TAGGED: #thermal-radiation, radiation

-

-

December 9, 2024 at 12:49 pm

thomas.fellinger

SubscriberHello,

I get an unknow error doing a thermal simulation by radiation:

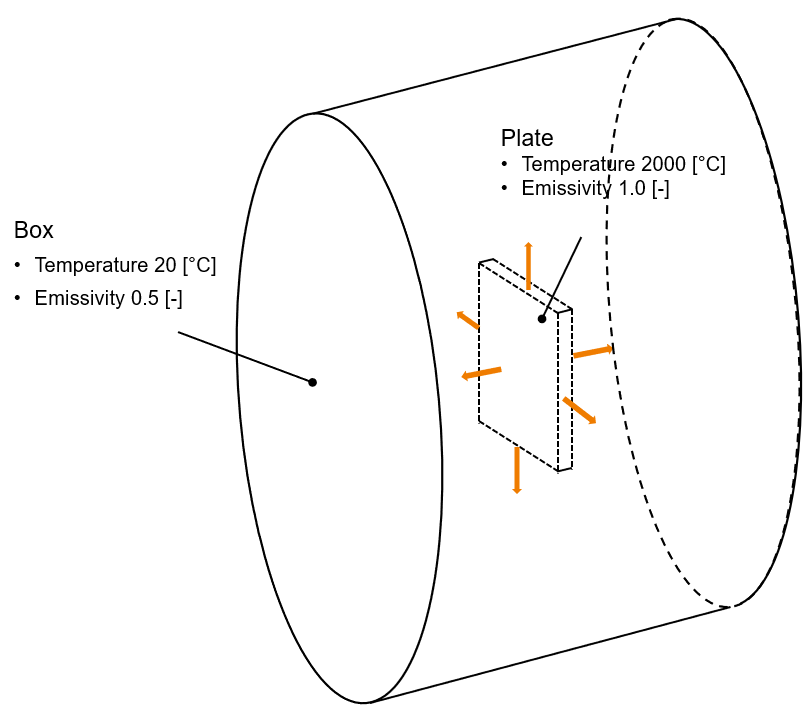

A plate with a certain temperature is surrounded by a box. I want to simulate to investigate the temperature over time.

If the box has a mesh size of 20mm and the plate 5mm than it works. Changing the mesh size only of the plate to 1mm, an unknow error occurs, see both solver output files below.

I also tried to reduce the mesh size of the box - no positive result.Someone my have an idea why this happens (solver setting, boundares, mesh,...)?

Case 1: Error 1mm mesh size of the plate, other bodies 20mm

Solver Output

Ansys Mechanical Enterprise Academic Research

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2022 R2 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2022 Ansys, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2022 R2

Point Releases and Patches installed:

ANSYS, Inc. License Manager 2022 R2

Discovery 2022 R2

SpaceClaim 2022 R2

Ansys Sherlock 2022 R2

Autodyn 2022 R2

LS-DYNA 2022 R2

CFD-Post only 2022 R2

CFX (includes CFD-Post) 2022 R2

Chemkin 2022 R2

FENSAP-ICE 2022 R2

Fluent (includes CFD-Post) 2022 R2

Polyflow (includes CFD-Post) 2022 R2

Forte (includes EnSight) 2022 R2

TurboGrid 2022 R2

ICEM CFD 2022 R2

Aqwa 2022 R2

Speos 2022 R2

Speos HPC 2022 R2

optiSLang 2022 R2

Additive 2022 R2

Customization Files for User Programmable Features 2022 R2

Mechanical Products 2022 R2

Remote Solve Manager Standalone Services 2022 R2

Ansys Sound - SAS 2022 R2

Viewer 2022 R2

ACIS Geometry Interface 2022 R2

AutoCAD Geometry Interface 2022 R2

Catia, Version 4 Geometry Interface 2022 R2

Catia, Version 5 Geometry Interface 2022 R2

Catia, Version 6 Geometry Interface 2022 R2

Creo Elements/Direct Modeling Geometry Interface 2022 R2

Creo Parametric Geometry Interface 2022 R2

Inventor Geometry Interface 2022 R2

JTOpen Geometry Interface 2022 R2

NX Geometry Interface 2022 R2

Parasolid Geometry Interface 2022 R2

Solid Edge Geometry Interface 2022 R2

SOLIDWORKS Geometry Interface 2022 R2

***** MAPDL COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

DISTRIBUTED MEMORY PARALLEL REQUESTED

15 PARALLEL PROCESSES REQUESTED WITH SINGLE THREAD PER PROCESS (FORCED)

TOTAL OF 15 CORES REQUESTED

INPUT FILE NAME = E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\ScrA868\dummy.dat

OUTPUT FILE NAME = E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\ScrA868\solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

GPU ACCELERATOR OPTION REQUESTED

1 GPU ACCELERATOR DEVICES REQUESTED

RELEASE= 2022 R2 BUILD= 22.2 UP20220516 VERSION=WINDOWS x64

CURRENT JOBNAME=file0 13:36:36 DEC 07, 2024 CP= 0.219

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

*** NOTE *** CP = 3.438 TIME= 13:36:41

The /CONFIG,NOELDB command is not valid in a distributed memory

parallel solution. Command is ignored.

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 13.6113889

TITLE=

Test_Radiation--Transient Thermal (B5)

ACT Extensions:

LSDYNA, 2022.2

5f463412-bd3e-484b-87e7-cbc0a665e474, wbex

/COM, ANSYSMotion, 2022.2

20180725-3f81-49eb-9f31-41364844c769, wbex

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\ScrA868\

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = E:\Test_Beam_1.63MW_Sig5mm\Test_Radiation_files\dp0\SYS-30\MECH\

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = E:\Test_Beam_1.63MW_Sig5mm\Test_Radiation_files\user_files\

--- Data in consistent NMM units. See Solving Units in the help system for more

MPA UNITS SPECIFIED FOR INTERNAL

LENGTH = MILLIMETERS (mm)

MASS = TONNE (Mg)

TIME = SECONDS (sec)

TEMPERATURE = CELSIUS (C)

TOFFSET = 273.0

FORCE = NEWTON (N)

HEAT = MILLIJOULES (mJ)

INPUT UNITS ARE ALSO SET TO MPA

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R2 22.2 ***

Ansys Mechanical Enterprise Academic Research

00000000 VERSION=WINDOWS x64 13:36:41 DEC 07, 2024 CP= 3.438

Test_Radiation--Transient Thermal (B5)

