-

-

April 12, 2023 at 9:05 pm

André Henrique

SubscriberI am not able to generate the mesh of my project, the mesh simply fails or gives the following problem. "the meshing has completed, but some elements are not compliant with the applied shape checking criteria ansys".

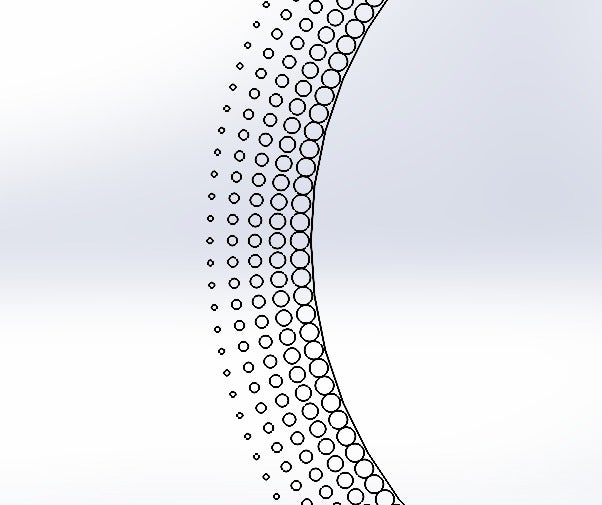

The solutions I tried didn't work. I'm still learning about Meshing, so I don't have much knowledge to troubleshoot the problem.The Geometry is as follows, it consists of several tubes varying in size around a larger cylinder as shown in the attached image.

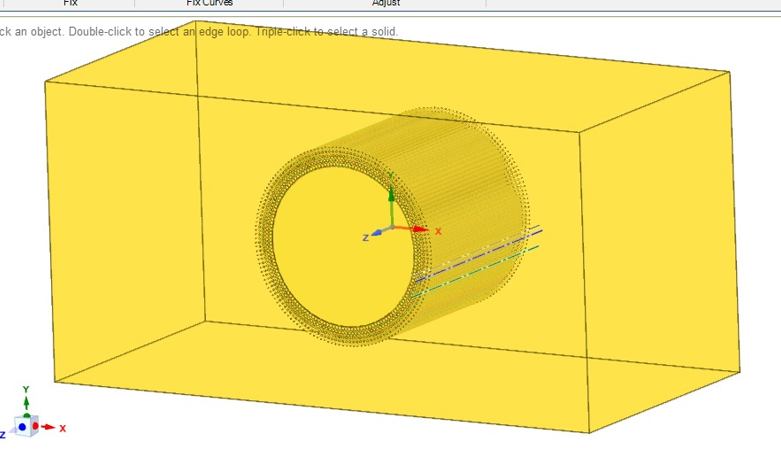

Still, there is an Enclosure that covers geometry,

From what I understand, the part that is giving error is the Enclousure Meshing process.

-

April 13, 2023 at 1:51 pm

Rob

Forum ModeratorIs the tube the same size (z direction) as the box? How far apart are the annular sections, and did you split them out? Which solver are you going to be using?

-

April 13, 2023 at 2:15 pm

André Henrique

SubscriberThe box is larger than the tube in the z direction, it is 200mm larger

-

April 13, 2023 at 2:16 pm

André Henrique

SubscriberAnd yes, they are different components

-

April 13, 2023 at 3:16 pm

Rob

Forum ModeratorOK. If they're different components, how large are the cells relative to the gaps? If the surface facet is large compared to the gap you'll get some very skew cells.

-

April 13, 2023 at 4:45 pm

-

April 13, 2023 at 11:58 pm

André Henrique

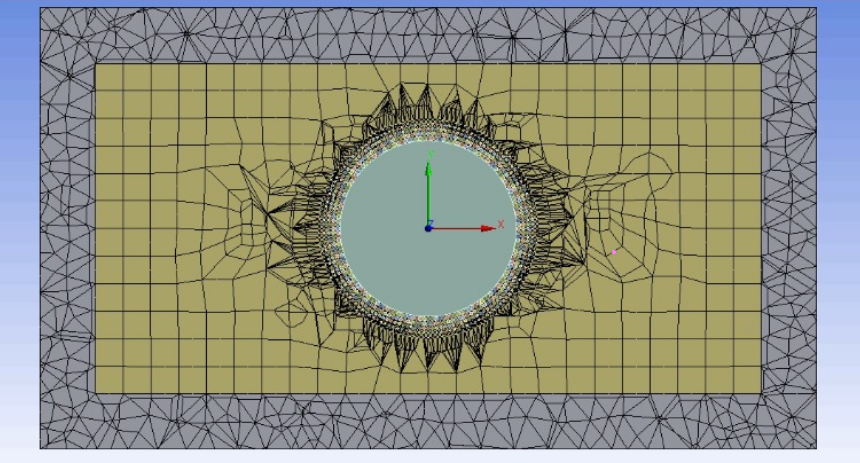

SubscriberI disabled the Check Mesh Quality option and managed to generate the mesh (otherwise it would not be possible to generate it due to the errors described above), but the mesh appears to be of poor quality. I'm just using body sizing and MultiZone. Please, check right below what I have got.

*As you can see in the image below, there is also a larger solid surrounding the others in this case (it's a PML). -

April 14, 2023 at 12:56 pm

Rob

Forum ModeratorThat mesh is pretty impressive. I've not seen the Meshing tool achieve something that messed up and not crash before!

Assuming the smaller tubes don't touch, you need a cell size that's smaller than that gap otherwise nothing can flow between the tubes. Read up on proximity and curvature size functions. Read up on hard and soft sizing, and then using the above work out why hard should be used with extreme caution.

There's a physics option in Meshing too. That sets defaults for smoothing etc. Make sure you've got the correct physics and solver selected.

-

April 16, 2023 at 6:00 pm

André Henrique

SubscriberOkay, I will read then.

Thanks.

-

- The topic ‘Problems in the meshing of my geometry’ is closed to new replies.

-

4592

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.