-

-

April 3, 2024 at 3:09 pm

hatamimasoud68

SubscriberHi all

I'm simulating the suppressor in ANSYS Fluent and I have problems with my results.

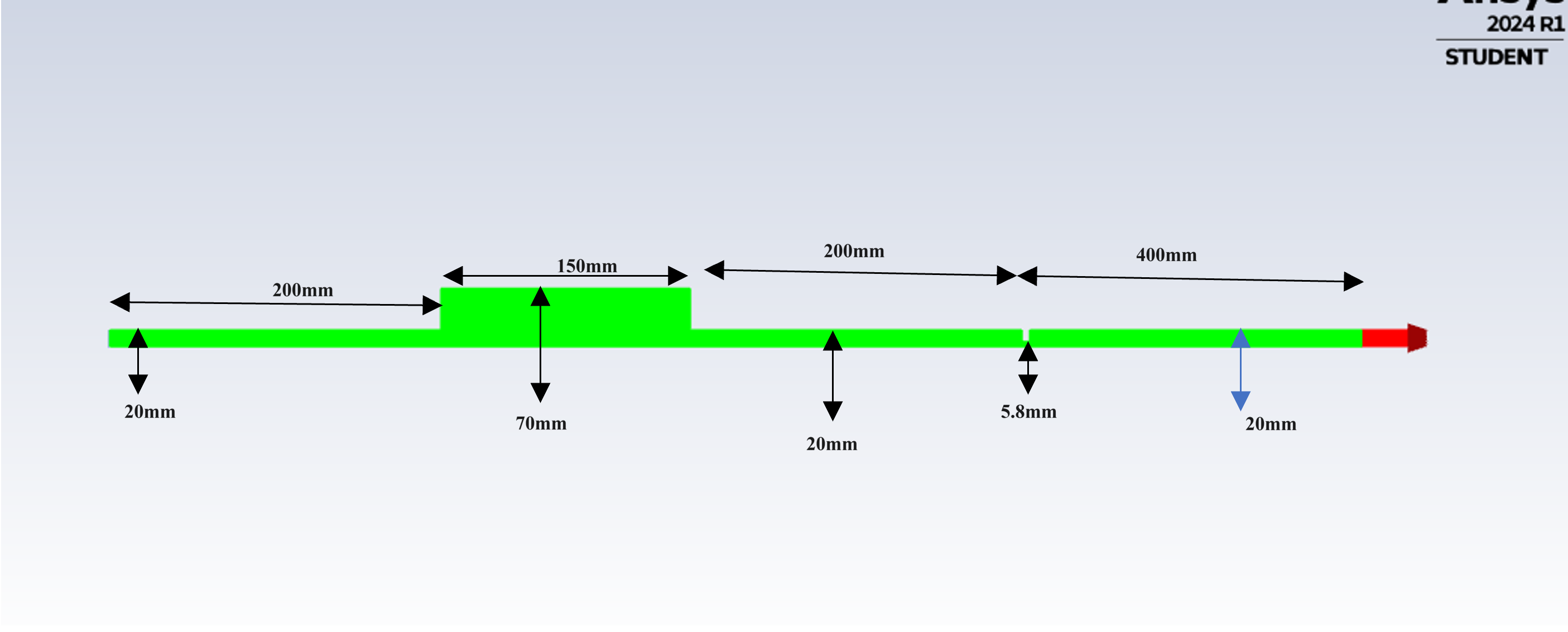

suppressor is fed by a gear pump, and the mean mass flow rate is 2.87 kg/s. We extract the mass flow and velocity using sensors. You can see the setup of the experiment here:

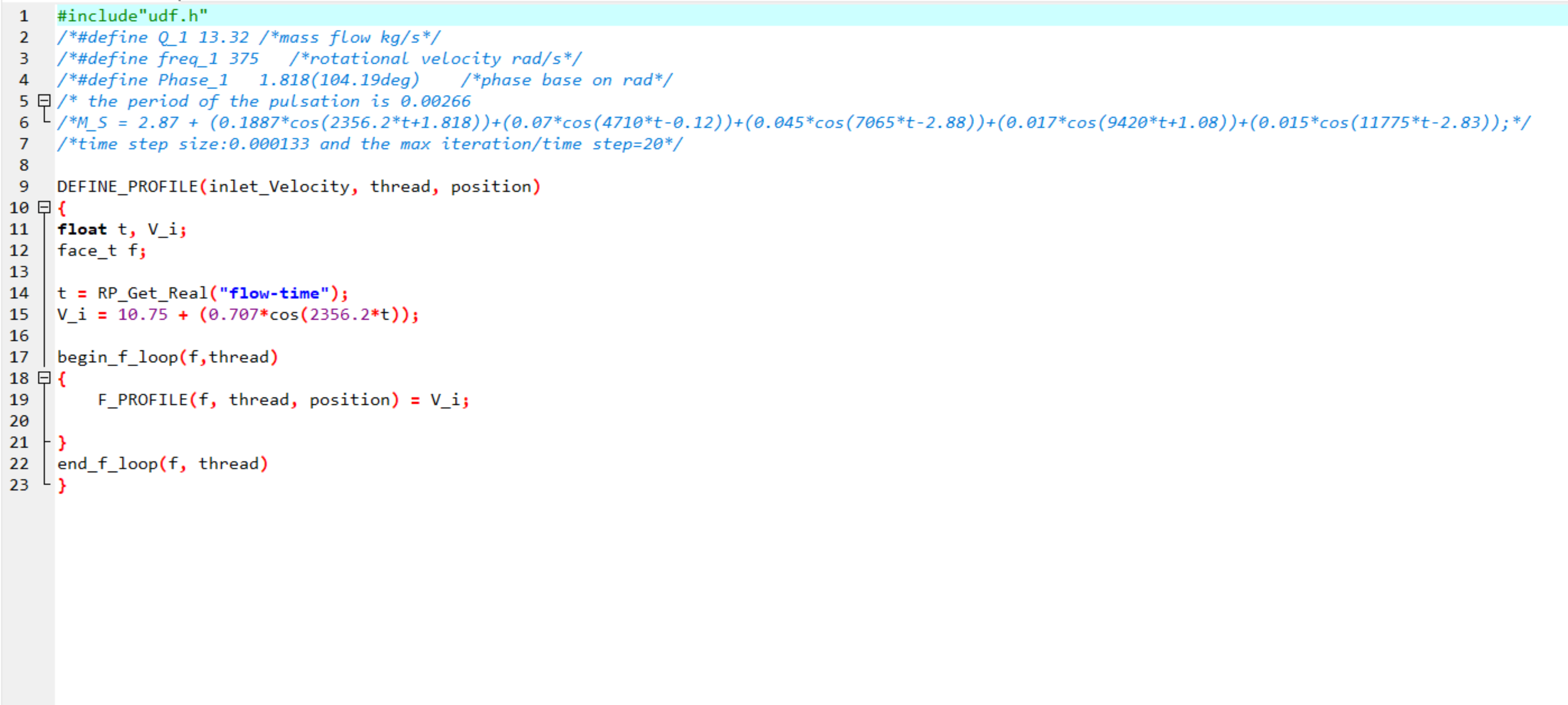

At the first step, I used the simple geometry that included the simple pipe with the chamber in the middle to see the pressure difference before and after the chamber, but to get a constant pressure at the outlet, I used an orifice with a diameter of 5.8 meters, and after the orifice, I extended the geometry to have a fully developed rejime and set a constant pressure of 5 bars for the outlet. I use a velocity inlet with UDF to set the inlet as a pulsative velocity. Here are my UDF and geometry.