***** MAPDL ANALYSIS DEFINITION (PREP7) *****

*********** Nodes for the whole assembly ***********

*********** Elements for Body 1 "cover1" ***********

*********** Elements for Body 2 "cover2" ***********

*********** Elements for Body 3 "cover3" ***********

*********** Elements for Body 4 "cover4" ***********

*********** Elements for Body 5 "End1" ***********

*********** Elements for Body 6 "End2" ***********

*********** Elements for Body 7 "SYS-29\400x400x5\Solid" ***********

*********** Send User Defined Coordinate System(s) ***********

*********** Send Materials ***********

*********** Create Contact "Contact Region" ***********

Real Constant Set For Above Contact Is 9 & 8

*********** Create Contact "Contact Region 2" ***********

Real Constant Set For Above Contact Is 11 & 10

*********** Create Contact "Contact Region 3" ***********

Real Constant Set For Above Contact Is 13 & 12

*********** Create Contact "Contact Region 4" ***********

Real Constant Set For Above Contact Is 15 & 14

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Element Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Define Temperature Constraint ***********

*********** Define Temperature Constraint ***********

*********** Create "ToSurface(Closed)" Radiation ***********

*********** Create "ToSurface(Closed)" Radiation ***********

***************** Define Uniform Initial temperature ***************

***** ROUTINE COMPLETED ***** CP = 33.188

--- Number of total nodes = 3895043

--- Number of contact elements = 960

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 828438

--- Number of condensed parts = 0

--- Number of total elements = 829398

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 13.6130556

****************************************************************************

************************* SOLUTION ********************************

****************************************************************************

***** MAPDL SOLUTION ROUTINE *****

PERFORM A TRANSIENT ANALYSIS

THIS WILL BE A NEW ANALYSIS

STEP BOUNDARY CONDITION KEY= 1

USE PRECONDITIONED CONJUGATE GRADIENT SOLVER

CONVERGENCE TOLERANCE = 1.00000E-08

MAXIMUM ITERATION = NumNode*DofPerNode* 1.0000

CONTACT INFORMATION PRINTOUT LEVEL 1

DO NOT SAVE ANY RESTART FILES AT ALL

DO NOT COMBINE ELEMENT MATRIX FILES (.emat) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ELEMENT SAVE DATA FILES (.esav) AFTER DISTRIBUTED PARALLEL SOLUTION

Use Full Nonlinear Thermal Transient Solution

NLHIST: ADDED NODAL RESULTS HISTORY FOR:

NAME = MAX_TEMP

ITEM/COMP = TEMPMAX

NODE = 0

NLHIST: ADDED NODAL RESULTS HISTORY FOR:

NAME = MIN_TEMP

ITEM/COMP = TEMPMIN

NODE = 0

********* Initial Time Increment Check And Fourier Modulus *********

Specified Initial Time Increment: 0.05

Estimated Increment Needed, le*le/alpha, Body 1: 13.957

Estimated Increment Needed, le*le/alpha, Body 2: 13.957

Estimated Increment Needed, le*le/alpha, Body 3: 13.957

Estimated Increment Needed, le*le/alpha, Body 4: 13.957

Estimated Increment Needed, le*le/alpha, Body 5: 9.39451

Estimated Increment Needed, le*le/alpha, Body 6: 9.39453

Estimated Increment Needed, le*le/alpha, Body 7: 0.0563124

****************************************************

******************* SOLVE FOR LS 1 OF 1 ****************

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

SET ACCORDING TO TABLE PARAMETER = _LOADVARI939

Memory resident data base increased from 2048 MB to 4096 MB.

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

REAL= 20.0000000 IMAG= 0.00000000

SELECT COMPONENT _CM617

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

324788 ELEMENTS (OF 829398 DEFINED) SELECTED FROM

984002 SELECTED NODES BY ESLN COMMAND.

GENERATE SURFACE LOAD RDSF ON SURFACE DEFINED BY ALL SELECTED NODES

EMISSIVITY = 1.00 ENCLOSURE NUMBER = 1.

NUMBER OF RDSF ELEMENT FACE LOADS STORED = 328000

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 3895043 STEP 1

3895043 NODES (OF 3895043 DEFINED) SELECTED BY NSEL COMMAND.

ENCLOSURE= 1 VIEWFACTOR SCALE METHOD = 1

ITERATIONS = 100

TOLERANCE = 1.000000047E-03

SELECT COMPONENT _CM676

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

29398 ELEMENTS (OF 829398 DEFINED) SELECTED FROM

84844 SELECTED NODES BY ESLN COMMAND.

GENERATE SURFACE LOAD RDSF ON SURFACE DEFINED BY ALL SELECTED NODES

EMISSIVITY = 0.500 ENCLOSURE NUMBER = 1.

NUMBER OF RDSF ELEMENT FACE LOADS STORED = 27966

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 3895043 STEP 1

3895043 NODES (OF 3895043 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 3895043 STEP 1

3895043 NODES (OF 3895043 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 1215626 STEP 1

829398 ELEMENTS (OF 829398 DEFINED) SELECTED BY ESEL COMMAND.

PRINTOUT RESUMED BY /GOP

DO NOT USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 2 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 2 SUBSTEPS AS A MAXIMUM

USE 2 SUBSTEPS AS A MINIMUM

TIME= 0.10000

INCLUDE TRANSIENT EFFECTS FOR ALL DEGREES OF FREEDOM THIS LOAD STEP

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE FFLU ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE MISC ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

CONVERGENCE ON HEAT BASED ON THE NORM OF THE N-R LOAD

WITH A TOLERANCE OF 0.1000E-03 AND A MINIMUM REFERENCE VALUE OF 0.1000E-02

USING THE L2 NORM (CHECK THE SRSS VALUE)

UNDER RELAXATION FOR RADIATION FLUX= 0.10000

TOLERENCE FOR RADIOSITY FLUX= 0.00001

USING JACOBI ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 3D ENCLOSURES.

USING GSEIDEL ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 2D ENCLOSURES.

MAXIMUM NUMBER OF ITERATIONS= 1000

TOLERENCE FOR ITERATIVE SOLVER= 0.00010

RELAXATION FOR ITERATIVE SOLVER= 0.10000

HEMICUBE RESOLUTION= 100

MIN NORMALIZED DIST BEFORE AUTO SUBDIVIDE= 1.000000000E-09

SELECT COMPONENT _CM617

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

324788 ELEMENTS (OF 829398 DEFINED) SELECTED FROM

984002 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 328002

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 328000

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 328002

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 328000

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 4223045 STEP 1

4223045 NODES (OF 4223045 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 1543626 STEP 1

1157398 ELEMENTS (OF 1157398 DEFINED) SELECTED BY ESEL COMMAND.

SELECT COMPONENT _CM676

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

29398 ELEMENTS (OF 1157398 DEFINED) SELECTED FROM

84844 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 28440

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 27966

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 28440

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 27966

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 4251485 STEP 1

4251485 NODES (OF 4251485 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 1571592 STEP 1

1185364 ELEMENTS (OF 1185364 DEFINED) SELECTED BY ESEL COMMAND.

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

*** NOTE *** CP = 67.344 TIME= 13:36:52

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 15 processes per solution.

