-

-

February 11, 2024 at 1:11 pm

n n

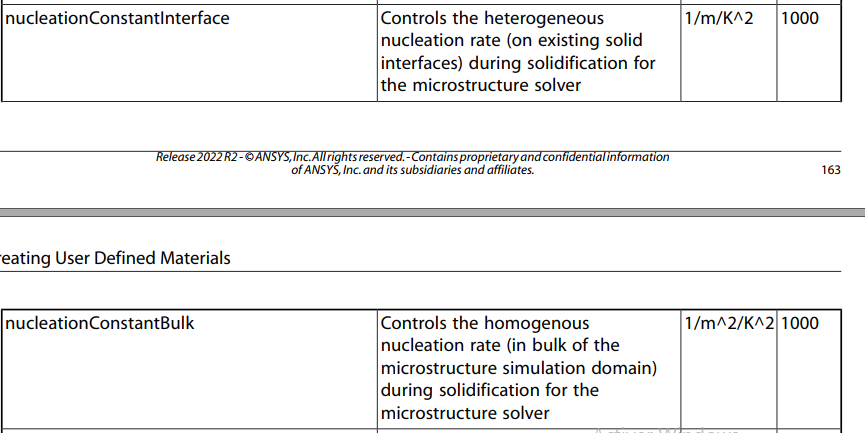

SubscriberHello i want to ask about the signification about these coefficient used in ansys additive what they represent exactly in the nucleation law

what is the value of the nucleation parameter used in ansys additive? what is the value of the fraction solid used in ansys additive in the microstructure simulation ?

-

February 14, 2024 at 9:57 pm

John Doyle

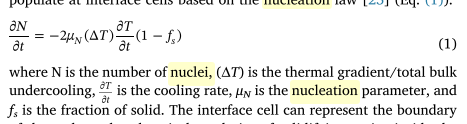

Ansys EmployeeIs your last screenshot (referring to 'number of nuclei' and 'nucleation parameter') part of the Ansys online docs? It looks like an outside reference.

-

February 15, 2024 at 9:40 am

n n

Subscriberit refers to this article:

J. Akram, P. Chalavadi, D. Pal, and B. Stucker, “Understanding grain evolution in additive manufacturing through modeling,” Addit. Manuf., vol. 21, no. March, pp. 255–268, 2018, doi: 10.1016/j.addma.2018.03.021.

i think in this article they used ansys additive so the same assumtions and models are true is it ?

-

February 15, 2024 at 4:03 pm

-

February 16, 2024 at 11:29 am

n n

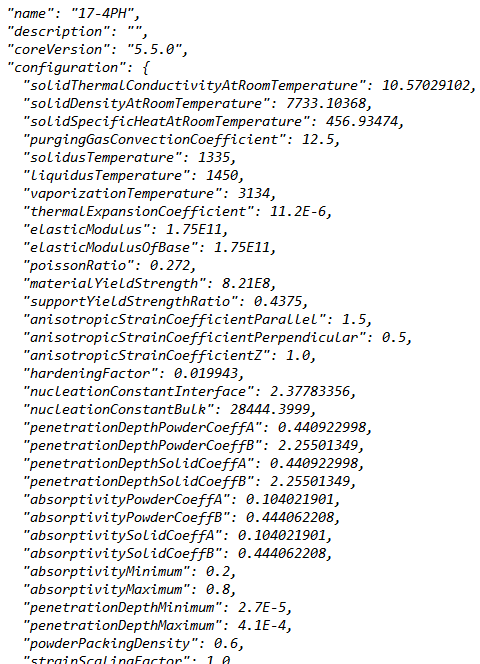

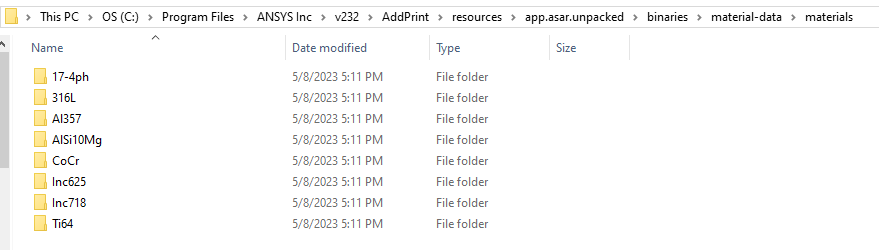

Subscriberis these materials properties available for Ti6Al4V ?

