-

-

August 9, 2019 at 12:01 pm

-

August 9, 2019 at 12:01 pm

EliasAlekseeff96

Subscriber

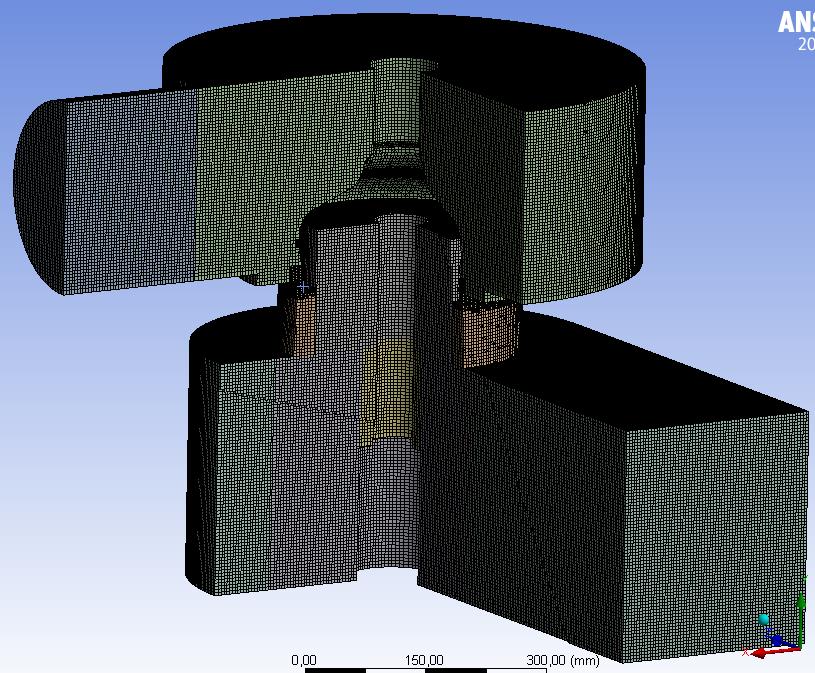

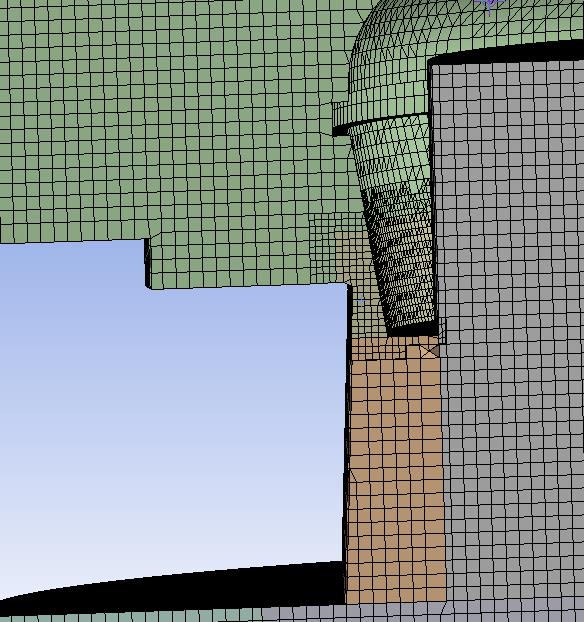

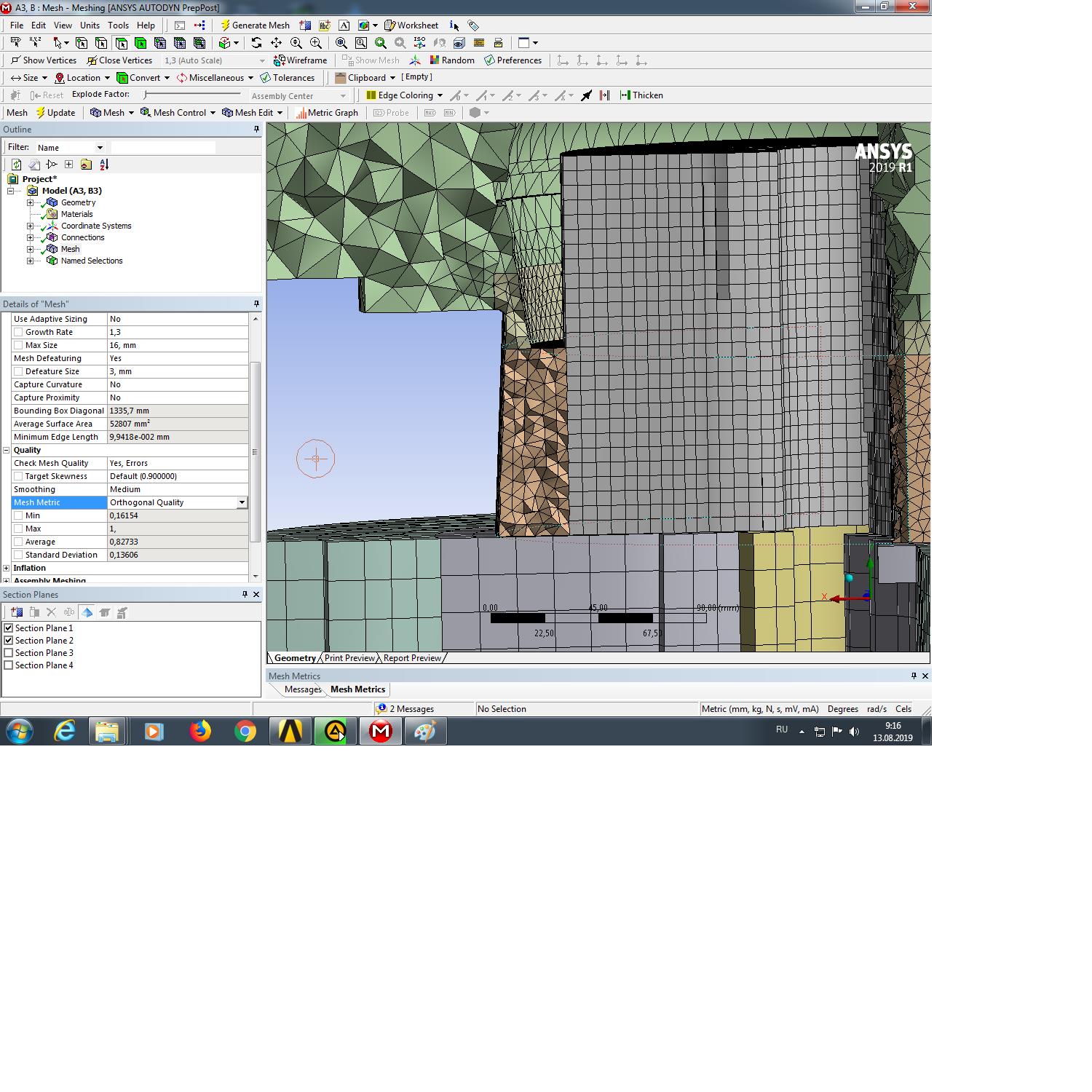

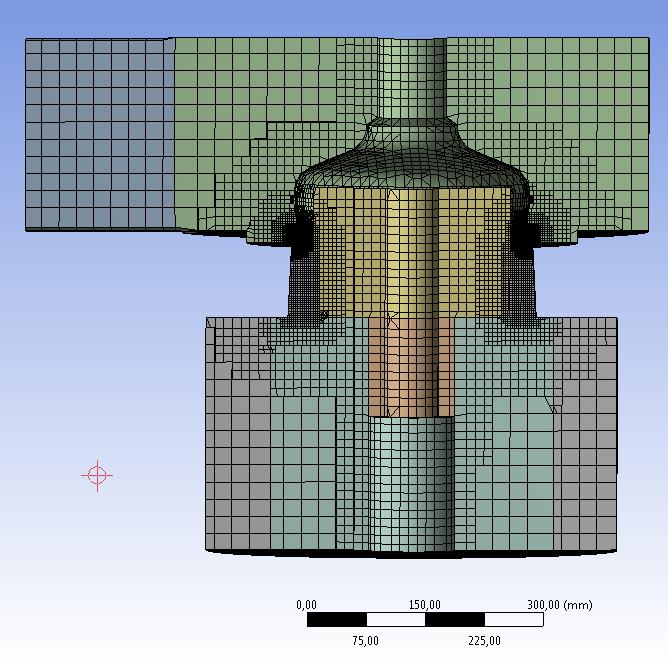