***** MAPDL SOLVE COMMAND *****

CALCULATING VIEW FACTORS USING HEMICUBE METHOD

RETRIEVED 1 ENCLOSURES.

TOTAL OF 355966 DEFINED ELEMENT FACES.

# ENCLOSURE = 1 # SURFACES =355966 # NODES =356442

******************************************************************************

V I E W F A C T O R S M O O T H I N G

******************************************************************************

Smoothing of viewfactor matrix...

Max iterations = 100

Tolerance = 0.001

row sum total should be = 355966.0000

row sum total before forcing symmetry = 355965.9605

row sum total after forcing symmetry = 355965.9605

row sum total after smoothing = 355966.0025

Raw rowsum error min = -5.0902e-05

Raw rowsum error max = 8.3447e-07

Raw rowsum error mean = -1.1107e-07 +/- 4.1666e-07

Symmetric rowsum error min = -5.0902e-05

Symmetric rowsum error max = 8.3447e-07

Symmetric rowsum error mean = -1.1107e-07 +/- 6.2869e-08

Smoothed rowsum error min = -3.5763e-07

Smoothed rowsum error max = 5.9605e-07

Smoothed rowsum error mean = 6.9275e-09 +/- 1.4241e-09

number of iterations to smooth = 1

******************************************************************************

E N D O F V I E W F A C T O R S M O O T H I N G

******************************************************************************

TIME OF CALCULATION FOR THIS ENCLOSURE = 1659.38

CHECKING VIEW FACTOR SUM

VIEW FACTOR CALCULATION COMPLETE

WRITING VIEW FACTORS TO FILE file0.vf

VIEW FACTORS WERE WRITTEN TO FILE file0.vf

*** WARNING *** CP = 2502.359 TIME= 15:15:12

Some radiation enclosures have viewfactor scaling. Use VFSM,STAT

command to check the status. Also note that scaling is ignored if the

viewfactor sum is <= 0.0.

*** WARNING *** CP = 2504.047 TIME= 15:15:12

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** CP = 2512.906 TIME= 15:15:15

The model data was checked and warning messages were found.

Please review output or errors file (

E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\ScrA868\file0.err ) for

these warning messages.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R2 22.2 ***

Ansys Mechanical Enterprise Academic Research

00000000 VERSION=WINDOWS x64 15:15:15 DEC 07, 2024 CP= 2513.234

Test_Radiation--Transient Thermal (B5)

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . TEMP

ANALYSIS TYPE . . . . . . . . . . . . . . . . .TRANSIENT

SOLUTION METHOD. . . . . . . . . . . . . . .FULL

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

EQUATION SOLVER OPTION. . . . . . . . . . . . .PCG

TOLERANCE. . . . . . . . . . . . . . . . . . 1.00000E-08

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** NOTE *** CP = 2513.766 TIME= 15:15:15

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** NOTE *** CP = 2513.766 TIME= 15:15:16

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

*** NOTE *** CP = 2520.984 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 8 and contact element type 8 has been set up. The

companion pair has real constant set ID 9. Both pairs should have the

same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.704990738E-05 was detected between contact

element 1214749 and target element 1214870.

You may move entire target surface by : x= 1.685318E-05, y=

2.582569568E-06, z= 4.680688417E-19,to reduce initial penetration.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 9 and contact element type 8 has been set up. The

companion pair has real constant set ID 8. Both pairs should have the

same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.295

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.705060237E-05 was detected between contact

element 1214809 and target element 1214690.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 10 and contact element type 10 has been set up. The

companion pair has real constant set ID 11. Both pairs should have

the same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.703900632E-05 was detected between contact

element 1215012 and target element 1215134.

You may move entire target surface by : x= 7.33329464E-06, y=

-1.538019916E-05, z= 8.119307397E-20,to reduce initial penetration.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 11 and contact element type 10 has been set up. The

companion pair has real constant set ID 10. Both pairs should have

the same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 17.922

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.703995895E-05 was detected between contact

element 1215073 and target element 1214953.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 12 and contact element type 12 has been set up. The

companion pair has real constant set ID 13. Both pairs should have

the same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.705299849E-05 was detected between contact

element 1215229 and target element 1215349.

You may move entire target surface by : x= -2.583037783E-06, y=

1.685623545E-05, z= 4.453532888E-19,to reduce initial penetration.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 13 and contact element type 12 has been set up. The

companion pair has real constant set ID 12. Both pairs should have

the same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.295

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.705332427E-05 was detected between contact

element 1215288 and target element 1215170.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 14 and contact element type 14 has been set up. The

companion pair has real constant set ID 15. Both pairs should have

the same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.70139613E-05 was detected between contact

element 1215492 and target element 1215613.

You may move entire target surface by : x= -1.535759236E-05, y=

-7.322515696E-06, z= 3.647501262E-20,to reduce initial penetration.

****************************************

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Symmetric Deformable- deformable contact pair identified by real

constant set 15 and contact element type 14 has been set up. The

companion pair has real constant set ID 14. Both pairs should have

the same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 17.922

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 2521.172 TIME= 15:15:17

Max. Initial penetration 1.701500617E-05 was detected between contact

element 1215552 and target element 1215433.

****************************************

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 1185364

...Number of nodes: 4251485

...Decompose to 15 CPU domains

...Element load balance ratio = 1.028

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 0.10000

NUMBER OF SUBSTEPS. . . . . . . . . . . . . . . 2

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . YES

TRANSIENT (INERTIA) EFFECTS

THERMAL DOFS . . . . . . . . . . . . . . . . ON

TRANSIENT INTEGRATION PARAMETERS

THETA. . . . . . . . . . . . . . . . . . . . 1.0000

OSCILLATION LIMIT CRITERION. . . . . . . . . 0.50000

TOLERANCE. . . . . . . . . . . . . . . . . . 0.0000

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS

LABEL REFERENCE TOLERANCE NORM MINREF

HEAT 0.000 0.1000E-03 2 0.1000E-02

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

VENG ALL

FFLU ALL

CONT ALL

MISC ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 1000, BY SOLUTION CONTROL LOGIC.

