-

-

July 1, 2019 at 11:05 pm

ygauri

SubscriberHello,

I am performing Modal Analysis on Gas Compression Skid. Parts like engine and compressor are bolted to pedestal in reality. So while performing Modal analysis what type of connections I should use?

I tried to use bonded connection between two faces but not getting desired output. Looking for some helpful guidance urgently.

-

July 2, 2019 at 12:16 am

peteroznewman

SubscriberI would also have chosen bonded contact. Why do you think you are not getting the desired output?

-

July 2, 2019 at 12:43 am

ygauri

SubscriberI am not sure. I think may be my connections in region of bolts should not be bonded and must be something different. Is there a way to give contact region of certain diameter around the holes, so that rest of area will be free and only the region falling within that diameter will be bonded.

-

July 2, 2019 at 12:45 am

peteroznewman

SubscriberPlease reply with some images of your geometry and show me what your area of concern is.

You can divide faces and bond only on local areas instead of the whole face.

-

July 2, 2019 at 12:51 am

ygauri

Subscriber

So basically my entire modal is huge and many different parts. So to avoid long computational time, I am using block of same weight as of original engine. An engine is mounted on feet and then feet on pedestal. So what's best way to connect engine on feet and feet on pedestal to get correct natural frequencies?

Also I am not considering Pre-Stress Analysis because for modal analysis unbalance forces don't need be consider, correct?

Thank you in advance for all your help and guidance Sir. I really appreciate it.

-

July 2, 2019 at 12:59 am

peteroznewman

SubscriberBonding the whole flat surface of the grey foot to the pedestal is overly stiff.

You can instead make a beam connection between the ID of each bolt hole in the foot with the adjacent bolt hole in the pedestal. You get to specify the beam radius and its material.

-

July 2, 2019 at 1:02 am

ygauri

Subscriberyes, I will try that and will let you know whether it worked or no. Also its fine if I don't consider Pre-Stress Analysis for my modal?

-

July 2, 2019 at 11:05 am

peteroznewman

SubscriberI doubt the Pre-Stress will move the Modal results very much at all, but it is easy to setup and run both ways to check.

-

July 2, 2019 at 2:15 pm

ygauri

Subscriberis there way in ANSYS to apply directly horizontal and stretch components value of unbalance forces at CG?

Also for connections: connection between pedestal and plate, I have selected edge of pedestal (brown color geometry) and entire surface of plate (dark grey flat surface) is that appropriate or it will make my modal again overly stiff?

-

July 2, 2019 at 2:25 pm

peteroznewman

SubscriberHow many bolts hold the brown pedestal to the grey plate? Put holes in both parts and use Beams to connect the two holes.

The best way to apply a horizontal force to the CG of a body is to use an Acceleration load. Calculate a = Force/mass. Note that the acceleration applies to all mass in the model, not to a single body.

-

July 2, 2019 at 2:34 pm

ygauri

SubscriberThanks for the info sir, but brown pedestal will be welded to plate. And welding will be done at the boundaries of pedestal. So for that what would be the appropriate connection.

-

July 2, 2019 at 4:37 pm

ygauri

SubscriberAlso I am getting many extra natural frequencies and mode shapes that are not according to my expected results.

-

July 2, 2019 at 6:56 pm

peteroznewman

SubscriberMake the four sides of the brown pedestal a Fixed Support and suppress the grey plate from the analysis.

Please describe the experimental results and how they were measured and then describe the Modal analysis results.

-

July 2, 2019 at 8:09 pm

ygauri

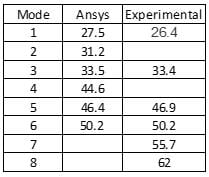

SubscriberI am trying to extract 6 mode shapes. The values are as follows in Hz from Modal Analysis:

27.5, 31.2, 33.5, 44.6, 46.4, 50.2.

I am just trying to match the results with the report I have from some outsourced company. According to them for same model I should get results as:

26.4, 33.4, 46.9, 50.2, 55.7 and 62.