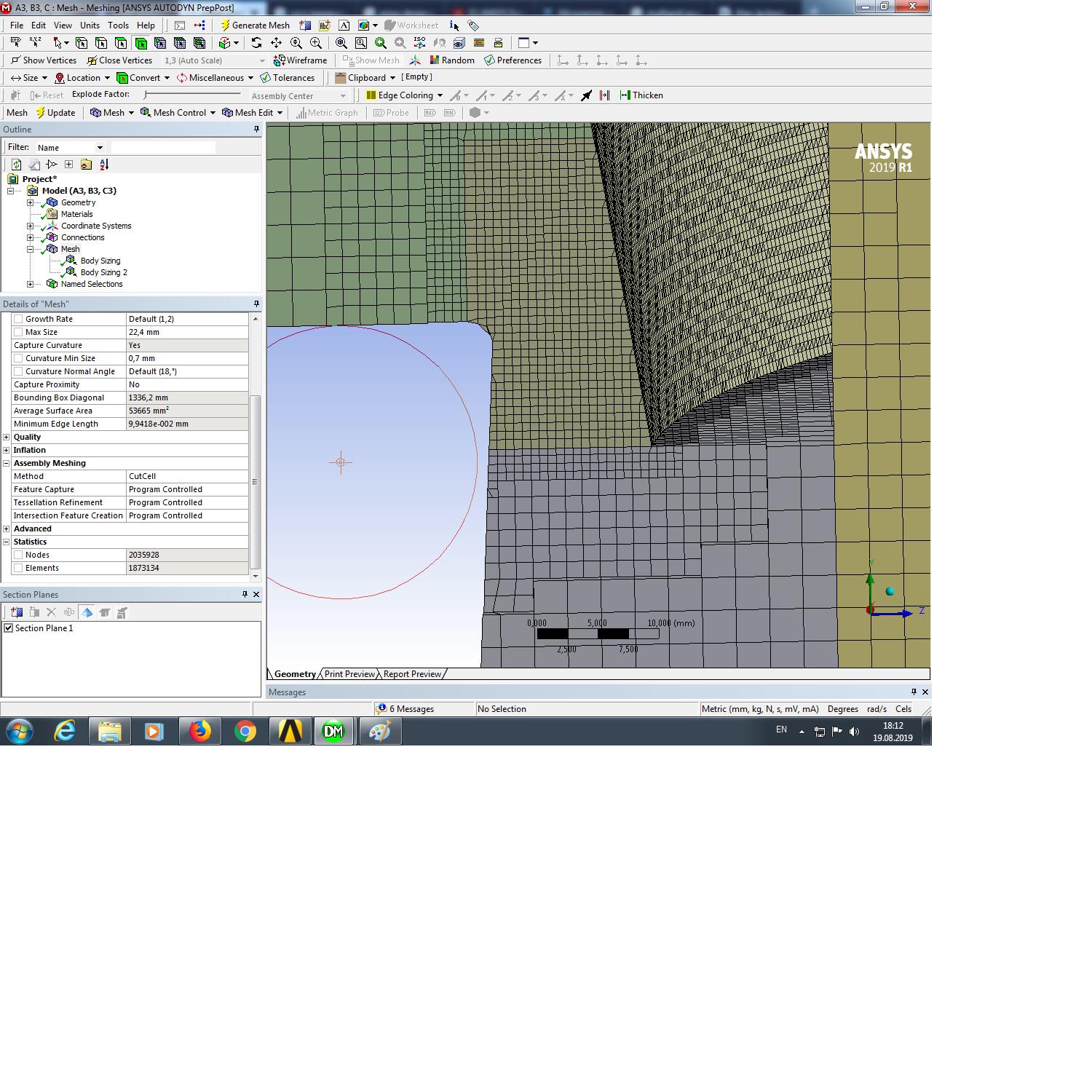

I have the body (Fig 1) with sharp narrowing of the middle part (Fig 2).

Basic settings:

Solver Pressure-Based, Steady

Fluid is a superheated steam (model water vapor -- real gas soave redlich kwong),

Boundary conditions -

at the inlet (cylinder) use “pressure inlet” (912 000 Pa),

at the outlet (rectangle) use “mass flow outlet” (12 kg/s),

I use the equations Energy, viscous -- k-epsilon -- standard -- standard wall functions.

Solution Methods - SIMPLE (I was select for all parameters “second order upwind&rdquo

.

.

