-

-

June 4, 2021 at 9:05 am

Emperor

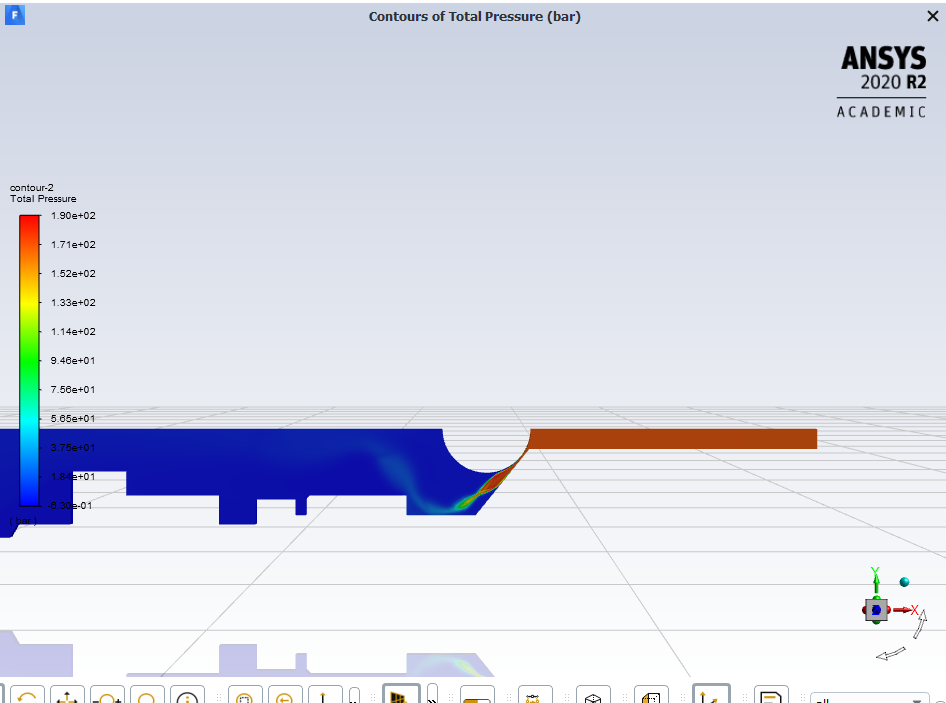

SubscriberJune 4, 2021 at 10:22 amKeyur Kanade

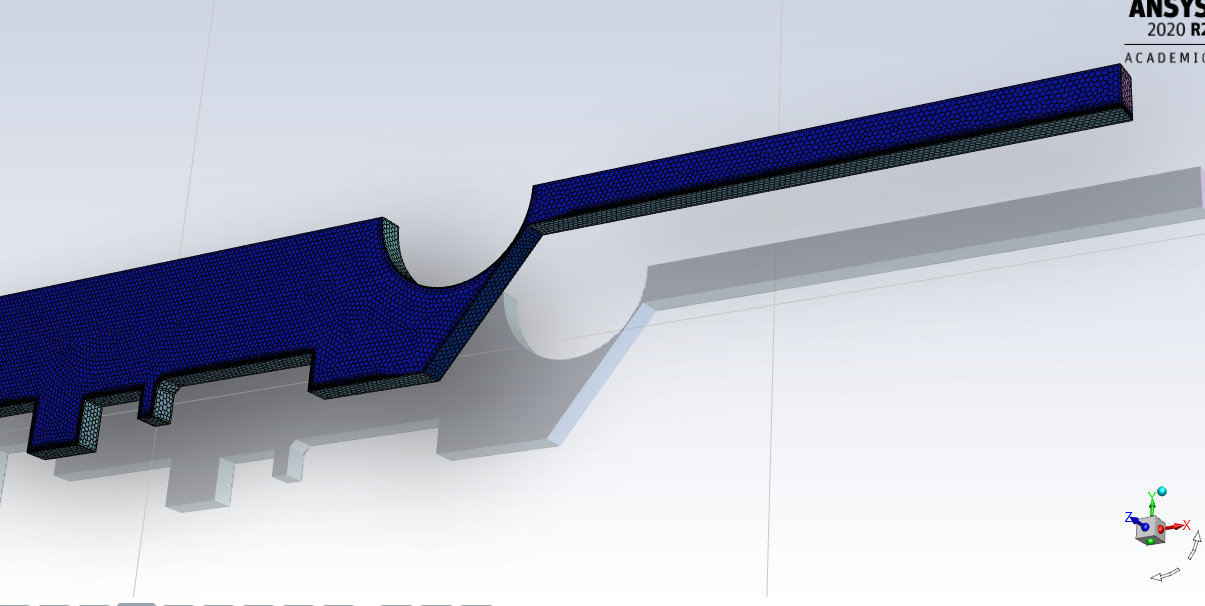

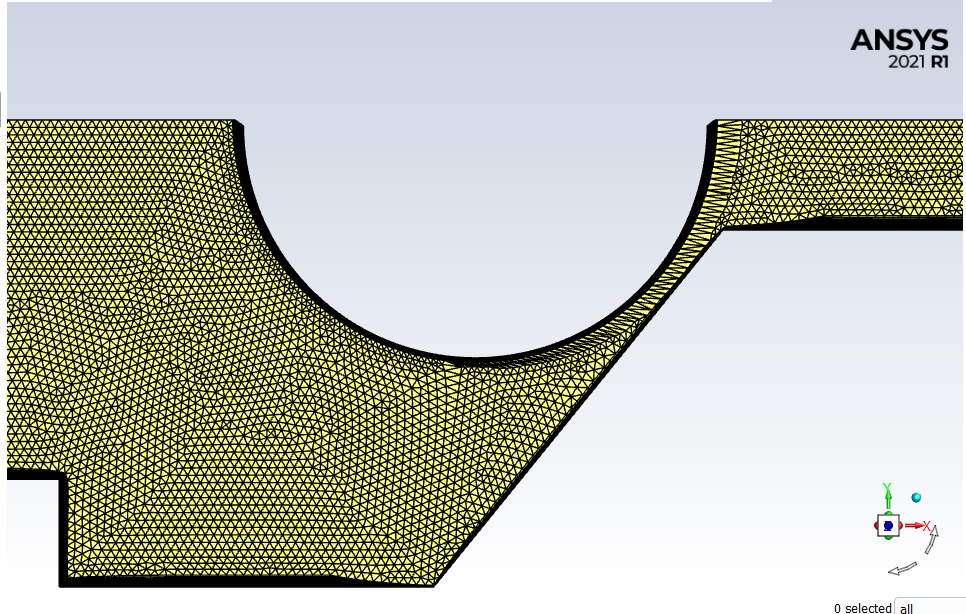

Ansys EmployeeWhat is question? From images it looks good mesh.

Regards Keyur

How to access Ansys Online Help Document

How to show full resolution image

Guidelines on the Student Community

How to use Google to search within Ansys Student Community

June 4, 2021 at 10:33 amEmperor

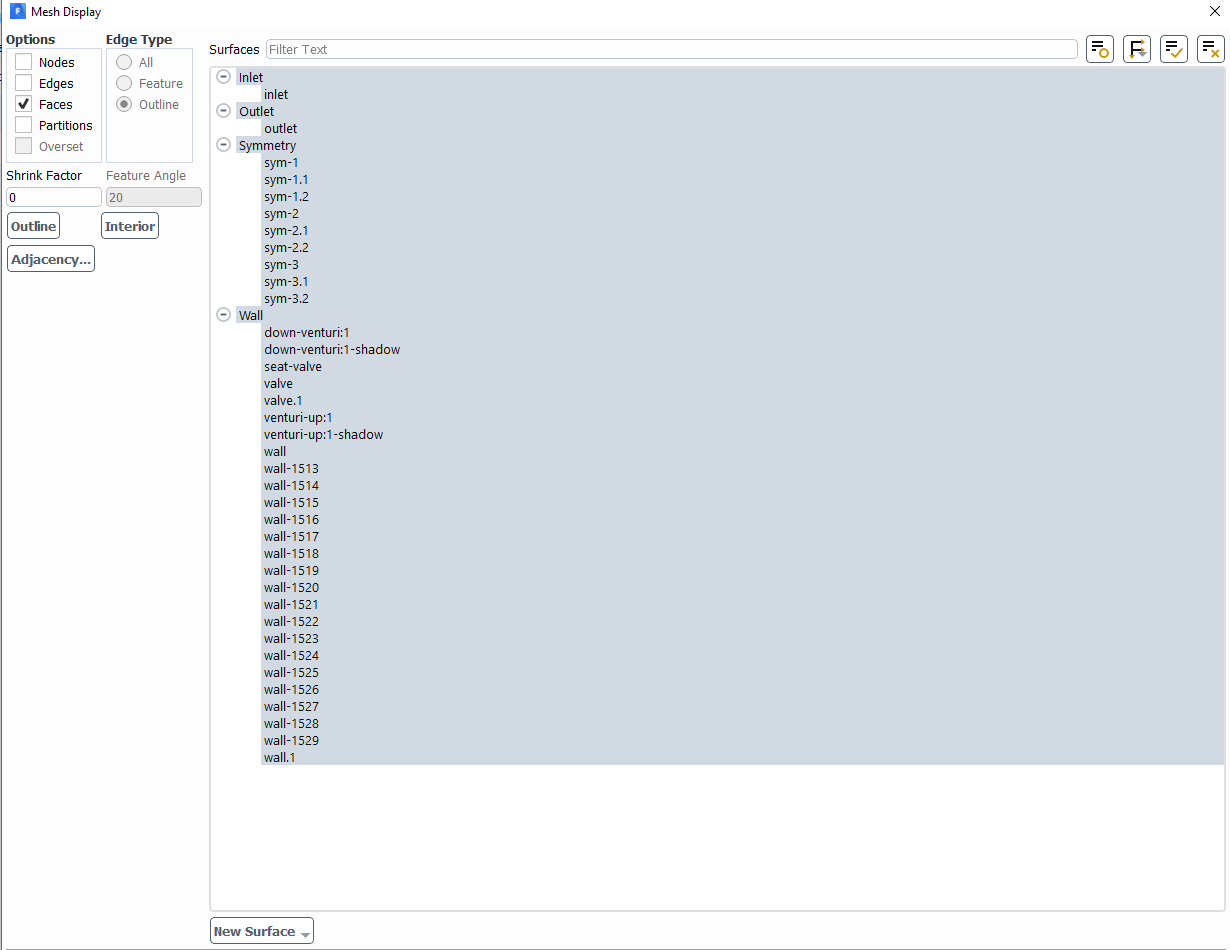

Subscriberthe questions are:

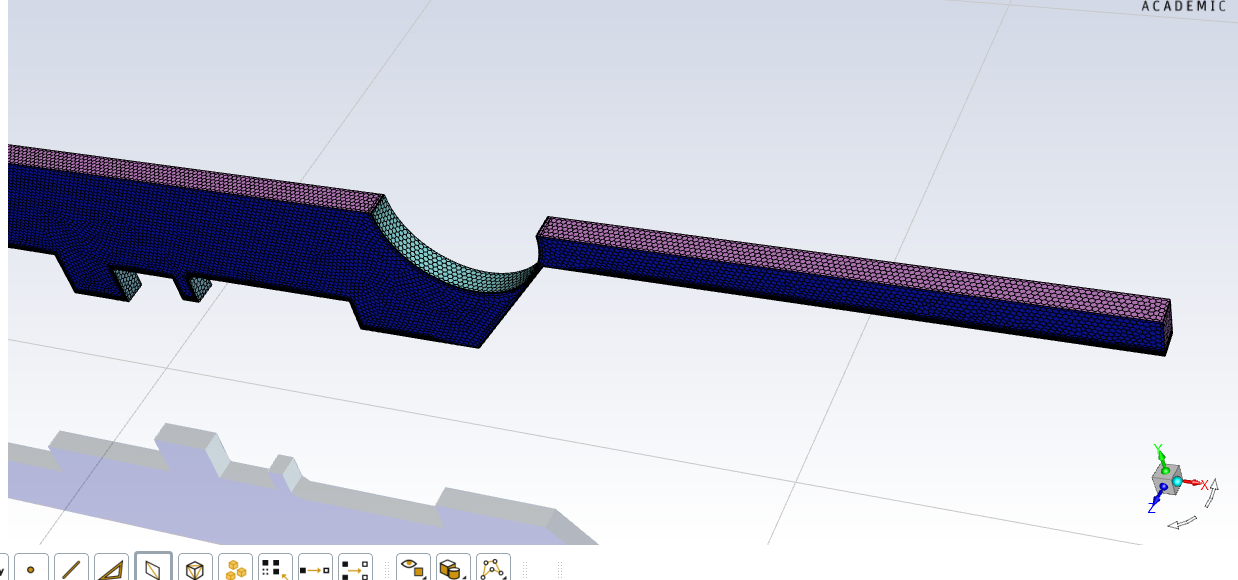

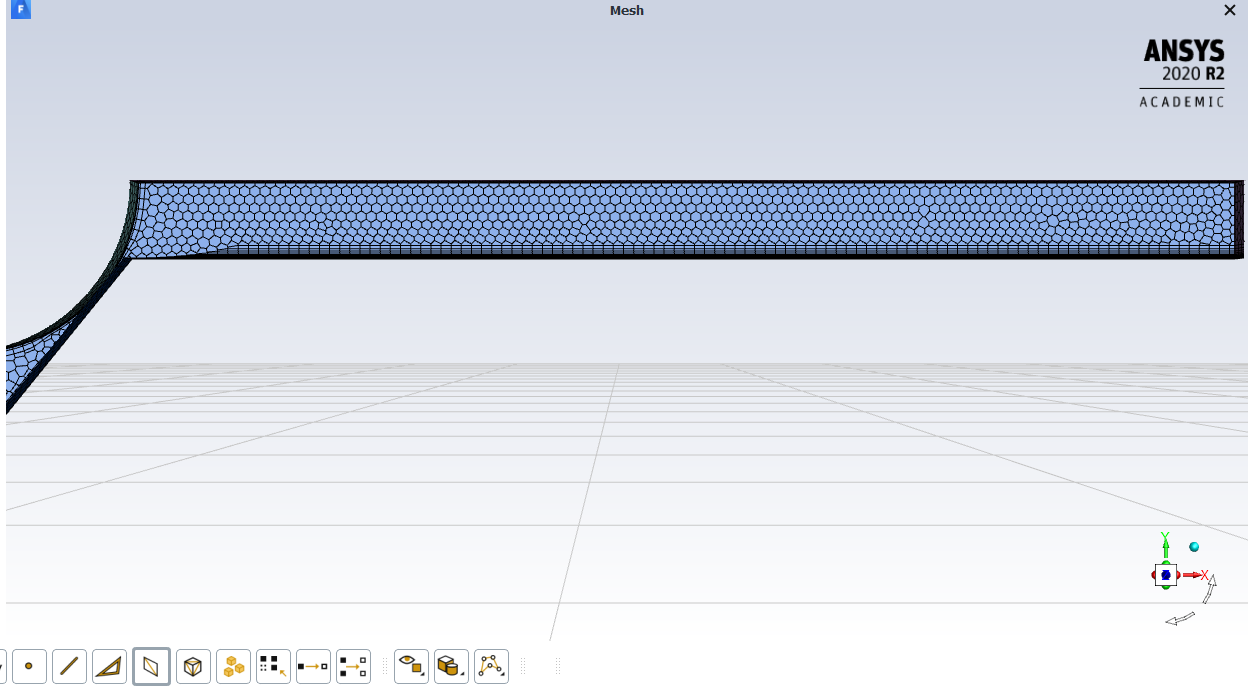

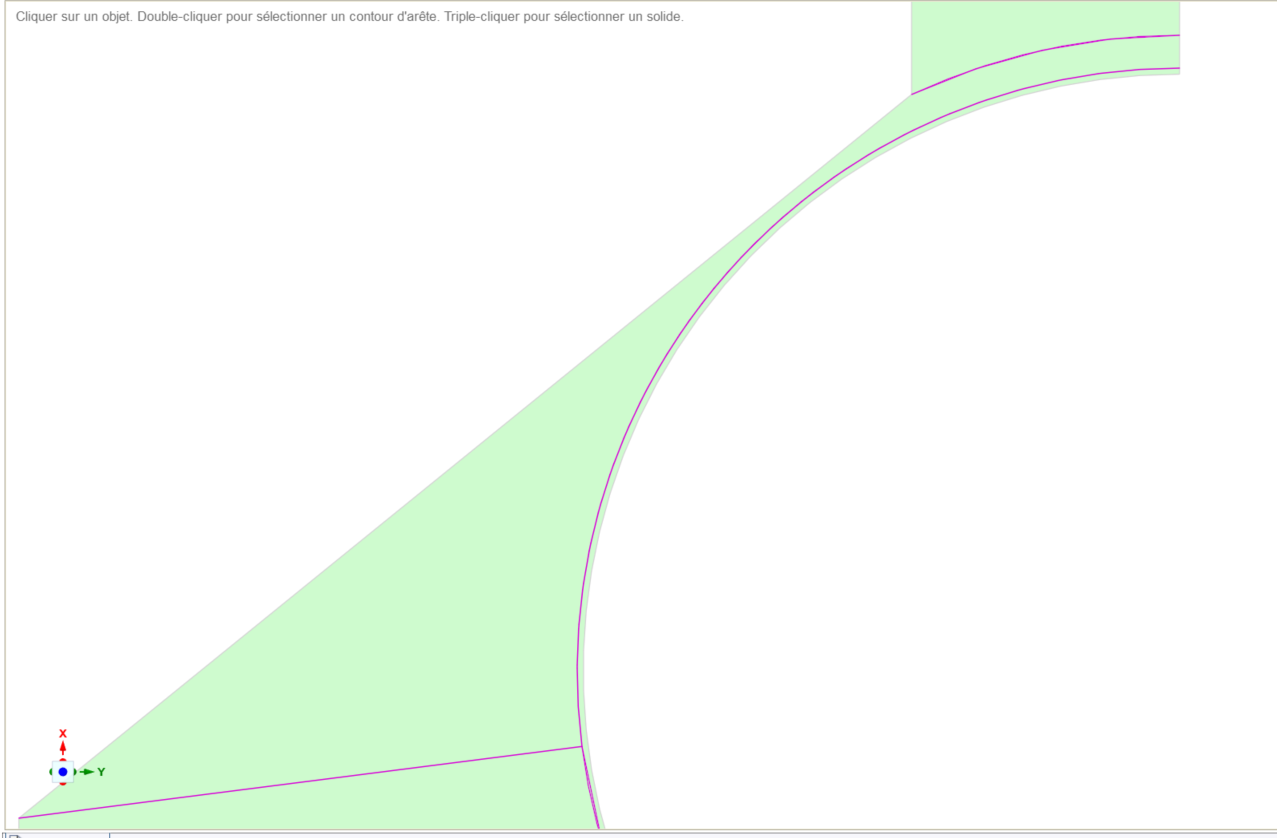

1- how to put a single element in the thickness? (if it is possible)

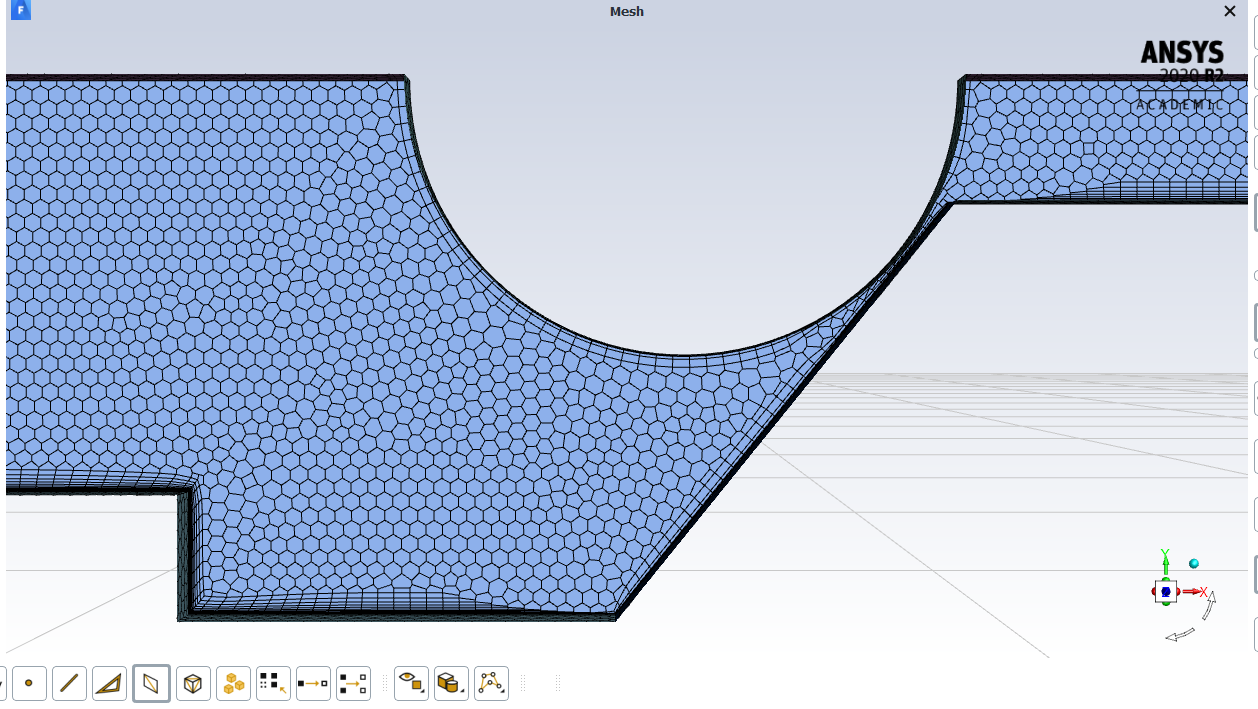

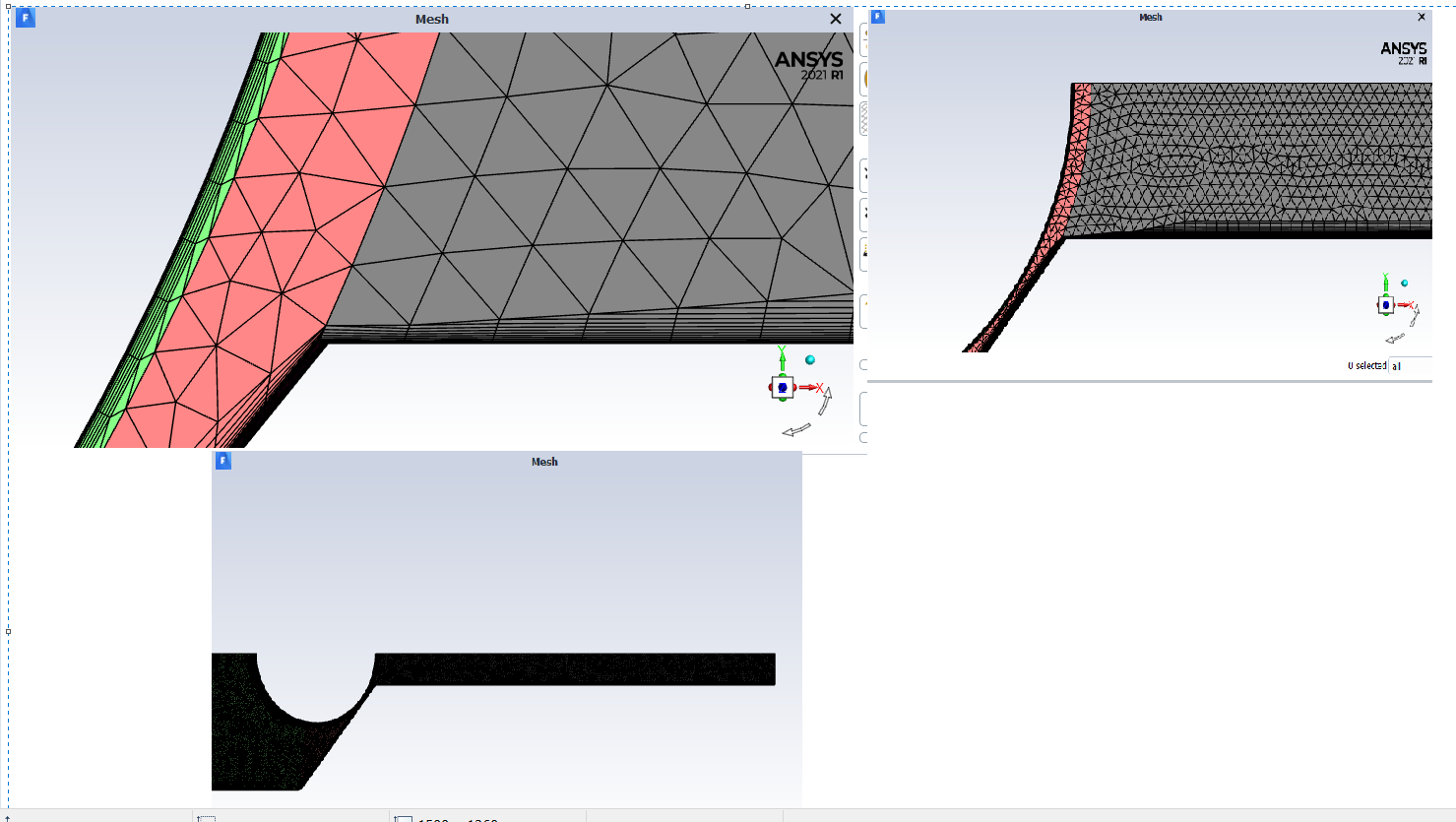

2- the boundary layer (picture 3 and 4) is not continuous on the walls of the ball and the sidewall, doesn't this cause a problem?

