-

-

May 8, 2024 at 3:41 pm

Purnima Janjanam

SubscriberHello

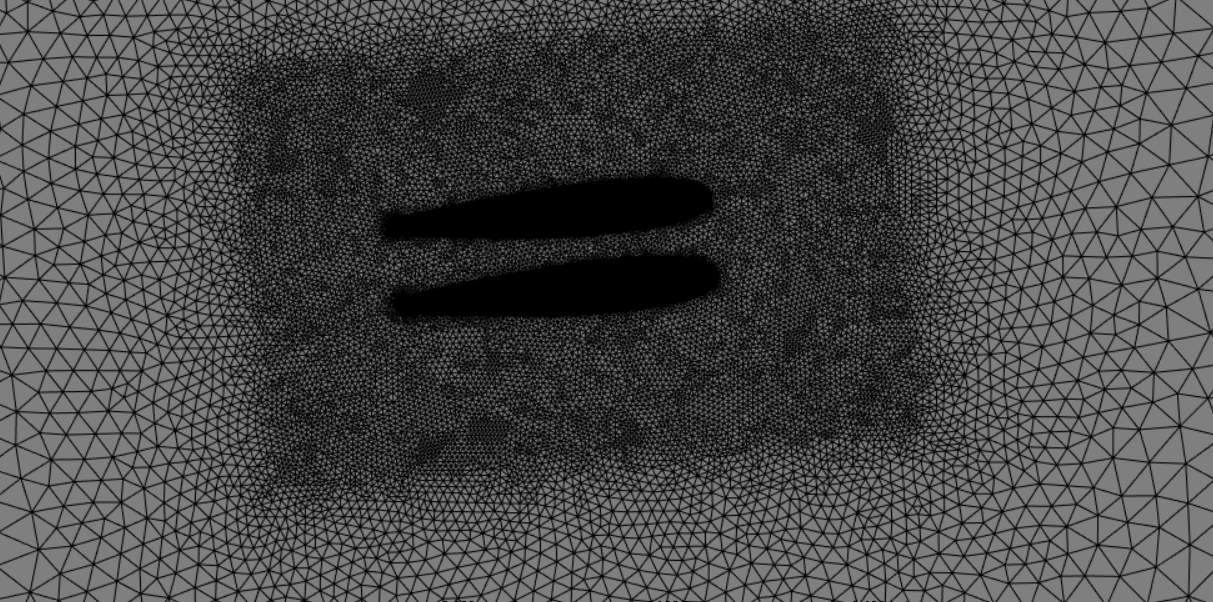

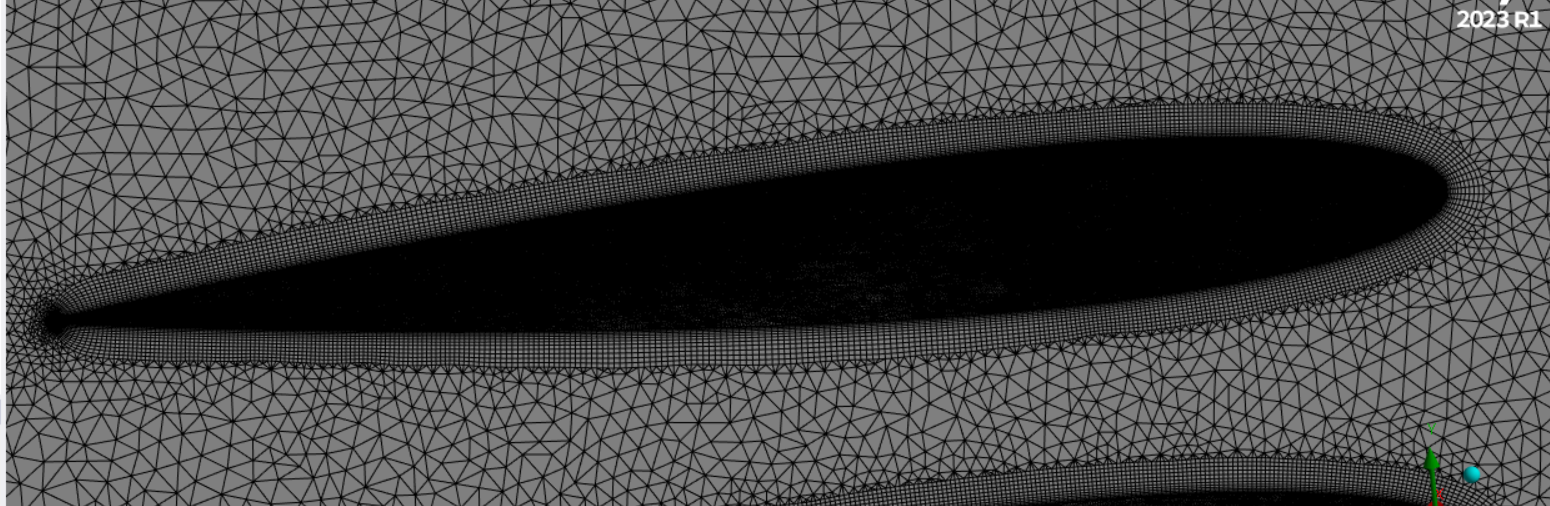

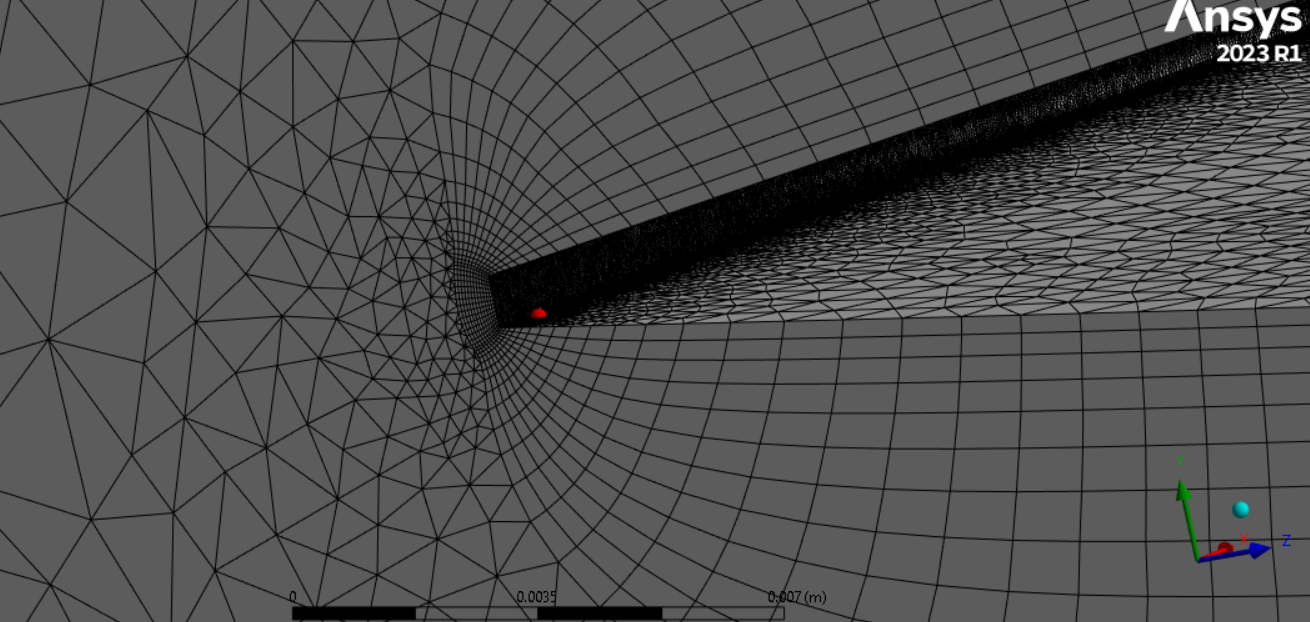

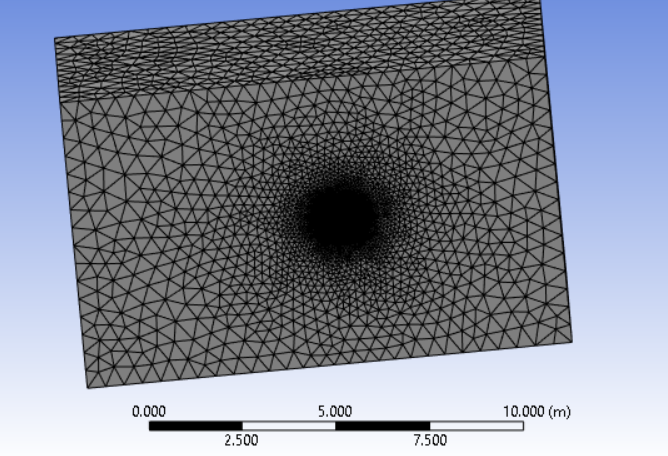

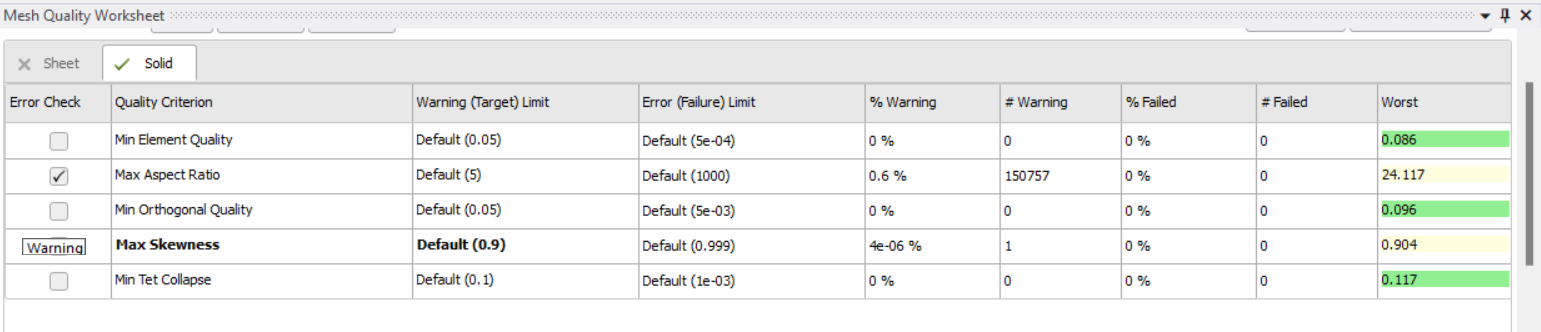

I am trying to generate a mesh for a 3d ring wing and the mesh quality is not good enough near the trailing edge. It has a skewness of 0.96 and Max aspect ratio of 20. I used body of influence, face sizing, edge sizing. I also tried sizing smaller near the trailing edge. What else can i do to improve it?

-

May 9, 2024 at 9:47 am

Rob

Forum ModeratorHave a careful look at the mesh in that region: what is happening to cause the poor mesh? This comes up fairly regularly, so also have a look in Search to see what's been covered in the previous threads.

-

July 4, 2024 at 8:42 pm

Purnima Janjanam

SubscriberActually, I am able to get good mesh quality with all the quality parameters. But when I run it in fluent the results are oscillating. Can you tell me why is that happening and how can I prevent it?

-

July 5, 2024 at 11:01 am

Rob

Forum ModeratorPlease post some images. I suspect I know the problem, but images will confirm things.

