TAGGED: peteroznewman

-

-

August 25, 2021 at 2:25 pm

Ashish151215

SubscriberHi peteroznewman, I've reading your posts constantly.Currently I'm working on a model that has bolt pretensions in it. When I preload the bolt in step 1 at 5000N & lock in subsequent steps. The working load at end of simulation comes out to be more than 5000 N ( somewhere around 5003 N). Isn't it wrong? I also tried simulating a simple double shear joint with 10 N load & 5000 N pretension. The result comes same as 5003N working load at bolt. Also FOS is 0.1 at just 10N load which should not be the case in reality. Can you please help where the problem could be.

August 26, 2021 at 12:01 ampeteroznewman

SubscriberAfter tensioning a bolt to 5000 N, any tensile load supported by the bolt will naturally increase the working load above 5000 N so that is normal.

I don't know how you are measuring FOS, so I can't comment on that.

There are many ways you may have made a mistake in the model. You can either upload many images explaining exactly how you built the model, or you can attach a Workbench Project Archive .wbpz file to your reply. You create that by using File, Archive.

August 26, 2021 at 6:05 amAshish151215

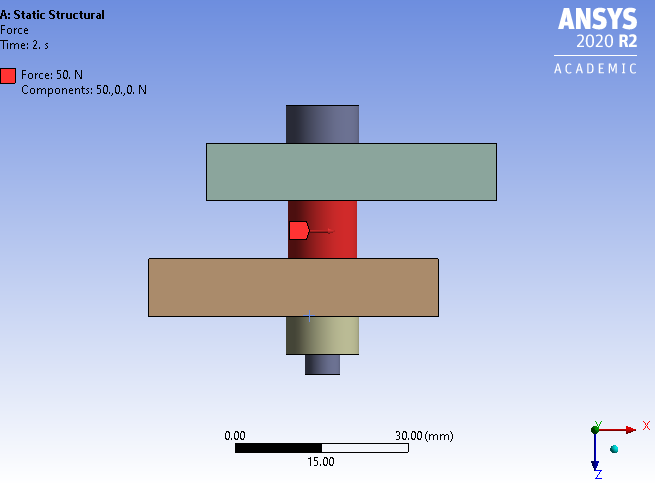

SubscriberIn this model I wanted to check the shear load on the spacer.

Kindly check if model is correct or not? Also I want to see fatigue life of bolt in Zero based loading. Consider the force (50N) being applied constantly by a cylinder on the spacer. The FOS of bolt comes out to be 0.19.

Even if i don't apply a load, the pretension only gives a stress of somewhere around 500 Mpa. Are these results practical? The Max. stress is 86.7 Mpa for infinite bolt life. Can you please make me understand how can one achieve full design life of a bolt in ansys?

I've reduced the mesh size due to file size limit

August 26, 2021 at 11:51 ampeteroznewman

SubscriberThe bolt seems to be an M6 bolt since I measured it as having a 6 mm shaft diameter.

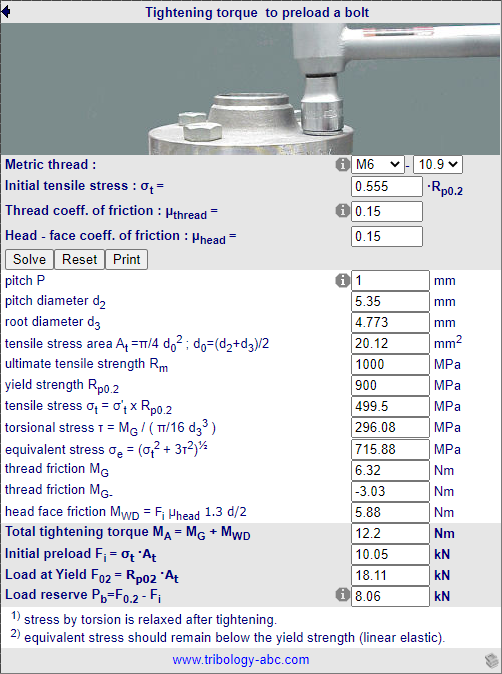

I recommend you use a Bolt Preload Calculator such as this one: https://www.tribology-abc.com/calculators/e3_6a.htm

Bolts come in a variety of material strengths. In the image above, I have selected a Grade 10.9 material which has a yield strength of 900 MPa.