RADIOSITY SOLVER CALCULATION

Case 2: No error 5mm mesh size of the plate, other bodies 20mm

Solver Output

Ansys Mechanical Enterprise Academic Research

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2022 R2 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2022 Ansys, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2022 R2

Point Releases and Patches installed:

ANSYS, Inc. License Manager 2022 R2

Discovery 2022 R2

SpaceClaim 2022 R2

Ansys Sherlock 2022 R2

Autodyn 2022 R2

LS-DYNA 2022 R2

CFD-Post only 2022 R2

CFX (includes CFD-Post) 2022 R2

Chemkin 2022 R2

FENSAP-ICE 2022 R2

Fluent (includes CFD-Post) 2022 R2

Polyflow (includes CFD-Post) 2022 R2

Forte (includes EnSight) 2022 R2

TurboGrid 2022 R2

ICEM CFD 2022 R2

Aqwa 2022 R2

Speos 2022 R2

Speos HPC 2022 R2

optiSLang 2022 R2

Additive 2022 R2

Customization Files for User Programmable Features 2022 R2

Mechanical Products 2022 R2

Remote Solve Manager Standalone Services 2022 R2

Ansys Sound - SAS 2022 R2

Viewer 2022 R2

ACIS Geometry Interface 2022 R2

AutoCAD Geometry Interface 2022 R2

Catia, Version 4 Geometry Interface 2022 R2

Catia, Version 5 Geometry Interface 2022 R2

Catia, Version 6 Geometry Interface 2022 R2

Creo Elements/Direct Modeling Geometry Interface 2022 R2

Creo Parametric Geometry Interface 2022 R2

Inventor Geometry Interface 2022 R2

JTOpen Geometry Interface 2022 R2

NX Geometry Interface 2022 R2

Parasolid Geometry Interface 2022 R2

Solid Edge Geometry Interface 2022 R2

SOLIDWORKS Geometry Interface 2022 R2

***** MAPDL COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

DISTRIBUTED MEMORY PARALLEL REQUESTED

15 PARALLEL PROCESSES REQUESTED WITH SINGLE THREAD PER PROCESS (FORCED)

TOTAL OF 15 CORES REQUESTED

INPUT FILE NAME = E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA\dummy.dat

OUTPUT FILE NAME = E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA\solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

GPU ACCELERATOR OPTION REQUESTED

1 GPU ACCELERATOR DEVICES REQUESTED

RELEASE= 2022 R2 BUILD= 22.2 UP20220516 VERSION=WINDOWS x64

CURRENT JOBNAME=file0 13:16:55 DEC 07, 2024 CP= 0.156

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

*** NOTE *** CP = 3.406 TIME= 13:17:00

The /CONFIG,NOELDB command is not valid in a distributed memory

parallel solution. Command is ignored.

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 13.2833333

TITLE=

Test_Radiation--Transient Thermal (B5)

ACT Extensions:

LSDYNA, 2022.2

5f463412-bd3e-484b-87e7-cbc0a665e474, wbex

/COM, ANSYSMotion, 2022.2

20180725-3f81-49eb-9f31-41364844c769, wbex

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA\

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = E:\Test_Beam_1.63MW_Sig5mm\Test_Radiation_files\dp0\SYS-29\MECH\

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = E:\Test_Beam_1.63MW_Sig5mm\Test_Radiation_files\user_files\

--- Data in consistent NMM units. See Solving Units in the help system for more

MPA UNITS SPECIFIED FOR INTERNAL

LENGTH = MILLIMETERS (mm)

MASS = TONNE (Mg)

TIME = SECONDS (sec)

TEMPERATURE = CELSIUS (C)

TOFFSET = 273.0

FORCE = NEWTON (N)

HEAT = MILLIJOULES (mJ)

INPUT UNITS ARE ALSO SET TO MPA

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R2 22.2 ***

Ansys Mechanical Enterprise Academic Research

00000000 VERSION=WINDOWS x64 13:17:00 DEC 07, 2024 CP= 3.406

Test_Radiation--Transient Thermal (B5)

***** MAPDL ANALYSIS DEFINITION (PREP7) *****

*********** Nodes for the whole assembly ***********

*********** Elements for Body 1 "cover1" ***********

*********** Elements for Body 2 "cover2" ***********

*********** Elements for Body 3 "cover3" ***********

*********** Elements for Body 4 "cover4" ***********

*********** Elements for Body 5 "End1" ***********

*********** Elements for Body 6 "End2" ***********

*********** Elements for Body 7 "SYS-29\400x400x5\Solid" ***********

*********** Send User Defined Coordinate System(s) ***********

*********** Send Materials ***********

*********** Create Contact "Contact Region" ***********

Real Constant Set For Above Contact Is 9 & 8

*********** Create Contact "Contact Region 2" ***********

Real Constant Set For Above Contact Is 11 & 10

*********** Create Contact "Contact Region 3" ***********

Real Constant Set For Above Contact Is 13 & 12

*********** Create Contact "Contact Region 4" ***********

Real Constant Set For Above Contact Is 15 & 14

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Element Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Define Temperature Constraint ***********

*********** Define Temperature Constraint ***********

*********** Create "ToSurface(Closed)" Radiation ***********

*********** Create "ToSurface(Closed)" Radiation ***********

***************** Define Uniform Initial temperature ***************

***** ROUTINE COMPLETED ***** CP = 10.750

--- Number of total nodes = 351363

--- Number of contact elements = 960

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 60438

--- Number of condensed parts = 0

--- Number of total elements = 61398

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 13.2836111

****************************************************************************

************************* SOLUTION ********************************

****************************************************************************

***** MAPDL SOLUTION ROUTINE *****

PERFORM A TRANSIENT ANALYSIS

THIS WILL BE A NEW ANALYSIS

STEP BOUNDARY CONDITION KEY= 1

CONTACT INFORMATION PRINTOUT LEVEL 1

DO NOT SAVE ANY RESTART FILES AT ALL

DO NOT COMBINE ELEMENT MATRIX FILES (.emat) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ELEMENT SAVE DATA FILES (.esav) AFTER DISTRIBUTED PARALLEL SOLUTION

Use Full Nonlinear Thermal Transient Solution

NLHIST: ADDED NODAL RESULTS HISTORY FOR:

NAME = MAX_TEMP

ITEM/COMP = TEMPMAX

NODE = 0

NLHIST: ADDED NODAL RESULTS HISTORY FOR:

NAME = MIN_TEMP

ITEM/COMP = TEMPMIN

NODE = 0

********* Initial Time Increment Check And Fourier Modulus *********

Specified Initial Time Increment: 0.05

Estimated Increment Needed, le*le/alpha, Body 1: 13.957

Estimated Increment Needed, le*le/alpha, Body 2: 13.957

Estimated Increment Needed, le*le/alpha, Body 3: 13.957

Estimated Increment Needed, le*le/alpha, Body 4: 13.957

Estimated Increment Needed, le*le/alpha, Body 5: 9.39451

Estimated Increment Needed, le*le/alpha, Body 6: 9.39453

Estimated Increment Needed, le*le/alpha, Body 7: 0.481464

****************************************************

******************* SOLVE FOR LS 1 OF 1 ****************

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

SET ACCORDING TO TABLE PARAMETER = _LOADVARI939

SPECIFIED CONSTRAINT TEMP FOR PICKED NODES

REAL= 20.0000000 IMAG= 0.00000000

SELECT COMPONENT _CM617

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

13748 ELEMENTS (OF 61398 DEFINED) SELECTED FROM

43202 SELECTED NODES BY ESLN COMMAND.

GENERATE SURFACE LOAD RDSF ON SURFACE DEFINED BY ALL SELECTED NODES

EMISSIVITY = 1.00 ENCLOSURE NUMBER = 1.

NUMBER OF RDSF ELEMENT FACE LOADS STORED = 14400

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 351363 STEP 1

351363 NODES (OF 351363 DEFINED) SELECTED BY NSEL COMMAND.

ENCLOSURE= 1 VIEWFACTOR SCALE METHOD = 1

ITERATIONS = 100

TOLERANCE = 1.000000047E-03

SELECT COMPONENT _CM676

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

29398 ELEMENTS (OF 61398 DEFINED) SELECTED FROM

84844 SELECTED NODES BY ESLN COMMAND.

GENERATE SURFACE LOAD RDSF ON SURFACE DEFINED BY ALL SELECTED NODES

EMISSIVITY = 0.500 ENCLOSURE NUMBER = 1.

NUMBER OF RDSF ELEMENT FACE LOADS STORED = 27966

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 351363 STEP 1

351363 NODES (OF 351363 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 351363 STEP 1

351363 NODES (OF 351363 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 134026 STEP 1

61398 ELEMENTS (OF 61398 DEFINED) SELECTED BY ESEL COMMAND.

PRINTOUT RESUMED BY /GOP

DO NOT USE AUTOMATIC TIME STEPPING THIS LOAD STEP

USE 2 SUBSTEPS INITIALLY THIS LOAD STEP FOR ALL DEGREES OF FREEDOM

FOR AUTOMATIC TIME STEPPING:

USE 2 SUBSTEPS AS A MAXIMUM

USE 2 SUBSTEPS AS A MINIMUM

TIME= 0.10000

INCLUDE TRANSIENT EFFECTS FOR ALL DEGREES OF FREEDOM THIS LOAD STEP

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE RSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE EANG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE VENG ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE FFLU ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE CONT ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

WRITE MISC ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

CONVERGENCE ON HEAT BASED ON THE NORM OF THE N-R LOAD

WITH A TOLERANCE OF 0.1000E-03 AND A MINIMUM REFERENCE VALUE OF 0.1000E-02

USING THE L2 NORM (CHECK THE SRSS VALUE)

UNDER RELAXATION FOR RADIATION FLUX= 0.10000

TOLERENCE FOR RADIOSITY FLUX= 0.00001

USING JACOBI ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 3D ENCLOSURES.

USING GSEIDEL ITERATIVE SOLVER FOR RADIOSITY SOLUTION

FOR 2D ENCLOSURES.

MAXIMUM NUMBER OF ITERATIONS= 1000

TOLERENCE FOR ITERATIVE SOLVER= 0.00010

RELAXATION FOR ITERATIVE SOLVER= 0.10000

HEMICUBE RESOLUTION= 100

MIN NORMALIZED DIST BEFORE AUTO SUBDIVIDE= 1.000000000E-09

SELECT COMPONENT _CM617

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

13748 ELEMENTS (OF 61398 DEFINED) SELECTED FROM

43202 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 14402

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 14400

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 14402

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 14400

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 365765 STEP 1

365765 NODES (OF 365765 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 148426 STEP 1

75798 ELEMENTS (OF 75798 DEFINED) SELECTED BY ESEL COMMAND.

SELECT COMPONENT _CM676

SELECT ALL ELEMENTS HAVING ANY NODE IN NODAL SET.

29398 ELEMENTS (OF 75798 DEFINED) SELECTED FROM

84844 SELECTED NODES BY ESLN COMMAND.

BEFORE SYMMETRIZATION:

NUMBER OF RADIATION NODES CREATED = 28440

NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 27966

AFTER SYMMETRIZATION:

FULL NUMBER OF RADIATION NODES CREATED = 28440

FULL NUMBER OF RADIOSITY SURFACE ELEMENTS CREATED = 27966

ALL SELECT FOR ITEM=NODE COMPONENT=

IN RANGE 1 TO 394205 STEP 1

394205 NODES (OF 394205 DEFINED) SELECTED BY NSEL COMMAND.

ALL SELECT FOR ITEM=ELEM COMPONENT=

IN RANGE 1 TO 176392 STEP 1

103764 ELEMENTS (OF 103764 DEFINED) SELECTED BY ESEL COMMAND.

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

*** NOTE *** CP = 16.109 TIME= 13:17:01

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 15 processes per solution.

***** MAPDL SOLVE COMMAND *****

CALCULATING VIEW FACTORS USING HEMICUBE METHOD

RETRIEVED 1 ENCLOSURES.

TOTAL OF 42366 DEFINED ELEMENT FACES.

# ENCLOSURE = 1 # SURFACES = 42366 # NODES = 42842

******************************************************************************

V I E W F A C T O R S M O O T H I N G

******************************************************************************

Smoothing of viewfactor matrix...

Max iterations = 100

Tolerance = 0.001

row sum total should be = 42366.0000

row sum total before forcing symmetry = 42365.9937

row sum total after forcing symmetry = 42365.9937

row sum total after smoothing = 42365.9997

Raw rowsum error min = -4.5061e-05

Raw rowsum error max = 8.3447e-07

Raw rowsum error mean = -1.4800e-07 +/- 4.5422e-07

Symmetric rowsum error min = -4.5061e-05

Symmetric rowsum error max = 8.3447e-07

Symmetric rowsum error mean = -1.4800e-07 +/- 5.8700e-08

Smoothed rowsum error min = -2.3842e-07

Smoothed rowsum error max = 4.7684e-07

Smoothed rowsum error mean = -7.6563e-09 +/- 1.4846e-10

number of iterations to smooth = 1

******************************************************************************

E N D O F V I E W F A C T O R S M O O T H I N G

******************************************************************************

TIME OF CALCULATION FOR THIS ENCLOSURE = 28.7812

CHECKING VIEW FACTOR SUM

VIEW FACTOR CALCULATION COMPLETE

WRITING VIEW FACTORS TO FILE file0.vf

VIEW FACTORS WERE WRITTEN TO FILE file0.vf

*** WARNING *** CP = 58.953 TIME= 13:17:41

Some radiation enclosures have viewfactor scaling. Use VFSM,STAT

command to check the status. Also note that scaling is ignored if the

viewfactor sum is <= 0.0.