-

July 5, 2024 at 4:25 pm

-

July 9, 2024 at 1:25 pm

Rob

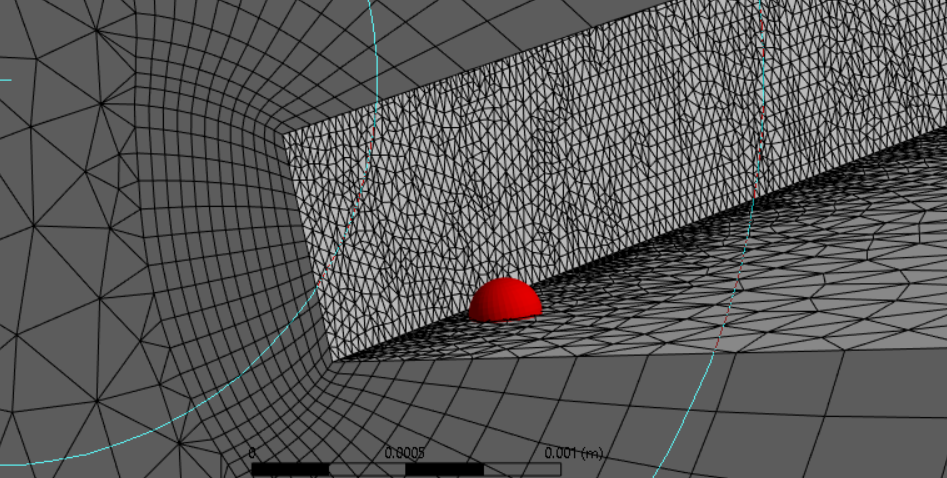

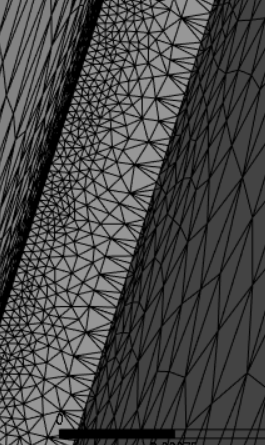

Forum ModeratorYou need to review the mesh at the back of the airfoil - the jump in cell size is excessive. I suspect the cell skew isn't good either.

The other potential issue is flow related. Do you expect a single result or for the jet from between the two airfoils to oscillate?

-

July 9, 2024 at 4:48 pm

Purnima Janjanam

SubscriberThe mesh goes like this somewhere in the middle even when the sizing settings are set to hard. Can you tell me what can i do to make it better.

If I decrease size the number of nodes will increase and my cluster cannot handle it to run the simulation. so I'm trying to limit my number of nodes by limiting the size.

I expect the flow between to airfoils to oscillate. But I was trying to find a single result if I could get one. This is more of experimenting to understand what's happening.

-

July 12, 2024 at 2:10 pm

Rob

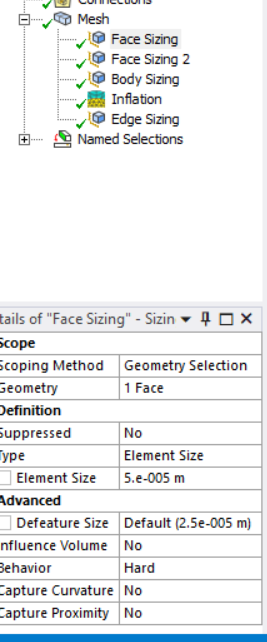

Forum ModeratorHave a look at what sizing you're using. If you're using a mix of hard edge/surface control and size function then odd things can happen.

If the jet is likely to oscillate you may find the residuals don't drop for a steady run. That's why we use monitor points.

-

July 18, 2024 at 2:42 am

Purnima Janjanam

SubscriberWhat are monitor points?

-

July 18, 2024 at 10:43 am

Rob

Forum ModeratorThey're points we use to monitor flow data. Monitors in general will be covered in the early tutorials in Fluent's Help materials.

-

July 18, 2024 at 7:57 pm

Purnima Janjanam

Subscriber1. These are the sizings I used. All sizing are hard. Can you suggest any changes here.