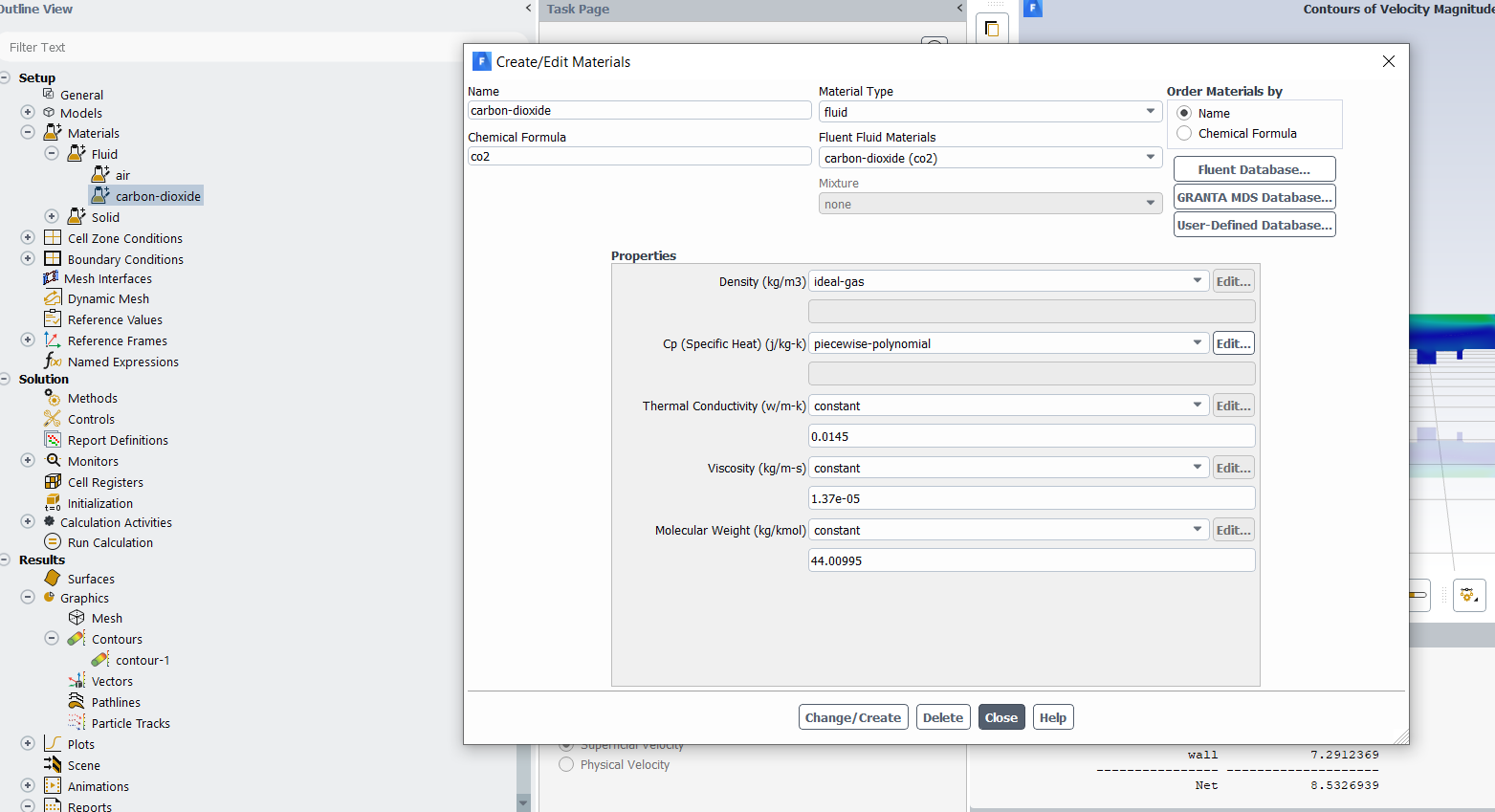

The calculation is static with compressible CO2, k-w sst turbulence model. I set all residuals to 1e-6 and it seems to have trouble converging at the first few iterations, should I be concerned?

June 4, 2021 at 11:17 amRob

Forum ModeratorThe inflation won't fit into the narrow gap so it's compressing and then losing layers. If the ortho quality is good you don't need to do anything. There's not an option for forcing the mesh to extrude from one side to the other (yet) so you either need to reduce the surface facet size or number of inflation layers if the quality is poor.

June 4, 2021 at 11:59 amJune 4, 2021 at 1:33 pmRob

Forum ModeratorHave a look at the flow field. I'd focus on immediately downstream of the valve and also the step.

June 4, 2021 at 2:04 pmEmperor

SubscriberI would like to reduce the number of boundary layer on the balle which is a wall, but I notice the application of boundary layer is done at the same time on all walls, is there any way to do it on the walls and then on the ball?

it is applied directly to all walls.

it is applied directly to all walls.

How can I put two boundary layers on both walls?

June 4, 2021 at 3:07 pmRob

Forum ModeratorHave a look in the Add Boundary Layer section, you look to be able to add multiple inflation sets using the surface labels.

June 5, 2021 at 9:59 pmEmperor

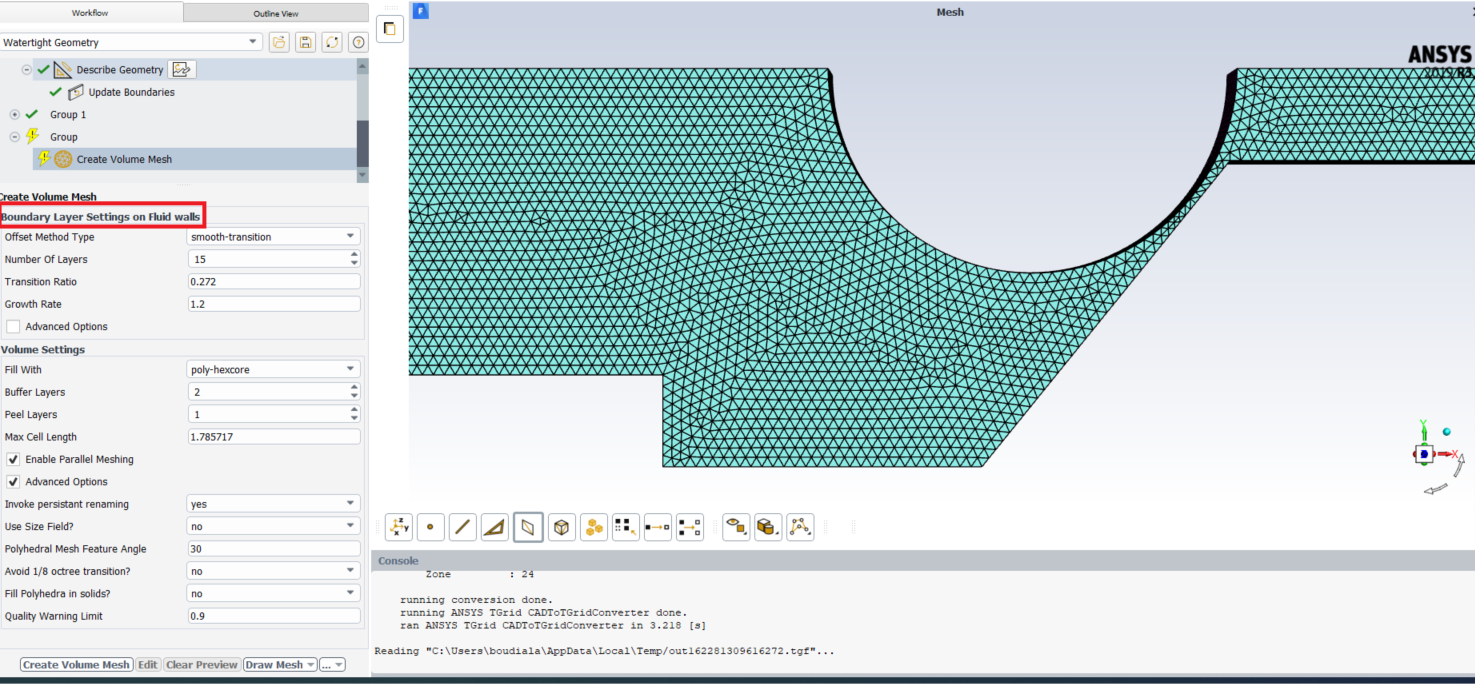

SubscriberI looked for the add boundary layer section, but there is none, I just have what is on the image below that allows you to add the boundary layer to all walls at once! I am on a 2019R3 version. Maybe there is an extra manipulation to do?

