-

-

March 19, 2025 at 11:56 pm

mohammad.nabil

SubscriberI am

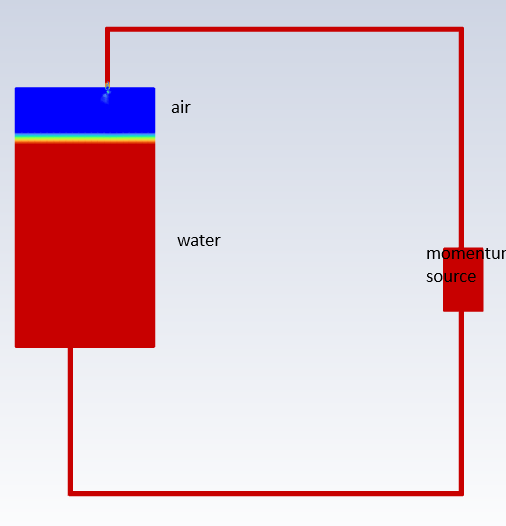

working on a closed-loop fluid circuit in ANSYS Fluent and using a momentum source to simulate a pump. However, despite applying the source term, the flow rate remains unchanged, and I don’t see the expected increase in velocity within the loop.

working on a closed-loop fluid circuit in ANSYS Fluent and using a momentum source to simulate a pump. However, despite applying the source term, the flow rate remains unchanged, and I don’t see the expected increase in velocity within the loop.Here’s what I have tried so far:

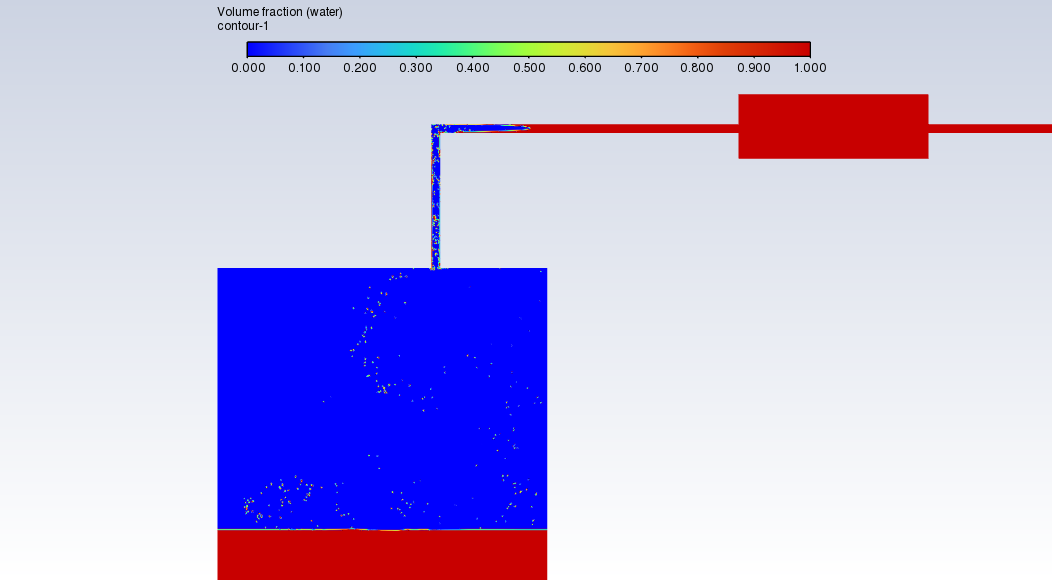

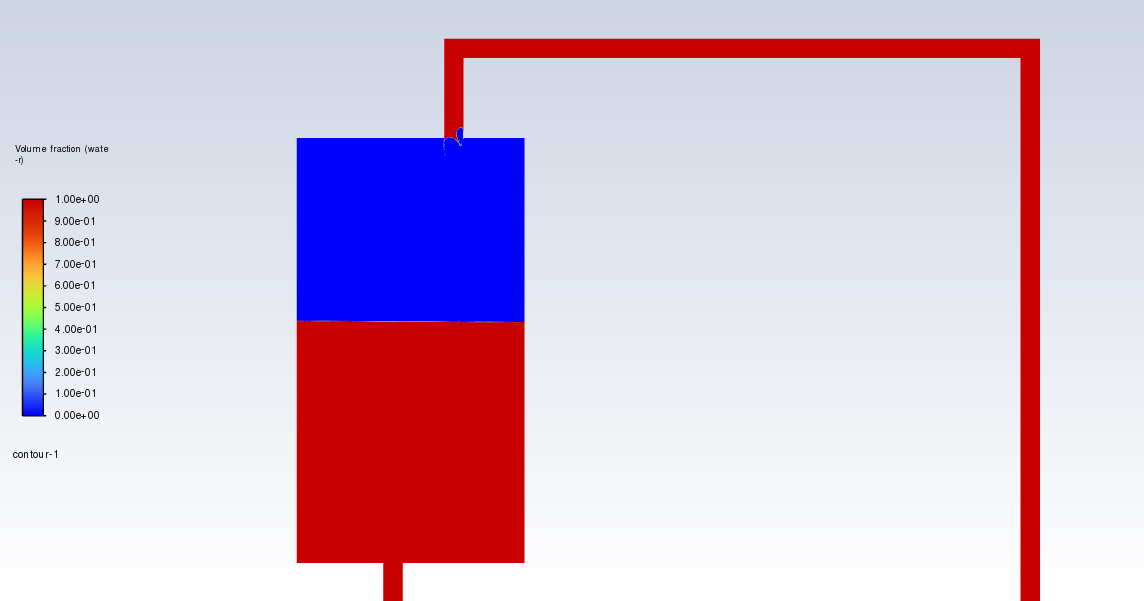

- Applied the momentum source in the pump region in the image.

- Increased the source term magnitude significantly, but no noticeable effect on the flow rate.

- Checked boundary conditions—since this is a closed-loop system, there are no inlets or outlets, just walls.

I was expecting the momentum source to drive the flow, similar to how a pump would, but it doesn’t seem to be working. I have attached an image of my setup for reference.

Has anyone encountered this issue before? Are there additional settings or considerations I should check?

Any insights would be greatly appreciated!

Thanks in advance.

-

March 20, 2025 at 11:28 am

Rob

Forum ModeratorYou should get a flow, but as it's sealed and you may not have balanced the source with the loop pressure loss there's a good chance of winding speed up to infinity.

-

March 20, 2025 at 1:13 pm

mohammad.nabil

SubscriberThank you for your reply.

