-

-

November 6, 2023 at 5:00 pm

charles-web

SubscriberDear Everyone,

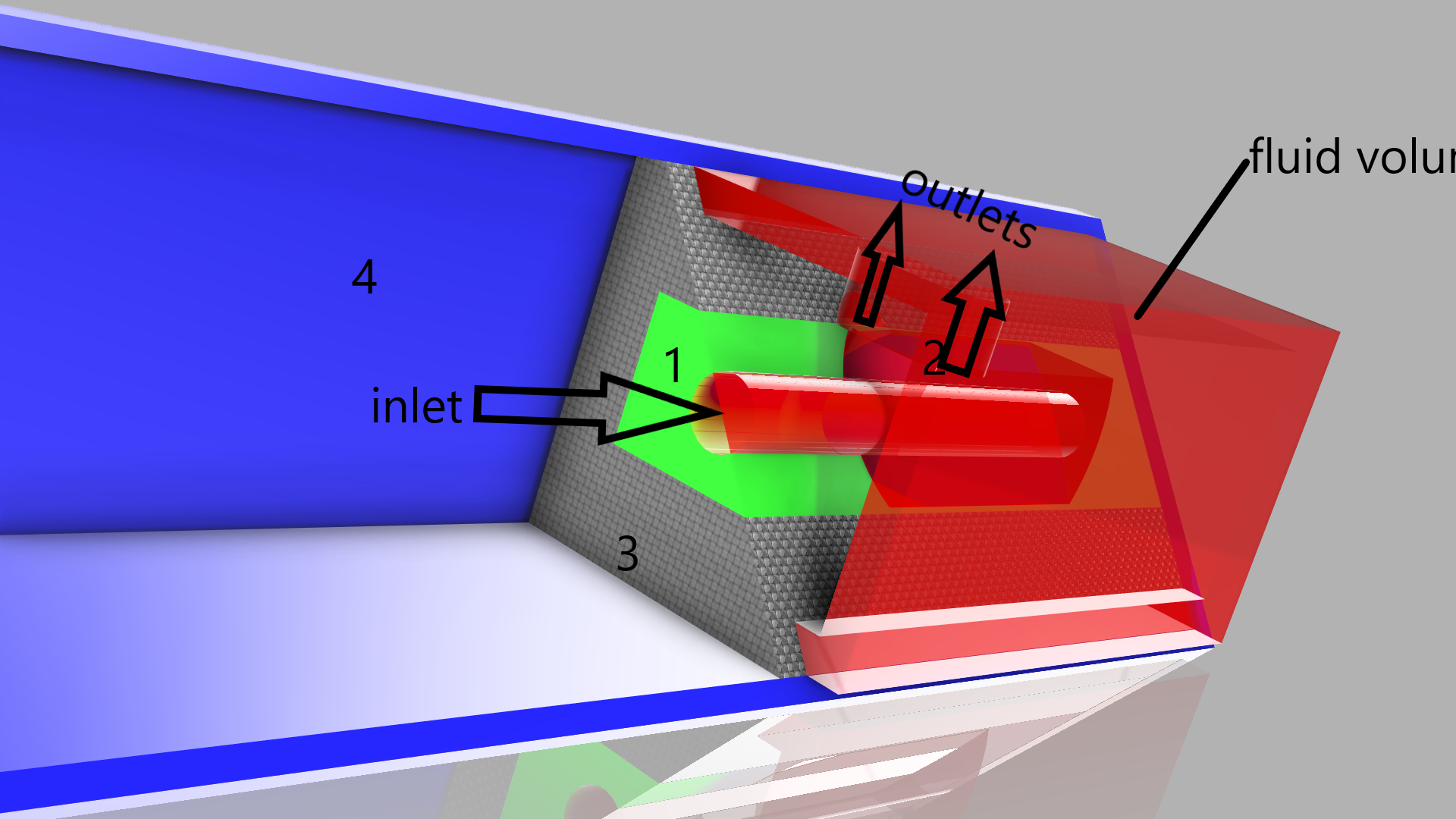

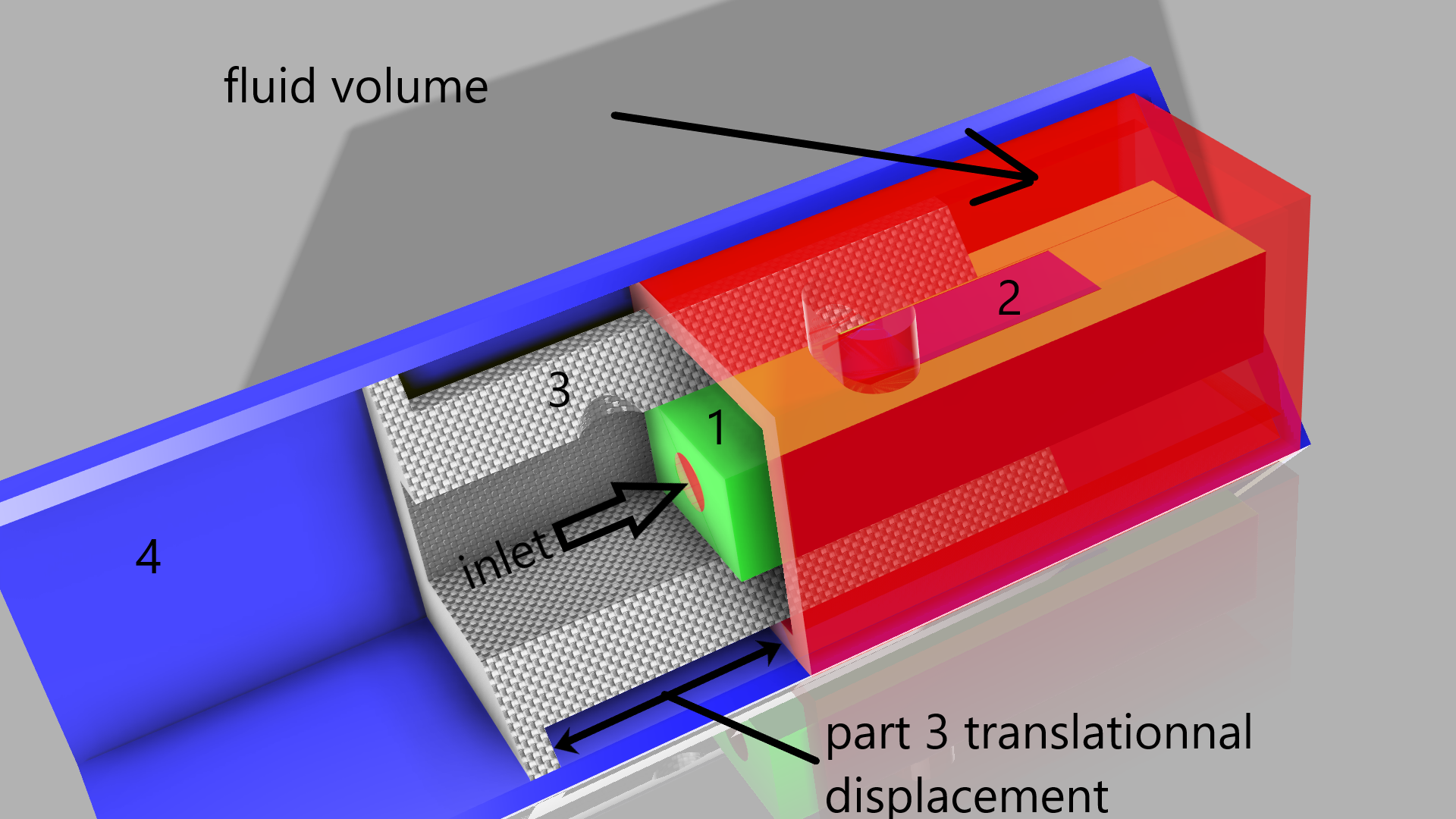

