-

-

November 5, 2018 at 6:12 pm

dinler

SubscriberHello everybody,

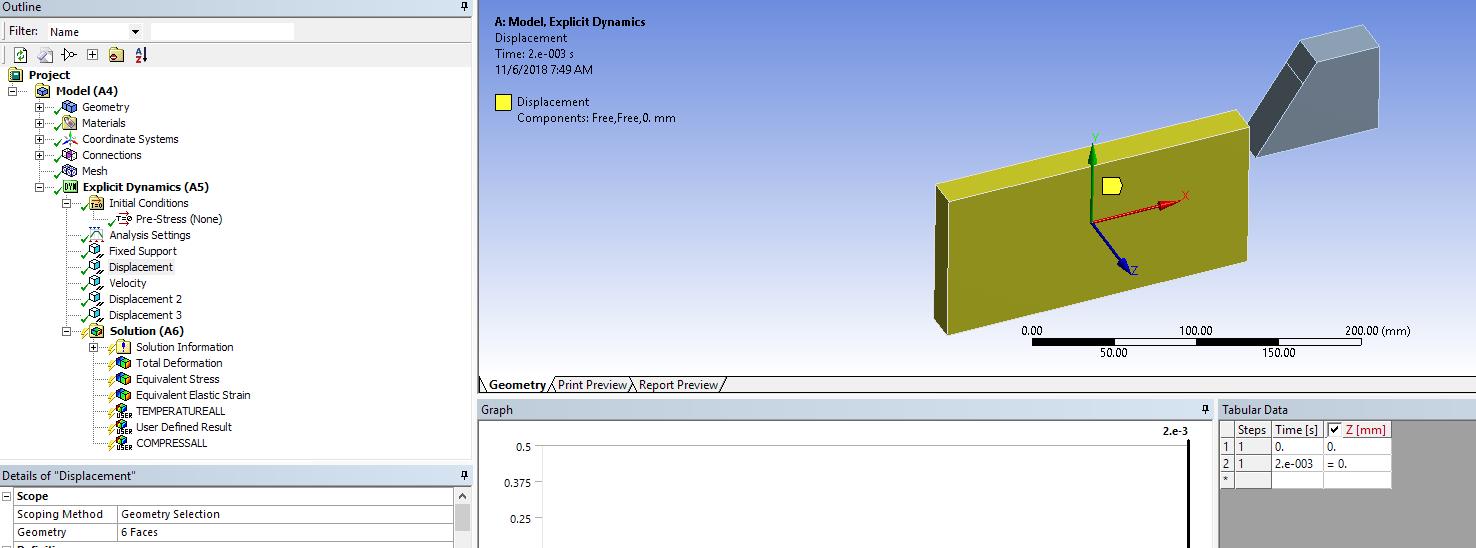

My simulation is not working as intended. It is not removing any chip.

Details are below;

I defined two materials; a milling insert as Ceramic Insert Al203 and the workpiece as gray cast iron. Gray cast iron is defined as perfectly plastic.

I have defined friction between materials. Workpiece is fixed underneath. Insert has an angular velocity of 900 rpm and feed velocity of 0.03m/s.

I attach the archieve file and a screenshot showing the problem. Thank you all for your help.

-

November 5, 2018 at 7:00 pm

Sandeep Medikonda

Ansys EmployeeDinler, Please post inline images of your setup, boundary conditions etc.

Not everyone on the community is able to download files.

Regards,

Sandeep -

November 6, 2018 at 4:14 am

-

November 6, 2018 at 12:51 pm

Sandeep Medikonda

Ansys EmployeeIs it even moving and making contact as intended?

Why is it developing deforming in the picture, is it just due to the inertial forces from Angular velocity?

Your boundary conditions are not being properly defined, use a constant velocity b.c as I show here and constrain all the other movements using the displacement boundary condition. In that post, I did it by constraining Z, where needed:

Regards,

Sandeep -

November 13, 2018 at 3:36 pm

dinler

SubscriberSir,

I redefined the boundary conditions as below and made it work, one minor problem though. I want the insert to rotate in a circular arc(I defined -900rpm on insert) however when 2 bodies collide, insert slowly slips in +x direction. Is there anyway that insert only rotates and follow the arc, and all 5 DOF's restricted like revolute joint.

-

November 13, 2018 at 4:37 pm

Sandeep Medikonda

Ansys EmployeeDinler,

You can always use a Remote Displacement to do this and try inserting an initial rotation velocity for the one degree of freedom that is not constrained.

Regards,

Sandeep

Best Practices on the Student Community -

November 16, 2018 at 7:17 am

dinler

SubscriberDear SandeepMedikonda,

After changing velocity to angular velocity, It worked. Why it is not working with velocity though? Sorry if it is a newbie question. Thank you for your help.

-

May 15, 2019 at 5:04 am

edwardbastianh

SubscriberDear SandeepMedikonda

now, im doing the same simulation with ansys 19.0. i have a problem, that the chip formation is not formed. there's just red dots during the simulation. how do i get the chip formation for my simulation with ansys explicit dynamic. thank you

-

May 15, 2019 at 6:48 am

Sandeep Medikonda

Ansys EmployeeYou might need to use a plastic material definition. Check what material model you are using? As a test try using AL 1100-O from the Engineering database. See if that helps.

If it doesn't please open a new discussion, describe your model with pictures, i.e., geometry, materials, boundary conditions and analysis settings.

You are more likely to get help when you open your own discussion. You can always link to any discussion or post using the #Permalink. Take a moment to review the Guidelines on the Student Community

-

- The topic ‘Milling Simulation Help’ is closed to new replies.

-

3797

-

1388

-

1188

-

1095

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.