TAGGED: brittle-failure, static-structural

-

-

November 18, 2022 at 5:06 am

Eddie2324

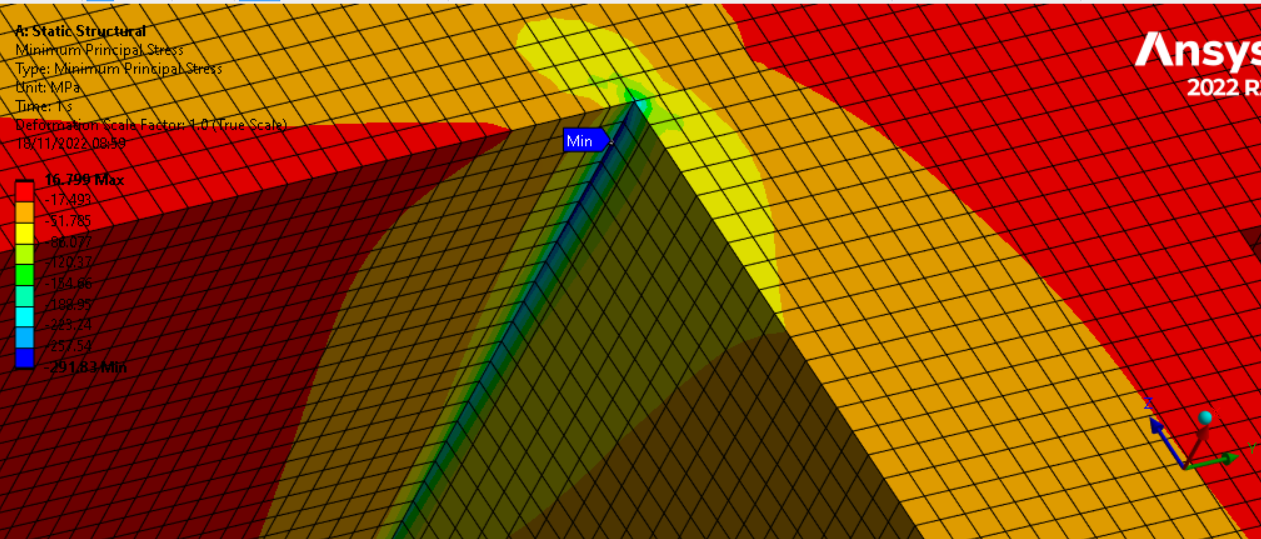

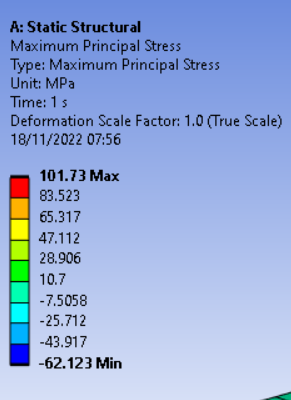

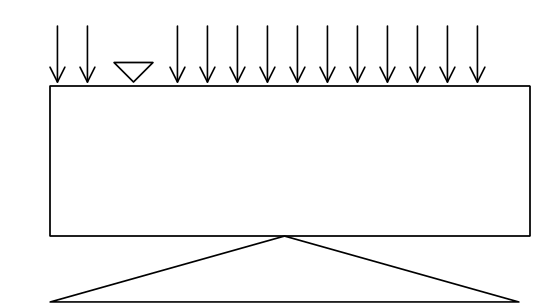

SubscriberHello, I am trying to analyse a cast iron mould part which squeze between the mold and the hyrolic press during the operation. I prepared model, defined the brittle material as a lineer( Different ultimate tensile and compression), but I am not quite sure about how to evaluate the result correctly, as far as I know I should use mohr coulomb failure tool to define the safety factor and check for the principal stresses. According to that I see no failure in the model also checked in mohr coulomb tool for ultimate tensile and compression however If I wanted to check the von misses stress There is a short edge between two parpenticular parts which has failed(my tensile is 200 mpa the edge has 240 mpa stress).