So according to me I am getting extra modes in-between. I have used I beam connection for holes with dia of 0.5. For fixtures I have used elastic support to the base plate because that will be filled with concrete. The value for elastic support I have used is of 10000.

To describe my setup: Engine, compressor frame and cylinders are mounted on pedestal. Entire pedestal is mounted on plate called deck plate. Deck plate is welded to frame made up of I beams.

-

July 3, 2019 at 2:10 pm

ygauri

SubscriberI am trying to extract 6 mode shapes. The values are as follows in Hz from Modal Analysis:

27.5, 31.2, 33.5, 44.6, 46.4, 50.2.

I am just trying to match the results with the report I have from some outsourced company. According to them for same model I should get results as:

26.4, 33.4, 46.9, 50.2, 55.7 and 62.

So according to me I am getting extra modes in-between. I have used I beam connection for holes with dia of 0.5. For fixtures I have used elastic support to the base plate because that will be filled with concrete. The value for elastic support I have used is of 10000.

To describe my setup: Engine, compressor frame and cylinders are mounted on pedestal. Entire pedestal is mounted on plate called deck plate. Deck plate is welded to frame made up of I beams.

So is there anyway that you can guide me to rectify my mistake, so that can get desired results.

-

July 3, 2019 at 2:53 pm

peteroznewman

SubscriberHere is how I would lay out the frequencies and the modes.

Please rerun the Modal analysis and request 12 modes and fill in the next few cells to see if you get close to 62 Hz.

When a structure is symmetric, ANSYS will report a double mode, one for each coordinate direction, but an experimental report will see only one mode, and will not report a double mode. I haven't seen the shape of the modes but that could be happening for one of the closely spaced modal frequencies. You haven't shown the mesh, you might find that as you refine the mesh, you get slight movement in these frequencies. Please reduce the element size and rerun the Modal analysis.

While ANSYS shows mode shapes, what is in the experimental report on the mode shape? How did they determine a resonance frequency? Did they use accelerometers to measure the response of the structure? How many locations did they monitor? How many axes did they monitor? It is quite easy for a sensor to miss a mode that is calculated by ANSYS if a mode does not excite the motion at that particular location. That happened in this example.

-

July 3, 2019 at 3:50 pm

ygauri

Subscriberyes sir, that might be case of double mode. And the report with which I am comparing is of Modal Analysis using ANSYS. In short I have report of modal analysis performed using ANSYS by someone else and I am trying to perform the modal analysis on same modal and get the same outputs. But somehow m y output is not similar to him not even mode shapes. I will post mode shapes as well in a while to give you idea about how my model is behaving.

-

July 3, 2019 at 4:42 pm

-

July 3, 2019 at 6:16 pm

peteroznewman

SubscriberOh, I thought the outside company was providing an experimental result, so you should have their mode shapes if it is a Modal analysis.

Do you know how to Suppress Geometry? Go in and suppress all the geometry except for the brown pedestal, the four feet and the engine block. Make the four sides of the brown pedestal a Fixed Support.

Click on Mesh and in the Details window, you want to make sure it is using Quadratic elements and has at least two element through the thickness of the thin walled part of feet.

-

July 3, 2019 at 6:26 pm

ygauri

SubscriberYes sir, I have their mode shapes. So by doing this suppress thing, what should be expected?

Just to know about connections?

While importing modal ANSYS generates the connections on it owns, so if check overlapping it says few connections are overlapping, so is there any easy way to fix those overlapping. It seems if one face has many connections then ANSYS consider it as overlapping.

Also the solving method I am using is Direct because its giving me error in PCG metho (iterative)

Also the mode shapes from other company has same mode shapes (first 2 mode shapes) to mine but the frequency values are different.

-

July 3, 2019 at 6:36 pm

ygauri

SubscriberSo sir, to have atleast two elements through thickness, I should just select the feet and use Num cells across gap =2 ?

-

July 3, 2019 at 6:47 pm

peteroznewman

SubscriberSuppressing unnecessary geometry will result in the Modal analysis taking less time to solve. That is all.

Turn off the automatic detection of contacts on Attach. However, suppressing does not require a new Attach. Delete all the new contacts that were created.