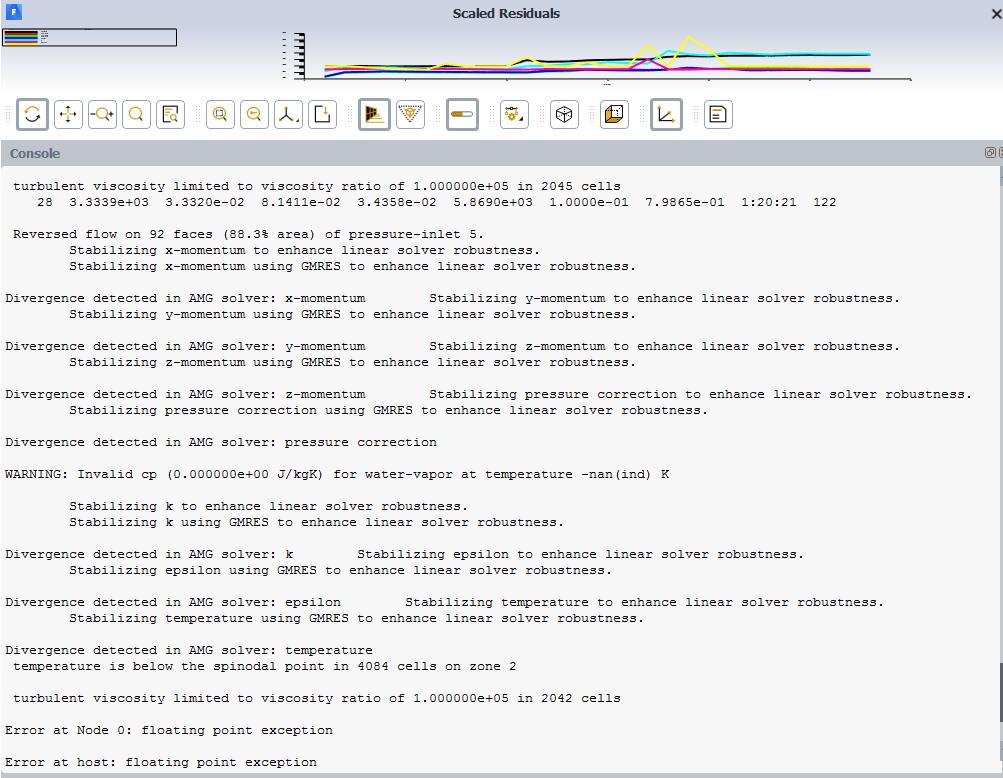

In Solution Controls Under-Relaxation Factors for Momentum, Turbulent Kinetic Energy, Energy set 0.1, as there were problems with the error "Divergence detected in AMG solver: pressure correction" and "Divergence detected in AMG solver temperature". These settings helped solve the problems.

Standard Initialization of the inlet is used.