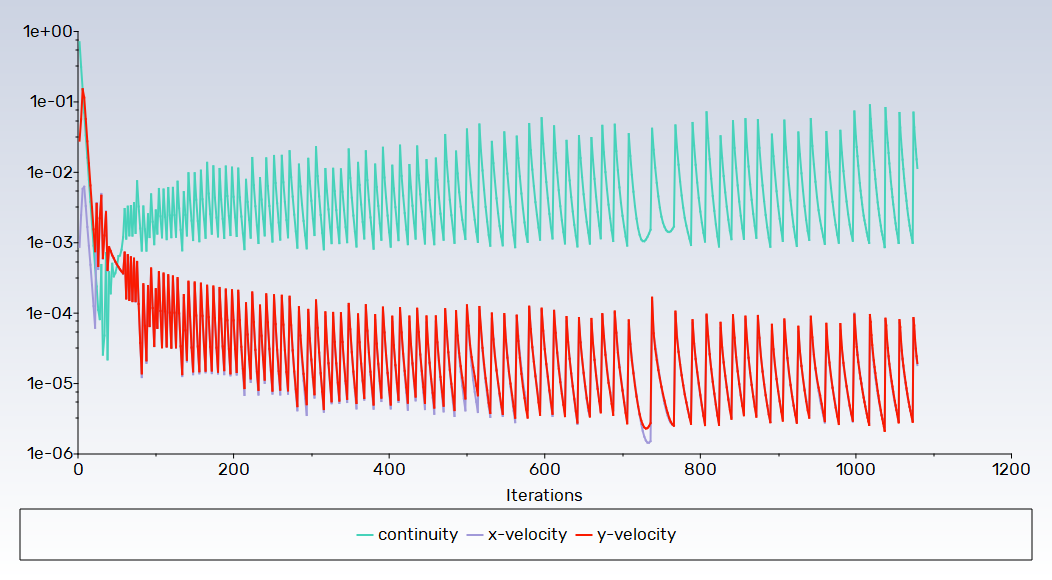

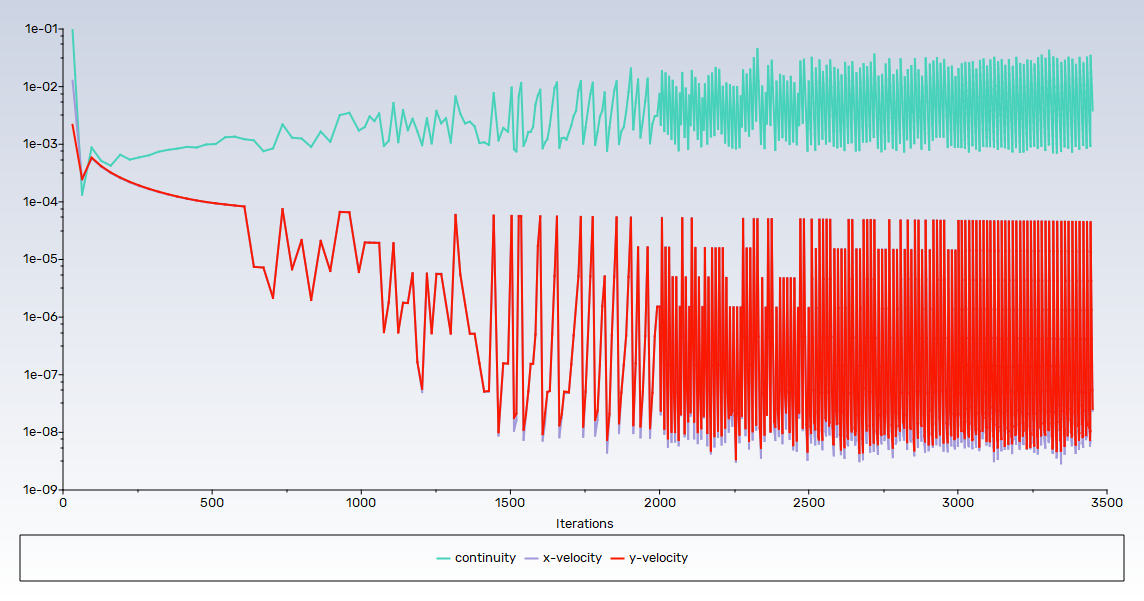

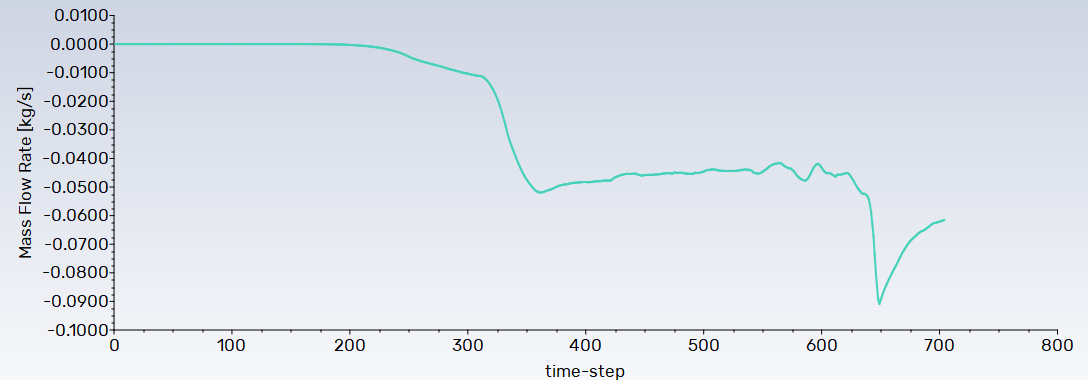

Indeed, after several iterations, the flow tends to reverse and move upward within the circuit. Additionally, the flow rate exhibits high-frequency fluctuations. How can I address this issue? I would appreciate any insights you could share.

