-

-

March 15, 2024 at 2:00 pm

andrew o'sullivan

SubscriberHi,

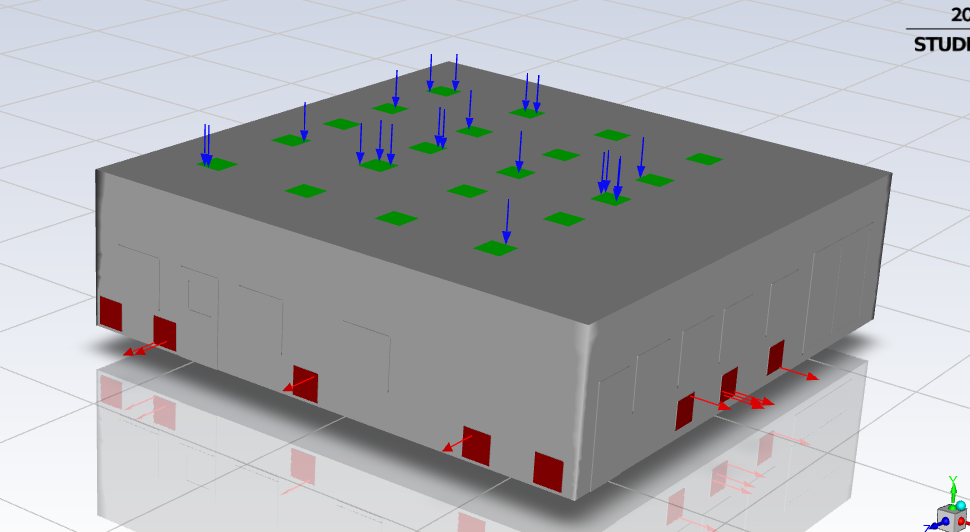

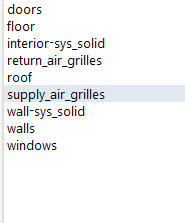

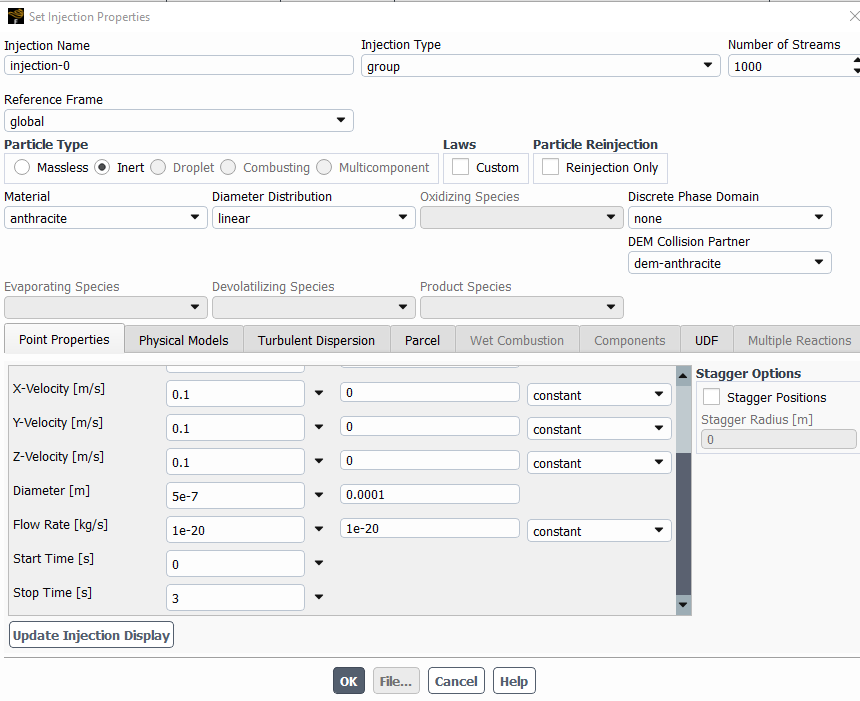

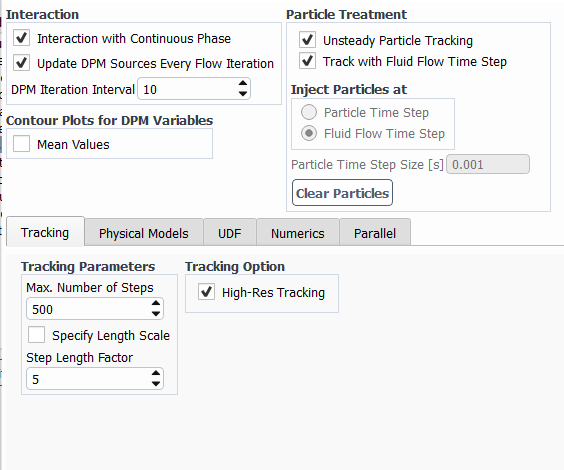

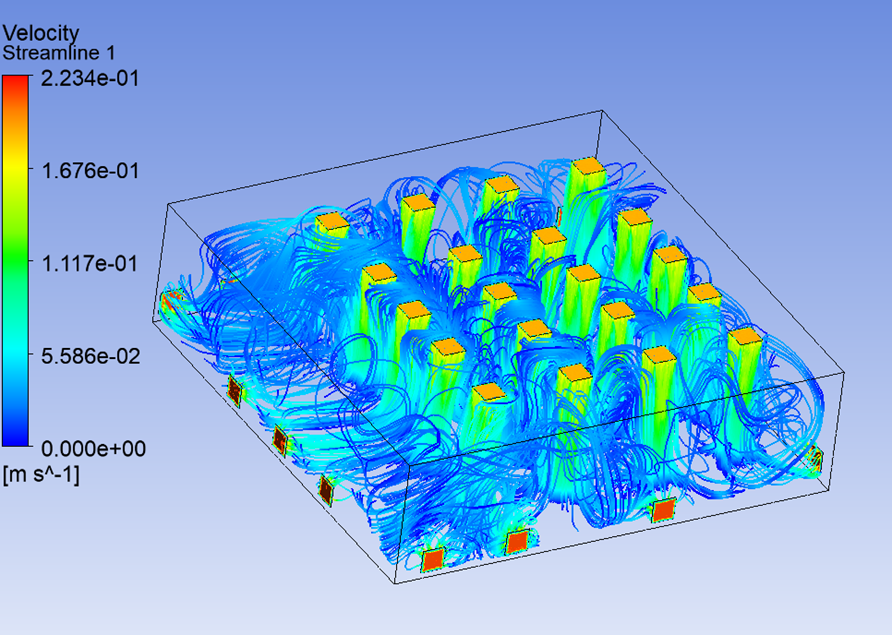

I am currently doing my final year project on cleanroom optimization, the goal is to use CFD analsyis using the student Ansys software. My main goal using Ansys fluent is to have a large number of particles (around 200,00 at 0.5 MIcrons) in the 3D model and as the air change occurs in the room I want to track the removal of the perticles over the time period selected. My model is setup and I am currently figuring out exact parameters that need to be entered in Ansys setup to make this simulation possible. Any help would be appreciated, I will attach photos below to what my setup currently looks like,my main concern is the particle injection setup and the transient time setup Thanks.

-

March 15, 2024 at 2:42 pm

Rob

Forum ModeratorIs the air flow transient? Why have you turned the DEM collision on? Do you need particles or is a species tracer suitable?

-

March 15, 2024 at 3:16 pm

andrew o'sullivan

SubscriberHi Rob, thanks for the reply, the airflow is transient and DEM is on as I was testing different simulations. Particles is needed yes.

-

March 15, 2024 at 3:33 pm

Rob

Forum ModeratorWhat transients are there in the air flow? I ask as trying to model a whole room domain (air change rates in the order of 10's of minutes) relative to the flow transient time scale (fractions of a second) can become excessively long. Running transient particles onto a steady airflow is much more efficient.