Direct solving is best unless it is a very large model and you run out of RAM.

Two elements through the thickness is a Global setting. It might cause your frequencies to move around a little because of a better quality mesh.

-

July 3, 2019 at 7:21 pm

ygauri

Subscriberso if my modal is created in solidworks and all the parts are matted properly then I don't need to create any contacts in ANSYS?

-

July 3, 2019 at 7:36 pm

peteroznewman

SubscriberThe mates in SolidWorks keep the solid bodies in the correct location in space.

When the geometry comes into ANSYS for the first time, you have to either manually or automatically define Contacts.

If you have the SolidWorks CAD interface, so ANSYS brings the model straight into Mechanical from SW, then you can bring geometry updates from SW into Mechanical and all the work you have previously done creating contacts should be maintained and all the contacts will simply update to the new geometry.

-

July 3, 2019 at 8:55 pm

-

July 3, 2019 at 9:42 pm

-

July 3, 2019 at 10:25 pm

peteroznewman

SubscriberThe Mesh setting for Proximity that I showed in my post above is what automatically puts 2 elements through the thickness. Did you do that? It sometimes doesn't take if some other settings are way off, like the element size.

-

July 3, 2019 at 10:31 pm

ygauri

SubscriberYes, I tried with that just now, still the output is not according to expectation.

-

July 3, 2019 at 10:40 pm

peteroznewman

SubscriberWould you like to save a Workbench Project Archive .wbpz file and attach that after you reply with the version of ANSYS you are using? I will take a look. Note the file size must be < 120 MB.

-

July 3, 2019 at 10:43 pm

ygauri

Subscribercan I email you that file sir?

Would be happy to get your email id.

-

July 3, 2019 at 11:19 pm

ygauri

SubscriberIs there way to arrange meeting via webex to better understand my modal. Because sir I won't be able to upload file because of my privacy issues.

-

July 3, 2019 at 11:54 pm

peteroznewman

SubscriberIf you do a Save As in SolidWorks, and keep only 6 solids: the four feet, the pedestal and the block, and you slice off the left end of the pedestal to simplify it further, that surely has no issues with privacy since there is nothing confidential in those 6 solids. That would be a nice small assembly to do a modal on.

I don't use my email to help students with their problems on this site, I only use that for paid work.

If you have a Webex account, I would be willing to talk with you in a web meeting. If you don't have webex, open a free account on www.join.me and you can share your screen with me. What time zone are you in? I am available today.

-

July 8, 2019 at 6:25 pm

ygauri

SubscriberHello Sir,

I have attached the file for which performing modal analysis. If I talk about the connections then, all the outer two holes of feet are bolted to pedestal. The pedestal is welded at boundaries to deck plate and finally deck plate is welded at boundaries to foundation made up of I beams. Also the cylinders are bolted to cross head guide supports and they are bolted to compressor frame. Also those cylinders are bolted to T supports and they are welded to deck plate.

I tried but getting same off values of frequency as I have shared while ago.

I would be happy sir if you can help me with my modal. Let me know after having look to my modal.

