-

-

July 28, 2022 at 8:11 pm

jmoss

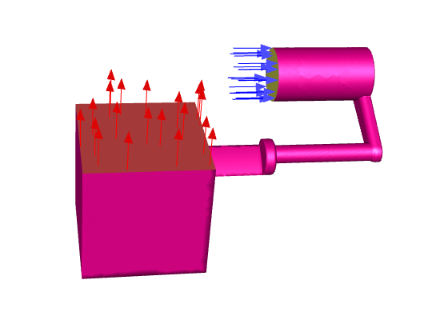

SubscriberHello, Being new to CFD and Fluent, I was hoping for some help w/ a problem where I'm given an initial inlet pressure and need to determine the leakdown time to reach ambient pressure. I want to run the sim starting with the flow volume full of oil and have a piston push out a known portion of that volume. Will this require dynamic mesh setup in a transient analysis, or can it be determined with a steady state analysis and some hand calcs using the volumetric flow rate from the SS results? Thanks in advance!

-

July 29, 2022 at 5:28 am

Prashanth

Ansys EmployeeHey

I see two ways you can approch this problem. You can use dynamic meshing with layering approach to calculate the leakdown time. Orelse keep it simple and change it into a multiphase problem if the flow rate and time is what you are after. But I don't think this can made into a steady case problem as you are dealing with a time dependent study.

-

July 29, 2022 at 2:26 pm

jmoss

SubscriberThanks for your reply. Multiphase does sound more simple than dynamic mesh. Just to clarify, you mean vent the known volume into an empty tank as the second phase (air)?

-

July 30, 2022 at 10:05 am

Prashanth

Ansys EmployeeSure, that's one of the way you can approach this. It's upto you, play with different settings and solve it.

-

August 2, 2022 at 1:40 pm

jmoss

SubscriberIdeally, I would like to use one volume that consists of the oil volume and the empty tank to be filled.

Do I need to split the solid in SpaceClaim in order to patch the oil to the region of the volume that I would like to start as filled?

-

August 2, 2022 at 1:54 pm

Prashanth

Ansys EmployeeAn easier way is to patch it using region based cell registers (solution>cell registers)

-

August 8, 2022 at 7:32 pm

jmoss

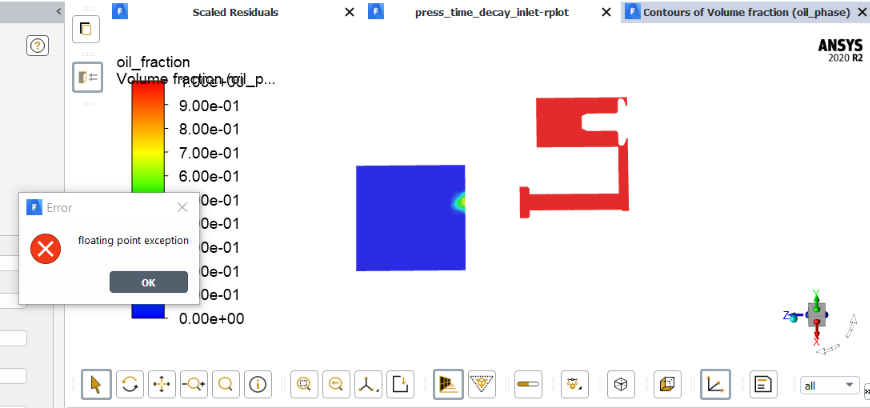

SubscriberI continue to get a "floating point exception" error about 50-90 iterations into the solution. How do I fix this?

My fluent setup is as follows:

Pressure based

Multiphase (VOF) air- primary, oil-secondary

Laminar

standard initialization from the inlet

0.18bar initial pressure @ inlet

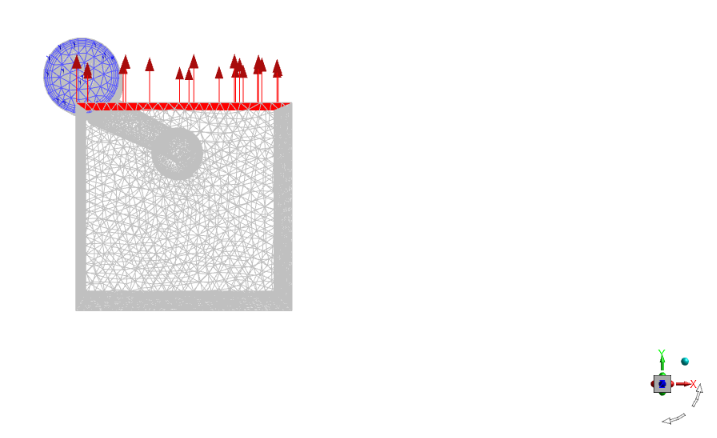

I've attached pics of the volume and mesh for clarity. Thanks in advance!