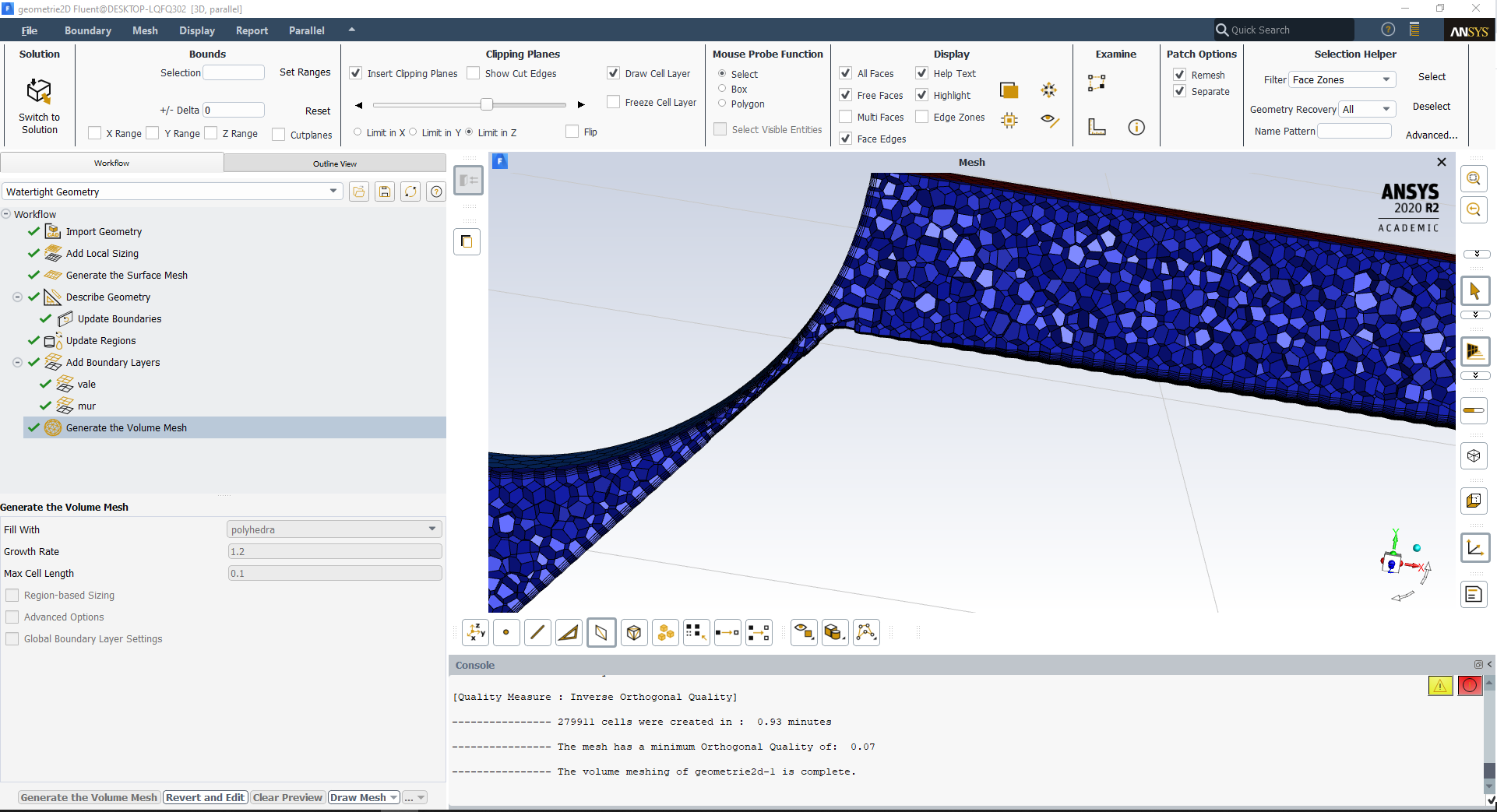

June 7, 2021 at 9:50 amEmperor

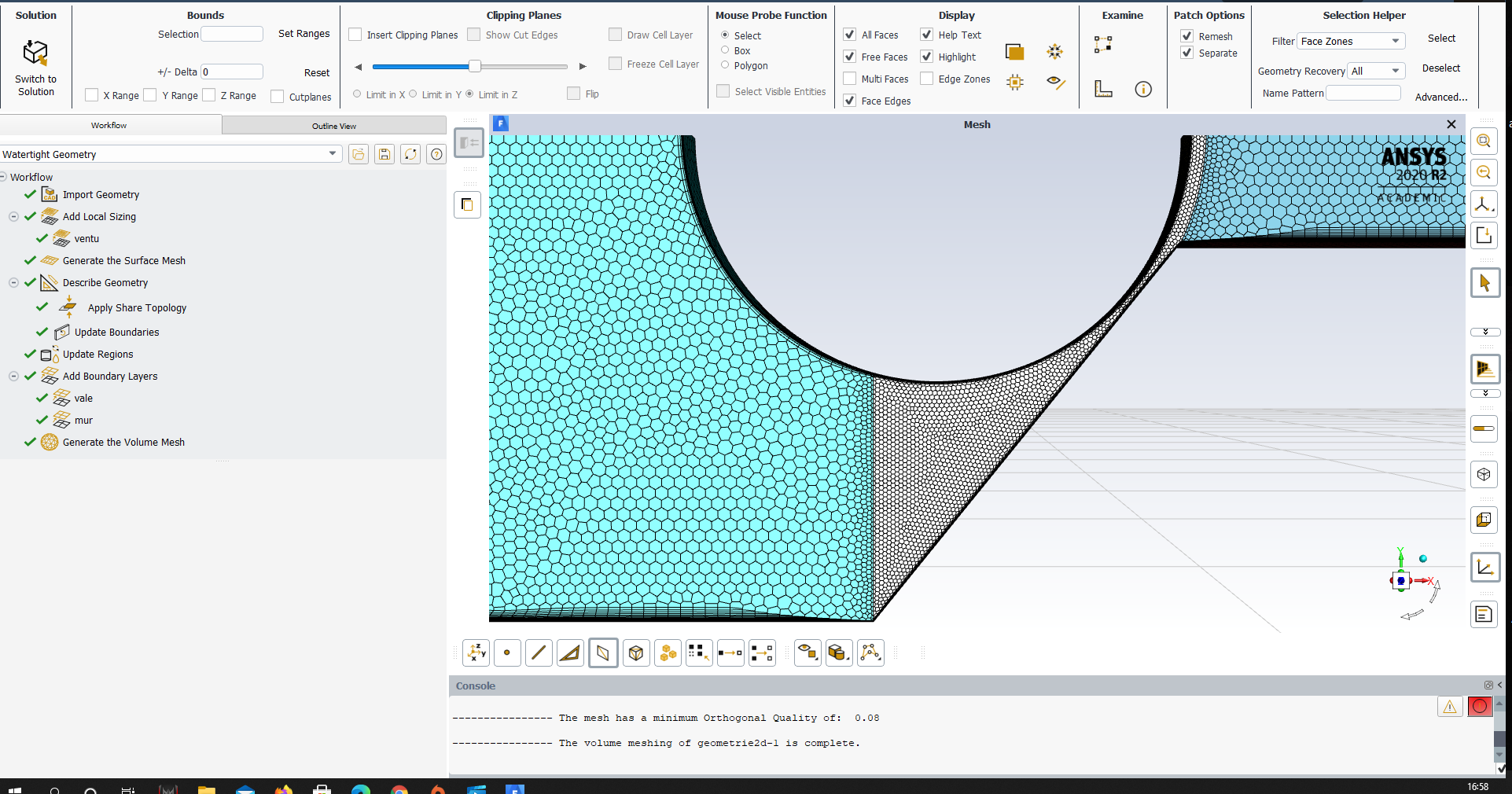

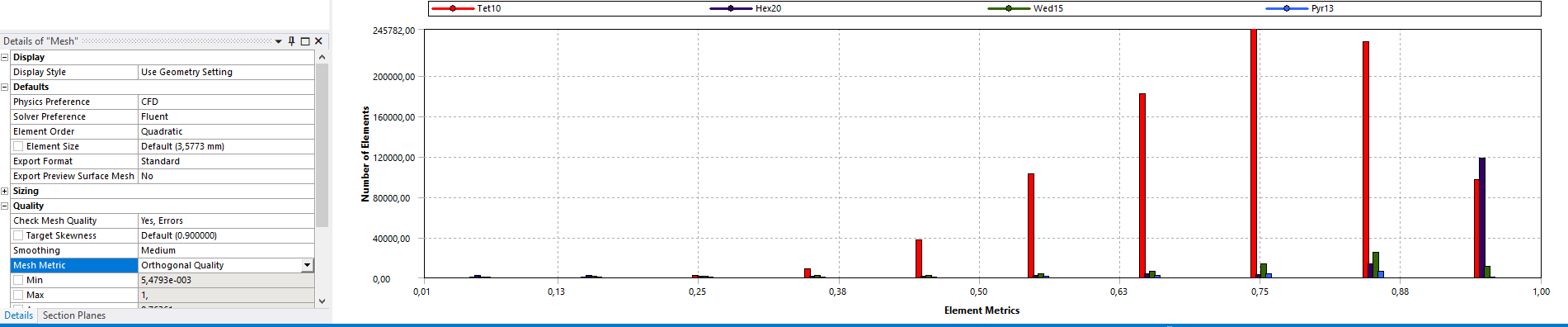

SubscriberHi, iIt seems that it is possible on the 2020R2 version and not the 2019. But I just ask about the minimum orthogonal quality, I think we should be at 0.1 and here I am at 0.06. But the output shows[Quality Measure : Inverse Orthogonal Quality]

---------------- 279911 cells were created in : 0.93 minutes

---------------- The mesh has a minimum Orthogonal Quality of: 0.07

---------------- The volume meshing of geometrie2d-1 is complete.

Is it a good mesh? Why is it different from the quality I had in the 2019 version yet it's the same features just the boundary layer changes?!?

June 7, 2021 at 10:40 amaitor.amatriain

SubscriberIn versions prior to 2020R2, when the cell aspect ratio within the boundary layer exceeds certain threshold, Fluent mesher splits the cells in two. This does not happen in the 202021 and 2021R1 versions, and it may be the cause of the variations that you are noticing.

June 7, 2021 at 11:52 amEmperor

Subscriberthank you for your answer. So the controlled mesh in the 2019 version would be more interesting? How could I then correct this on the 2020 version?

June 7, 2021 at 1:34 pmEmperor

Subscriberit seems that the transition ration plays an important role, knowing that I put 15 elements on the boundary layer and I am in smooth-transition, how is calculated the height of the first boundary layer? thank you

June 7, 2021 at 1:54 pmRob

Forum ModeratorThe boundary layer maths are covered in the manual, and cell height is generally a function of some of facet size, first cell height, last cell height and number of layers.

June 7, 2021 at 2:02 pmaitor.amatriain

SubscriberI personally prefer not to have the cells split in two.

Based on my experience, aspect ratio is not crucial in RANS simulations (of course, with some limits, even though I cannot imagine a good mesh in the outer region that has a maximum aspect ratio of 10.000 in the BL, for example). In the case of LES, there is something wrong if Fluent meshing performs the mentioned splitting (the initial mesh should have a maximum aspect ratio less than 10 and the correction should not be done).

In regards to the height of the first boundary layer, it depends on your application. The ideal situation is to have wall y+<1, although values between 1 and 10 are good for RANS simulations when no transitions model is used. In order to compute the height in dimensional variables, just type "y plus calculation" on the Internet and you will find some online calculators for your specific case.

June 7, 2021 at 2:12 pmEmperor

Subscriberthank you for your reaction.

the calculator will calculate the value of y necessary to have y+ = 1. I would like to know how to enter the value of y in the calculator because? Is it in function of transition ratio?

June 7, 2021 at 2:18 pmaitor.amatriain

SubscriberI see no option of choosing the height of the first layer in the smooth-transition offset method. Just number of layers, transition ratio and growth rate.

June 7, 2021 at 2:26 pmEmperor

Subscriberok, I'll try to see if there is a relation between all this!