The ANSYS version is R1 2019

-

July 8, 2019 at 7:13 pm

peteroznewman

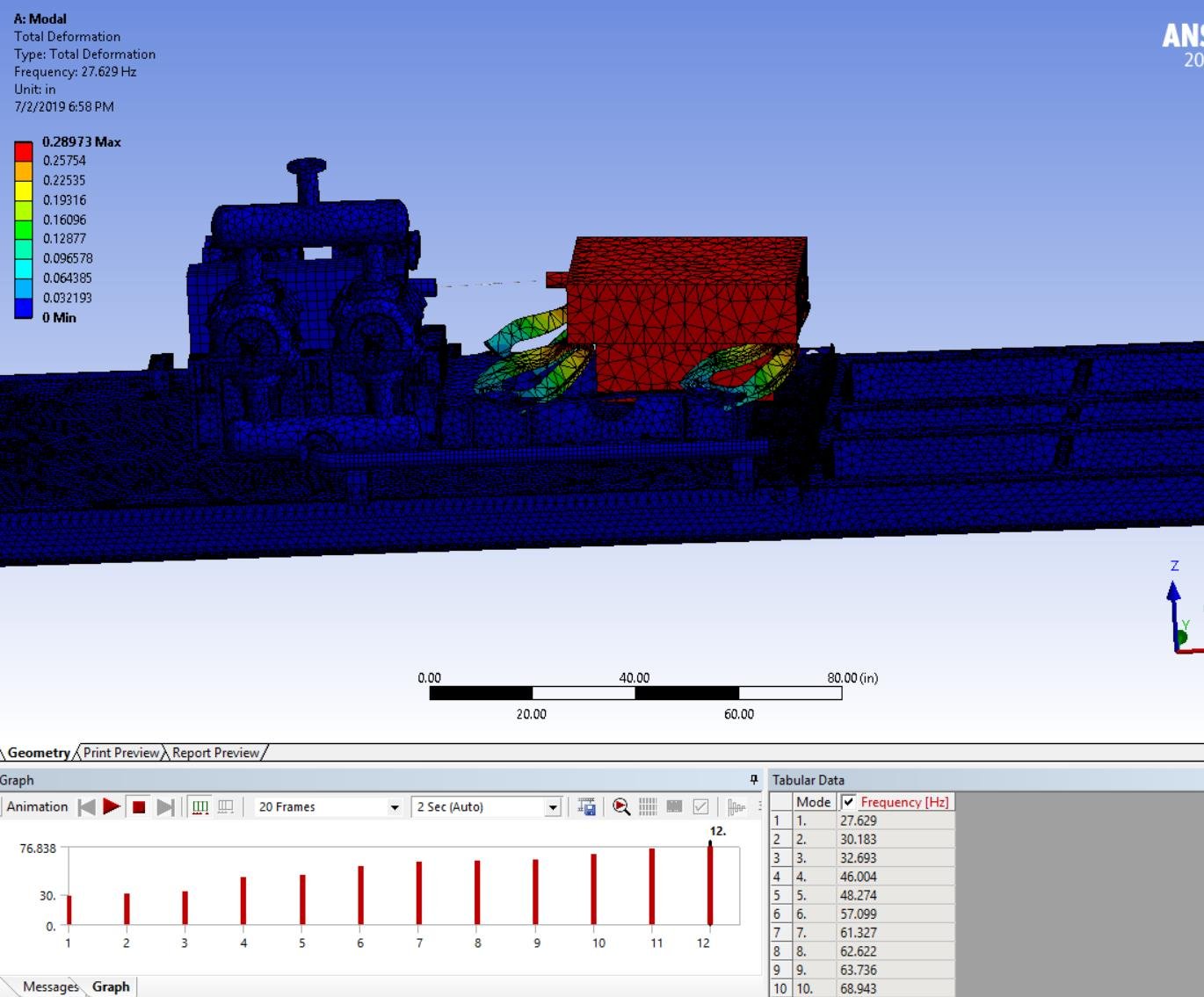

SubscriberI thought you were only interested in the Modal of the grey block on the feet.

Why do you have all this other geometry which is not even hollow?

Isn't this all you want in the Modal analysis?

What is the true mass of the Grey Engine Block?

The properties show it has a mass of 3,700 kg. Is that correct?

-

July 8, 2019 at 8:05 pm

ygauri

SubscriberHello,

I am interested in mode shapes of engine and compressor and cylinders. So that's why I have included that. All the dimensions with proper materials are in lbs and inch. I have attached the updated file. The output I am expecting is:

Frequency (Hz): Mode shape of:

1.26.4 Engine

2. 33.4 Engine

3. 46.9 cylinders and compressor frame

4. 50.2 cylinders and compressor frame

5. 55.7 cylinders and compressor frame

6. 62 Engine

-

July 8, 2019 at 8:12 pm

peteroznewman

SubscriberTo get the proper frequency, you have to get the stiffness and the mass correct.

I asked you what the mass of the engine was. Please answer.