-

August 9, 2022 at 5:00 am

Prashanth

Ansys EmployeeCheck these:

(1) Is the calculation implicit or explicit ?

(2) Did you change operating density from default ?

(3) Are you considering surface tension ?

(4) Is the gravity direction set properly ?

(5) Is the volume fraction at the boundaries (also backflow VF at outlets) set properly ?

(6) Which p-v scheme you are using ?

(7) What time step size have you set ?

(8) Have you checked the patched domain before calculation ?

(9) Did you change the advanced stability controls (velocity limiting etc) ?

(10) And finally, are you trying to simulate something unphysical ?

Also these might help: User's guide ; Theory guide

-

August 10, 2022 at 12:31 pm

jmoss

Subscriber(1) Is the calculation implicit or explicit ? implicit

(2) Did you change operating density from default ? no

(3) Are you considering surface tension ? no

(4) Is the gravity direction set properly ? -9.81 in Y-direction

(5) Is the volume fraction at the boundaries (also backflow VF at outlets) set properly ? VF set to zero at both inlet and outlet.

(6) Which p-v scheme you are using ? SIMPLE, PRESTO! And bounded second order implicit transient formulation

(7) What time step size have you set ? 0.01 size, 100 steps

(8) Have you checked the patched domain before calculation ? everytime, after I initialize