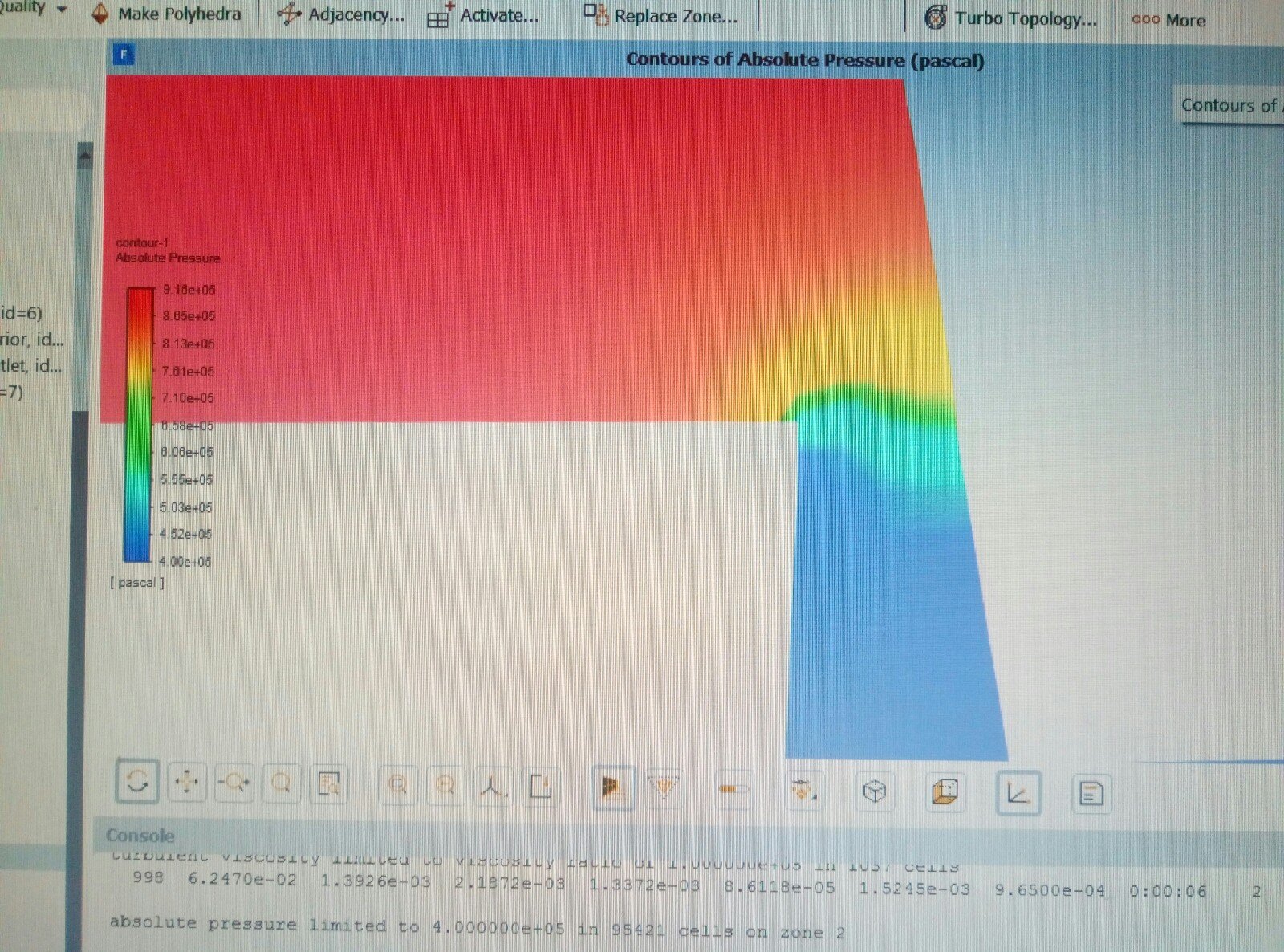

My problem is the pressure in the output region drops to values lower boundary pressure, which is set in the Solution Controls Limits, default is 1 Pa, and the result is 1 Pa, I increase the lower boundary Solution Controls Limits for pressure to 100 000 Pa, in result I have 100 000 Pa, I increase the lower boundary to 400 000 Pa, in result I have 400 000 Pa, the real result should be around 550 000 Pa. I used different versions of the grid such as Tetra, Hexa (CutCell), broke into separate parts of the body and created for each of its own, used a different size for grid’s elements, the result is the same, I was getting lower pressure limit from Solution Controls Limits .Does anyone know how to solve this? Thanks.

-

August 9, 2019 at 12:04 pm

-

August 9, 2019 at 12:32 pm

Amine Ben Hadj Ali

Ansys EmployeeCan you formulate your question once again? Thanks!

-

August 11, 2019 at 6:07 am

EliasAlekseeff96

SubscriberOutlet pressure drops to the lower pressure limit set in Solution Controls Limits