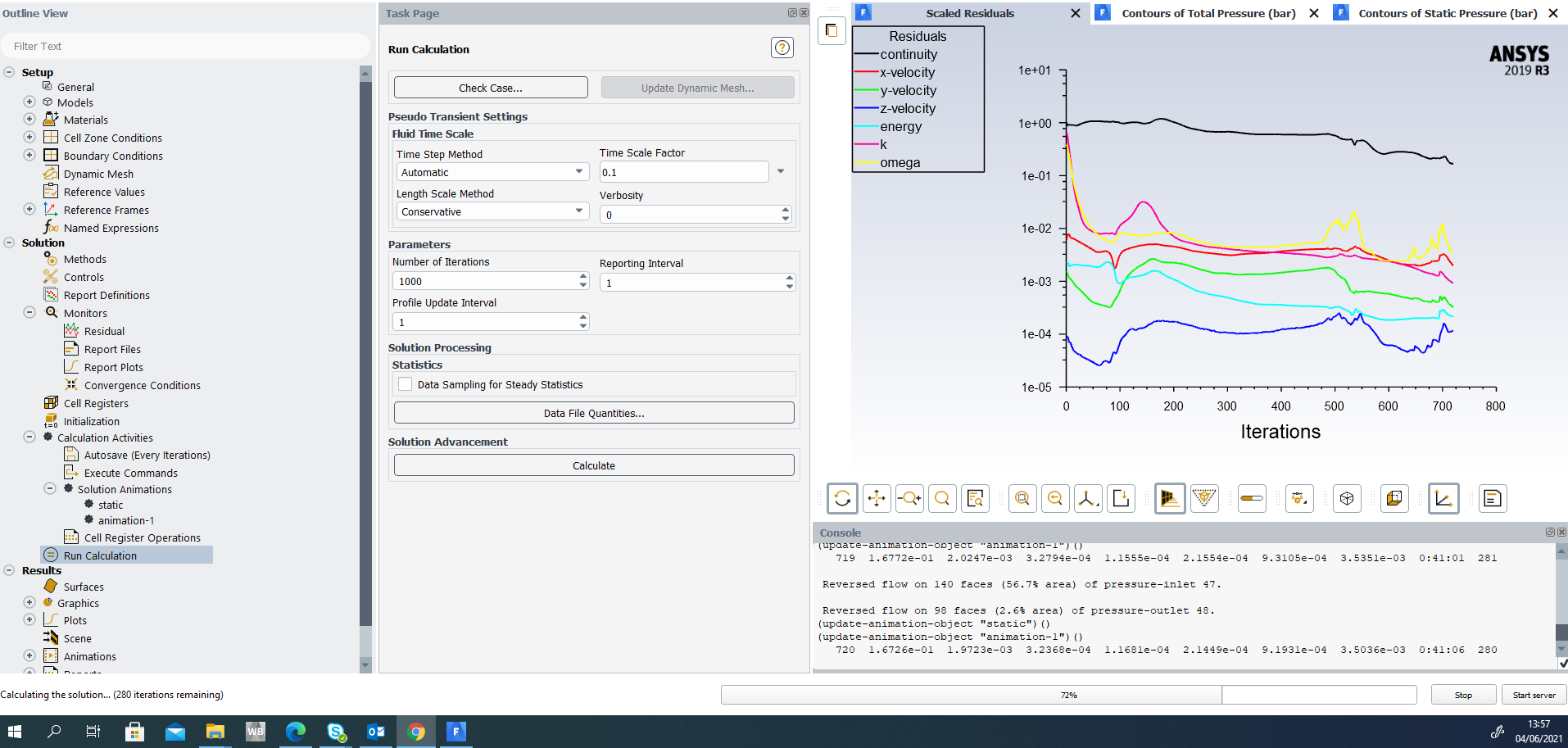

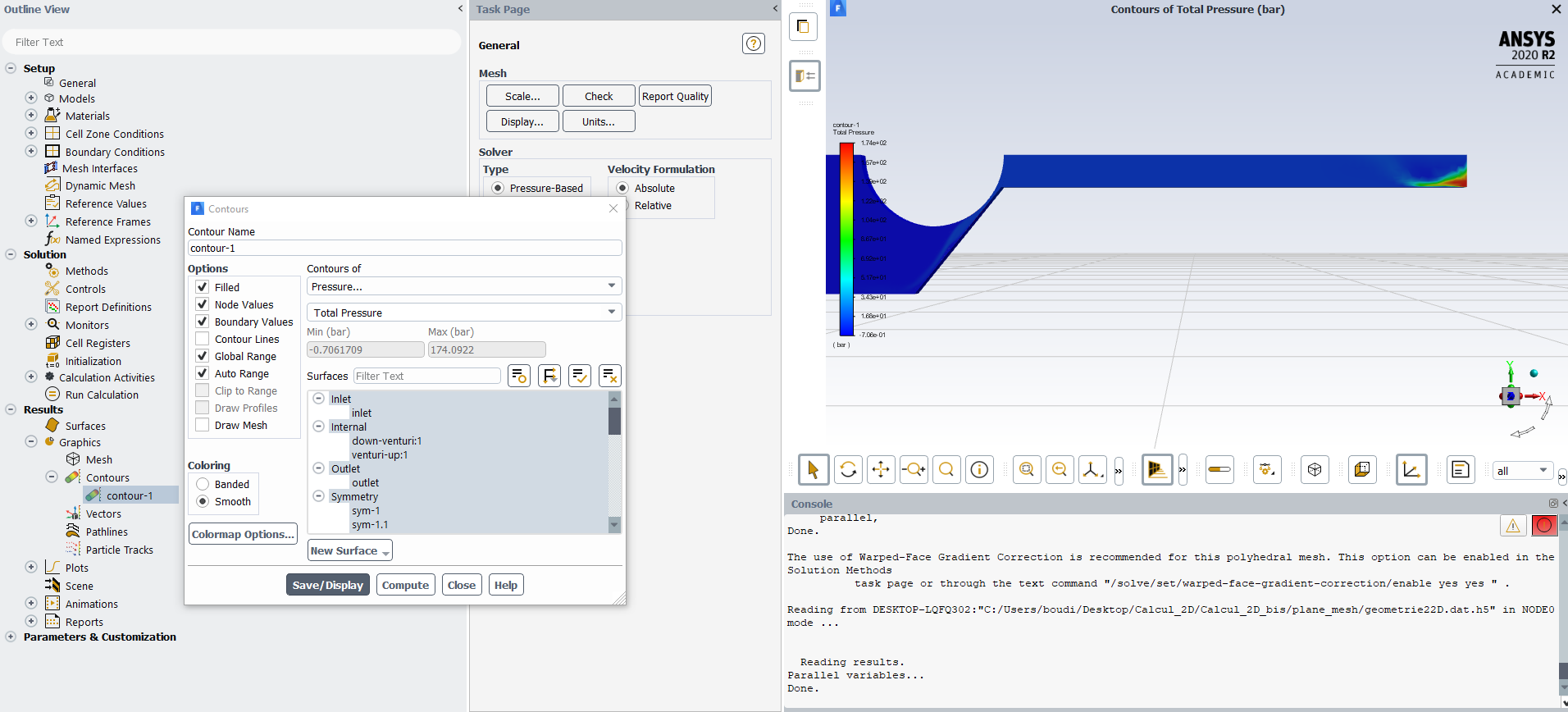

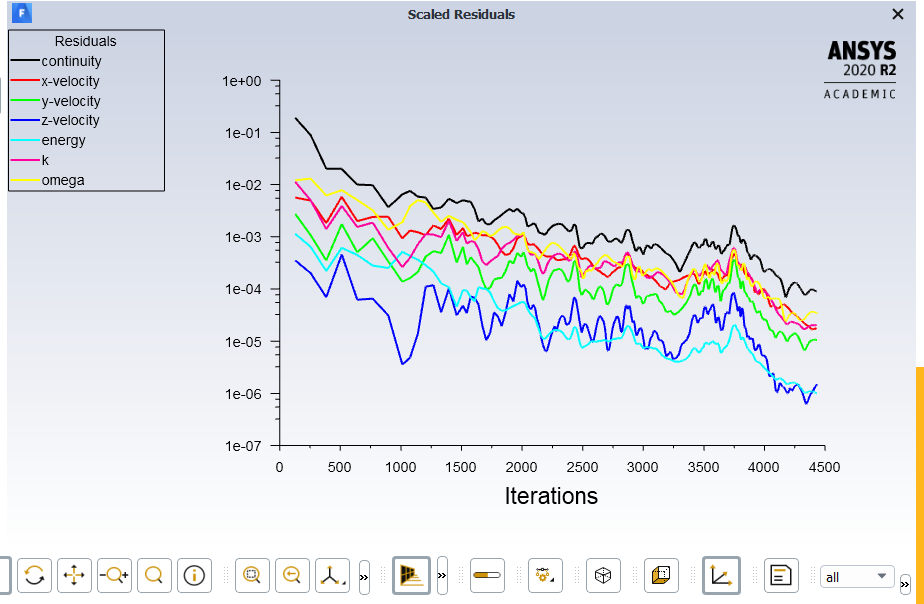

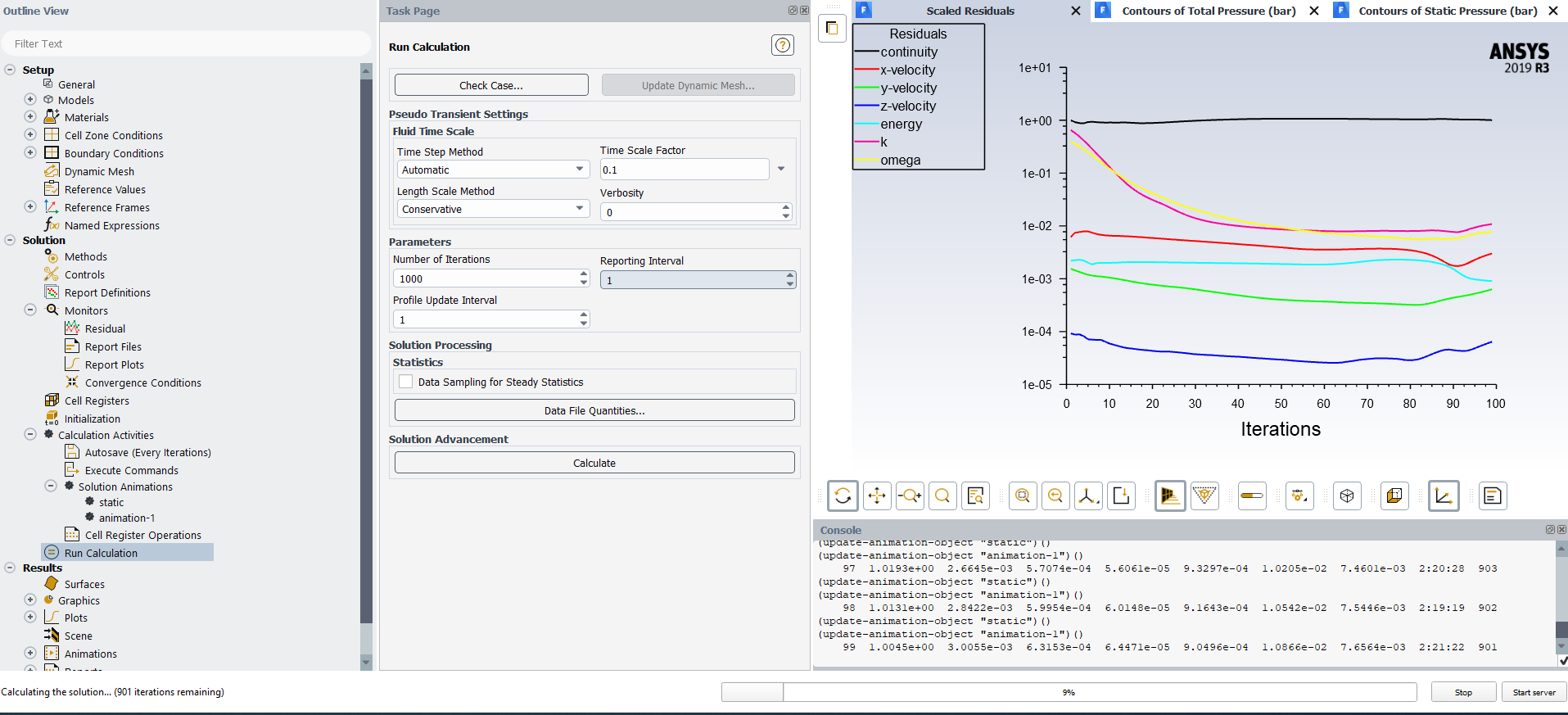

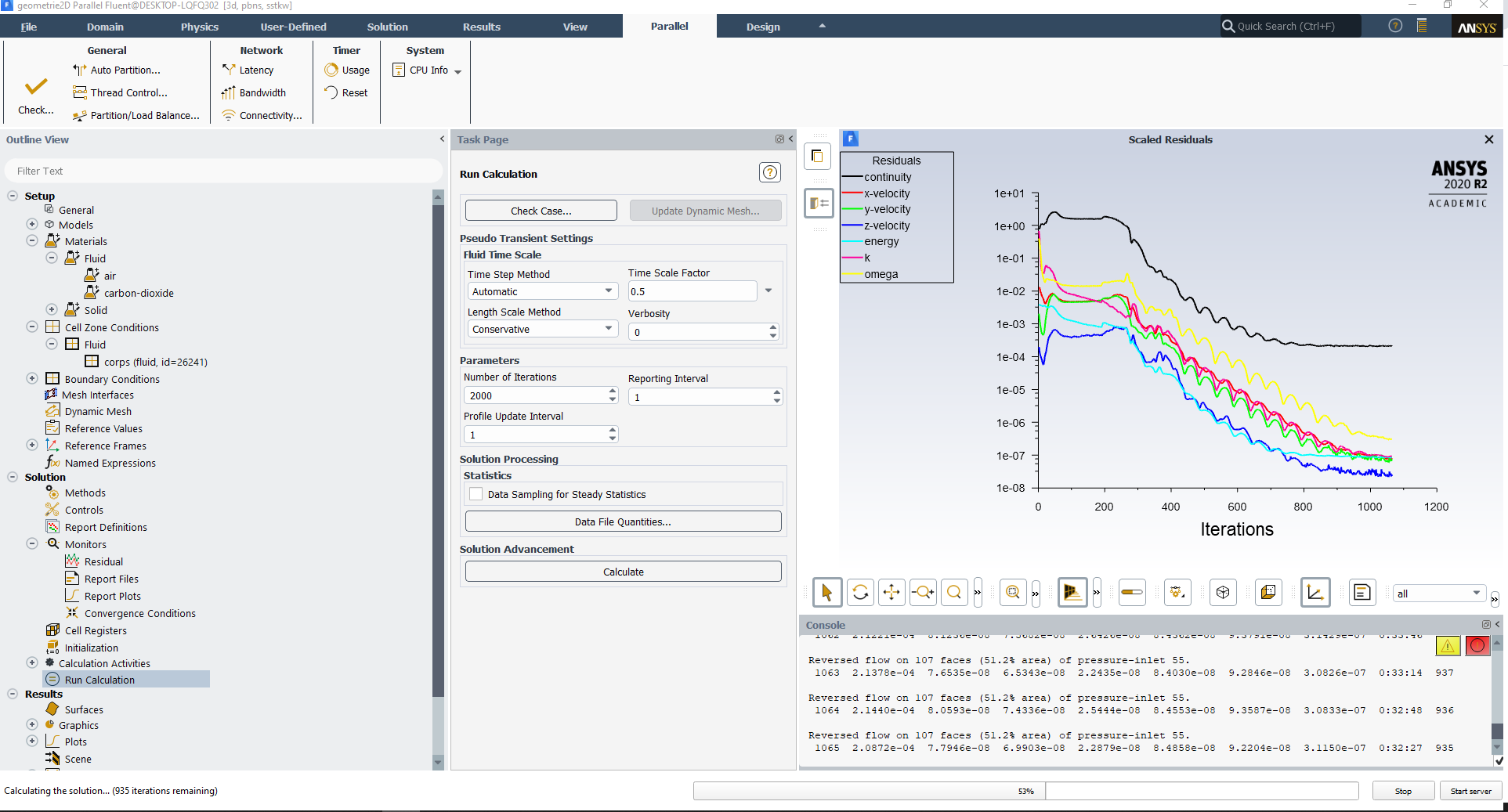

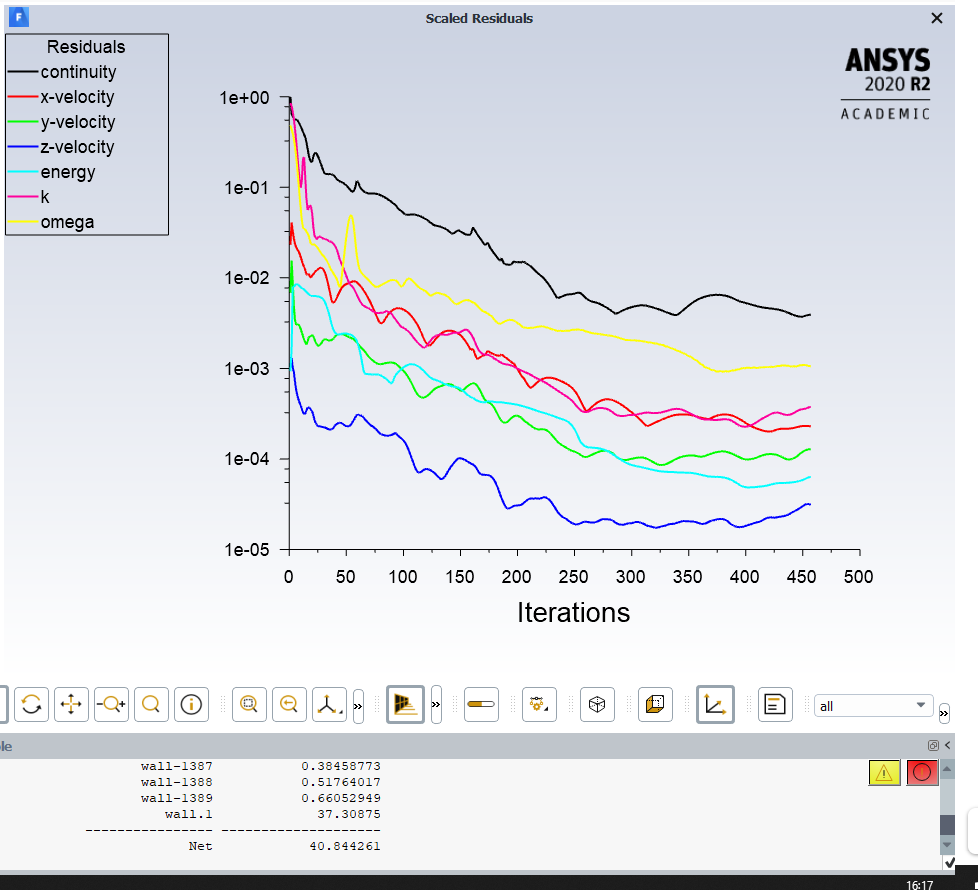

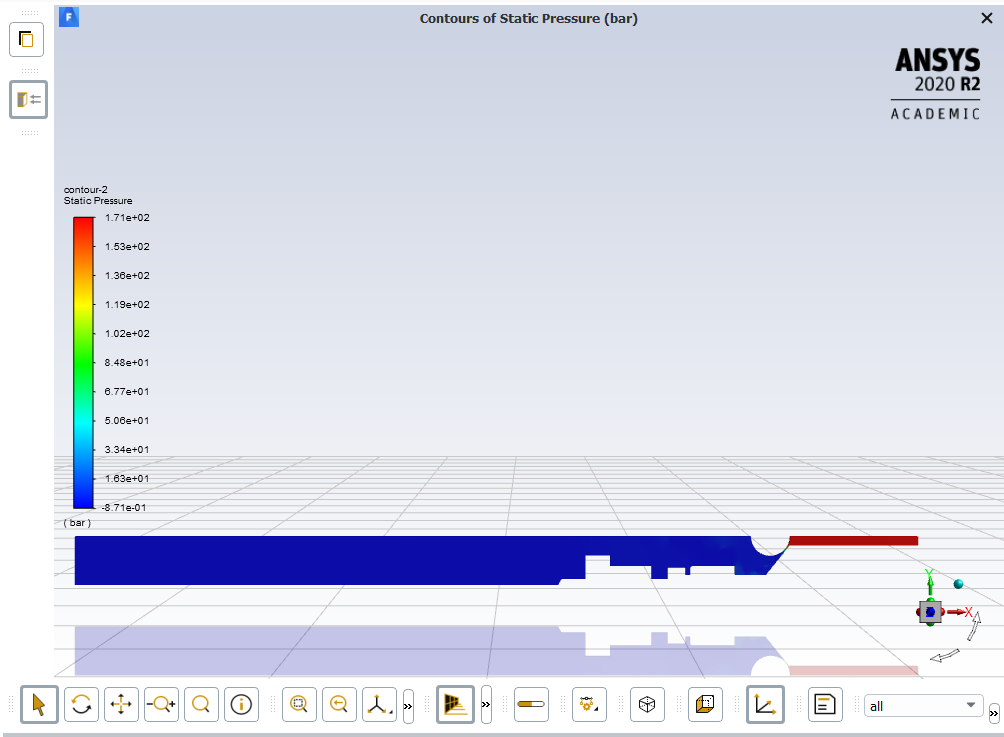

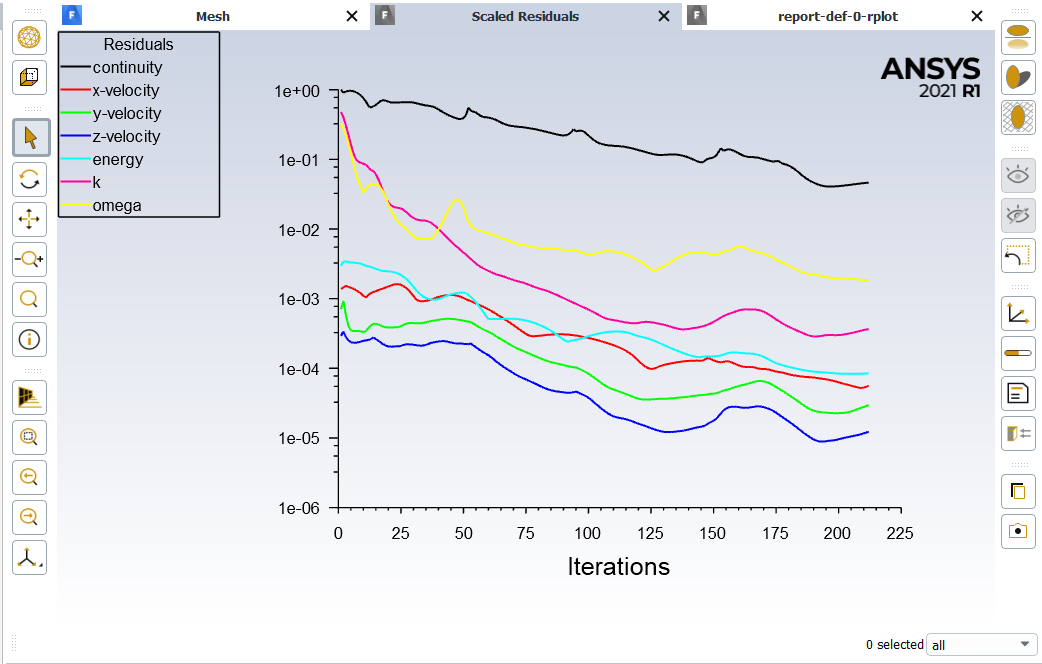

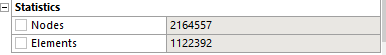

So I remeshed and I got an orthogonal quality of 0.15, which seems good. So I restarted the static calculation but the residual continuity seems to have stabilized even though I asked for a residual value of 1e-4 and it stabilizes before. Should I exploit this result? Is there anything else that can be modified so that the residual continuity converges to the imposed value?said "Take a look at the flow field. I would focus on immediately downstream of the valve and also on the walk." How? It's a compressible gaz (so ideal gaz)

June 7, 2021 at 2:30 pmaitor.amatriain

Subscriber2e-4 for a time scale of 0.5 seems okay. Do you see something in the results that does not convince you?

June 7, 2021 at 2:39 pmEmperor

Subscriberwhat bothers me is that the continuity residual does not reach the value of 1e-4

June 7, 2021 at 2:43 pmaitor.amatriain

SubscriberWhich value is reached when you set time scale to 0.1?

Convergence is usually good if continuity residual is less than 1e-3.

