-

-

March 13, 2024 at 7:50 am

Midjan Jusic

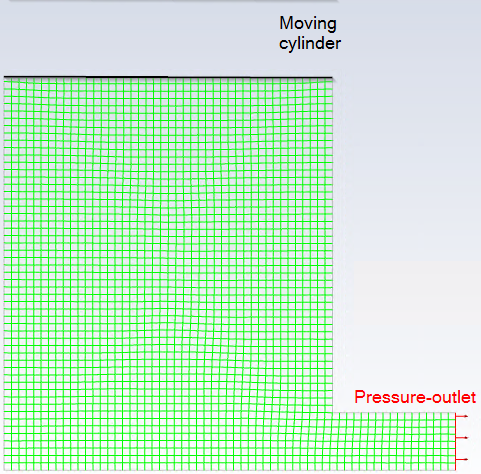

SubscriberI attempted to move the 'moving cylinder' downwards to press the water beneath it through the pressure outlet. To achieve this, I adjusted the dynamic mesh settings several times and experimented with various variations (Layering, Smoothing, Remeshing).

I created two dynamic mesh zones:

- 'moving cylinder' as a rigid body

- 'interior' as deforming

While the translation of the 'moving cylinder' is successful, the remeshing process does not work correctly. The mesh above the 'moving cylinder' stretches instead of generating new layers. I also tried using triangles. How can I avoid this problem?

Thanks!

-

March 13, 2024 at 6:05 pm

Federico

Ansys EmployeeThis looks like a classic Layering case.

Make sure you specify the ideal cell height for each layer in the Meshing Options tab from the Dynamic Mesh Zones dialog box.

Layering will split layers that are 1.4 times this ideal height and collapse those that are 0.2. The default is height is 0, which means to remeshing for the layer, which I suspect is why you're seeing the stretching you are showing.

-

March 13, 2024 at 6:06 pm

-

March 28, 2024 at 6:58 am

Midjan Jusic

SubscriberThank you for these answers. I have one more question regarding this. In the case I described, do I need to create more than one dynamic mesh zone? Or would a single dynamic mesh zone be sufficient for the moving cylinder?

Another question concerns how I can lower the cylinder depending on pressure. I've attempted this using the pressure-inlet boundary condition, but it doesn't result in any movement.

Thank you.

-

March 28, 2024 at 5:18 pm

Federico

Ansys EmployeeYes exactly, you can do with only the cylinder if you define the proper Cell Height in the Meshing Options as per my previous post.

-

-

April 4, 2024 at 7:31 am

Midjan Jusic

SubscriberThank you. But does that mean, that my cell height has to be exact the same size as my mesh element size? The element size of my mesh is 9 mm. I specified the cell height in dynamic mesh also as 9 mm. Still the problem with stretching mesh above the cylinder.

-

April 4, 2024 at 12:18 pm

Federico

Ansys EmployeeThe cell height you specify is the ideal cell height for the adjacent cell layer.

Fluent will collapse cells with height < 0.2*[ideal cell height], and split cells with height > 1.4*[ideal cell height]

0.2 and 0.4 are correspondingly the collapse and split factors by default. You can change these settings in the Layering settings.

-

-

April 10, 2024 at 7:23 am

Midjan Jusic

SubscriberHello, thank you for the answer. I tried it again. I still have problems with splitting cells above the cylinder. Collapsing below the cylinder works perfect.

If I build the model like here:

everything works. But I need the area above the cylinder to define a pressure-inlet, because I want to move the cylinder by giving pressure in the pressure-inlet.

Question 1:

Do you have any idea, why the collapsing process works but the splitting not? The cells are still stretching above the cylinder. I tried various cell heights and splitting parameters.

Question 2:

If I definied a body force with -9.81 m/s in Y direction because I have water in my model. How can I make sure, that the cylinder does not fall downwards with -9.81 m/s? I want to move the cylinder with pressure at pressure-inlet.

Thanks a lot!

-

April 10, 2024 at 1:38 pm

Federico

Ansys Employee1) Do you have 2 different adjacent zones on either side of your cylinder? If so, make sure you define a cell height for both sides. In the picture I shared, there was only 1 adjacent zone.

-

April 10, 2024 at 1:42 pm

Federico

Ansys Employee2) You will need to enable the 6DOF solver to have the cylinder move in response to pressure forces. 12.6. Using Dynamic Meshes (ansys.com)

-

April 12, 2024 at 6:15 am

Midjan Jusic

SubscriberHello, I think I discovered the reason for the stretching but I'm still looking for a solution:

I just have one interior-face for the mesh. The area above and below the cylinder is just one zone in my case. I think the cell-row above and below the cylinder is one row, instead of two. If the cylinder moves downwards and the cell-row below collapses (due to the collapsing factors), the cell-row above the cylinder collapses also. Thats why it seams like a "stretching-process". If I try to separate the cell zones in Ansys fluent, the two "not-touching" cylinder lines also separate. After that I cant combine them anymore, because they dont touch each other.

Do you know how I can separate the cell zone in two cell zones (one above, one below) in the mesher, bevor I start to configurate the set-up?

Thanks!

-

- The topic ‘Problems with dynamic mesh settings while mesh motion’ is closed to new replies.

-

5179

-

1838

-

1387

-

1249

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.