-

August 12, 2019 at 4:46 am

Amine Ben Hadj Ali

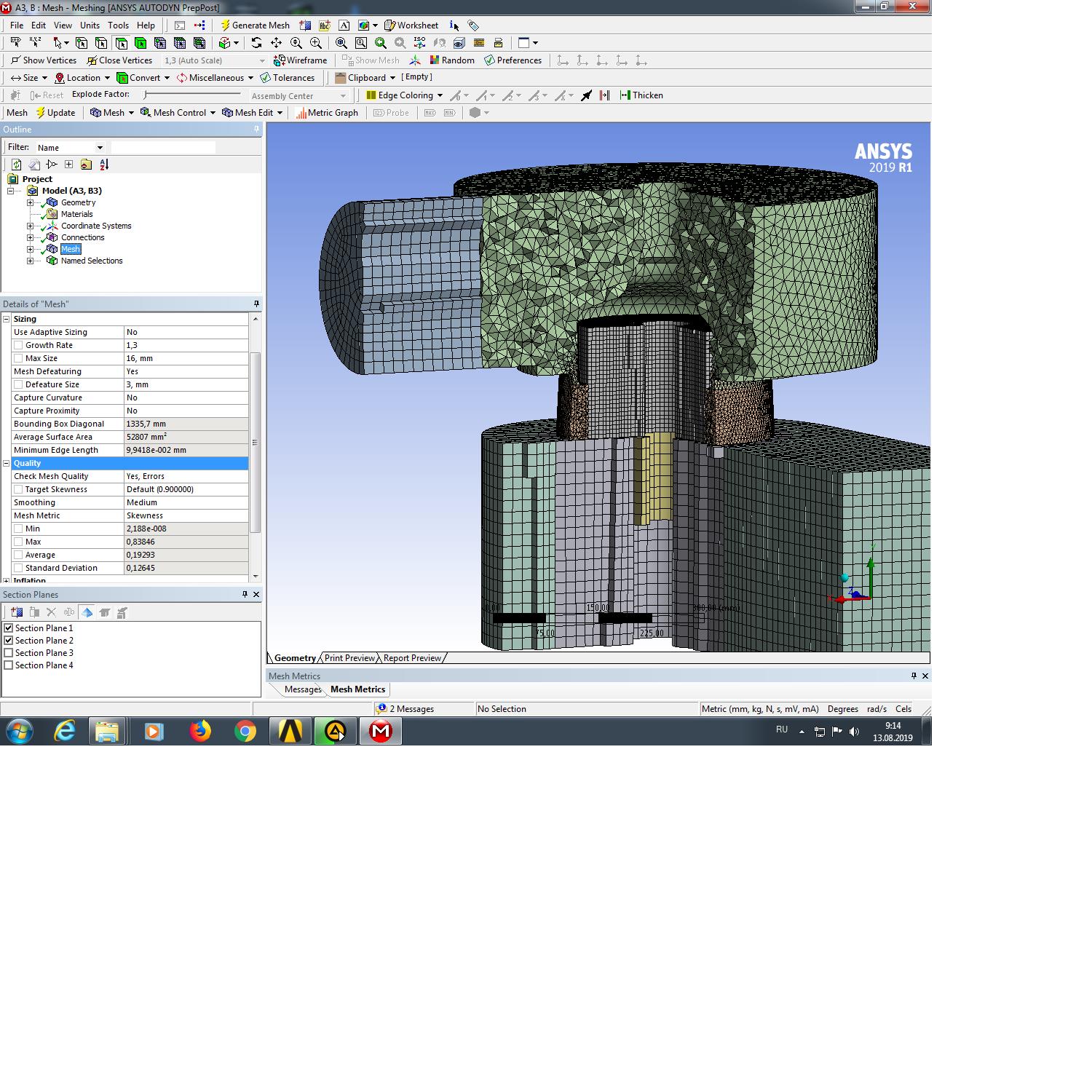

Ansys EmployeeCan you add some more details about mesh quality? -

August 13, 2019 at 6:30 am

-

August 13, 2019 at 9:34 am

Rob

Forum ModeratorI suspect you need a lot more mesh in that region: I think there are only 2-3 cells across the gap? You've also got several discontinuities in the mesh suggesting you're using mesh interfaces: that's not ideal and combined with a large jump in cell size won't help convergence or accuracy.

-

August 13, 2019 at 4:00 pm

EliasAlekseeff96

SubscriberThanks for answer, yeah, in this case used ~3 cells, early i used cutcell mesh with 9 cells. "You've also got several discontinuities in the mesh suggesting you're using mesh interfaces" - how may i fix it?

-

August 14, 2019 at 4:44 am

Amine Ben Hadj Ali

Ansys EmployeeThrough Sensible sizings -

August 14, 2019 at 2:28 pm

EliasAlekseeff96

Subscriber"Through Sensible sizings" Do You mean manually select ratio (proportions)

of size elements? What remarks do You have for my settings?

-

August 14, 2019 at 3:08 pm

Rob

Forum ModeratorUse a share topology operation (SpaceClaim) or multibody part (DesignModeler). Mesh quality is a lot more than just getting good cells: there's resolution & growth rate to consider too.

-

August 19, 2019 at 3:18 pm

-

August 19, 2019 at 8:38 pm

Raef.Kobeissi

SubscriberIs there a possibility to upload the case? -

August 20, 2019 at 2:51 pm

EliasAlekseeff96

SubscriberSorry, I can't do it.

-

August 20, 2019 at 4:02 pm

Amine Ben Hadj Ali

Ansys EmployeeMultibody part is when you put all bodies into a single part and the mesh will be then conformal.

Check mesh quality again.

-

- The topic ‘outlet pressure drop’ is closed to new replies.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Issue to compile a UDF in ANSYS Fluent

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

- Continuing SAG Mill Simulation with New Particle Batch in Rocky

-

4512

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.