TAGGED: petroz, structures

-

-

June 7, 2023 at 10:45 am

amit.moond

SubscriberHi Guys,

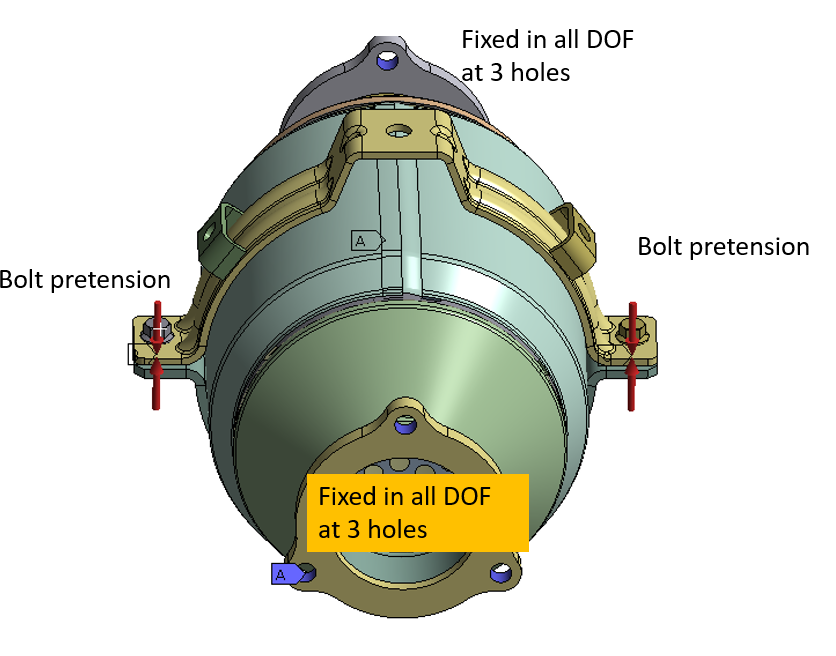

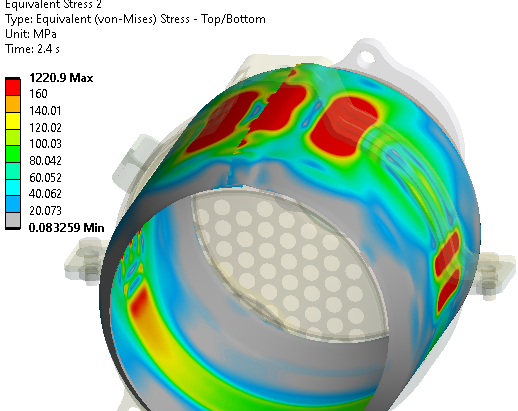

I want to determine collapsing force of a cylindrical shell having 1.5mm thickness due to clamp force generated by bolted torque. for that puprose initially i have performed static stuructral analysis and found that von mises stress comes out to be 1200Mpa on shell and clamp than i have done buckling analysis and strange results i got.

1) as per yield strength of material my shell is failed becaouse 1200Mpa> 220MPa @ 18000N load.

2) in buckling analysis i found critical load = 58000N

can any one tell me how isit possible that in static it is failed but in buckling it is ok.

Bolt pretension is 18000N.

-

June 8, 2023 at 5:15 pm

dlooman

Ansys EmployeeI guess you're saying the static "failed" because the stress is higher than yield, but apparently it didn't fail either. Linear buckling would occur when the structure became unstable and that's unrelated to the yield stress. For example, a very short column would never buckle even if the compressive stress was >> yield.

-

June 16, 2023 at 5:42 am

prakash

SubscriberOK..

I have one more query related to these results:

- Actual field observation: as per customer feedback, no dent or deformation is oberserved on the surface even applying more than 18000N~ 16Nm torque.

- FEM simulation: As shown in above images, we are getting very high stresses which means material is failed at 18000N load.

Could you tell what I need to do in order to validate simulation results with experimental??

-

-

June 12, 2023 at 6:18 am

amit.moond

SubscriberThanks Dave,

I have another query related to same kind of geometry.

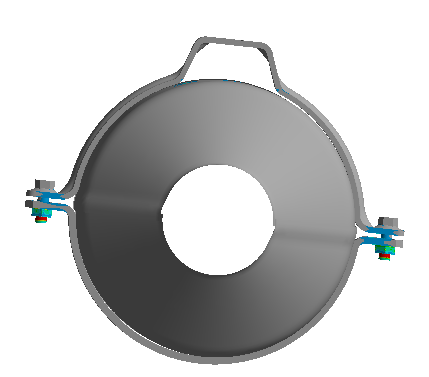

I am applying the bolt pretension of 18000N but this much force is not able to tighten the clamps(attaching the image)

Here the max stresses appear only on the bolt shank and around 6000MPa.

i have tried with different type of connections.

Between clamp face and bolt head: bonded and Friction

Here bonded connection behaves well as if i use friction contact then bolt and clamp moves apart.

also the connection between the thiin metallic sheet and the clamp is no seperation. Here no seperation works well. Also i have to use dispacement constraints for X and Z as zero otherwise this will also not work.

If i use frictional contact than again these two clamps moves apart from the thin metallic sheet.

any comments?

-

June 12, 2023 at 2:53 pm

dlooman

Ansys EmployeeProbably better to create a new post for this contact issue. It may be commented on by a contact expert.

-

June 16, 2023 at 10:02 am

prakash

SubscriberOK..

I have one more query related to these results:

- Actual field observation: as per customer feedback, no dent or deformation is oberserved on the surface even applying more than 18000N~ 16Nm torque.

- FEM simulation: As shown in above images, we are getting very high stresses which means material is failed at 18000N load.

Could you tell what I need to do in order to validate simulation results with experimental??

-

June 16, 2023 at 1:23 pm

dlooman

Ansys EmployeeYour highest contour range goes from 160 to 1221. It's hard to tell how local the highest stress is. Perhaps if the contact stiffness between the strap and the vessel was reduced the stresses would be better distributed.

-

June 17, 2023 at 3:31 am

prakash

SubscriberOK,

- How may I know the contact stiffness??

- and how to reduce contact stiffness??

-

-

June 17, 2023 at 3:50 am

sachin.kumar

SubscriberOK,

- How may I know the contact stiffness??

- and how to reduce contact stiffness??

- should I go with non-linear maerial properties(plastic region)??

-

June 21, 2023 at 2:37 pm

dlooman

Ansys EmployeeIf using default contact stiffness you can check the output. Or you can manually specify a lower factor than the default 1.0. Perhaps 0.01. Specifying nonlinear material properties makes the analysis more realistic.

-

- The topic ‘performing Static and buckling analysis.’ is closed to new replies.

-

4602

-

1510

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.