-

-

July 14, 2023 at 5:39 pm

rahmadilahi658

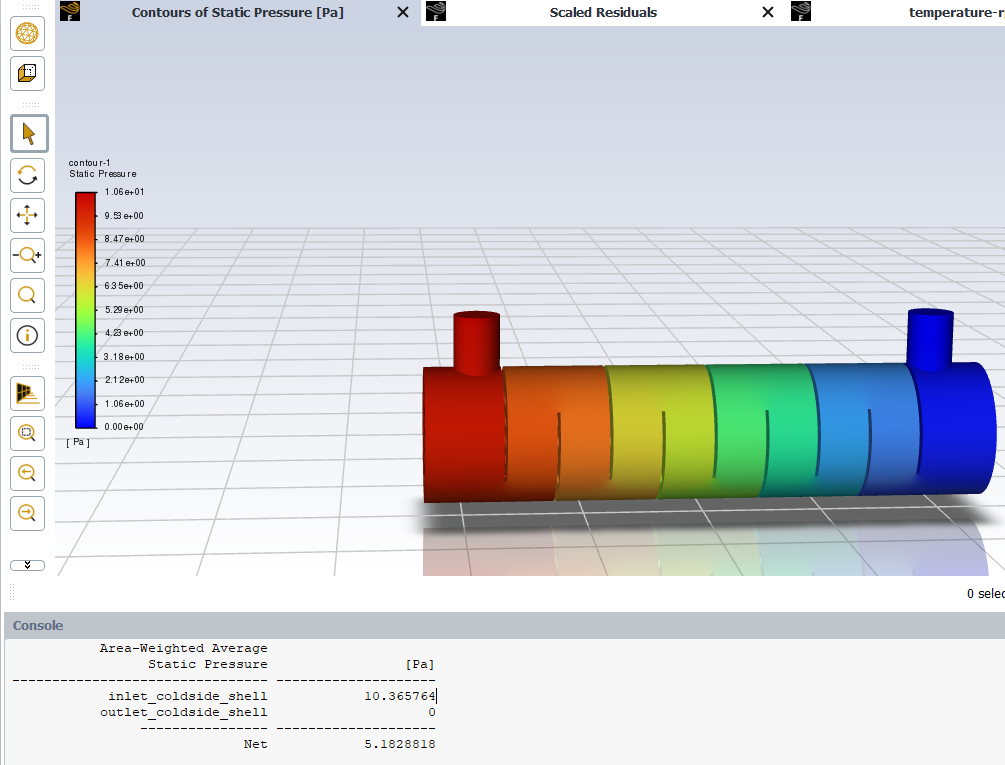

SubscriberI am confused by finding the pressure drop value of my shell and tube design. From the theoretical calculation I get a value of 46299.34 pa using the kern equation while the simulation is 10,365764 pa. Please help me so that my simulation value of pressure drop is the same as my theoretical calculation.

-

July 14, 2023 at 6:00 pm

Federico

Ansys EmployeeHello,

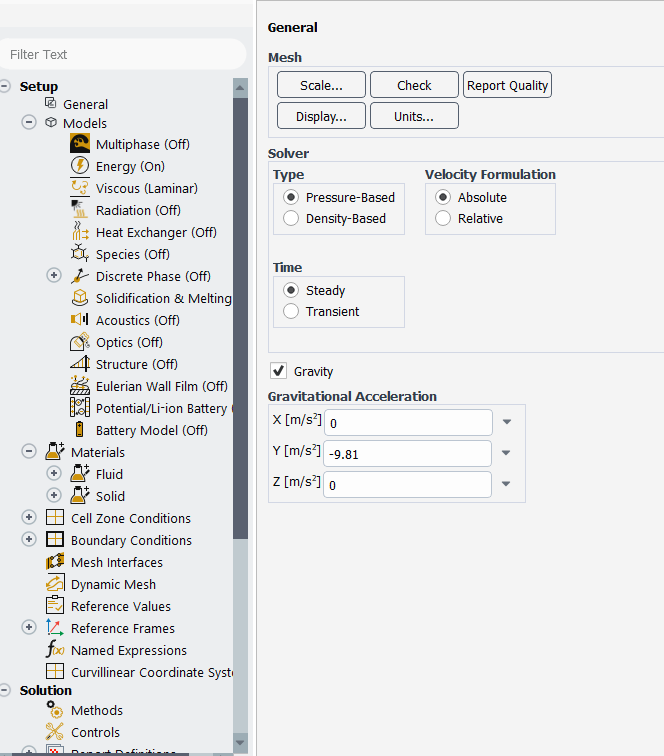

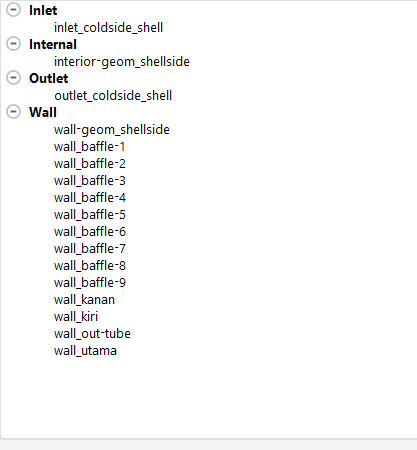

we might need more information on how you set up your simulation to be in position to help you. What are the boundary conditions? What models are you using?

-

July 14, 2023 at 6:49 pm

-

July 17, 2023 at 8:09 am

NickFL

SubscriberMany, many sources of potential error. Here are the simpliest do debug.

- Is it scaled correctly? Are you sure of your HEx size in the Fluent model? It would not be the first time someone made this mistake.

- Does it have the correct material properties? Default is air.

- Double check your mass flux. Does it match what you put in your hand calculation?

-

July 17, 2023 at 8:23 am

Rob

Forum ModeratorTo add to Nick's comments. Please also post images of the cross section pressure loss (centre plane) and midway between two baffles. Did you model the tubes or use a porous media? Given the number of tubes in a typical HX you'll need a lot of mesh to resolve these.

-

- The topic ‘Pressure drop Heat Exchanger Shell and Tube’ is closed to new replies.

-

5159

-

1836

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.