-

-

December 26, 2023 at 4:47 pm

Prasanna M

SubscriberThe steel shaft moves inside the hydraulic seal fitted inside the steel hub. The seal material is (Elastomer, non-linear material). Before shaft displacement, the hydraulic seal is in prestress condition (or in a pre-compressed state). I am not getting how to model this (precompression) in a static structural system.

Do i simulate pre-compression in system A and then connect system A with system B. If its OK then how do i connect it?

The correct sequence of operation is as follows: 1. Initially seal gets fitted into the hub. This makes seal pre-compressed. 2. The shaft moves inside the pressure-loaded seal.

-

December 26, 2023 at 6:08 pm

peteroznewman

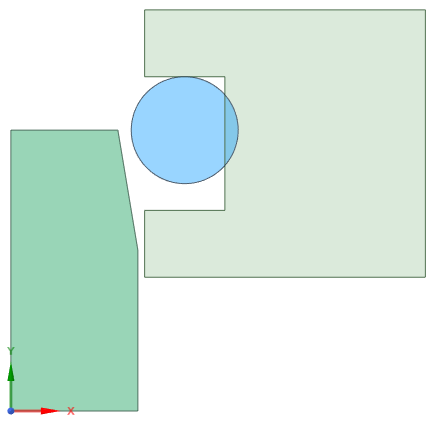

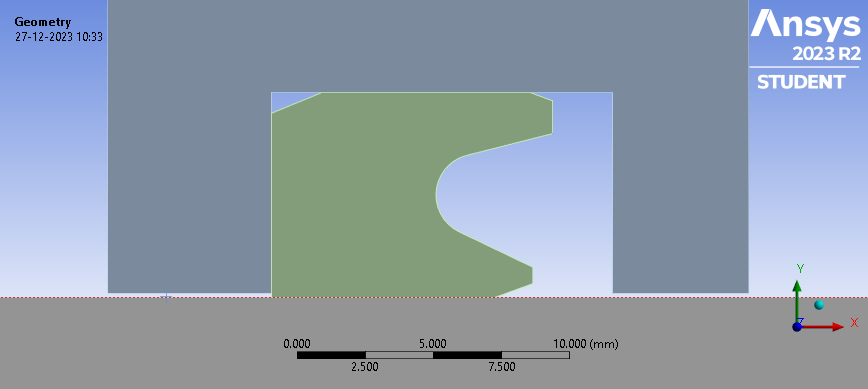

SubscriberI recomend you create an Axisymmetric model. That means the axis of the shaft lies along the Y axis and the cross-section profile of the shaft, hub and original dimensions of the seal are drawn on the +X side of the Y axis. Each of those profiles needs to be a surface body in the X-Y plane. It’s not a problem that the profile of the seal overlaps with the profile of the groove in the hub. Draw the shaft below the seal and put a shallow angle chamfer so the chamfer edge will be inside the seal inner diameter.

In Workbench, add a Static Structural analysis. Click on Geometry and access the Properties on the right side. On the line item called Analysis Type change it from 3D to 2D, then double click on the Model cell.

In Mechanical, click on the Geometry branch and in the details, set the 2D Behavior to Axisymmetric. Assign the rubber material to the seal. Under Analysis Settings, make this a 2 step analysis, turn on Large Deflection and configure the Auto Time Stepping to be On. Set the Initial and Minimum Substeps to be 100 for both Step 1 and Step 2. The Maximum Substeps can be 1000.

On the Mesh branch, set the Element Order to Linear. This will generally help the contact algorithm.

Put a Displacement on the top of the hub of Y = 0 for both step 1 and 2, so it can’t move along the Y axis. Put a Displacement on the bottom of the shaft and in the Tabular Data, make Y = 0 for step 1 and for step 2 make Y a value big enough to move the shaft up through the seal until the chamfer has passed the seal. For each of these displacements, leave X Free, the axisymmetric condition keeps the bodies on the axis.

Add Frictional contact between the seal and the groove in the hub. Add another Frictional contact between the seal and the chamfer and side of the shaft. In Step 1, the overlap of the seal and groove will be resolved. In Step 2, the shaft will squeeze the seal as it slides into the seal. Add a Contact Tool under the Connections folder. After meshing, Generate Initial Contact Status. Check that the second contact shows as Near Open and not Far Open. If it is Far Open, increase the Pinball Radius until it shows Near Open.

There are a few other settings that will help the solution to converge such as setting keyop(6)=1, but we can get to those once the model solves and shows a convergence problem.

-

December 27, 2023 at 5:14 am

-

-

December 27, 2023 at 12:28 pm

peteroznewman

SubscriberYes, a U-cup seal can be used similar to the O-ring seal I sketched.

I’m assuming the sketch you show represents a shaft or tube wall in light grey. What is the OD of the shaft/tube? Your geometry has the axis of revolution horizontal. Axisymmetric models require the axis of revolution to be the Y axis. That means you must rotate the group of 3 surfaces 90 degrees clockwise and translate them along the X axis so the edge representing the OD of the shaft/tube is at the +X coordinate of OD/2.

Cut an angle on the shaft/tube so there is a gap to the U-cup if you want to do the 2-step solution described above.

If there is significant pressure on one side of the seal, Ansys has a clever way to apply that pressure on the seal in an incremental way to determine if the seal will leak. See this workshop. Be sure to download the attachments.

-

- The topic ‘Precompression of hydraulic seal and reciprocation of shaft inside the seal’ is closed to new replies.

-

3597

-

1243

-

1092

-

1068

-

953

© 2025 Copyright ANSYS, Inc. All rights reserved.