-

-

January 29, 2024 at 5:50 pm

deepesh.p.gurdasani

SubscriberDo I need to face split the bolt shank compulsorily for applying bolt pretension?

Suppose bolt is used to join/connect two random shaped plates of some thickness, bolt head to top surface of first plate would be frictional, Nut to the surface of second plate would be frictional, nut to bolt shank's face splitted part would be bonded, bolt shank to surface of hole of first and second plate frictional connection (Please correct me if the steps are wrong).

So now there is a face split from end of second plate thickness till the end of nut. Should bolt pretension be applied at the rest of bolt shank above face spliited line ?

Thanks

-

January 29, 2024 at 7:31 pm

peteroznewman

SubscriberIf the bolt shank between the nut and the head is one face, that could be used to apply a bolt pretension load.

Splitting the bolt shank face at the nut to keep the bonded contact separate from the rest of the shank is required.

If the bolt shank sits at the center of a clearance hole, and if the bolt pretension applied in step 1 is high enough, and if the frictional contact between the two plates has a high enough friction coefficient, then the two plates should not slip under any loads applied in step 2 and there is no need for frictional contact between the bolt shank and the two clearance holes. If the two plates do slip under applied loads in step 2, that bolted joint is inadequate and should be redesigned.

-

January 30, 2024 at 2:18 pm

deepesh.p.gurdasani

SubscriberThanks for the reply.

For applying Bolt pretension, local coordinate system is to be created, right?

So, while the local coordinate system is created, should we select the whole bolt body Or just the bolt shank that starts from Upper surface of first and ends at lower surface of second plate (So, here the surface split from lower surface of second plate/start of nut to the end of nut is excluded) ?

Thanks

-

January 30, 2024 at 10:49 pm

peteroznewman

SubscriberNo local coordinate system is needed.

Do NOT select the whole bolt body.

Select the cylindrical face of the bolt shank that goes from the head to the split edge at the nut. That face defines an axial direction. Internally, the software will split the mesh and introduce a translational joint to pull the two new free mesh faces toward each other to create the preload.

-

February 14, 2024 at 2:38 pm

deepesh.p.gurdasani

SubscriberThanks for the reply.

What if there are two washers (one each at bolt head side and nut's side)

The washer at upper plate (Bolt head's side) to bolt shank - bonded.

Washer to upper plate/first plate - frictional.

bolt head to washer - frictional.

Washer at second plate/bottom plate to bolt shank - bonded.

Washer to bottom plate - frictional.

nut to washer - frictional

Are these type of contacts correct where are two washers for a single bolt ?

Thanks

-

February 15, 2024 at 6:44 am

peteroznewman

SubscriberIt’s possible to use Frictional Contact on every contact pair as long as the Initial Contact Status is Closed. If it is Near Open by some tiny amount, you can use Adjust to Touch to close the contact.

Bonded contact takes less computation, so it can be beneficial to use that in select locations.

I would not bond the clearance hole of a washer to a bolt shank. I would only bond a washer flat face to a bolt head or a nut face.

-

February 15, 2024 at 3:28 pm

deepesh.p.gurdasani

Subscriberwasher flat face to top and bottom plate should also be given bonded/frictional contact, right?

-

February 16, 2024 at 1:08 am

peteroznewman

SubscriberYes.

-

February 17, 2024 at 7:10 am

deepesh.p.gurdasani

SubscriberThanks

-

February 17, 2024 at 7:14 am

deepesh.p.gurdasani

SubscriberAlso,

To verify the stress in bolt by hand calculation,

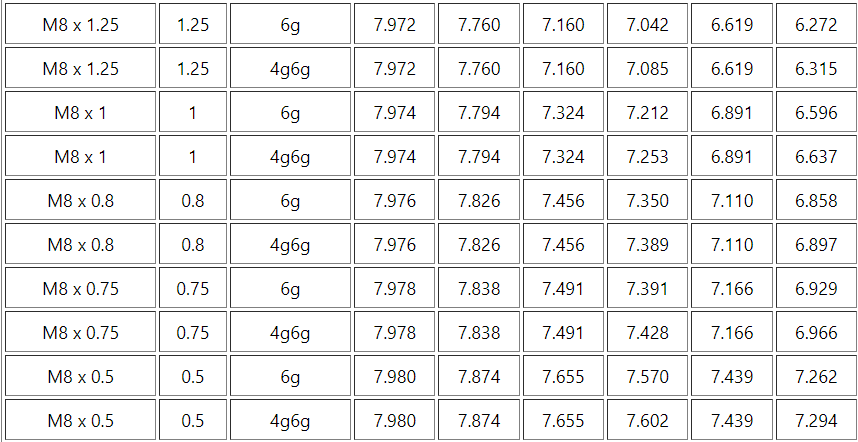

We use first Torque = K.D.P (Nut factor, Nominal Diameter[Here for M8 bolt, the dia. value would be 8 mm, right? ], Preload)

Tensile Stress = F/A [Area = (pi/4) * d^2] [Here also d = 8, as bolt is M8]

Am I correct in the above calculation ? especially where dia. value is to be substituted. Please correct me if I am wrong.

