-

-

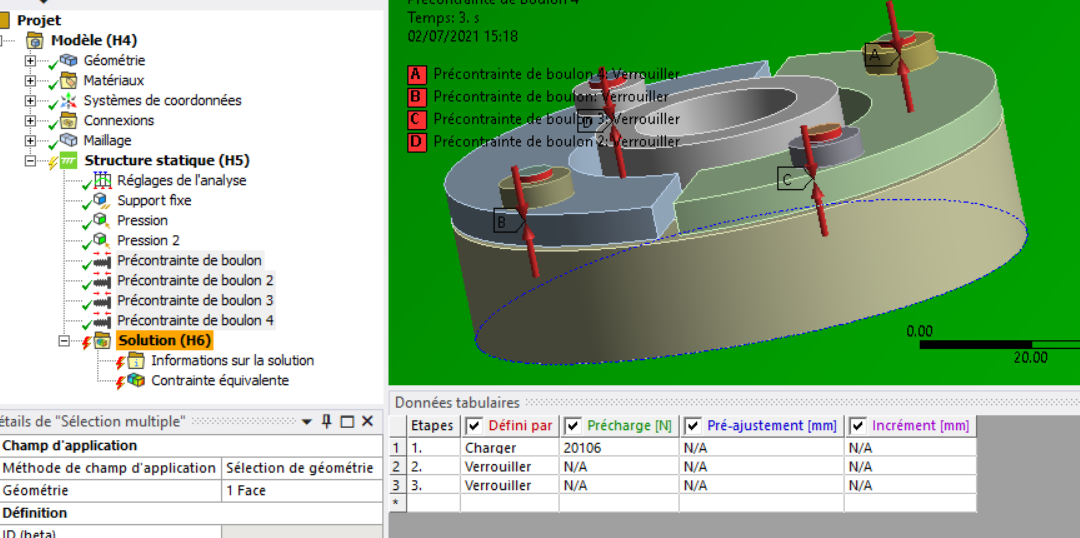

July 2, 2021 at 1:28 pm

oumaimalahmar.ol

Subscriberhello, plzzzzzzzzzzzzzz,

can someone tell me where I made the mistake because the calculation does not work and when I deactivate bolt pretension the calculation turns so I do not know what is my problem with the bolts.

@peteroznewman help me.

Thank you

July 2, 2021 at 1:39 pmErKo

Ansys EmployeeHi

Can you look on some tutorial like the one below and follow these steps. Finally Make sure that all parts are connected say bonded to start with, and that you have a fixed support.

If you still get an error after following the tutorial, please include from the solution information (search for error)the error message, and paste it here.

All the best

Erik

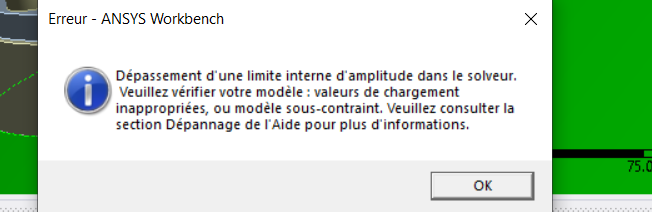

July 2, 2021 at 2:12 pmJuly 2, 2021 at 2:47 pmErKo

Ansys EmployeeHi

Can you please translate that so we can try and help you.

Also you can look in the solution information to get the message in english.

Thanks

Erik

July 2, 2021 at 3:30 pmJuly 3, 2021 at 4:19 ampeteroznewman

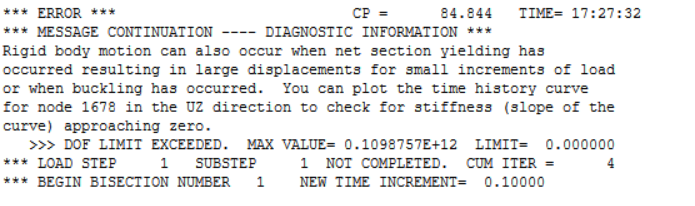

SubscriberDoes this error occur during the bolt pretension step?

Is Plasticity defined for the bolt material with a zero Tangent Modulus?

If so, use the bolt diameter to calculate the bolt area A in square mm.

Calculate the stress in MPa using F/A where F = 20106 N

Compare that stress with the Yield Strength of the bolt material in MPa.

If the stress is larger than the Yield Strength, that is the cause of this error.

July 9, 2021 at 6:50 amoumaimalahmar.ol

Subscriber

thank you for your response, effectively the stress is larger than the yield strength.

what can I do, even if I decrease the force the same error is displayed.

July 9, 2021 at 7:01 amErKo

Ansys EmployeeHi

Without looking at the model it is hard to say, but very likely there could be a rigid body motion of some parts.

Perhaps, the contact between the two cylinder halves, and the bottom cylinder is probably not active (assuming there a contact there defined) since there is a large gap between as far as we can see - so move these parts together so they just touch and assign initially a bonded contact between these parts. ALso make sure the contact between bolts and their different parts they connect to are there. Finally we need at least one fixed support say (which there is), and also switch off the material nonlinearities (set Nonlinear Effects to No for all parts). So try those things and let us know how it goes.

All the best

Erik

July 9, 2021 at 12:13 pmpeteroznewman

SubscriberI assume that what we see in the image is the bolt has a nut.

There is a clue that the bolt is not modeled correctly because we should not see any red on the far side of the nut.

There is a clue that the bolt is not modeled correctly because we should not see any red on the far side of the nut.

The bolt shank should have its face cut where it first enters the nut. The face that is in the nut and protrudes from the nut is selected for bonded contact with the nut.

The face that is below the head and before the nut is selected to have the Bolt Pretension applied.

The mistake in your model is that you don't have two faces on the bolt shaft.

Viewing 8 reply threads- The topic ‘problem in boundary condition ( bolt pretension)’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4678

-

1565

-

1386

-

1242

-

1021

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.