TAGGED: bc, internal-flows, mesh

-

-

September 3, 2025 at 11:22 am

a.y.al-wardi

SubscriberHi,

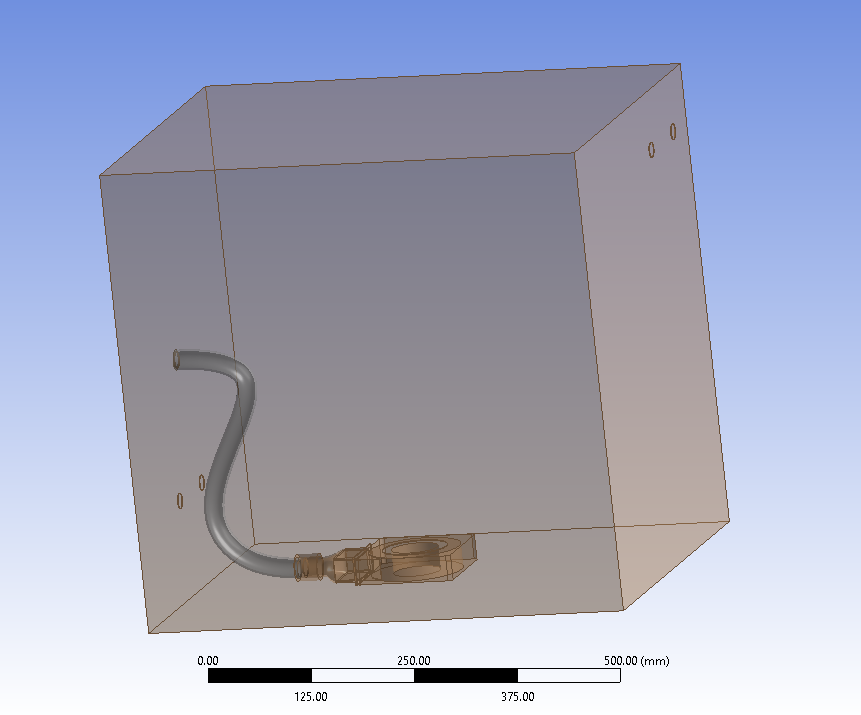

Chamber 490×570×600 mm, 4 inlets (~19 mm), 1 outlet (~20 mm), internal fan hub and hose.

Hex-dominant mesh fails around internal components; full tetrahedral mesh runs.

In both cases solver crashes (floating-point exception, continuity spikes, reversed flow and turbulent viscosity limited in x number of cells)I used velocity inlets + pressure outlet and also tried pressure inlets + mass flow outlet boundary conditions.

Questions: Best meshing approach for domain with internal components (such as hose)? Tips for stabilizing transient runs?

Below is a picture of the geometry (domain with hose, fan casing booleaned out).

-

September 3, 2025 at 11:42 am

SRP

Ansys EmployeeHi,

Apply local size controls around the hose, fan hub and small faces. Where two parts touch (fan hub, hose joins), ensure shared topology so the mesher can create conformal faces. Check geometry and repair it during the CAD stage to avoid any issue in the simulation.

You can check course on meshing: Mesh Generation using Ansys Fluent Meshing | Ansys Courses

-

- You must be logged in to reply to this topic.

-

3827

-

1389

-

1188

-

1100

-

1015

© 2025 Copyright ANSYS, Inc. All rights reserved.