By the way also When I checked the negative principal stress I see -234 Mpa(but my ultimate strenght for compression is 800 Mpa) in the same failed edge in von misses stress. Does it mean my material is failed?

Should I be worried about the failure of von misses stress for a ductile material or should I only check for max min principal stress for a failure? As I can see from other topics usally everyone checks for the principal stresses but I could not be sure about it.

Also I am seeing values like this, is positive values tensile and negative compression? You can see my model as basicaly below sketch, since I am applying force like that, so I expected to see compression stresses on my part %90 of the part I see positive values. Is that normal?

Thanks.

-

November 18, 2022 at 10:27 am

peteroznewman

SubscriberHello Eddie,

Tensile stress is positive and compressive stress is negative.

There are three Principal Stresses: Maximum, Minimum and Middle.

Plot the Minimum Principal Stress to see the extreme value of compressive stress, which is the minimum value of the Minimum Principal stress.

The maximum value of Maximum Principal Stress is good for brittle materials to compare with Ultimate Tensile Strength. The minimum value of Minimum Principal Stress is compared with Ultimate Compressive Strength for brittle materials.

The maximum value of Equivalent Von Mises Stress is used on ductile materials to compare with the Yield Strength.

You also need to learn about stress singularities. You will find that the extreme values of stress will change with element size at that sharp corner you show in the image. If you mesh with elements twice as large, the stress will go down a lot. If you mesh with elements half as large, the stress will go up a lot. If you continue to make the element size smaller and smaller, the stress will keep increasing without any limit (until your computer runs out of resources). The way to find the true stress is to open the geometry and add a blend radius that is needed on that edge. Brittle materials can't have sharp corners becuase that is where a crack will start. If you have a ductile material, you can add a plasticity material model and allow the elements at that sharp corner to go past yield.

-

November 18, 2022 at 11:59 am

Eddie2324

SubscriberHello Peter,

Thank you very much, this is really good and simple explanation for understand the minimum and maximum principle stress, I was looking internet for few hours but deep theoritical information made me confuse about it. This is a brittle material and actually there was radius on that corners but I decided to remove this rounds to make the body more simple to mesh cause I had some trouble about meshing(You also replied my questions about meshing in other topick and thank you for that too :) ) I have few questions too ;

- If sharp corners like that caused stress singularities, I guess removing all rounds on the geometry is not a good idea, how can I decide to which rounds should stay and which rounds should been removed? Is every sharp corner may cause stress singularaties?

- You mentioned about the use of von misses for the yield of material. If a wanted to check the fail of ductile material( I mean beyond the plastic yield point, ultimate strength) can I still check with the von misses or should I check the max principal stress since I am checking the breaking of material with the ultimate tensile strenght( As far as I know break of the material is checking with the ultimate tensile strength for ductile material, please correct me if I am wrong.)

Thank you very much.

-

-

November 18, 2022 at 6:36 pm

peteroznewman

SubscriberSince you only care about the extreme stress in the model, you can solve with all blends removed, then add the blends back in on the few edges near the region of high stress.

Ductile materials have a material property called Elongation at Break (or just Elongation). If you turn on plasticity in the material model, plastic strain will develop in elements that exceed yield strength. Plot Total Equivalent Strain (elastic+plastic) and compare that with Elongation to judge failure.

-

November 21, 2022 at 4:44 am

Eddie2324

SubscriberThanks for the great information.

-

-

- The topic ‘Questions About Failure Of Brittle Material’ is closed to new replies.

- The legend values are not changing.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- APDL, memory, solid

- Convergence error in modal analysis

- How to model a bimodular material in Mechanical

- Meaning of the error

- Simulate a fan on the end of shaft

- Real Life Example of a non-symmetric eigenvalue problem

- Nonlinear load cases combinations

- How can the results of Pressures and Motions for all elements be obtained?

-

3862

-

1414

-

1220

-

1118

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.