-

-

May 9, 2024 at 7:46 pm

javat33489

SubscriberHi all.

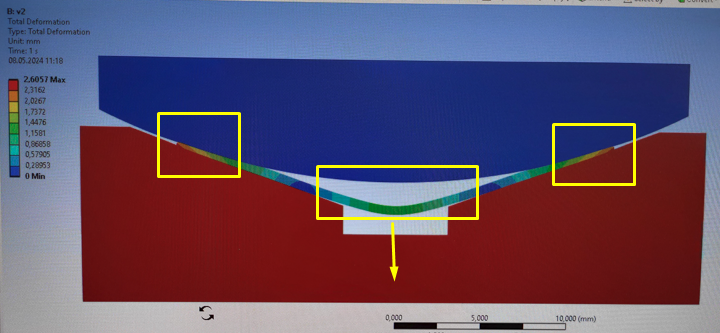

I'm doing a calculation of shaping a sheet into a bent sheet. The punch presses on the sheet, after which the sheet remains in the desired shape.

I'm solving a plane problem + 1/2 symmetry.

The problem is that when the punch presses on the sheet, and on the sides it presses it against the platform, the sheet bends greatly from the punch. Something like an impulse occurs:Why? How to fix it? -

May 10, 2024 at 9:41 am

peteroznewman

SubscriberIs the contact between the punch and sheet frictionless? That would explain why the center of the sheet goes down further than you expect. The reason is the wedge angle between the punch and the die since the punch has a radius and the die has a flat plane. The angle between the punch and die at the end of the sheet causes a tangential force on each end of the sheet to push it toward the center.

One way to fix that is to make the punch have the same two flats at the same angle as the die, except put a blend at the tip of the punch where there is a gap in the die. Another way to fix that is to add friction to the simulation, but that may not be as reliable as the first method.

-

May 10, 2024 at 9:58 am

javat33489

SubscriberI use friction, but I also tried without friction, the result is the same

-

-

May 10, 2024 at 10:09 am

peteroznewman

SubscriberMaybe more friction would help, maybe not. As I said, this is not the reliable method. Change the geometry to eliminate the wedge angle.

-

May 10, 2024 at 10:38 am

javat33489

SubscriberThanks for the answer, I understand you

-

-

- The topic ‘Problem when calculating sheet forming’ is closed to new replies.

-

5274

-

1875

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.