*** WARNING *** CP = 59.047 TIME= 13:17:42

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** CP = 59.484 TIME= 13:17:42

The model data was checked and warning messages were found.

Please review output or errors file (

E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA\file0.err ) for

these warning messages.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R2 22.2 ***

Ansys Mechanical Enterprise Academic Research

00000000 VERSION=WINDOWS x64 13:17:42 DEC 07, 2024 CP= 59.594

Test_Radiation--Transient Thermal (B5)

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . TEMP

ANALYSIS TYPE . . . . . . . . . . . . . . . . .TRANSIENT

SOLUTION METHOD. . . . . . . . . . . . . . .FULL

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .SYMMETRIC

*** NOTE *** CP = 59.812 TIME= 13:17:42

This nonlinear analysis defaults to using the full Newton-Raphson

solution procedure. This can be modified using the NROPT command.

*** NOTE *** CP = 59.812 TIME= 13:17:42

The conditions for direct assembly have been met. No .emat or .erot

files will be produced.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 8 and contact element type 8 has been set up. The

companion pair has real constant set ID 9. Both pairs should have the

same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.704990738E-05 was detected between contact

element 133149 and target element 133270.

You may move entire target surface by : x= 1.685318E-05, y=

2.582569568E-06, z= 4.680688417E-19,to reduce initial penetration.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 9 and contact element type 8 has been set up. The

companion pair has real constant set ID 8. Both pairs should have the

same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.295

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.705060237E-05 was detected between contact

element 133209 and target element 133090.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 10 and contact element type 10 has been set up. The

companion pair has real constant set ID 11. Both pairs should have

the same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.703900632E-05 was detected between contact

element 133412 and target element 133534.

You may move entire target surface by : x= 7.33329464E-06, y=

-1.538019916E-05, z= 8.119307397E-20,to reduce initial penetration.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 11 and contact element type 10 has been set up. The

companion pair has real constant set ID 10. Both pairs should have

the same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 17.922

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.703995895E-05 was detected between contact

element 133473 and target element 133353.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 12 and contact element type 12 has been set up. The

companion pair has real constant set ID 13. Both pairs should have

the same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.705299849E-05 was detected between contact

element 133629 and target element 133749.

You may move entire target surface by : x= -2.583037783E-06, y=

1.685623545E-05, z= 4.453532888E-19,to reduce initial penetration.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 13 and contact element type 12 has been set up. The

companion pair has real constant set ID 12. Both pairs should have

the same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.295

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.705332427E-05 was detected between contact

element 133688 and target element 133570.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 14 and contact element type 14 has been set up. The

companion pair has real constant set ID 15. Both pairs should have

the same behavior.

ANSYS will keep the current pair and deactivate its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 13.216

Average contact pair depth 14.814

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 3.7036

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.70139613E-05 was detected between contact

element 133892 and target element 134013.

You may move entire target surface by : x= -1.535759236E-05, y=

-7.322515696E-06, z= 3.647501262E-20,to reduce initial penetration.

****************************************

*** NOTE *** CP = 60.891 TIME= 13:17:42

Symmetric Deformable- deformable contact pair identified by real

constant set 15 and contact element type 14 has been set up. The

companion pair has real constant set ID 14. Both pairs should have

the same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Pure thermal contact is activated.

The emissivity is defined through the material property.

Thermal convection coefficient, environment temperature, and

heat flux are defined using the SFE command.

Target temperature is used for convection/radiation calculation

for near field contact.

Small sliding logic is assumed

Contact detection at: Gauss integration point

Average contact surface length 17.922

Average contact pair depth 22.753

Average target surface length 14.984

Default pinball region factor PINB 0.25000

The resulting pinball region 5.6884

Initial penetration/gap is excluded.

Bonded contact (always) is defined.

Thermal contact conductance coef. TCC 255.64

Heat radiation is excluded.

*** NOTE *** CP = 60.891 TIME= 13:17:42

Max. Initial penetration 1.701500617E-05 was detected between contact

element 133952 and target element 133833.

****************************************

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 103764

...Number of nodes: 394205

...Decompose to 15 CPU domains

...Element load balance ratio = 1.101

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

TIME AT END OF THE LOAD STEP. . . . . . . . . . 0.10000

NUMBER OF SUBSTEPS. . . . . . . . . . . . . . . 2

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS. . . . 15

STEP CHANGE BOUNDARY CONDITIONS . . . . . . . . YES

TRANSIENT (INERTIA) EFFECTS

THERMAL DOFS . . . . . . . . . . . . . . . . ON

TRANSIENT INTEGRATION PARAMETERS

THETA. . . . . . . . . . . . . . . . . . . . 1.0000

OSCILLATION LIMIT CRITERION. . . . . . . . . 0.50000

TOLERANCE. . . . . . . . . . . . . . . . . . 0.0000

TERMINATE ANALYSIS IF NOT CONVERGED . . . . . .YES (EXIT)

CONVERGENCE CONTROLS

LABEL REFERENCE TOLERANCE NORM MINREF

HEAT 0.000 0.1000E-03 2 0.1000E-02

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

RSOL ALL

EANG ALL

VENG ALL

FFLU ALL

CONT ALL

MISC ALL

SOLUTION MONITORING INFO IS WRITTEN TO FILE= file.mntr

MAXIMUM NUMBER OF EQUILIBRIUM ITERATIONS HAS BEEN MODIFIED

TO BE, NEQIT = 1000, BY SOLUTION CONTROL LOGIC.