(9) Did you change the advanced stability controls (velocity limiting etc) ? no

(10) And finally, are you trying to simulate something unphysical ? no

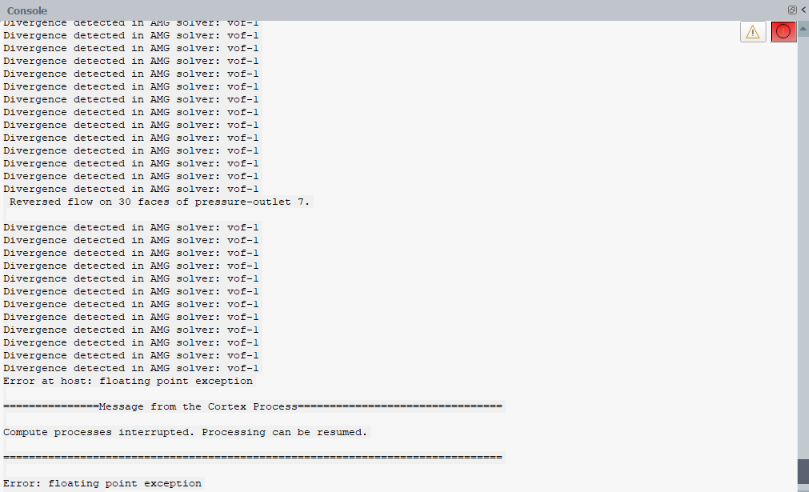

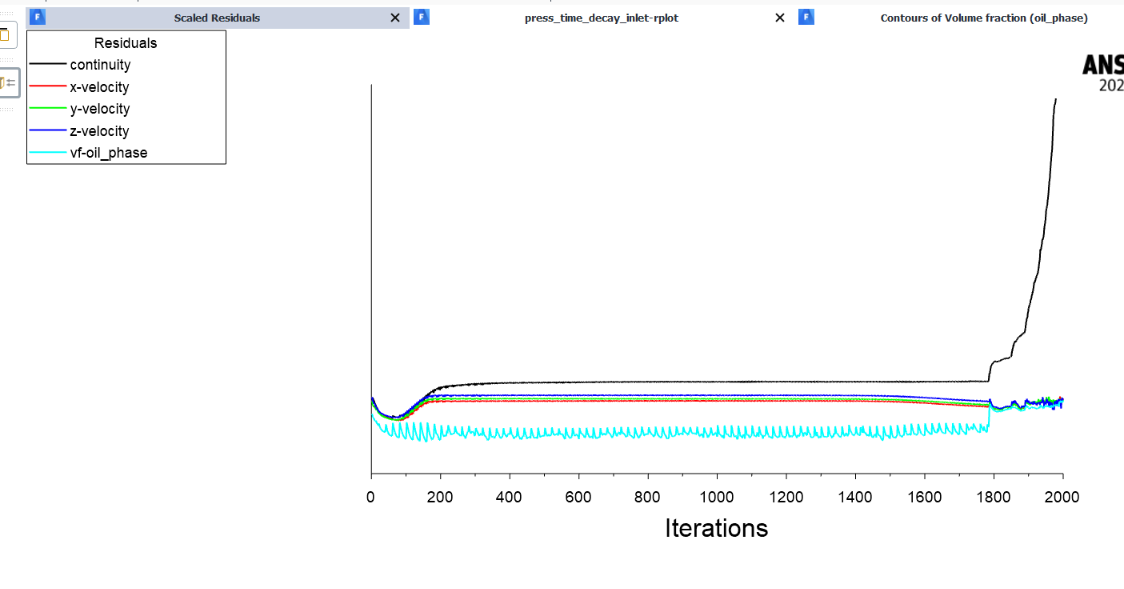

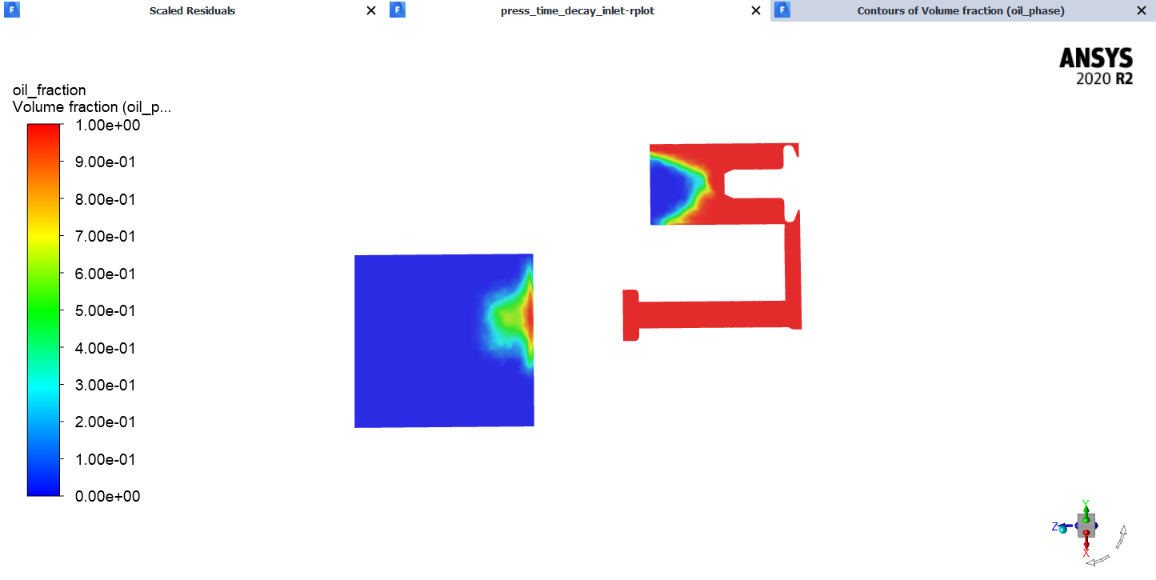

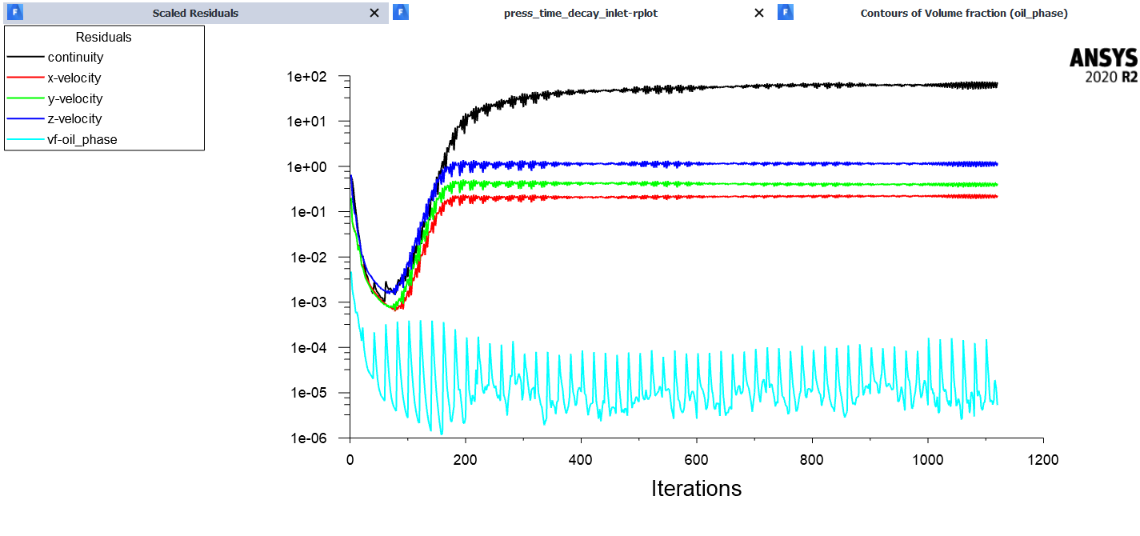

Note* continuity residual skyrockets toward end of calculation when “floating point exception” occurs (please see attached pic)

-

August 10, 2022 at 3:29 pm

Rob

Forum ModeratorHow does the flow field look at around 1200 iterations? What values are the residuals, not being able to see the y-axis scale isn't helpful.