Don't use the DEM option, if you have enough particles in the system to need DEM you'll struggle to breathe the air.... You may also want to clean up (remove) the various doors/details unless you intend to mesh at that level of detail, and I don't recommend that!

-

March 15, 2024 at 4:52 pm

andrew o'sullivan

SubscriberI can make the airflow steady state if it will work with the particles better, I presumed the airflow dispersing and being extracted by the return ducts counted as being transient. Is it possible to set a velocity parameter for the return air ducts, so the air is extracted at a given velocity? You think I should remove the doors/windows from the model completely?.

-

March 15, 2024 at 5:03 pm

Rob

Forum ModeratorBreaking the question up.

- If the HVAC flow is continuous and (more or less) constant flow it's probably steady state. Run and see what happens.

- Particles can be run onto steady flow using transient, have a look at the options. You may want to review turning the flow equations off in the Solver Controls too.

- If you don't need details it's best to remove them. If you need them, you need to resolve with the mesh. I always try and eliminate anything I don't need in a model as it'll speed up the solution and it's one less setting to think about.

-

March 26, 2024 at 11:41 am

andrew o'sullivan

Subscriber -

March 26, 2024 at 11:42 am

-

March 26, 2024 at 12:17 pm

Rob

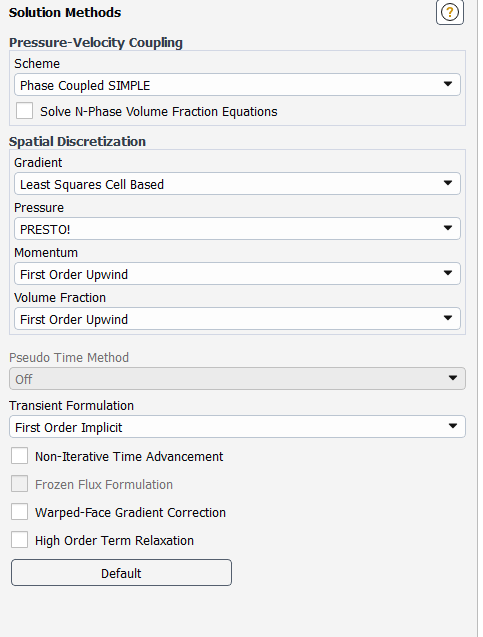

Forum ModeratorRun the air flow alone steady to start with. That'll give you an idea of what's going on in the room. Why are you solving a volume fraction equation? For Pressure equation have a look at Body Force Weighted if you have buoyant flow.