-

February 16, 2024 at 11:31 am

n n

Subscriberi want thes data for the titanium alloy and not for the 17-4PH

-

February 16, 2024 at 1:27 pm

-

February 16, 2024 at 1:52 pm

n n

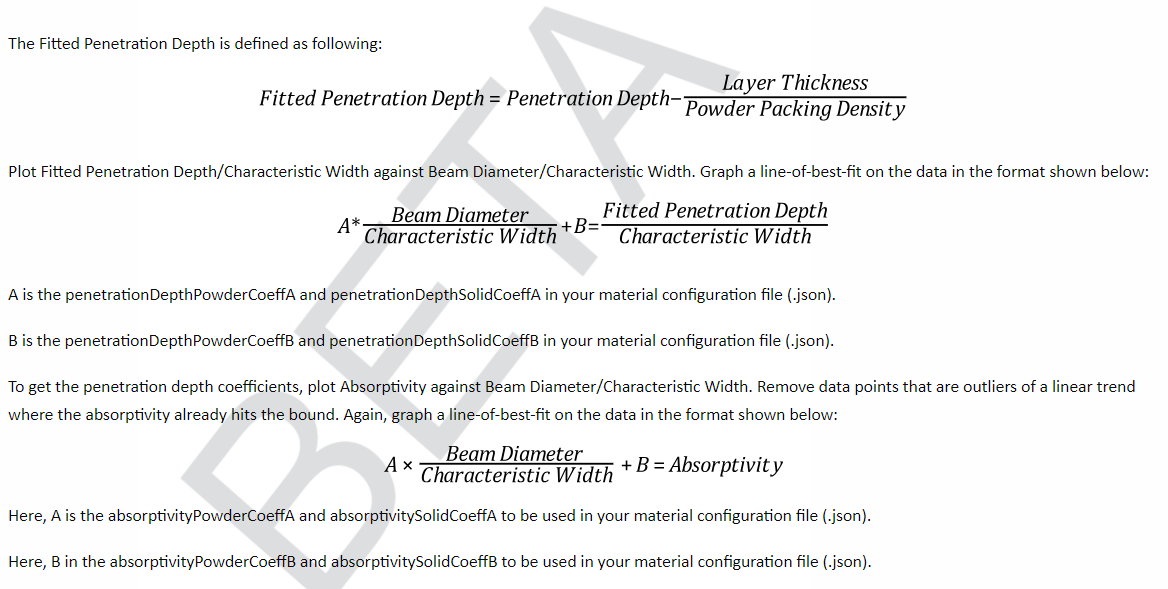

Subscriberthank you for your response, what does it mean coeff A and B for penetration depth and absorptivy coeff a and coeff b -

February 16, 2024 at 2:19 pm

John Doyle

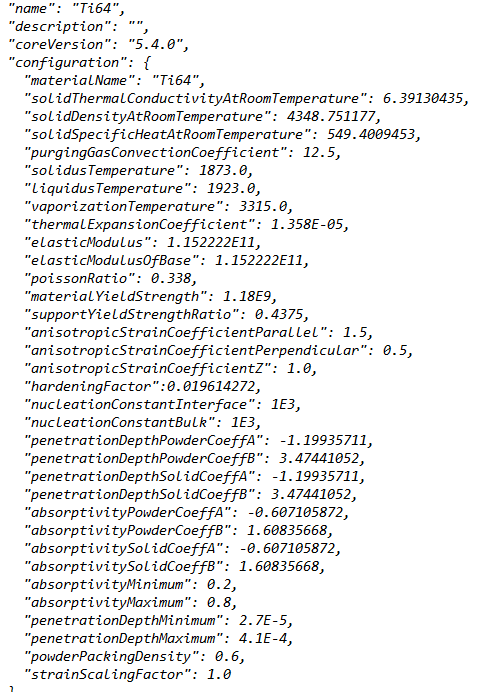

Ansys EmployeeThey are used by material tuning tool. Below is from R2024-R1 beta docs...

'The penetration depth is defined as the distance a laser heat source can reach down to the material at its 95% cumulative energy. During the additive manufacturing process, the laser can vaporize material in the melt pool, which may sometimes create a vapor cavity within the melt pool. Depending on the laser power level, the vapor cavity size will vary. In general, a larger vapor cavity will contribute to a deeper penetration depth since less energy is lost within the vapor cavity. Our simplified volumetric heat source model does not cover the vapor cavity formation phenomenon, therefore, we need to include coefficients to tune the model with respect to different materials and process parameters.

Four penetration depth coefficients that will be determined by the tuning process are:

penetrationDepthPowderCoeffA

penetrationDepthPowderCoeffB

penetrationDepthSolidCoeffA

penetrationDepthSolidCoeffB

-

- The topic ‘microstructure ansys additive’ is closed to new replies.

-

5094

-

1830

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.