-

August 11, 2022 at 2:50 pm

-

-

August 10, 2022 at 5:40 pm

Prashanth

Ansys EmployeeHey

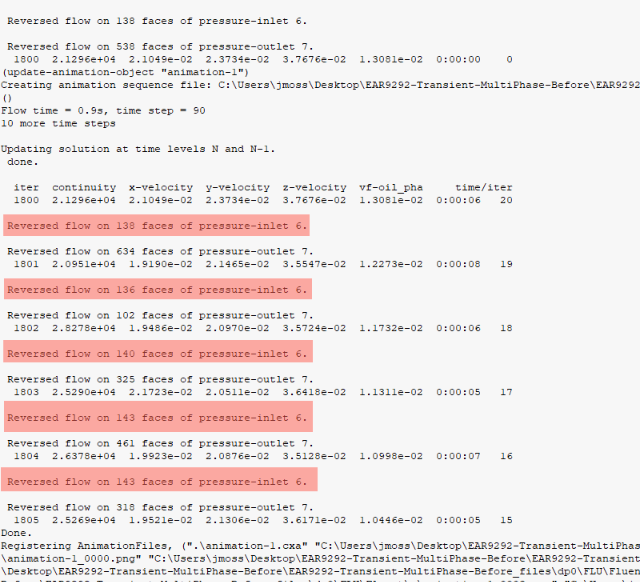

I think the domain (the cylindrical part patched with secondary phase) is not exactly aligned with the gravity vector or do correct me if I'm wrong. In that case, did you experience reversed flow (check in transcript file) at the inlet ?

-

August 11, 2022 at 2:58 pm

-

-

August 11, 2022 at 3:41 pm

Rob

Forum ModeratorThe reverse flow is because the oil is pouring out the bottom of the inlet. I'm still very unclear as to what you're trying to do.

-

August 11, 2022 at 5:18 pm

jmoss

SubscriberIm trying to obtain the time duration for the initial inlet pressure of 0.18 bar to reach ambient pressure (0 bar). I dont understand how the oil is pouring out the bottom of the inlet in the presence of the prescribed pressure? How can this be prevented? Turn off gravity?

-

August 11, 2022 at 5:57 pm

Prashanth

Ansys EmployeeSwitch off the multiphase, cover up the inlet (wall), use ideal gas for density (compressible), patch the cylinder with higher pressure (.18 gauge), create report wherever you want to calculate the time it takes for the pressure to reach ambient.

-

August 24, 2022 at 8:12 pm

jmoss

SubscriberI dont understand why oil is pouring out of the bottom of the inlet even with the gravity turned off. Isnt the pressure applied equally across the inlet surface shown above? How else could I prevent backflow at the inlet? Thanks!

-

September 1, 2022 at 6:42 pm

jmoss

SubscriberI cant create a volume fraction contour without turning on multiphase. therefore, how can I confirm that the volume is initially full of oil? And if I cover up the inlet how will the oil flow out the outlet?

-

September 1, 2022 at 6:44 pm

jmoss

Subscriberthere has to be a way to prevent backflow at the inlet. please advise.

-

September 1, 2022 at 8:14 pm

Prashanth

Ansys EmployeeHi

To prevent the secondary phase from leaking, you must change the position of that cylindrical domain part - make its axis inline with the gravity vector.

-

September 1, 2022 at 9:04 pm

jmoss

SubscriberThere is no gravity vector because I have gravity turned off. I noticed there is a toggle to prevent reverse flow at the outlet. Is there no other way to prevent reverse flow at the inlet?

-

September 2, 2022 at 5:33 am

Prashanth

Ansys EmployeeHi

Just to clarify again, my earlier suggestion "Switch off the multiphase, cover up the inlet (wall), use ideal gas for density (compressible), patch the cylinder with higher pressure (.18 gauge), create report wherever you want to calculate the time it takes for the pressure to reach ambient." can be used for your case if you are just trying to obtain "the time duration for the initial inlet pressure of 0.18 bar to reach ambient pressure (0 bar)."

For your goal, you don't need 2 phases.

And, using multiphase model without gravity can yield some unusual results. And you cannot prevent the oil from flowing backwards as the fluid will always choose the path of least resistance.

-

- The topic ‘pressure decay – time to reach ambient’ is closed to new replies.

-

5039

-

1729

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.