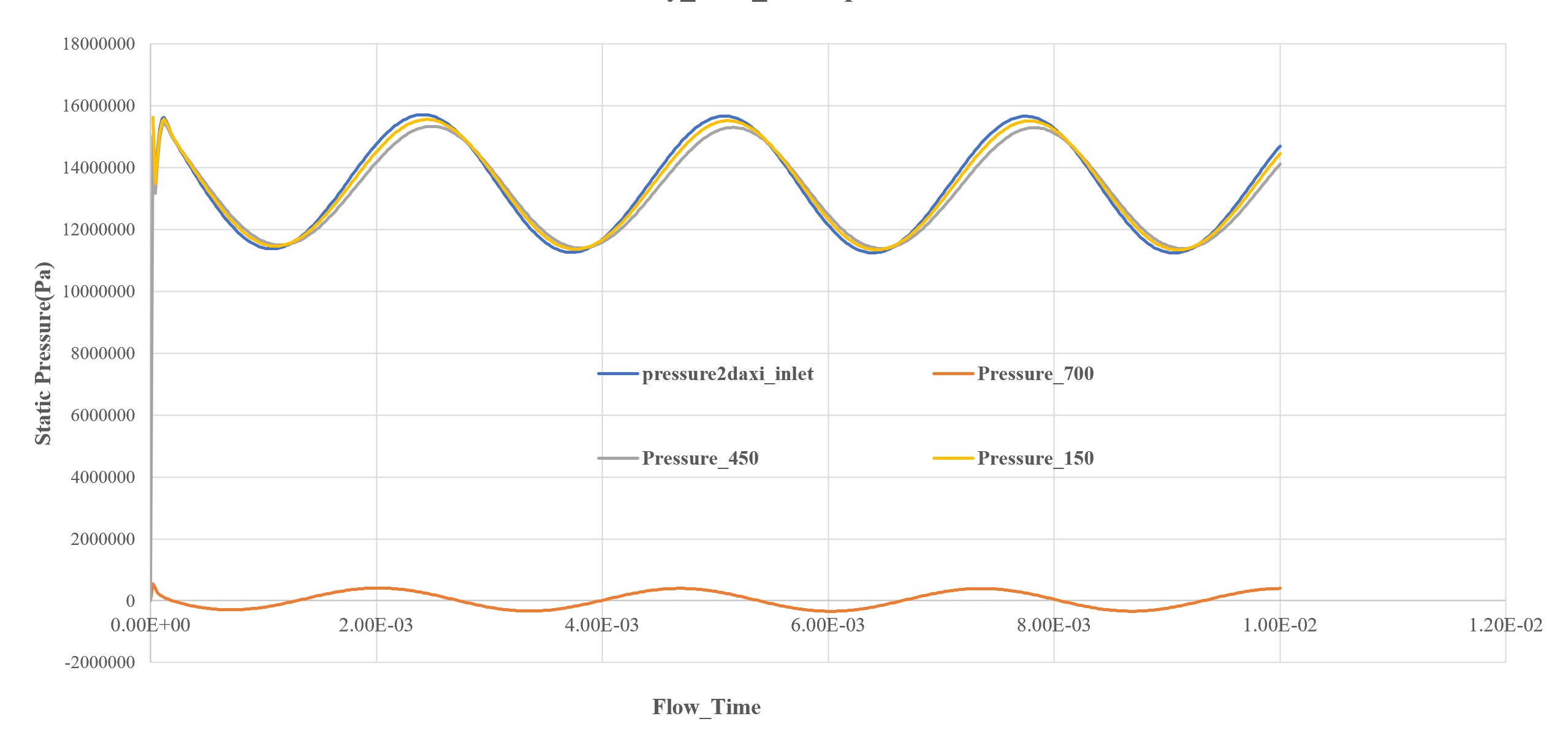

After this, I extract the pressure-time charts before and after the chamber, as well as at the inlet and after the orifice. but the pressure amplitude is very high, and I don't know why. My fluid is hydraulic oil with an 850 Kg/m^3 density and 0.039 dynamic viscosity. My frequency is 2356 rad/s (you can see it in Velocity UDF). I use 1e-6s for the time step. Here are my results.

After this, I extract the pressure-time charts before and after the chamber, as well as at the inlet and after the orifice. but the pressure amplitude is very high, and I don't know why. My fluid is hydraulic oil with an 850 Kg/m^3 density and 0.039 dynamic viscosity. My frequency is 2356 rad/s (you can see it in Velocity UDF). I use 1e-6s for the time step. Here are my results. Anyone who can help me decrease the amplitude of pressure or tell me where I am doing wrong???

pressure400=pressure after chamber

Pressure 700=pressure after orifice

pressure150=pressure before chamber

-

April 3, 2024 at 3:38 pm

Rob

Forum ModeratorIf you plot the velocity curve you're adding to Fluent (in Excel) and also plot the value from the inlet (surface report) how do they compare?

-

April 3, 2024 at 4:52 pm

hatamimasoud68

SubscriberDear Rob.

During the solve, I record the pressure at several points, including the inlet and 150, 450, and 650 mm away from the inlet. When I was done, I combined all of these variables into a single Excel file so that I could compare the pressures at different points.

-

April 4, 2024 at 8:29 am

Rob

Forum ModeratorOK, and how does the velocity look?

-

- The topic ‘Pulsative Pressure’ is closed to new replies.

-

5289

-

1885

-

1403

-

1268

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.