Thanks

-

February 17, 2024 at 10:43 am

peteroznewman

SubscriberIn Ansys, we only define preload force, P, and don't need to know Torque. Yes, you need to calculate a torque to put that on the drawing. You show a simple formula, but what value would you use for Nut Factor? That is going to depend on factors like whether the threads, head and washer are lubricated or dry.

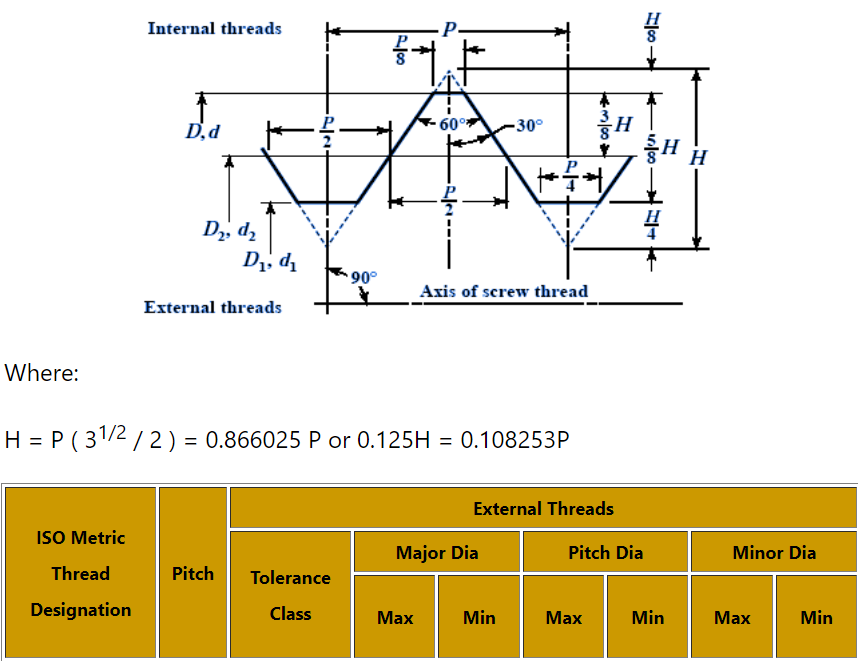

The tensile stress should be calculated from the minimum cross-sectional area based on the minimum minor diameter, not the nominal bolt diameter.

-

March 4, 2024 at 7:01 pm

deepesh.p.gurdasani

SubscriberThanks for the reply. Would it be possible for you to provide a simple example where your hand calculation would match the bolt pretension stress result in ansys ?

It would be of great help as I am unable to get the results that match hand calculation.

Thands in advance.

-

March 18, 2024 at 3:24 pm

deepesh.p.gurdasani

SubscriberJust for clarity, the stress is to be seen at the plates or at the bolt? If yes, shouldn't the stress to be checked be 'Normal stress' and not 'equivalent stress' ?

Thanks

-

March 18, 2024 at 3:39 pm

peteroznewman

SubscriberYes, the tensile stress in the bolt is a Normal Stress in a Coordinate System with a direction along the axis of the bolt.

-

March 19, 2024 at 2:27 pm

deepesh.p.gurdasani

Subscriberok. So, if the normal stress/equivalent stress on plate is below yield but on bolt is above yield, is that ok ? Any suggestions?

-

March 19, 2024 at 3:55 pm

peteroznewman

SubscriberEither reduce the preload tension on the bolt to reduce stress or use a larger bolt to get more cross-sectional area to lower the stress.

-

March 20, 2024 at 6:09 pm

deepesh.p.gurdasani

SubscriberThanks. Got it.

However, if you come across any online link or if possible, you yourself can share a simple model of bolt pretension results matching with hand calcuation (using approx. value would do for simplicity - like you shared details regarding nut factor, etc. above) will be of great help.

Thanks in advance.

-

- The topic ‘Regarding Bolt pretension’ is closed to new replies.

-

4623

-

1535

-

1386

-

1215

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.