June 7, 2021 at 2:52 pmEmperor

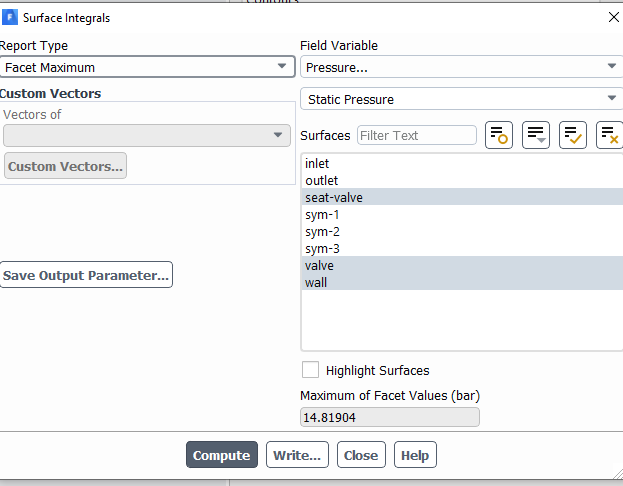

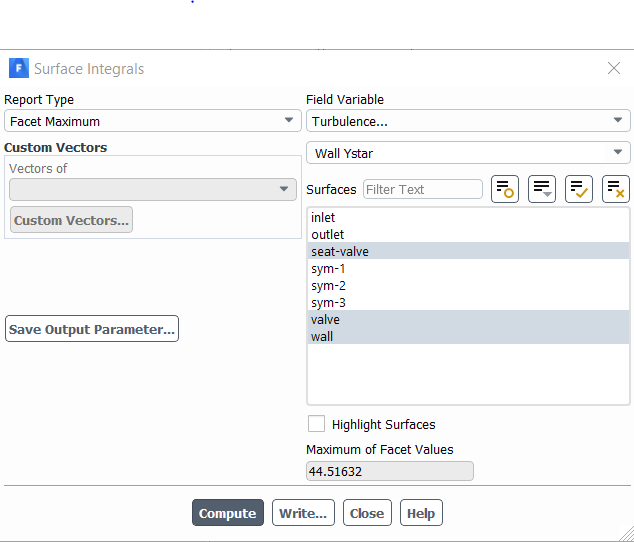

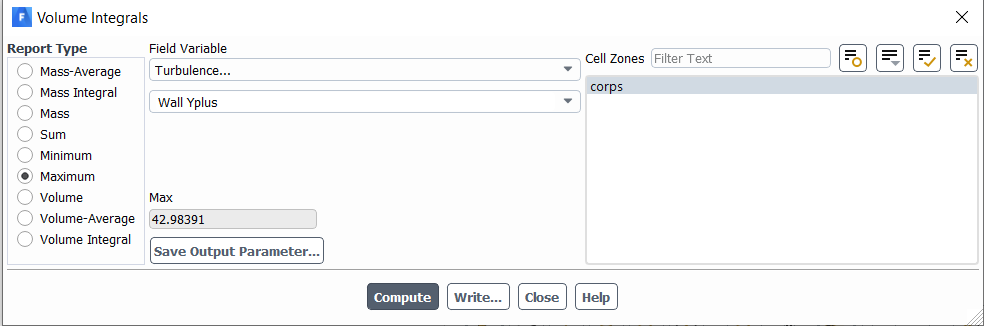

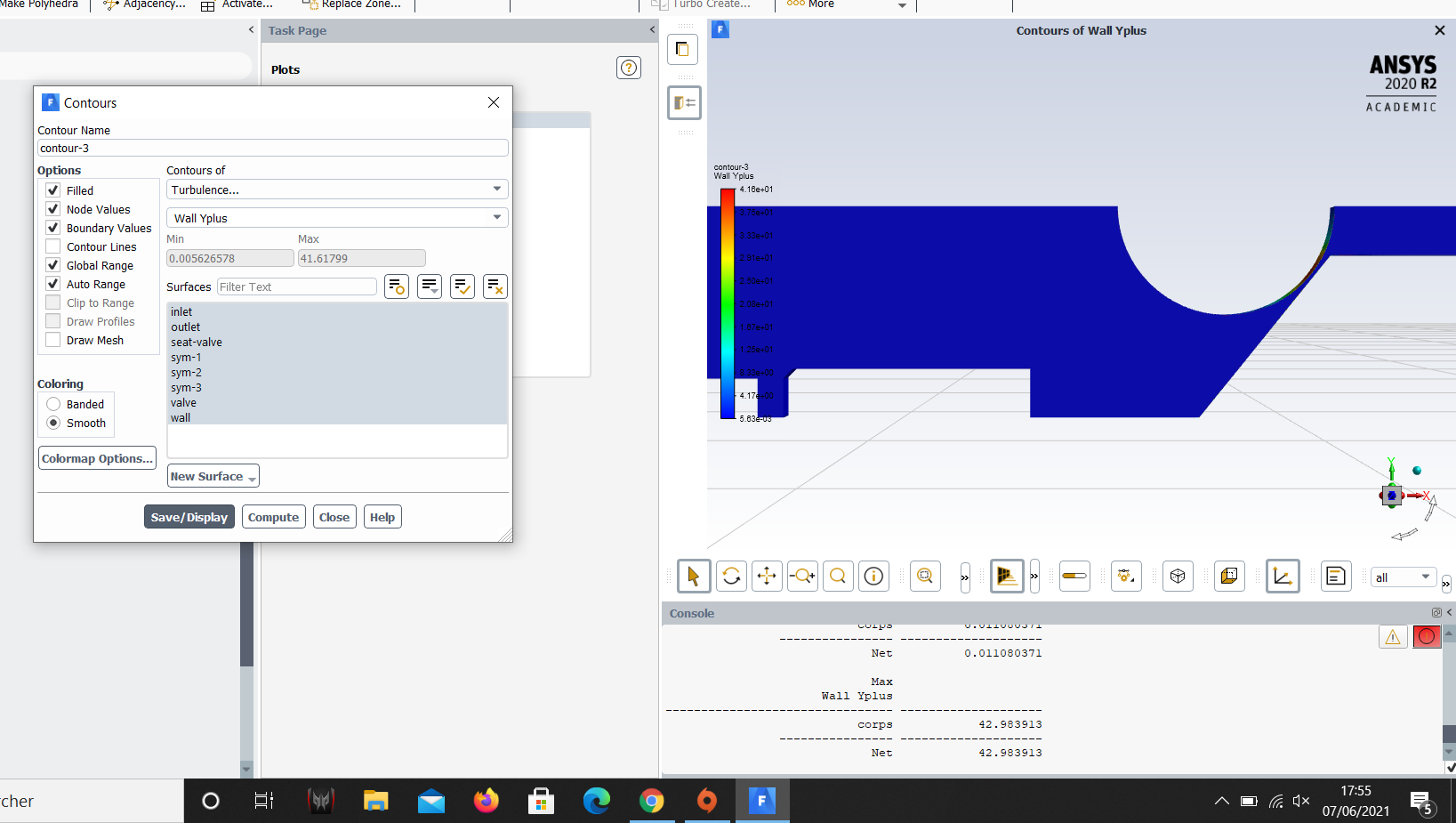

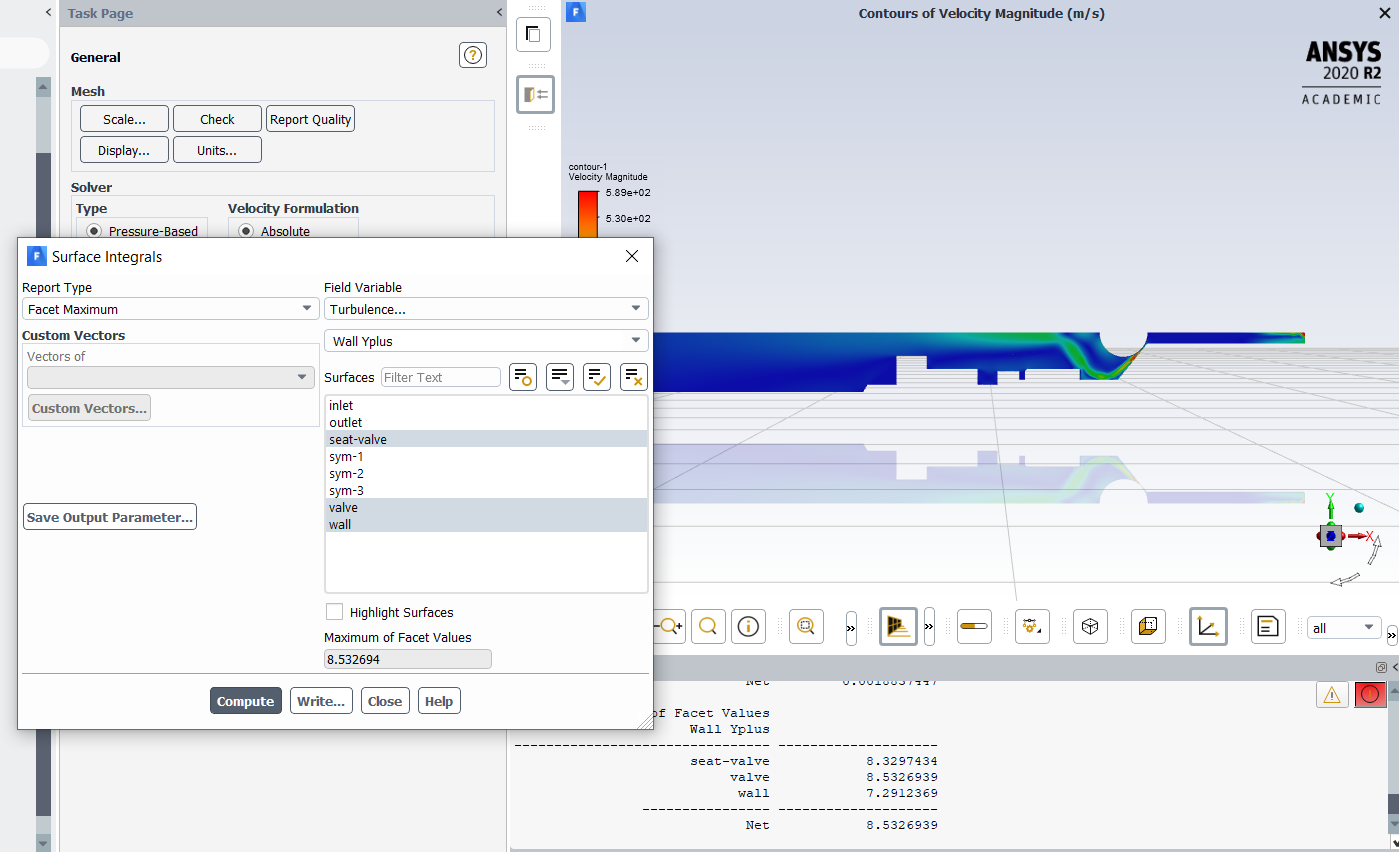

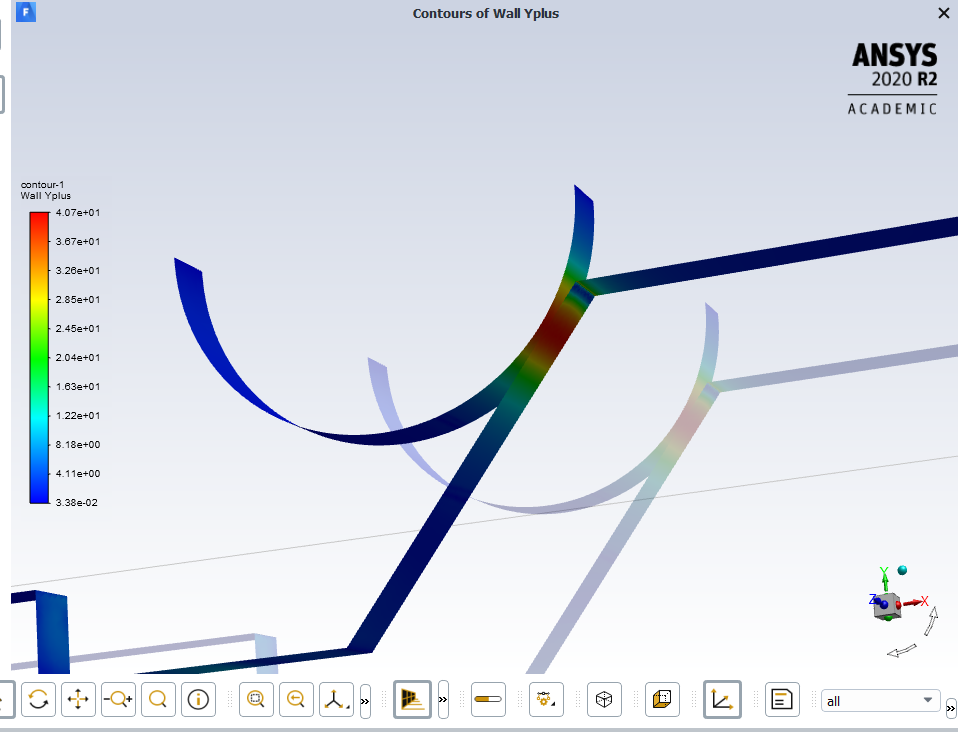

Subscriberthank you for your help!!! So I can consider that my calculation has converged in this case, I just wanted to check if I could reach the convergence at 1e-4. I have another question concerning the verification of the value of y+. Do I have to check it on all the walls of my model? Is it in the surface integrals (of the walls) or in the volume integrals? Should I check the maximum or the average?

June 7, 2021 at 3:09 pmaitor.amatriain

SubscriberYou should check this on all walls that are important in the flow. A visual inspection is enough in the majority of the cases.

June 7, 2021 at 3:20 pmJune 7, 2021 at 3:26 pmaitor.amatriain

SubscriberTurbulence - Wall Yplus

June 7, 2021 at 3:34 pmRob

Forum ModeratorAnd plot on the boundary values on the wall(s). If you need additional resolution then use adaption.

June 7, 2021 at 3:57 pmJune 8, 2021 at 1:45 pmRob

Forum ModeratorIt depends, you want around 1 for a really accurate drag & heat transfer prediction and 30-300 ish for a good solution.