The engine is represented by a large grey block. That block is likely stiffer than a real engine block. Simplifying the engine to a block has introduced an error in the stiffness.

-

July 8, 2019 at 8:13 pm

ygauri

SubscriberEngine mass should be 2200 kg

-

July 8, 2019 at 8:16 pm

peteroznewman

SubscriberI will create a material called Engine that will have 22/37 times the density of steel. Then that block will have a mass of 2200 kg.

-

July 8, 2019 at 8:19 pm

ygauri

SubscriberI have attached the new file consisting of accurate weight and material property.

This file has 2200 kg of weight.

-

July 8, 2019 at 8:26 pm

-

July 8, 2019 at 8:29 pm

ygauri

Subscriberso will these type of mesh give me the results that I mentioned before?

Also, If I try to use that proximity and keep it 2 elements through gap then even for 5 inch its generating more than 50 millions elements and takes long time to generate mesh.

So will it give me the accurate results that I wanted?

-

July 8, 2019 at 9:00 pm

ygauri

Subscribercan you brief me on the best combination for such good quality mesh?

-

July 8, 2019 at 9:05 pm

peteroznewman

SubscriberMode 1 and Mode 2 are both about 57 Hz.

For a 2200 kg mass, it would be possible to do a static structural analysis to compute the stiffness of one foot and do a hand calculation of what the first natural frequency must be from the mass and equivalent spring rate of four feet.

The mesh has 1.3 million nodes and I got the first 6 modes out in 19 minutes on 9 cores using the PCG solver. I spent about 20 minutes doing geometry cleanup to get it down to this small model.

-

July 8, 2019 at 9:10 pm

ygauri

Subscriberok, so according to report, I want first frequency to be 27 Hz and 2nd to be 33.4 HZ.

-

July 8, 2019 at 9:11 pm

peteroznewman

SubscriberWhen the shaft of the engine is connected to the next system, that will affect the natural frequency of the engine unless the coupling is very flexible.

-

July 8, 2019 at 9:13 pm

ygauri

Subscribertwo point masses of 38 lb are applied on flat front face of shaft and both the engine and compressor shaft are connected using spring connection, but that will have negligible effect

-

July 8, 2019 at 9:13 pm

peteroznewman

SubscriberAre the feet made of steel or aluminum? Aluminum is more flexible than steel, and that would lower the frequency.

-

July 8, 2019 at 9:14 pm

ygauri

Subscriberhigh carbon steel

-

July 8, 2019 at 9:17 pm

peteroznewman

Subscriber38 lbs = 17 kg which is only 0.7% of the 2200 kg mass of the engine. I think those point masses are insignificant.

-

July 8, 2019 at 9:19 pm

ygauri

Subscriberyes it has negligible effect on mechanical natural frequency of engine.

I guess if considered the entire modal with deck plate and foundation, then frequency might change. I am trying to apply line contact of pedestal on deck plate but not able to do so. Can you guide me on line contact and will if effect my modal?

-

July 8, 2019 at 9:20 pm

peteroznewman

SubscriberThe 57 Hz is what I get when the feet are bonded to the pedestal.

How many fasteners connect each foot to the pedestal?

Using two or three beam connections per foot to the pedestal will lower the frequency compared with the bonded result. -

July 8, 2019 at 9:21 pm

ygauri

Subscribertwo beam connections per foot to pedestal and also foot will be bolted to engine as well.

-

July 8, 2019 at 9:49 pm

ygauri

SubscriberAlso when you told about static structural analysis means going for Pre-Stressed modal analysis?

