-

-

March 15, 2023 at 5:56 pm

pcmac

SubscriberFor the Eulerian-Lagrangian model, should I turn on Eulerian in the multi-phase part and turn on DPM besides creating an injection, or should I only turn on DPM and create an injection? To be clear, imagine I want to track the behavior of the particle if it is trapped in the tank bottom. Why and when should I turn on Eulerian?

-

March 16, 2023 at 8:05 am

Amine Ben Hadj Ali

Ansys EmployeeIf you have only one particulate phase and it's volumetric loading is not so high, you might disable Eulerian and just run Single Phase + DPM (it is again multiphase but just deploying Euler-Lagrangian Framework).

-

March 20, 2023 at 4:14 am

pcmac

SubscriberGood day, DrAmine,

I am using the Ansys 2023 R1 version for Students. May I ask for your assistance in setting this method into my simulation? I am trying to mimic this process for my thesis, and as an innovative iteration, I will try to install a bottom weir structure to see how many particles the tank can trap and if the weir structure will benefit the enhancement of particle trapping. Attached is my main reference for my thesis. I've highlighted the important parts of the methodology of the study.

Thank you!

-

March 20, 2023 at 8:32 am

Amine Ben Hadj Ali

Ansys EmployeeCan you describe the process without that an Ansye Employee needs to follow (click on) the link you posted. Thanks.

-

March 20, 2023 at 8:51 am

pcmac

Subscriber- The trajectories of individual particles through the continuum fluid using the Lagrangian approach are calculated in FLUENT by the discrete phase model (DPM).

- The segregated solution algorithm was selected. The SST k–ω turbulence model was used to account for turbulence since this model is meant to describe better low Reynolds numbers flows such as the one inside our sedimentation tank

- The discretization schemes used were simple for the pressure, the PISO for the pressure–velocity coupling, and the second-order upwind for the momentum, the turbulence energy, and the specific dissipation.

- The water-free surface was modeled as a fixed surface; this plane of symmetry was characterized by zero normal gradients for all variables.

- As a first step, the fluid mechanics problem was solved in the absence of particles to find the steady-state flow field. The converged solution was defined as the solution for which the normalized residual for all variables was less than 10−6.

- In addition, the convergence was checked from the outflow rate calculated at each iteration of the run. The convergence was achieved when the flow rate calculated to exit the tank no longer changed.