-

March 20, 2025 at 2:27 pm

Rob

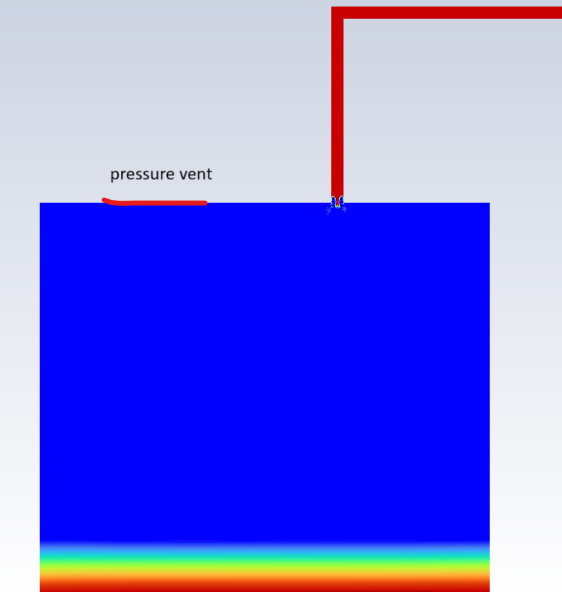

Forum ModeratorYou can try venting the air space. That should reduce pressure fluctuations and also anchors the solution back at the boundary pressure.

-

March 20, 2025 at 4:51 pm

-

March 20, 2025 at 4:54 pm

Rob

Forum ModeratorNo, I assume the backflow is set to air? How well resolved is the nozzle? Do you actually need the loop, what's wrong with just pushing liquid into a chamber?

-

March 20, 2025 at 5:06 pm

mohammad.nabil

SubscriberThe backflow volume fraction for water is currently set to 0. Fluent also keeps showing warnings for reversed flow.

I need the loop for further analysis. It is meshed with a resolution of 0.25 mm, and the loop diameter is 4.8 mm.

-

March 20, 2025 at 10:48 pm

mohammad.nabil

SubscriberI am getting negative pressure at the end of the loop/ at the top of the reservoir. Since the pressure at the vent is 0, It is creating a back flow. Is there any way to solve the problem?

-

March 21, 2025 at 9:41 am

Rob

Forum ModeratorBack flow is fine, and should be zero water. It's going to take some time for the system to settle down. For VOF you're meshing to resolve the free surface, and that will include any droplets that are formed. This is not going to be a small model.

-

March 22, 2025 at 4:22 am

mohammad.nabil

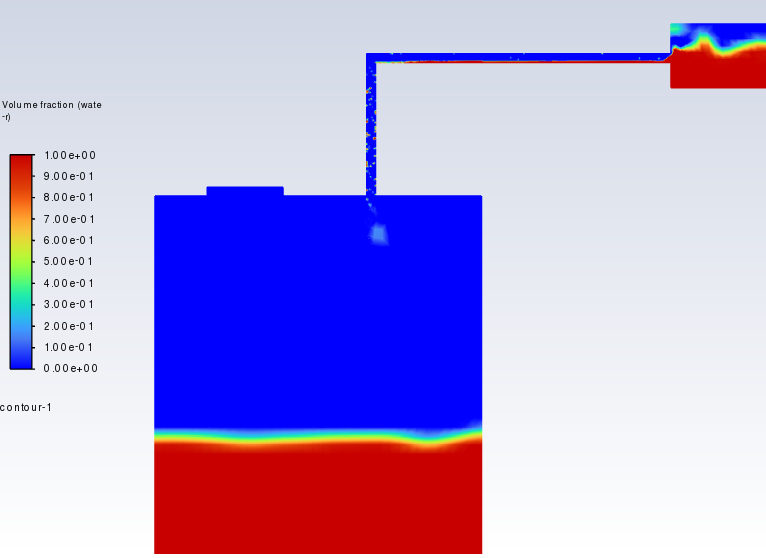

SubscriberThe system settles down after 6000 iteration and the flow rate is also 200ml/min. Exactly the flow that I want. But it is sucking air into the loop. It is all back flow of air. Even if I change the direction of the momentum, the schenario does not change. What could be the reason? I keep monitoring the pressure at the top of the reservoir and it keeps a negative pressure of -0.48Pa/m^2. Is this the reason for back flow?