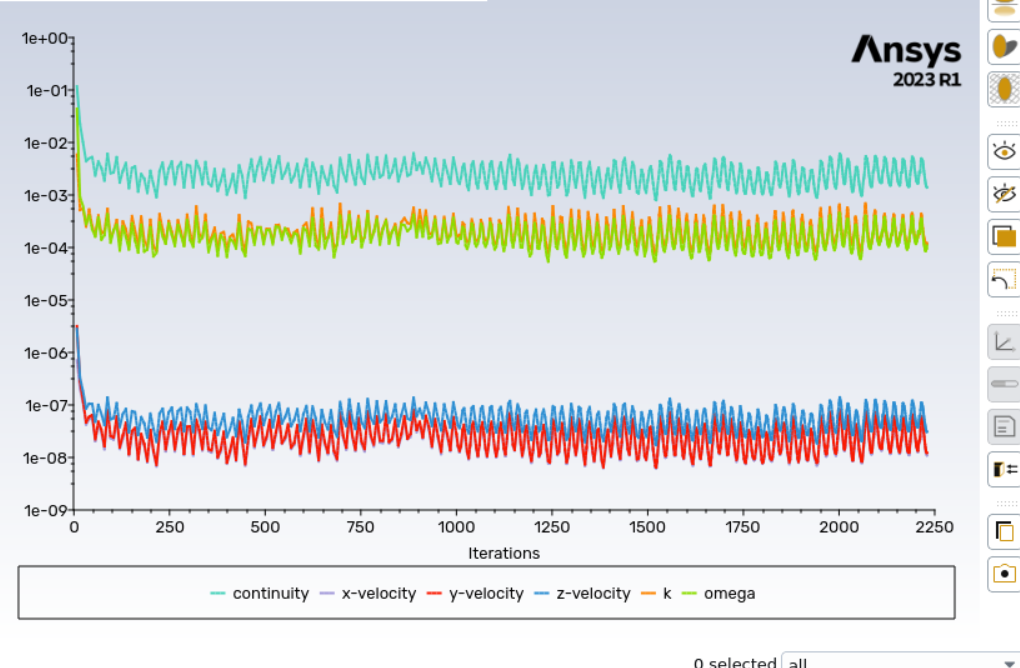

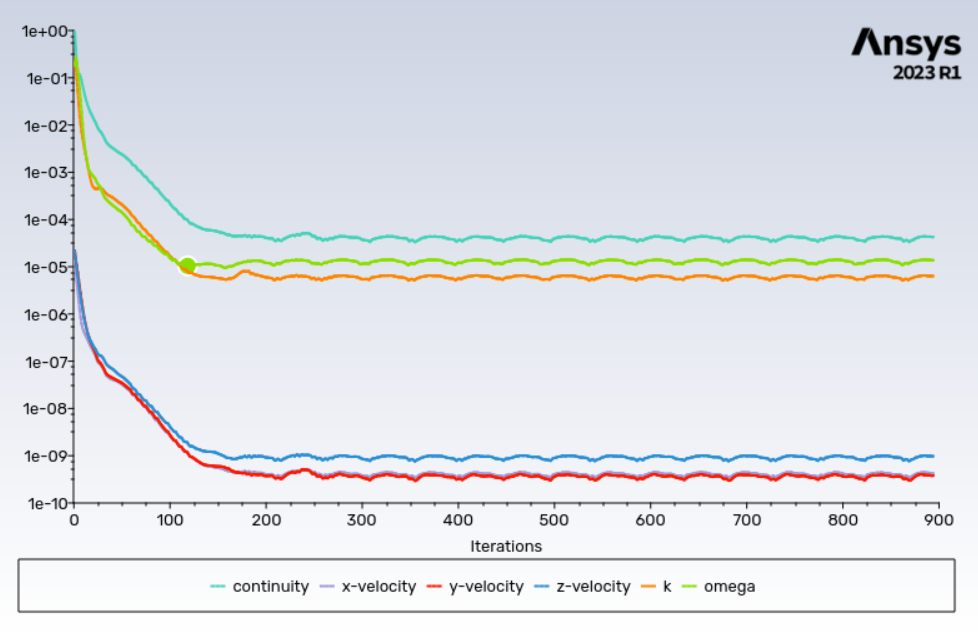

2. The oscillations for this mesh look like this. Do you think these are going to oscillate forever? I expect the flow to oscillate for this design. So can I conclude by saying these are the results for this design?

3. The results below are for another design. These oscillate at 3e^-5 (different from the other where they oscillate at 1e^-3). My converging conditions are 1e^-6. Do you think these will converge if mesh is more fine or will they also oscillate like the previous one?

4. Can you give me a breif idea about how to plot monitor points?

-

July 19, 2024 at 10:16 am

Rob

Forum ModeratorThose will almost certainly oscillate forever. Hence monitor points to see what the effect is on the solution. You MUST review all the solution data and not just rely on residuals to tell you what's going on: that should be covered in the Fluent courses in Learning as they're fairly close to what I teach when training commercial users.

-

July 19, 2024 at 11:40 am

Purnima Janjanam

SubscriberCan you kindly share me a link of this?

also, my results for drag and lift oscillate the same way. Do you think that could conclude the results (similar to monitor points).

-

July 22, 2024 at 9:57 am

Rob

Forum Moderatorhttps://innovationspace.ansys.com/learning-library/?p_type=learning-library&discipline[]=Fluids

If lift and drag are oscillating that's an indicator that the flow isn't stable. However, you need to review monitors (of which lift & drag are two), residuals (oscillating or noise at around 1e-2) and images. From what you've shown the result may be transient, but without a lot more images I can't be sure.

-

- The topic ‘Poor quality mesh at trailing edge for 3d wing’ is closed to new replies.

-

5274

-

1875

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.