-

July 9, 2019 at 12:28 am

peteroznewman

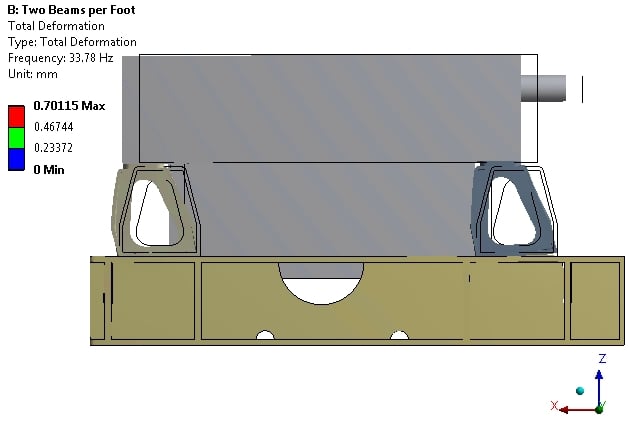

SubscriberWith two beams per foot on the outside edge of the foot, Mode 1 is now 34 Hz and Mode 2 is now 41 Hz, and Mode 3 is 61 Hz, which is the engine rotating about the Z axis through its center of mass.

There is still bonded contact to the engine at the top of each foot.

I switched to the Direct solver, and the solution was computed in 4 minutes on 9 cores with 94 GB of RAM allocated.

My comment about static structural was that you could calculate the stiffness of the foot in order to compute the natural frequency without running a modal analysis. Prestressed modal is probably not important but is simple to do it and see the effect on the result.

-

July 9, 2019 at 6:28 pm

ygauri

SubscriberHello Sir, it seems that values have improved.

so what other changes can be done to get 1st mode at26.5 Hz, 2nd at 33.5 Hz and 3rd at 62 Hz.

To be specific 1st mode shape should be Horizontal motion of engine along X, 2nd node shape should be stretch motion of engine and 3rd mode shape should be twisting motion of engine.

Somehow I am getting 26.8 Hz as 1st mode but not others.

I have split the face of engine , so that just small portion of feet is connected to engine block and not entire stiffness because it makes modal more stiff.

I am in Mountain Time zone in United States. If you would like we can have meeting and can show you the way I have used connections.

-

July 9, 2019 at 9:05 pm

ygauri

SubscriberHello Sir, can we arrange meeting today or tomorrow via webex please, so that it would easy for me to understand my mistakes and with your guidance I can rectify that mistake.

Would glad to arrange meeting with you.

-

July 9, 2019 at 11:42 pm

peteroznewman

SubscriberI am available between 8 and 11 PM Eastern time today (Tuesday) and tomorrow. That would be 6 to 9 PM Mountain time.

-

July 10, 2019 at 12:05 am

ygauri

SubscriberHello Sir, I am available tomorrow during that slot. So how to schedule meeting, will you send me meeting link or I should reply to this post?

-

July 10, 2019 at 12:35 am

peteroznewman

SubscriberDo you have a Webex account?

What time do you want to start tomorrow?

-

July 10, 2019 at 12:38 am

ygauri

Subscriberyes, I have and would like to start at 6 pm tomorrow.

-

July 10, 2019 at 12:46 am

ygauri

SubscriberI have created webex account.

-

July 10, 2019 at 12:52 am

peteroznewman

SubscriberGreat. At 6 PM Wednesday Mountain Time (8 PM Eastern), start your Webex meeting and when the meeting ID is created, reply in this thread and paste in the meeting ID and I will join your meeting.

-

July 10, 2019 at 2:33 pm

ygauri

Subscriberyes sir, that sounds good. Thank you.

-

July 10, 2019 at 11:17 pm

ygauri

Subscriber

Wednesday, Jul 10, 2019 6:00 pm | 1 hour | (UTC-07:00) Mountain Time (US & Canada)

Meeting number: 290 380 637

Password: b7Mk3ppH

https://emittechnologies-fe0f.my.webex.com/emittechnologies-fe0f.my/j.php?MTID=meec4bbeaf64e606560188cc601e475ec

Join by video system

Dial 290380637@emittechnologies-fe0f.my.webex.com

You can also dial 173.243.2.68 and enter your meeting number.

Join by phone

+1-510-338-9438 USA Toll

Access code: 290 380 637

-

July 10, 2019 at 11:18 pm

ygauri

SubscriberHello Sir,

I have replied with details to join meeting.

-

- The topic ‘Regarding Connecting two parts that will have nuts and bolts’ is closed to new replies.

-

4613

-

1530

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.