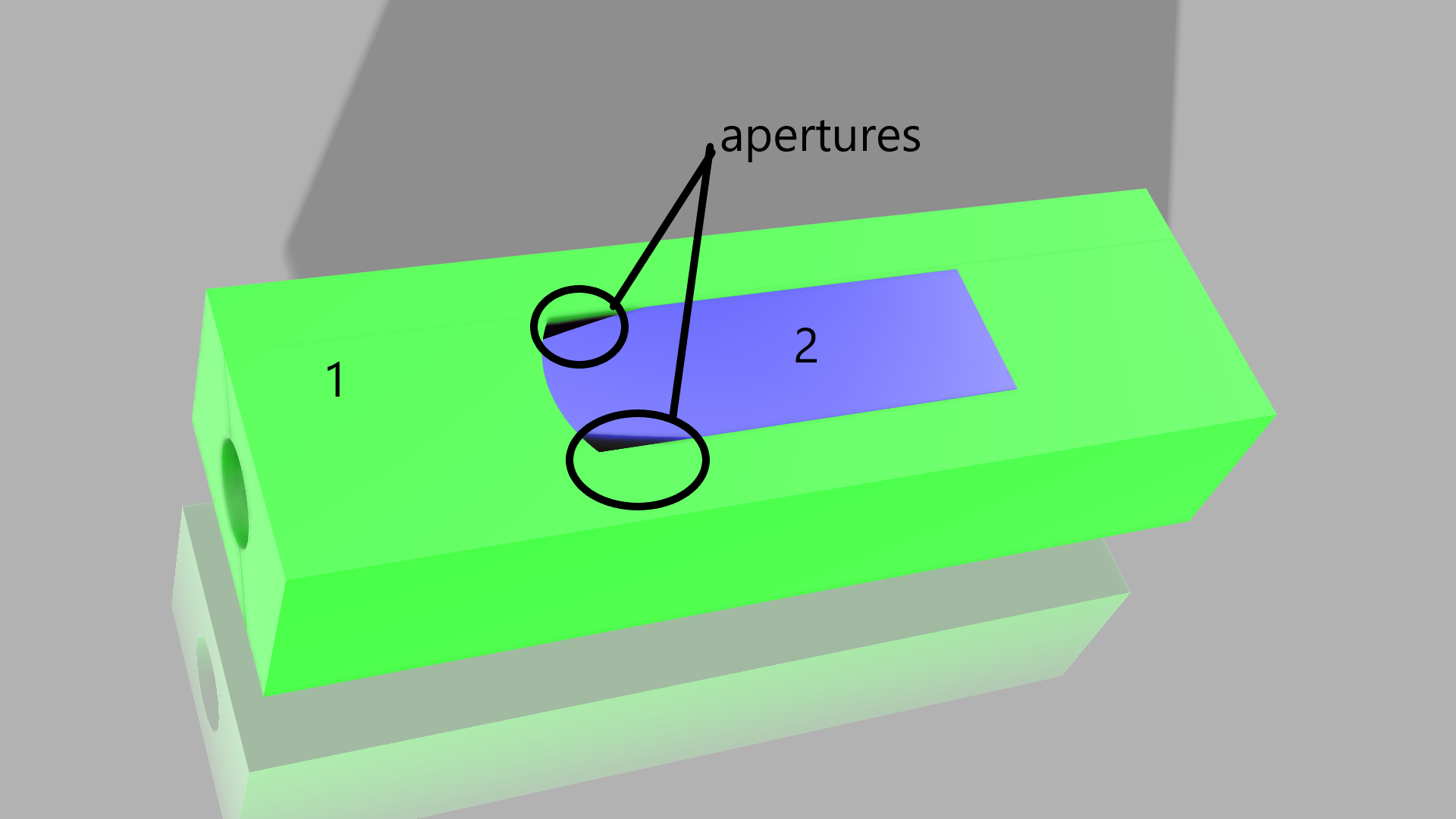

