-

-

April 27, 2019 at 11:19 am

Abdul Malik

SubscriberHello, community,

The question is regarding the multilinear material model. I want to ask regarding the force deflection graph shown below. The graph is a result of a non-linear analysis on welded plates in a longitudinal direction. The simulation shows a good correlation with experimental results but it deflects away from it after reaching a certain point. Anyone can explain why solver calculate in such a manner? Or can recommend any guide on how the solver solves the nonlinear material model in Ansys?

The only condition in which we get the drop in Ansys force-displacement curve is when we apply a too large displacement such as 15mm. which is not realistic because in the experimental study the specimen did not undergo such huge deformation. Furthermore, the difference remains constant no matter what the displacement is?

Many Thanks

Abdul Malik

-

April 28, 2019 at 2:10 am

peteroznewman

SubscriberIt looks like the ANSYS model has excellent agreement into the initial post-yield response. It is only well past yield that it doesn't track the experimental data.

In the experimental samples, is significant necking occurring?

What does the sample look like?

What kind of geometry flaws exist in the shape of the sample?

How is the sample held in the tensile testing machine?

How is the deformation measured?

What does the ANSYS model look like?

Did the ANSYS model have the same kind of geometry flaws that exist in the sample?

How is the model supported and loaded?

What does the mesh look like?

Were the results shown above plotted after a mesh convergence study?

If the sample exhibits necking, does the ANSYS model?

-

April 28, 2019 at 4:24 pm

Abdul Malik

SubscriberSorry for late response

It is an analysis of the fillet welded lap joints. the is no significant necking in the experimental sample.

Whereas, the material model values are obtained by a butt welded tensile test specimen.

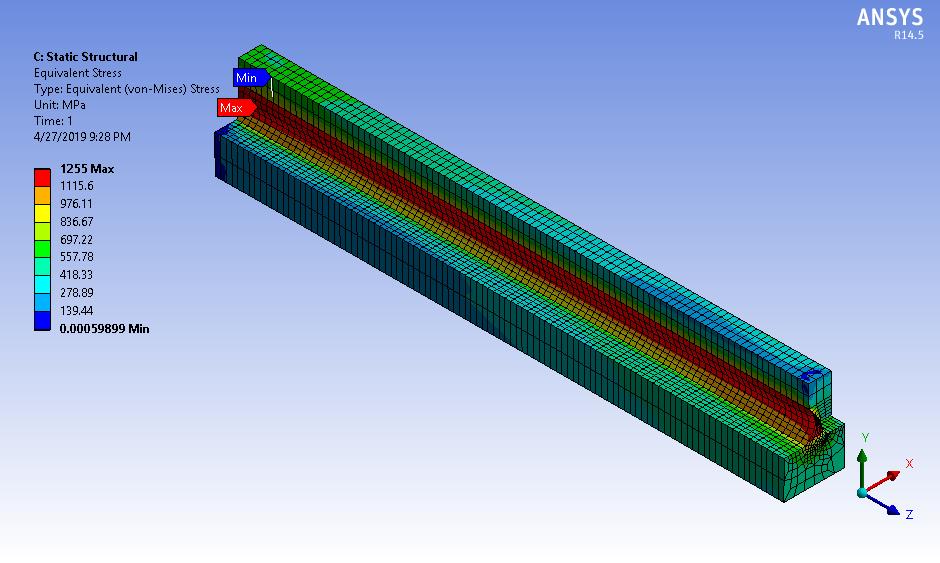

The sample is composed of two plates longitudinally welded together on sides. Below is the image of the welded part of the specimen.

The sample is held horizontally, loaded in the direction parallel to the weld seam under controlled path tensile loading.

In an experiment, the strain gauges were held at a height of 2cm above the top base plate. this same situation is simulated in Ansys to compute the deformation.

The boundary conditions are set as, fixed in the x-direction, displacement load is applied in the z-direction are applied at the surface. And for Y-direction a line is selected at the face to fix the Y-direction movement.

Yes, a convergence study is carried out before the convergence the deviation was much higher.

Many Thanks

-

April 29, 2019 at 7:07 pm

mrife

Ansys EmployeeAbdul

Which material model was used? Remember that the metal plasticity material models assume the the plastic strain region slopes do not curve down and turn negative. This is a theory assumption. The second question would be what is the material test data format - engineering or true stress-strain. If engineering did you transform it for input into Ansys WB Engineering Data? And did you solve this with large deformation turned on?

MIke

-

- The topic ‘Non-linear Material Model’ is closed to new replies.

-

4863

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.