-

March 24, 2025 at 9:30 am

Rob

Forum ModeratorConvergence? Equally, if the mesh isn't suitable and flow is too low then it's quite easy to get results like you have: water drains down the side and air rises.

-

March 24, 2025 at 2:10 pm

mohammad.nabil

SubscriberConvergence is good. Flow is supposed to be 200ml/min. The tube diameter is 4.8 mm. and the reservoir tank width is 177mm. I am not sure if this is causing any issue. for the reservoir, it is meshed with 5mm element size and the tube is meshed with 0.25mm. skewness is like 0.58 at the interface region between the tube and the reservoir. Also orthogonality is a bit poor around that region. But average mesh quality is above the standard.

I am meshing it again with finer elements. But meanwhile I would appreciate your thoughts.

-

March 24, 2025 at 2:24 pm

Rob

Forum ModeratorIt's difficult to say, was convergence good for all time steps? If the channel is 4.8mm and the reservoir modelled with 5mm cells do you expect to retain any droplets coming out of the nozzle?

-

March 24, 2025 at 8:17 pm

-

March 25, 2025 at 10:21 am

Rob

Forum ModeratorOK, so convergence is numerically just about there but otherwise questionable. The near random droplets in the reservoir highlight the convergence problem.

-

March 25, 2025 at 1:06 pm

mohammad.nabil

SubscriberThank you for pointing that out. Could you suggest me any ways to fix that issue? I doubt its a meshing problem.

-

March 25, 2025 at 1:39 pm

Rob

Forum ModeratorMesh & time step. With VOF you're tracking the free surface so any droplets need resolving - that means 5-10 cells over the droplet in some cases. There's a reason we added the VOF to DPM functions.

-

March 25, 2025 at 4:48 pm

mohammad.nabil

SubscriberThank you. I am going to definitely remind myself of this. I was worried about the stability. From a rough calculation I used CFL~0.073 but used explicit method. But I was not careful about the sensitivity of the VOF.

For now I have two questions.

- How do I know what willbe the minimum surface area of the droplets so that I can adjust my mesh element size?

- Could you mention some references where I can go and read about this specific issue?

-

March 25, 2025 at 5:29 pm

Rob

Forum Moderator1) You don't. We usually work out what we can afford to resolve and then set the VOF to DPM transition to be a little larger than that.

2) Not really. I'm only permitted to point you at Ansys materials (Learning is good) and things that are found from a search. Most of the public multiphase information is in Learning or the Ansys Learning Hub or documentation.

-

March 28, 2025 at 4:07 pm

mohammad.nabil

SubscriberI meshed the region with very fine elements. I also decreased the time step sizes.

I increased the diameter of the loop too. From 4.8mm to 15 mm. meshed it with 0.1mm elements.

Backflow is still occurring. The simulation is taking a long time due to the high-quality mesh, and it's still in the early stages. However, I'm not sure if things will change as it progresses. Is it because of boundary conditions? I have two momentum sources in the loop. Tow pressure outlet in the reservoir.I would appreciate your guidance after this.

-

March 28, 2025 at 4:22 pm

Rob

Forum ModeratorHow fast is the flow in the loop? Is there a scenario where the liquid can flow quickly enough down part of the pipe but leave space for the gas to rise?

-

June 10, 2025 at 7:56 pm

mohammad.nabil

SubscriberThe flow was very fast. like 4-5kg/sec. I didn't have the other scenario that you are saying.

What I found helpful is to first let gravity drive the fluid flow from the reservoir. Once it is settled after 10 seconds of simulation, I activate the momentum source with a very high value. It is now acting as a pump and fluid is coming back from the top. But the flow rate is not there. I need to adjust the strength of the source. But it looks like the fluid is now responding to the momentum source as I am tuning the values.

I am keeping the pressure outlet at the top of the reservoir. I think it makes a good reference point for pressure.

-

- You must be logged in to reply to this topic.

-

4673

-

1565

-

1386

-

1231

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.