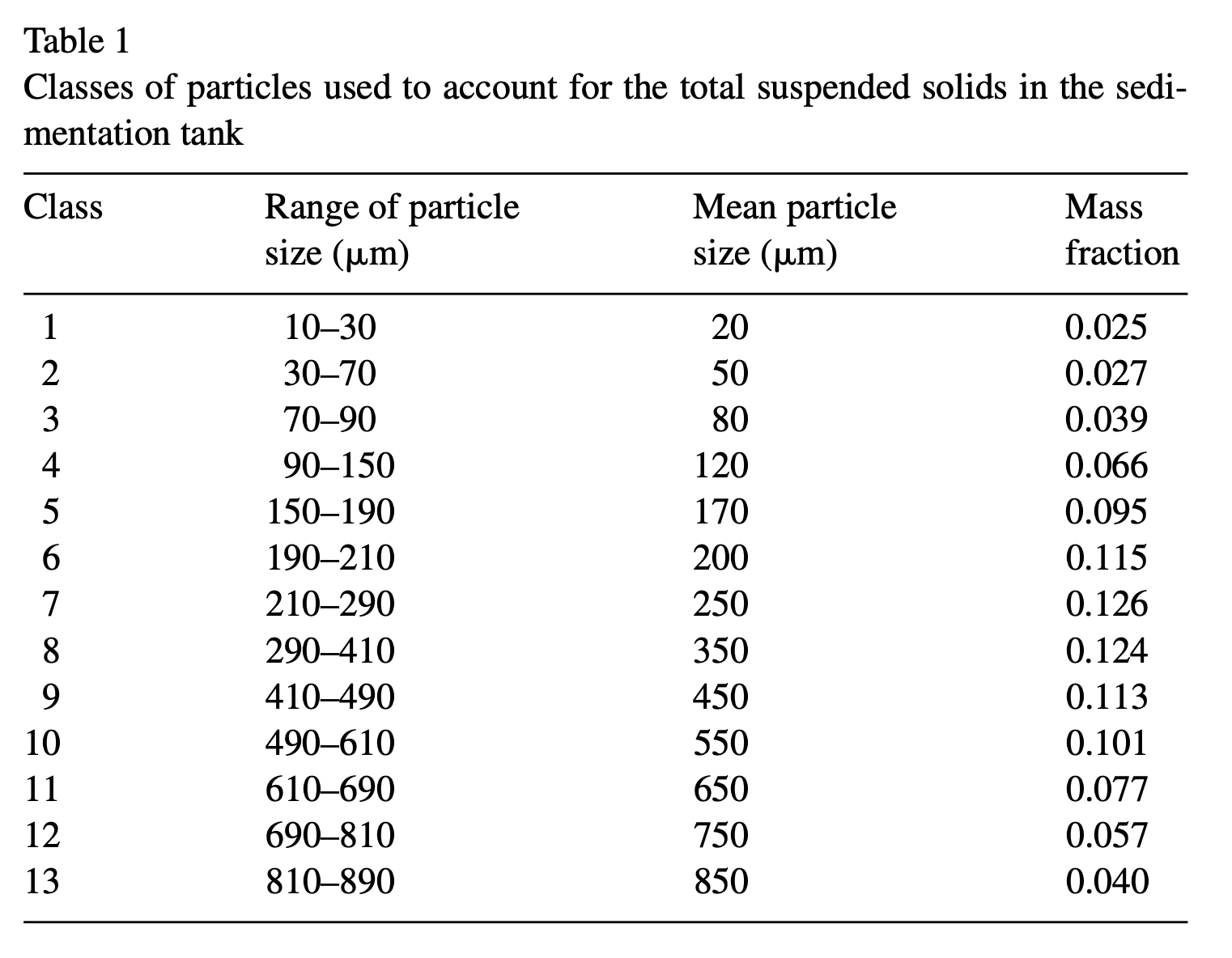

- The settling tank was simulated for a specific set of conditions used in the Thessaloniki treatment plant for which the particle size distribution at the inlet and outlet and the total settling efficiency has been experimentally measured. The inlet was specified as a plug flow of water at 0.085 m s−1, whereas the inlet turbulence intensity was set at 4.5%. The outlet was specified as a constant pressure outlet with a turbulence intensity of 6.0%. The water flow rate was 0.6 m3 s−1. Based on this rate, the inlet flow rate of particles was estimated as 0.15 kg s−1 using a measured solids concentration of 250 mg L−1, whereas the primary particle density was 1066 kg m−3.

- The effectiveness of particle settling is estimated as the percentage of solids settled over the rate of solids introduced from the feed.

-

March 20, 2023 at 8:57 am

pcmac

SubscriberI got lost in part 4 up to part 8. I’m not sure how to translate those into the Ansys setup.

-

March 20, 2023 at 10:03 am

Amine Ben Hadj Ali

Ansys EmployeeThey are not modelling a really free surface flow. They are modelling the free surface (air-water interface) as symmetry (free slip wall ) BC.

They are using Trapped BC for the particles and based on the amount of the particle beeing trapped at the wall they calcualte an efficiency.

-

March 20, 2023 at 11:26 am

pcmac

SubscriberIf that is the case, may I know how to simulate steps 4-8?

-

March 20, 2023 at 12:06 pm

Amine Ben Hadj Ali

Ansys EmployeeAs described in my last message. I recommend to go through Standard Fluent tutorials first. Aslo there is some material on the Ansys Learning Hub and Ansys Innovation Course which will be helfpul for you :).

-

March 20, 2023 at 3:25 pm

pcmac

SubscriberThank you, Sir!

-

March 25, 2023 at 2:48 pm

pcmac

SubscriberGood day, DrAmine,

In mimicking the steps of this study, how can I proceed with this step:

“As a first step, the fluid mechanics problem was solved in the absence of particles to find the steady-state flow field. The converged solution was defined as the solution for which the normalized residual for all variables was less than 10^(−6).”

And from that point, when I performed the grid independence test, how should I proceed into tracking about 25,000 particles following these steps:

"The inlet was specified as a plug flow of water at 0.085 m s−1, whereas the inlet turbulence intensity was set at 4.5%. The outlet was specified as a constant pressure outlet with a turbulence intensity of 6.0%. The water flow rate was 0.6 m3 s−1. Based on this rate, the inlet flow rate of particles was estimated as 0.15 kg s−1 using a measured solids concentration of 250 mg L−1, whereas the primary particle density was 1066 kg m−3 .”

Thank you!

-

March 27, 2023 at 1:26 pm

Amine Ben Hadj Ali

Ansys EmployeeThe first step consists in running only continious steady state flow without any particles. After you are happy with that and with the subsequent mesh sensitvitiy analysis you continue through injecting particles from the injection surface. There you input the properties of your injection: mass or mass flow rate, diameter distribution, etc.. I will first do that as post-processing step so assuming that the particles won't affect the flow. We have a standard Ansys Fluent tutorial dealing with DPM: please have a look into that! :)

-

May 6, 2023 at 7:58 pm

Mohamed Meskini

Subscriberhi DrAmine , can you give some indications about the Setup of the problem if you want

-

-

March 27, 2023 at 2:19 pm

pcmac

SubscriberThank you for the instruction, DrAmine!

-

May 6, 2023 at 4:36 pm

Mohamed Meskini

SubscriberHello pcmac , did you get an answer for your problem? i have the same project like you and i didn't find any answer for the Ansys Setup to simulate my problem ( settling tank, particule behavior )

-

May 6, 2023 at 6:33 pm

pcmac

SubscriberGood day, Mohamed Meskini. As of now, I am still trying to figure out the problem's setup.

-

May 6, 2023 at 7:56 pm

Mohamed Meskini

Subscriberokay Pcmac , if you get the answer tell me please, the same with me if i figure it out i will tell you.

good day Pcmac.

-

-

- The topic ‘Multiphase Flow in Sedimentation Tank (water & sand)’ is closed to new replies.

-

4703

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.