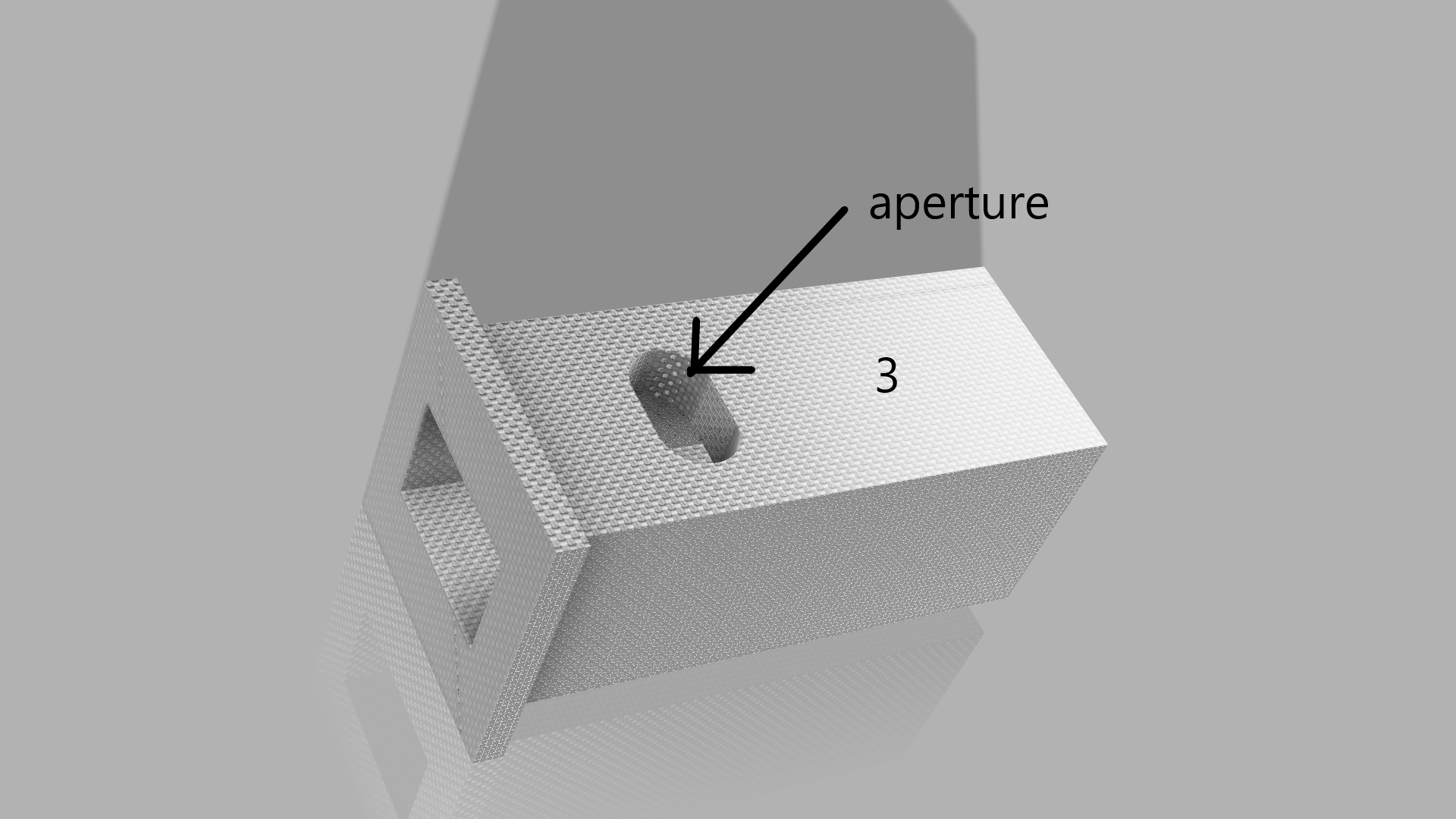

Body 1, 2, and 4 are fixed.Body 3 can be mobile.

