TAGGED: ansys-fluent, mixing-plane, mixture-of-gas, mutiphase, turbo-machinery

-

-

January 17, 2026 at 8:28 am

James411project

SubscriberHi everyone,

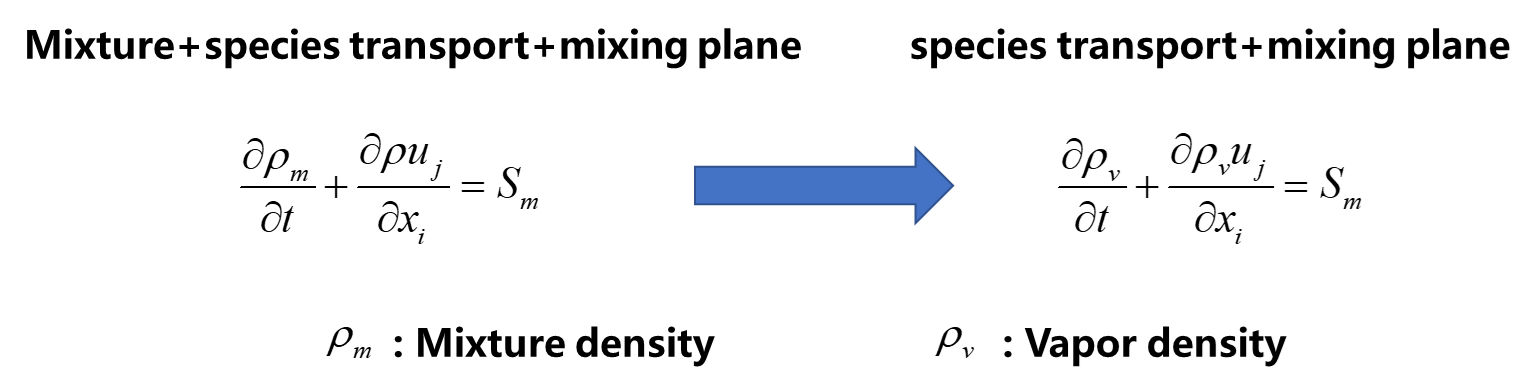

I am currently studying a geometric model of a two-stage turbine, with carbon dioxide, nitrogen, and water vapor as the working medium. Now, I aim to investigate the condensation of water vapor in the mixed working fluid during the expansion process. For this multiphase and multicomponent model, I plan to use the Mixture model + species transport + mixing plane model in Fluent. However, I found that the mixing plane model is not supported alongside the Mixture model. Strangely, only the Wet Steam model among the multiphase flow models supports this, and I also discovered that the species transport model can be used simultaneously with the mixing plane model. My current approach is to use only the species transport and mixing plane models, solving only the mass, momentum, and energy equations of the gas phase, and adding respective phase change source terms. Will this gas-phase-only method cause physical distortion? Additionally, are there better methods to model this problem?

Thank you in advance for your time and expertise. Any guidance or suggestions would be of immense help to my research.

-

January 20, 2026 at 11:24 am

Rob

Forum ModeratorMixing plane uses an averaging approach so https://ansyshelp.ansys.com/public/account/Secured?returnurl=/Views/Secured/corp/v252/en/flu_ug/section_kb4_blt_kjb.html%23section_e3f_zb3_2gb may well only work with specific models. It's not an approach I've used in many years.

Gas only could work, but you'd need to be careful with both latent heat and volume: vapour is somewhat less dense than most liquids! Do you have a common periodic angle for rotor & stator parts?

-

January 20, 2026 at 1:02 pm

James411project

SubscriberThank for your reply. In my research, the liquid phase mass fraction obtained from condensation is less than 0.1. Considering the density difference between the gas and liquid phases, it seems that the volume fraction of the liquid phase can be neglected. Additionally, my two-stage turbine system has stator-rotor-stator-rotor blade counts of 24-32-36-32, respectively, which do not share a common periodic angle. I also have the following questions and hope for your guidance:

1. Based on reviewing similar studies, most researchers have used the **stage model in CFX** or the **mixing plane method in Fluent**. I also noticed that Fluent offers three pitch change models for steady-state simulations in rotating frames: **mixing plane**, **pitch scale**, and **non-pitch scale**. After comparing these three models, I observed that the latter two do not perform circumferential averaging of the solution variables at the rotor-stator interfaces. Among these three models, which one would you recommend?

2. My current work is similar to the **wet steam model built into Fluent**, but my research requires considering the influence of **non-condensable gases (carrier gases)**, which the built-in wet steam model cannot handle. I have already developed a preliminary computational model using UDF and UDS. However, I also noticed that CFX has a similar model to Fluent’s wet steam model, called the **droplet phase change model**. I would like to know if CFX can directly account for the influence of non-condensable gases through its built-in models? This would greatly simplify my workflow.

Thank you very much for your time and assistance!

-

January 20, 2026 at 3:56 pm

Petros

Ansys EmployeeIf you care about mean quantities (stage efficiency, power/torque, pressurer ratio) then Mixing Plane can be the correct choice. If you care for strong rotor/stator interaction, wakes, forces and secondary flows then Frozen Rotor (Pitch-Scale/No Pitch-Scale in Fluent) is a better approach.

For the second part, it would be best answered by a multiphase expert.

-

January 21, 2026 at 12:38 am

James411project

SubscriberThank you for your professional reply

-

-

January 21, 2026 at 10:03 am

Rob

Forum ModeratorAnd for multiphase you'll need a UDF to include partial pressure effects because of the non condensable gas. I don't know what's public so please check in Search above. If volume fraction is low you may find the DPM model (potentially with some UDFs for injections) to be useful. However, how would you average droplets (in whatever model) on a mixing plane?

I understand that CFX has much the same issues but will need more coding for the phase change.

-

January 21, 2026 at 11:36 am

James411project

Subscriber"Thanks for the professional reply.

I have preliminarily established a model accounting for non-condensable gases using UDFs and UDSs.

specifically, I utilized UDS transport equations to enforce the conservation of droplet number density and liquid phase mass fraction. These liquid phase equations are coupled with the gas phase equations via source terms. The droplet number and liquid mass fraction are treated as two additional solution variables, and a simple algebraic relationship exists between them.

The calculation results indicate that the condensation characteristics, such as wetness, are reasonable. Additionally, at the rotor-stator interface, the two extra UDS variables are circumferentially averaged."

-

-

- 您必须登录才能回复此主题。

-

5199

-

1859

-

1387

-

1250

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.