Bolts come in a variety of material strengths. In the image above, I have selected a Grade 10.9 material which has a yield strength of 900 MPa.

You have assigned Structural Steel with a yield strength of 250 MPa to the bolt. Change the material yield strength of the bolt to a higher value and the bolt equivalent stress will be less than the new higher yield strength.

August 26, 2021 at 11:59 amAshish151215

SubscriberYes you are correct. I am using 12.9 grade bolt which has 1300 MPa UTS & 1100 MPa Yield strength. But in fatigue loading the strength of bolt usually reduces to 1/4 of Yield. So Peak stress should come under somewhere around 285 MPa.

Can you please confirm if the simulation is done right?

August 26, 2021 at 12:35 pmpeteroznewman

SubscriberIs the 50 N load in the X direction a cyclic load? Does it change from 0 to 50 N to build up cycles over its life?

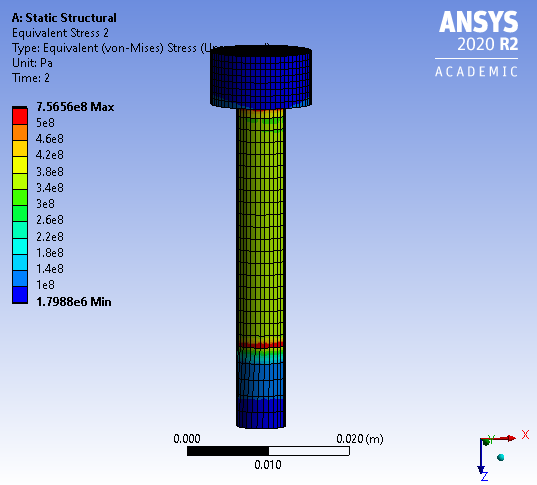

The bolt experiences almost zero change in stress due to the application of this 50 N load. Look at the bolt stress between the end of step 1 and the end of step 2. It goes from 553.25 MPa to 553.43 MPa. That is the alternating stress you should be using in the Fatigue calculation on the bolt.

The bolt experiences almost zero change in stress due to the application of this 50 N load. Look at the bolt stress between the end of step 1 and the end of step 2. It goes from 553.25 MPa to 553.43 MPa. That is the alternating stress you should be using in the Fatigue calculation on the bolt.

August 26, 2021 at 12:51 pmAshish151215

SubscriberYes it is cyclic loading. That is why i am selecting zero based loading cycle to calculate fatigue.

If I need to consider 553.25 & 553.43 Mpa. Do i need to use a ratio based loading?

August 26, 2021 at 2:08 pmpeteroznewman

SubscriberYes, calculate the ratio using those numbers.

August 26, 2021 at 2:08 pmAshish151215

SubscriberStill the FOS is at 0.74.

August 26, 2021 at 2:09 pmAshish151215

Subscriber& 50N is not very huge load for a M6 bolt to take. Am i interpreting the results wrong?

August 26, 2021 at 5:12 pmpeteroznewman

SubscriberLook at the unaveraged element stress results:

You can see a stress concentration where the shaft emerges from the nut. This is caused by the bonded contact.

You can see a stress concentration where the shaft emerges from the nut. This is caused by the bonded contact.

Change the contact to Frictional, and use the Geometric Modification, Contact Geometry Correction: Bolt Thread. This will require using a mesh density that has at least 4 elements per thread pitch to model the thread geometry. The result will be to spread the stress out over a larger area, thereby lowering the peak value.

/forum/discussion/30851/what-is-the-best-way-to-simulate-the-stress-along-the-threaded-bolt-untapped-hole

August 27, 2021 at 3:54 amAshish151215

SubscriberTried the method suggested by you. The results are still the same. Only difference is stress increased to 891 MPa in last step & 890 in 1st Step.

Ratio based loading gives FOS 0.51

Can you please solve the model for me to know bolt life & FOS. It would be really helpful. I'm stuck in a project because of this.

August 27, 2021 at 11:45 pmpeteroznewman

SubscriberI can't solve this model because it exceeds the Student license limits on nodes and elements.

Please show the mesh and the stress on the bolt after using the Contact Geometry Correction: Bolt Thread.

Viewing 12 reply threads- The topic ‘Problem in Bolt pretension & FOS’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5094

-

1829

-

1387

-

1248

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-