved edge where the point of maximum strain energy occurs. That mesh control is where you need to sweep through your set of element sizes. Make the Element Size a Parameter. On the Strain Energy result, make the Maximum value a Parameter. Now in the Parameter Table of Design Points, you can type the six element sizes and click Update All Design Points and let the automation step through the solutions for you.nAugust 24, 2020 at 8:09 pmaimeri42

SubscriberHello peteroznewman,Thank you for your feedback. What I realized is that I was looking at the maximum strain energy per element, and not the total strain energy. So whenever, I was decreasing the element size, since the area of the element is decreasing, the strain energy of the element is decreasing as well. Because of the simple shape, the results converge at much higher element size than 0.5mm for total strain energy.I have one question, though, if possible. I do not know how to parameterize like you suggested, do you have any tutorial for that? If so I would really appreciate it. In anyway, thank you very much for you help! nViewing 4 reply threads- The topic ‘Results are not converging – Static Structural’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3597

-

1283

-

1107

-

1068

-

983

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-