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 104 ITERATIONS

TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 15.1562

RAD FLUX CONVERGENCE VALUE= 1.00000 CRITERION= 0.100000E-04

**** CENTER OF MASS, MASS, AND MASS MOMENTS OF INERTIA ****

CALCULATIONS ASSUME ELEMENT MASS AT ELEMENT CENTROID

TOTAL MASS = 0.65239

MOM. OF INERTIA MOM. OF INERTIA

CENTER OF MASS ABOUT ORIGIN ABOUT CENTER OF MASS

XC = -200.00 IXX = 0.2670E+06 IXX = 0.2409E+06

YC = -200.00 IYY = 0.2670E+06 IYY = 0.2409E+06

ZC = -4.9274 IZZ = 0.3405E+06 IZZ = 0.2883E+06

IXY = -0.2610E+05 IXY = 0.2033E-03

IYZ = -642.9 IYZ = 0.5181E-02

IZX = -642.9 IZX = -0.4760E-02

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 0.921662E-01

2 0.921662E-01

3 0.921662E-01

4 0.921662E-01

5 0.138721

6 0.138721

7 0.628000E-02

Range of element maximum matrix coefficients in global coordinates

Maximum = 7563.16915 at element 133396.

Minimum = 558.91788 at element 49878.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 3009 SOLID279 0.266 0.000088

2 3009 SOLID279 0.234 0.000078

3 3009 SOLID279 0.188 0.000062

4 3009 SOLID279 0.094 0.000031

5 8201 SOLID279 0.656 0.000080

6 8201 SOLID279 0.641 0.000078

7 32000 SOLID279 1.203 0.000038

8 120 CONTA174 0.000 0.000000

9 120 TARGE170 0.000 0.000000

10 120 CONTA174 0.016 0.000130

11 120 TARGE170 0.000 0.000000

12 120 CONTA174 0.000 0.000000

13 120 TARGE170 0.000 0.000000

14 120 CONTA174 0.000 0.000000

15 120 TARGE170 0.000 0.000000

16 14400 SURF252 0.094 0.000007

17 27966 SURF252 0.141 0.000005

Time at end of element matrix formulation CP = 96.15625.

HT FLOW CONVERGENCE VALUE= 3.567 CRITERION= 0.4041E-01

DISTRIBUTED SPARSE MATRIX DIRECT SOLVER.

Number of equations = 113756, Maximum wavefront = 1

*** NOTE *** CP = 100.406 TIME= 13:18:17

This solution uses the GPU accelerator capability.

Process memory allocated for solver = 10.236 MB

Process memory required for in-core solution = 9.777 MB

Process memory required for out-of-core solution = 8.174 MB

Total memory allocated for solver = 239.611 MB

Total memory required for in-core solution = 230.076 MB

Total memory required for out-of-core solution = 176.083 MB

*** NOTE *** CP = 100.406 TIME= 13:18:17

The Distributed Sparse Matrix Solver is currently running in the

in-core memory mode. This memory mode uses the most amount of memory

in order to avoid using the hard drive as much as possible, which most

often results in the fastest solution time. This mode is recommended

if enough physical memory is present to accommodate all of the solver

data.

Distributed sparse solver maximum pivot= 59400.7117 at node 64209 TEMP.

Distributed sparse solver minimum pivot= 2111.0024 at node 256390 TEMP.

Distributed sparse solver minimum pivot in absolute value= 2111.0024 at

node 256390 TEMP.

*** WARNING *** CP = 100.516 TIME= 13:18:18

The Distributed Sparse Matrix Solver was not able to sufficiently

utilize the GPU accelerator device(s) during this equation solution.

This can be caused by one or more factors such as: the size of the

system of equations being solved; using older or less powerful GPU

hardware relative to the CPU core(s) involved; having insufficient

available memory on the GPU device. The check for GPU performance

terminates for the remainder of this session.

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 1980.

HT FLOW CONVERGENCE VALUE= 0.9189E-08 CRITERION= 3.213 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 209 ITERATIONS

TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 30.1094

RAD FLUX CONVERGENCE VALUE= 0.999699 CRITERION= 0.100000E-04

HT FLOW CONVERGENCE VALUE= 0.2924E+07 CRITERION= 746.6

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 1.536

HT FLOW CONVERGENCE VALUE= 0.1293E-07 CRITERION= 687.8 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 23 ITERATIONS

TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 3.29688

RAD FLUX CONVERGENCE VALUE= 0.352322E-05 CRITERION= 0.100000E-04

RADIOSITY FLUX CONVERGED AFTER ITERATION= 3 SUBSTEP= 1

HT FLOW CONVERGENCE VALUE= 1976. CRITERION= 687.8

EQUIL ITER 3 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1866E-02

HT FLOW CONVERGENCE VALUE= 0.1282E-07 CRITERION= 687.8 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 3

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 3009 SOLID279 0.250 0.000083

2 3009 SOLID279 0.234 0.000078

3 3009 SOLID279 0.141 0.000047

4 3009 SOLID279 0.047 0.000016

5 8201 SOLID279 0.531 0.000065

6 8201 SOLID279 0.562 0.000069

7 32000 SOLID279 0.609 0.000019

8 120 CONTA174 0.016 0.000130

10 120 CONTA174 0.016 0.000130

12 120 CONTA174 0.000 0.000000

14 120 CONTA174 0.000 0.000000

16 14400 SURF252 0.656 0.000046

17 27966 SURF252 0.938 0.000034

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 3009 SOLID279 0.031 0.000010

2 3009 SOLID279 0.031 0.000010

3 3009 SOLID279 0.047 0.000016

4 3009 SOLID279 0.031 0.000010

5 8201 SOLID279 0.047 0.000006

6 8201 SOLID279 0.078 0.000010

7 32000 SOLID279 0.250 0.000008

8 120 CONTA174 0.000 0.000000

10 120 CONTA174 0.000 0.000000

12 120 CONTA174 0.000 0.000000

14 120 CONTA174 0.000 0.000000

16 14400 SURF252 0.000 0.000000

17 27966 SURF252 0.000 0.000000

*** LOAD STEP 1 SUBSTEP 1 COMPLETED. CUM ITER = 3

*** TIME = 0.500000E-01 TIME INC = 0.500000E-01

HT FLOW CONVERGENCE VALUE= 0.2897E+07 CRITERION= 747.6

EQUIL ITER 1 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 1.287

HT FLOW CONVERGENCE VALUE= 0.1235E-07 CRITERION= 695.1 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 1

