-

-

May 16, 2024 at 7:51 pm

javat33489

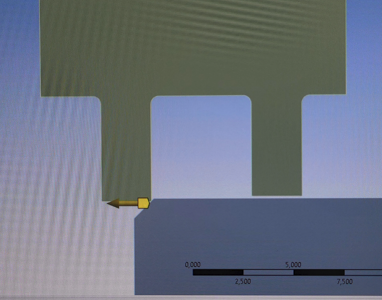

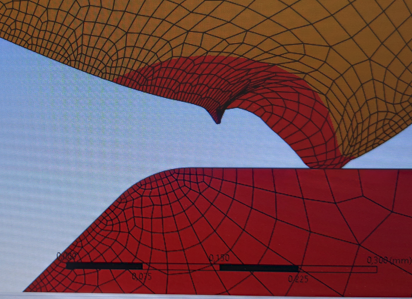

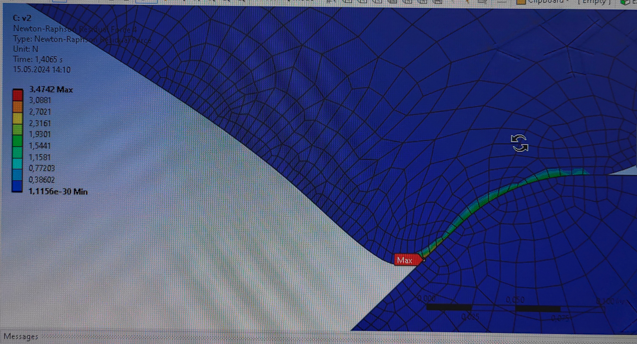

SubscriberHi all.I'm calculating the simplest rubber model, a flat problem.The bottom bar must go 5 mm for the rubber to fit on it.In reality, everything works, tests have been carried out.But the calculation is interrupted with an error and the mesh is distorted:Contact with friction, I tried a hundred different settings and life hacks, adjusting the contact does not help.I also tried disabling errors using the NCNV,0 command.I tried different types of grid (triangle and quad) and also changed the type from linear and back.In general, I tried a lot of solutions to the problem, but this does not help. I also tried solving it in the transient module.The Ogden or Neohukean rubber model usually worked well.The task always stops at 2.99 mm. Then I did an experiment, took three steps. 0s-0mm, 1s - 2.9 mm, 2s-2.9mm, 3s-5mm. At the second step, the bar simply stood still at 2.9 mm, the error still appeared, but at the second step the grid was distorted. This is weird.Tell me what to do? -

May 17, 2024 at 10:36 am

peteroznewman

SubscriberIf the end result is to get both fingers on the cylindrical surface, and you don't need to monitor the insertion force, I suggest you reduce the lead-in angle on the grey body. That may help expand the elastomer without the solution failing to converge. You may need to move the grey body more than 5 mm to get the elastomer onto the cylindrical surface.

-

Viewing 1 reply thread

- The topic ‘Problems with a simple tire model’ is closed to new replies.

Innovation Space

Trending discussions

Top Contributors

-

4612

-

1515

-

1386

-

1209

-

1021

Top Rated Tags

© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.