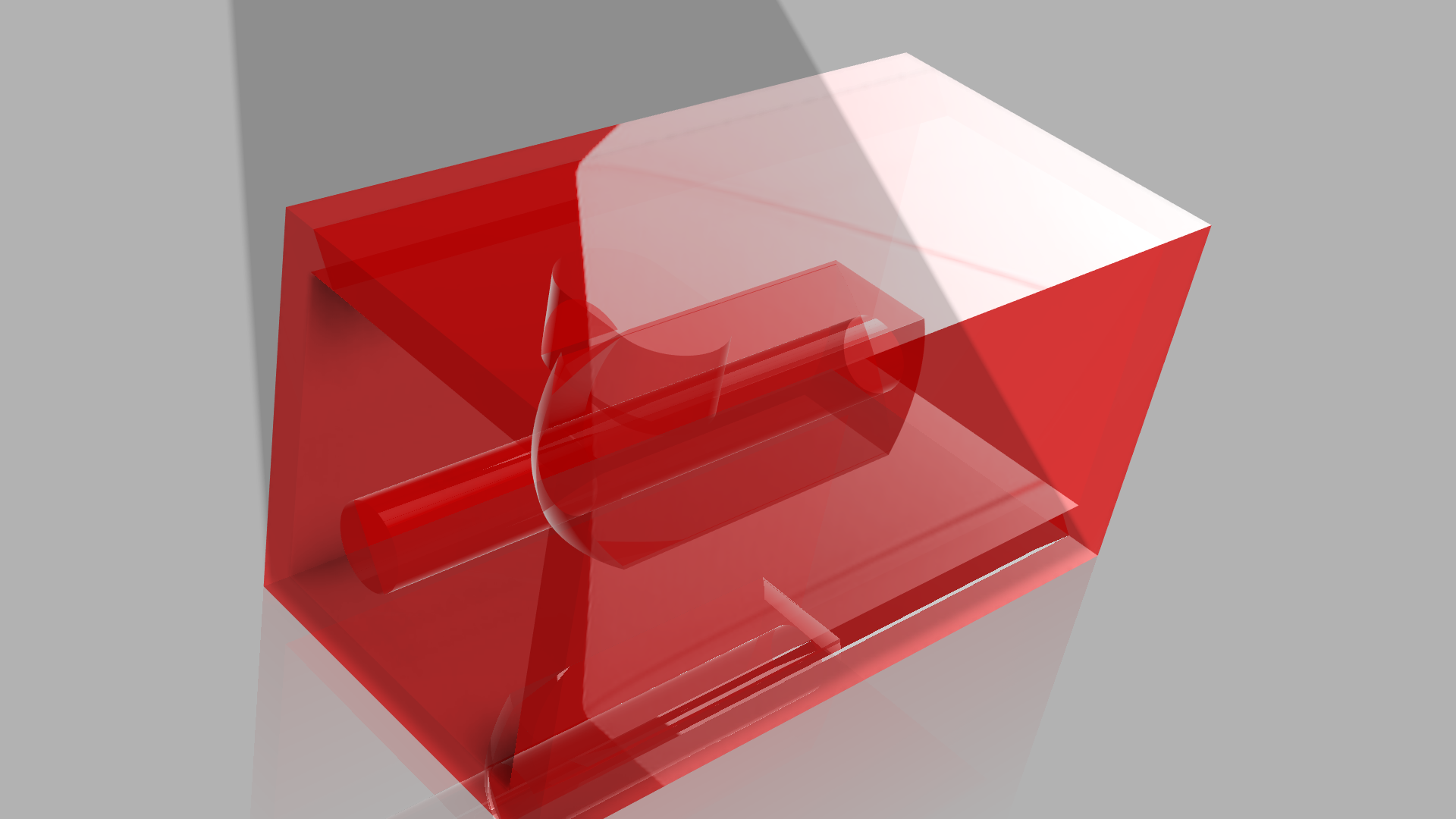

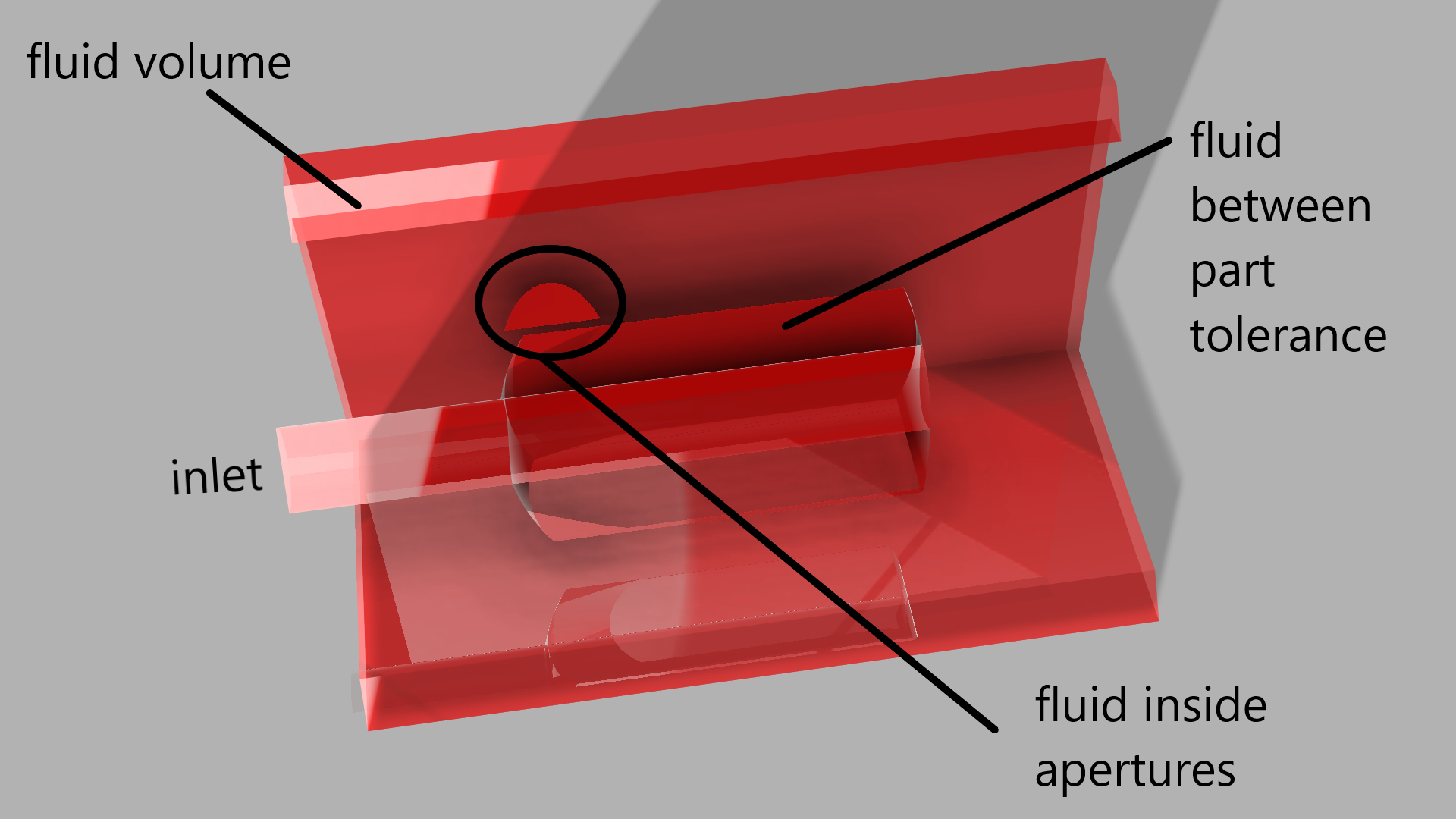

The transparent red component 5 represents the volume of the fluid.

I am looking to:

- Simulate the expansion of bodies 1, 2, and 3 based on fluid pressure.

- Simulate the pressure at different fluid flow outlets based on the pressure applied at the fluid inlet.

- Measure the maximum pressure applied to the mobile part 3 during its displacement until the flow outlets are in the closed position following the movement of the part.

let's see below for some drawing

-

November 7, 2023 at 4:29 pm

Rob

Forum ModeratorIs the component moving because of the pressure or due to preset motion? That will determine what you need to set up. For the meshing, if you're collapsing a region have a look at layering. For layering review the various incylinder examples as it's a very similar set up.

-

November 10, 2023 at 2:39 am

charles-web

Subscribermoving is due to pressure, but if you agree i will reformulate my request more simply :

lets take a look at this video (4min) :3d model is explained inside, i will simplify my request into steps :

so for the first one i want to size over-pressure apperture outlets inside my model, so i want to plot pressure over region, and also constraint and reaction force.

but i want equally to mesure relationship between pressure dropping and over-pressure apperture diameter.how can i do that ?

-

November 10, 2023 at 10:31 am

Rob

Forum ModeratorI can't see the video, but no matter as I'm not supposed to open attachments either!

If the components don't distort then moving mesh in Fluent can be used to push/pull components. As you want the component to move with pressure (as opposed to a pre-set motion speed) you'll need 6DOF (1DOF) to link pressure to motion. The region where the solid moves into/out of can be modelled using layering. Note, you cannot change topology so can't create or remove surfaces: it's explained in the Help and Tutorials in some detail.

-

November 10, 2023 at 1:14 pm

charles-web

Subscriberno in this model i’ve not included moving part problem for simplification, what’s sthe problem with the video, have you an error message ?

i casted it into public categorie, try it :

-

- The topic ‘pressure and part displacement’ is closed to new replies.

-

4618

-

1530

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.