RADIOSITY SOLVER CALCULATION

ENCLOSURE NUMBER= 1

RADIOSITY SOLVER CONVERGED AFTER 21 ITERATIONS

TIME OF RADIOSITY SOLVER FOR ENCLOSURE= 3.01562

RAD FLUX CONVERGENCE VALUE= 0.287387E-05 CRITERION= 0.100000E-04

RADIOSITY FLUX CONVERGED AFTER ITERATION= 1 SUBSTEP= 2

HT FLOW CONVERGENCE VALUE= 1658. CRITERION= 695.1

EQUIL ITER 2 COMPLETED. NEW TRIANG MATRIX. MAX DOF INC= 0.1565E-02

HT FLOW CONVERGENCE VALUE= 0.1329E-07 CRITERION= 695.1 <<< CONVERGED

>>> SOLUTION CONVERGED AFTER EQUILIBRIUM ITERATION 2

*** LOAD STEP 1 SUBSTEP 2 COMPLETED. CUM ITER = 5

*** TIME = 0.100000 TIME INC = 0.500000E-01

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

2.625 MB WRITTEN ON ELEMENT SAVED DATA FILE: file0.esav

3.062 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full

10.750 MB WRITTEN ON RESULTS FILE: file0.rth

*************** Write FE CONNECTORS *********

WRITE OUT CONSTRAINT EQUATIONS TO FILE= file.ce

****************************************************

*************** FINISHED SOLVE FOR LS 1 *************

*GET _WALLASOL FROM ACTI ITEM=TIME WALL VALUE= 13.3205556

FINISH SOLUTION PROCESSING

***** ROUTINE COMPLETED ***** CP = 156.156

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2022 R2 22.2 ***

Ansys Mechanical Enterprise Academic Research

00000000 VERSION=WINDOWS x64 13:19:14 DEC 07, 2024 CP= 156.156

Test_Radiation--Transient Thermal (B5)

***** MAPDL RESULTS INTERPRETATION (POST1) *****

*** NOTE *** CP = 156.391 TIME= 13:19:14

Reading results into the database (SET command) will update the current

displacement and force boundary conditions in the database with the

values from the results file for that load set. Note that any

subsequent solutions will use these values unless action is taken to

either SAVE the current values or not overwrite them (/EXIT,NOSAVE).

Set Encoding of XML File to:ISO-8859-1

Set Output of XML File to:

PARM, , , , , , , , , , , ,

, , , , , , ,

DATABASE WRITTEN ON FILE parm.xml

EXIT THE MAPDL POST1 DATABASE PROCESSOR

***** ROUTINE COMPLETED ***** CP = 156.391

PRINTOUT RESUMED BY /GOP

*GET _WALLDONE FROM ACTI ITEM=TIME WALL VALUE= 13.3205556

PARAMETER _PREPTIME = 1.000000000

PARAMETER _SOLVTIME = 133.0000000

PARAMETER _POSTTIME = 0.000000000

PARAMETER _TOTALTIM = 134.0000000

*GET _DLBRATIO FROM ACTI ITEM=SOLU DLBR VALUE= 1.10090012

*GET _COMBTIME FROM ACTI ITEM=SOLU COMB VALUE= 0.298892600

*GET _SSMODE FROM ACTI ITEM=SOLU SSMM VALUE= 2.00000000

*GET _NDOFS FROM ACTI ITEM=SOLU NDOF VALUE= 113756.000

/FCLEAN COMMAND REMOVING ALL LOCAL FILES

--- Total number of nodes = 351363

--- Total number of elements = 61398

--- Element load balance ratio = 1.10090012

--- Time to combine distributed files = 0.2988926

--- Sparse memory mode = 2

--- Number of DOF = 113756

EXIT MAPDL WITHOUT SAVING DATABASE

NUMBER OF WARNING MESSAGES ENCOUNTERED= 3

NUMBER OF ERROR MESSAGES ENCOUNTERED= 0

+--------------------- M A P D L S T A T I S T I C S ------------------------+

Release: 2022 R2 Build: 22.2 Update: UP20220516 Platform: WINDOWS x64

Date Run: 12/07/2024 Time: 13:19 Process ID: 454368

Operating System: Windows 10 (Build: 19045)

Processor Model: Intel(R) Core(TM) i9-14900K

Compiler: Intel(R) Fortran Compiler Version 19.0.5 (Build: 20190815)

Intel(R) C/C++ Compiler Version 19.0.5 (Build: 20190815)

Intel(R) Math Kernel Library Version 2020.0.0 Product Build 20191125

BLAS Library supplied by Intel(R) MKL

Number of machines requested : 1

Total number of cores available : 32

Number of physical cores available : 24

Number of processes requested : 15

Number of threads per process requested : 1

Total number of cores requested : 15 (Distributed Memory Parallel)

MPI Type: INTELMPI

MPI Version: Intel(R) MPI Library 2021.5 for Windows* OS

Number of GPUs requested : 1

GPU Acceleration: NVIDIA Library Requested and Enabled

GPU Device with ID = 0 is: NVIDIA RTX A4000

GPU Driver Version: 12.40

CUDA Version: 11.0

Job Name: file0

Input File: dummy.dat

Core Machine Name Working Directory

-----------------------------------------------------

0 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

1 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

2 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

3 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

4 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

5 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

6 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

7 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

8 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

9 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

10 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

11 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

12 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

13 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

14 pc-thofell-2 E:\Test_Beam_1.63MW_Sig5mm\_ProjectScratch\Scr13EA

Latency time from master to core 1 = 1.905 microseconds

Latency time from master to core 2 = 2.263 microseconds

Latency time from master to core 3 = 1.836 microseconds

Latency time from master to core 4 = 1.834 microseconds

Latency time from master to core 5 = 1.874 microseconds

Latency time from master to core 6 = 1.939 microseconds

Latency time from master to core 7 = 1.947 microseconds

Latency time from master to core 8 = 3.367 microseconds

Latency time from master to core 9 = 3.428 microseconds

Latency time from master to core 10 = 3.533 microseconds

Latency time from master to core 11 = 3.458 microseconds

Latency time from master to core 12 = 3.346 microseconds

Latency time from master to core 13 = 3.919 microseconds

Latency time from master to core 14 = 3.417 microseconds

Communication speed from master to core 1 = 14717.79 MB/sec

Communication speed from master to core 2 = 15699.82 MB/sec

Communication speed from master to core 3 = 16146.94 MB/sec

Communication speed from master to core 4 = 15991.68 MB/sec

Communication speed from master to core 5 = 16511.53 MB/sec

Communication speed from master to core 6 = 16200.23 MB/sec

Communication speed from master to core 7 = 15609.45 MB/sec

Communication speed from master to core 8 = 11298.80 MB/sec

Communication speed from master to core 9 = 11504.17 MB/sec

Communication speed from master to core 10 = 11157.13 MB/sec

Communication speed from master to core 11 = 10997.92 MB/sec

Communication speed from master to core 12 = 11750.88 MB/sec

Communication speed from master to core 13 = 11007.15 MB/sec

Communication speed from master to core 14 = 10467.92 MB/sec