-

March 26, 2024 at 3:39 pm

-

March 26, 2024 at 3:45 pm

Rob

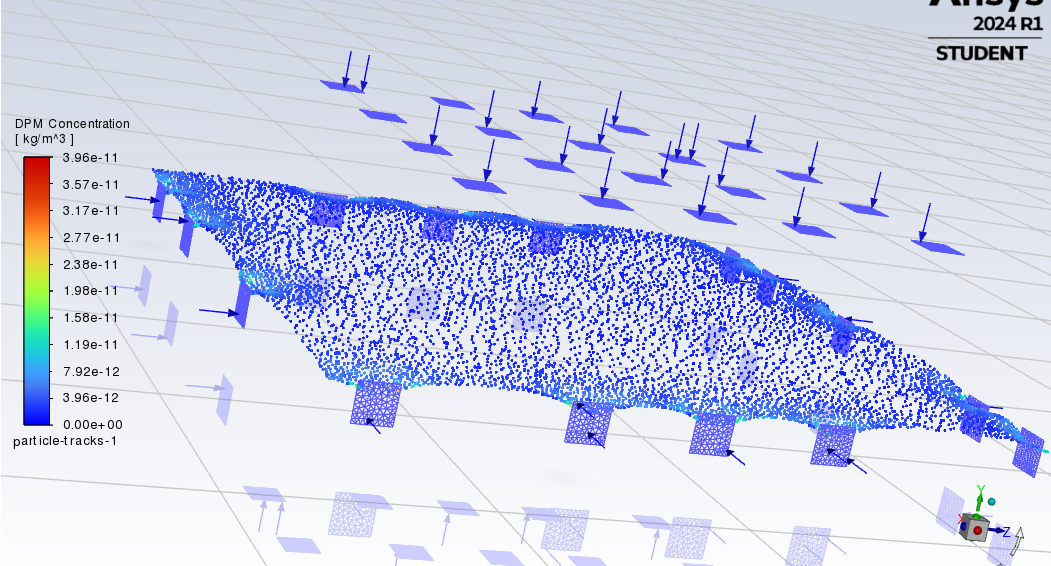

Forum ModeratorOK. That's best done in Fluent's post processing rather than CFD Post. Use the steady flow with transient coupled particles as you've shown. In Fluent you'll see DPM options in the contours list, one of those is DPM Concentration. Read the definition carefully in the User's Guide.

-

March 26, 2024 at 5:40 pm

andrew o'sullivan

SubscriberOkay thank you very much for the help.

-

March 28, 2024 at 4:36 pm

andrew o'sullivan

SubscriberHi Rob sorry another question, if the return air grilles shown have a return air velocity as they have an extract of 0.219 in real life, is the best thing to do set the ruturn grilles as inlet velocity and set the magniutude to a negative?, that is what I have been doing but the particles don't seem to be escaping as they should through these outlets.

-

April 2, 2024 at 12:48 pm

Rob

Forum ModeratorYou can use velocity bc's with a negative flow to remove air. Make sure there's a pressure boundary somewhere to prevent the solver from forming a vacuum or infinite pressure (you'll never balance the mass in & out).

DPM relies on the DPM boundary setting: is it Escape?

-

April 2, 2024 at 1:14 pm

andrew o'sullivan

SubscriberYes it is set to escape for the return grilles.

-

April 2, 2024 at 1:23 pm

Rob

Forum ModeratorIn which case particles reaching the surface will be removed. Where are the particles settling?

-

April 2, 2024 at 5:18 pm

andrew o'sullivan

SubscriberHow Do I find out where they are settling?

-

April 3, 2024 at 9:11 am

Rob

Forum ModeratorPost processing - where are the tracks/dots? If you're still using transient particles, how many 0.001s updates have you done? Most rooms have an air change rate in the order of 10minutes (mean) so you may not have run enough steps.

-

April 3, 2024 at 11:05 am

andrew o'sullivan

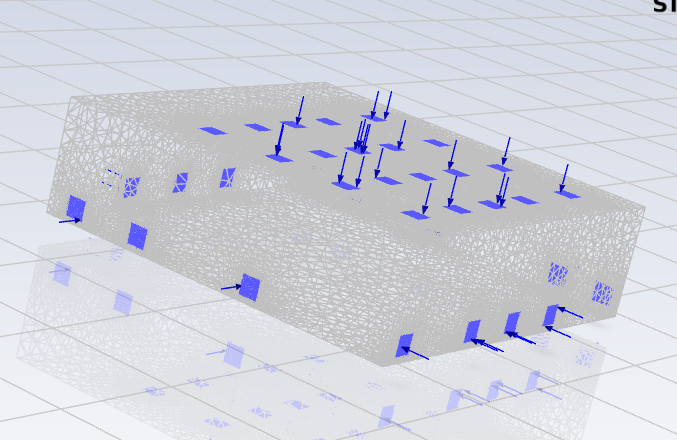

SubscriberHi Rob, I only plan on running the model for 10 seconds maximum as the real life cleanroom removes particles of a rate of 6000 every 10 seconds on average, What part of the model would you suggest I set the pressure outlet to?, as I tried the wall and the simulation is taking far too long. Why do you suggest I set the updates to 0.001 seconds?, below is the post processing results for a group injection with 300 parcel close to the centre of the model.

-

April 3, 2024 at 11:59 am

-

April 3, 2024 at 1:43 pm

Rob

Forum ModeratorI didn't suggest 0.001s, that's the value in one of your posts. Re the time, there's a reason I made the suggestions re steady flow a while back.

-

- The topic ‘Particle count in a room’ is closed to new replies.

-

5014

-

1681

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.