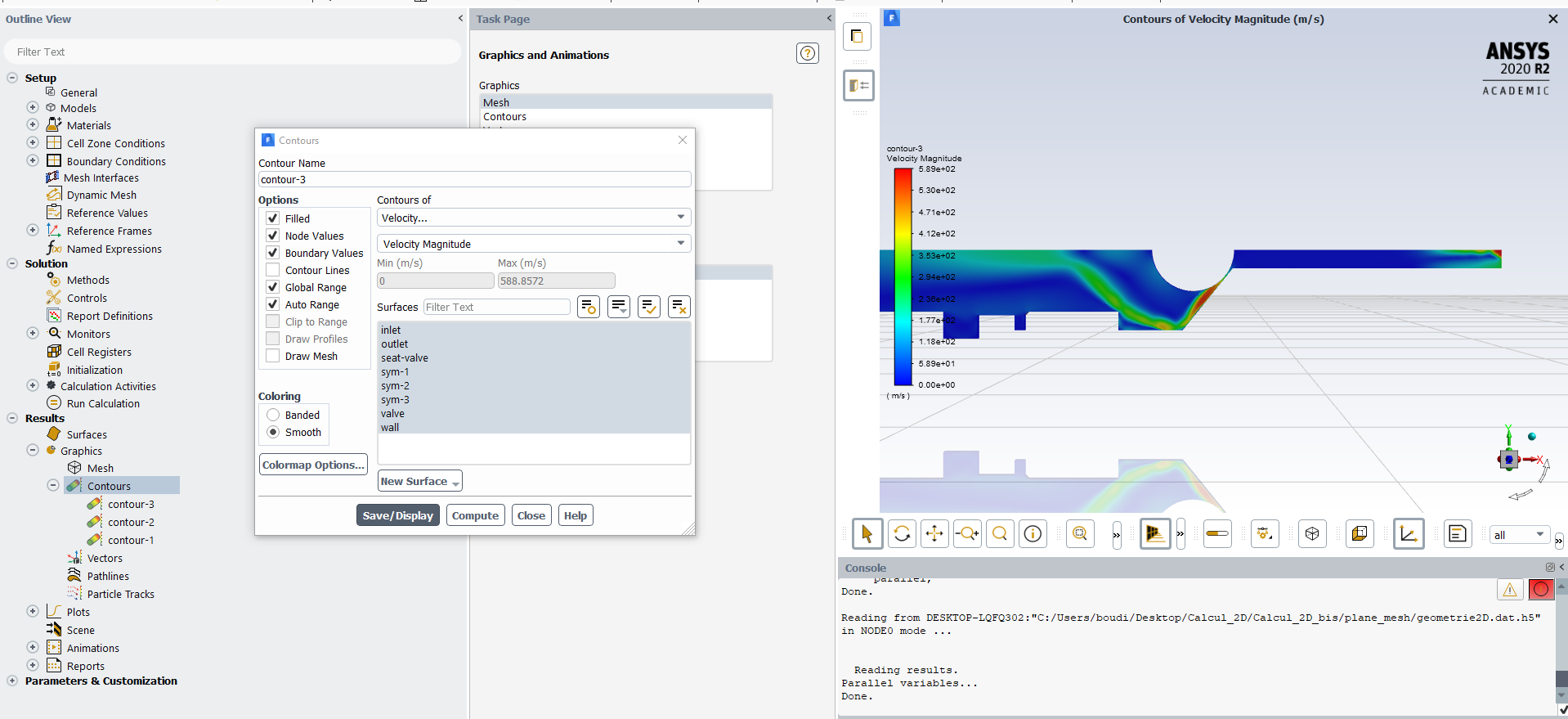

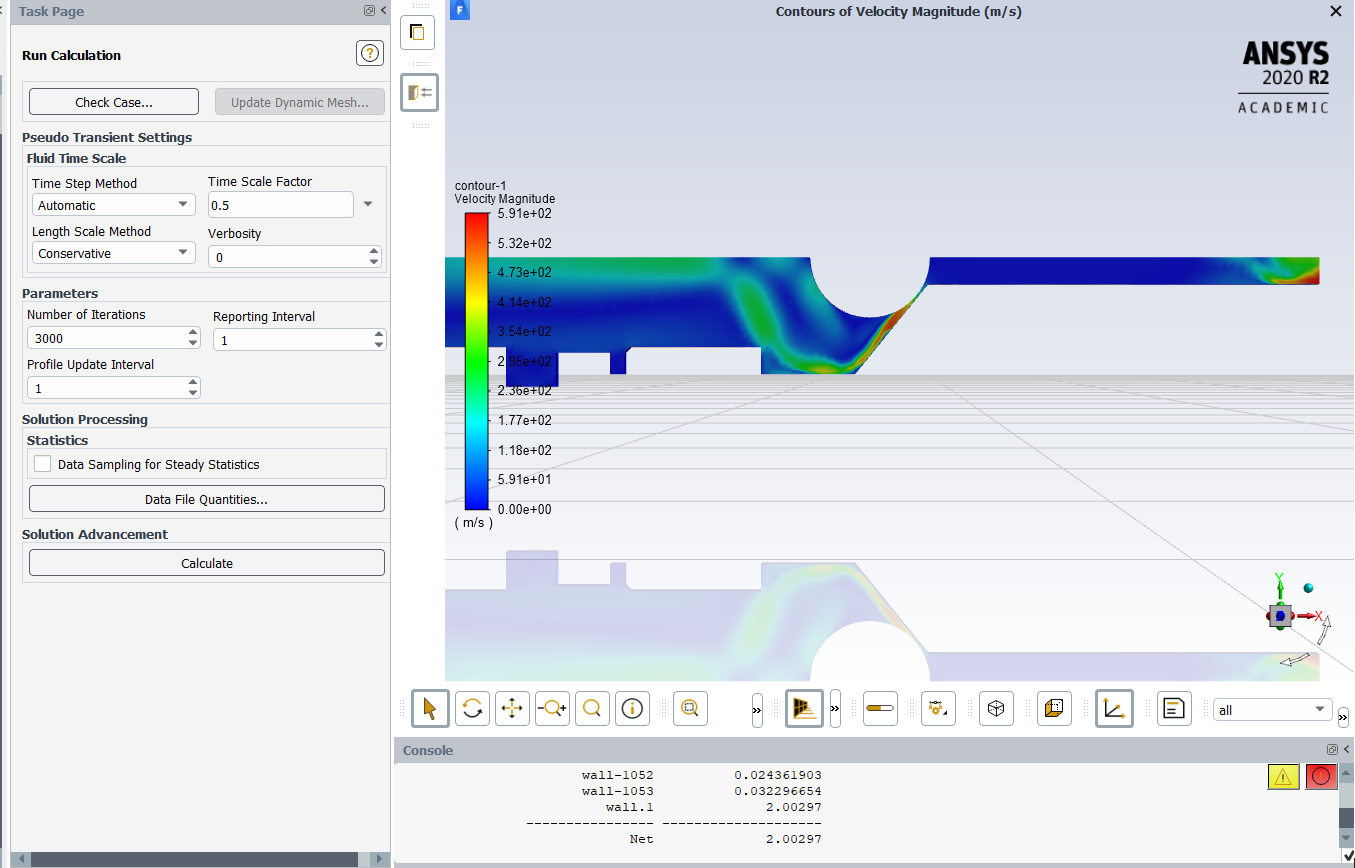

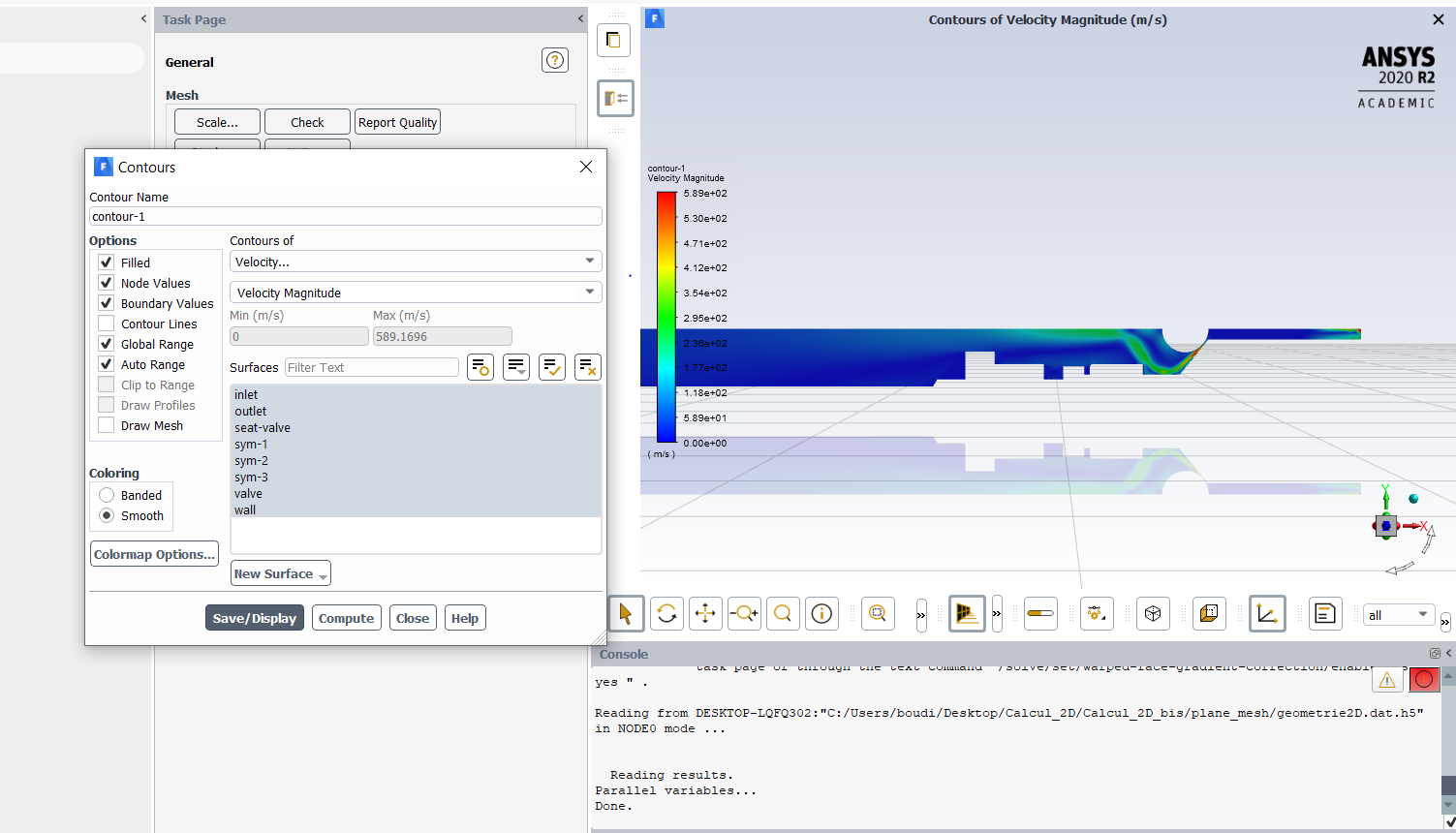

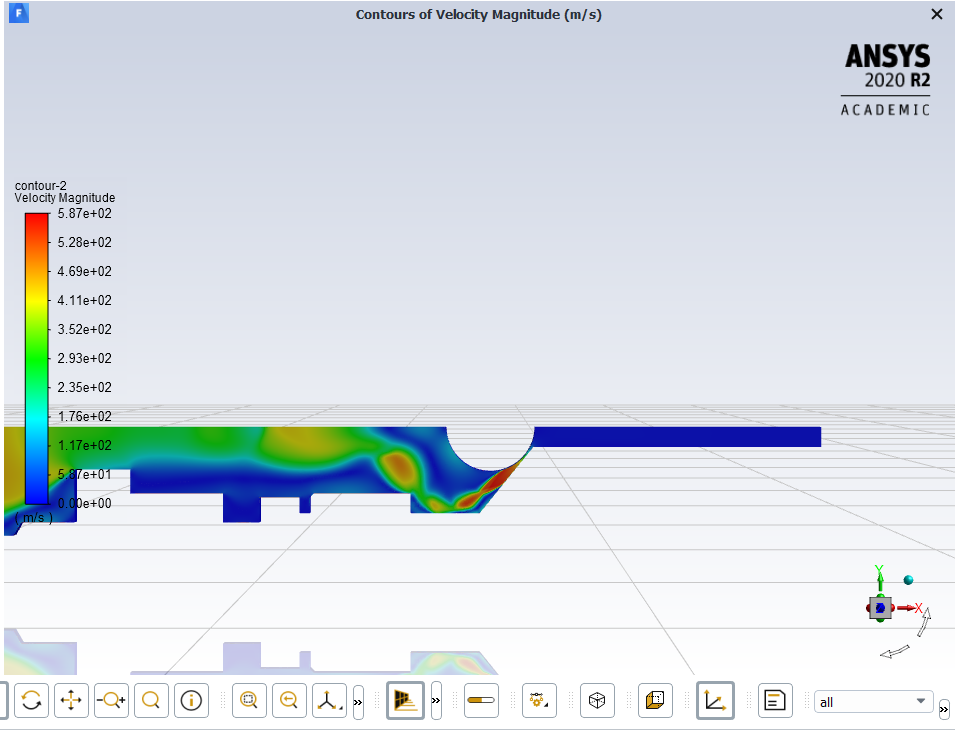

Check your inlet velocity - it looks very strange.

June 8, 2021 at 2:32 pmEmperor

Subscriberthe velocity is directly post processed, otherwise in input I have 170bar and at output I have 0bar. So I think that the value of the speed is high for this reason

June 8, 2021 at 2:42 pmaitor.amatriain

SubscriberI think that Rob's comment is because it is non-uniform.

June 8, 2021 at 3:58 pmRob

Forum Moderator^^ What says.

June 9, 2021 at 7:13 amEmperor

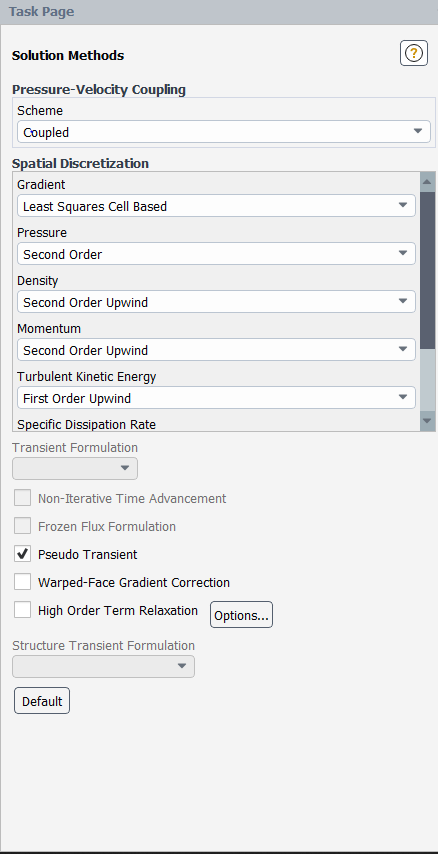

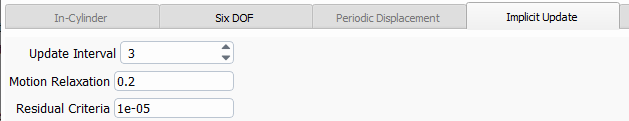

Subscriber,I don't understand why the speed profile has this tendency. I changed the size of the first boundary layer to y+ = 1, for the moment I'm still at y+ = 8 (I need to reduce it a bit more). Do you think it is maybe because I am on a pressure based solver and not a density based solver (because the velocities are very high and I think we exceed the speed of sound)? The parameters of the solver are below. I would also like to know whatand say.

June 9, 2021 at 7:44 amaitor.amatriain

SubscriberCould you please provide us with the following?

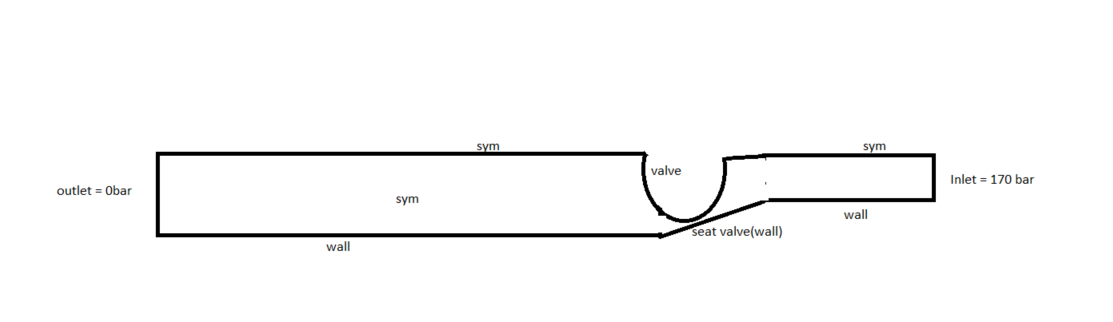

1) A sketch of the boundary conditions

2) Pictures of the mesh (cuts with x and y axes), specially in the region near the inlet.

June 9, 2021 at 8:00 amJune 9, 2021 at 8:17 amaitor.amatriain

SubscriberVelocity profile has no sense at the inlet. This is essentially a converging-diverging nozzle and velocity should be constant before the seat valve. Moreover, based on my experience with nozzle flow, I think that the mesh should be finer in the converging-diverging zone, even though this does not explain the strange velocity profile at the inlet.

Have you tried a 2D geometry? In RANS 3D and 2D results will be the same, and in 2D a finer mesh can be obtained with a lower cell count.

EDIT: Based on the "0 bar" BC at the outlet, I guess that you are setting a operating pressure different to 0. I think that it would be a better option to set it equal to 0:

8.14.3. Setting the Operating Pressure (ansys.com)

June 9, 2021 at 8:36 amEmperor

SubscriberI'm really new to ansys fluent mesh, I'm used to mechanical where if I want to make the mesh finer in an area of a body, I divide the body with the shared topology and refine that area. But in the fluent mesh how do I refine that area? Finally how can I get a clean mesh for good results? I didn't try a 2D mesh directly, I took a 2D face that I extruded (the goal is to work on a 3D model more complex than that)

June 9, 2021 at 8:38 amJune 9, 2021 at 8:40 amaitor.amatriain

Subscriber

In ANSYS SpaceClaim, the easiest option is to divide the geometry in different solids and create a group for each solid. Then, you can select mesh size of each body by means of "Body Sizing".

June 9, 2021 at 8:46 amEmperor

SubscriberShould I also use the shared topology?

June 9, 2021 at 8:58 amaitor.amatriain

SubscriberI am used to apply share topology in ANSYS SpaceClaim.

June 9, 2021 at 2:50 pmEmperor

SubscriberI tried the shared topology but I have the impression that it does not work well with the fluent mesher (I know it works with the workbench mesher), the mus of the shared topology which are supposed to be interiors it takes it as walls and it adds a lot of other useless zones so you have to sort everything by hand?

June 9, 2021 at 3:02 pmJune 9, 2021 at 3:04 pmaitor.amatriain

SubscriberI have never had any problem with Share Topology and Fluent Meshing. Concerning your comment about the zones, forget about the zones that are shown after creating the mesh. Just create groups with the zones that you want to use for something (e.g. inlets, outlets, boundary layers...)

June 11, 2021 at 10:26 amEmperor

Subscriberthe shared topology worked. I was able to get a result! Thanks for your help, it gives me hope.

However, the speed profile is still suspicious. Shouldn't I switch to a density-based solver? I have high input velocities, around 580m/s which gives a mach number around M=1.7 (supersonic regime).

June 11, 2021 at 10:28 amJune 11, 2021 at 11:00 amRob

Forum ModeratorPressure based is good for Mach 2-3 I'd only move to Density based for travelling shocks or much higher speeds.

June 11, 2021 at 12:02 pmEmperor

Subscriberhow to have a good velocity profile for this compressible fluid? I even set the viscosity on "sutherland".

June 11, 2021 at 12:30 pmRob

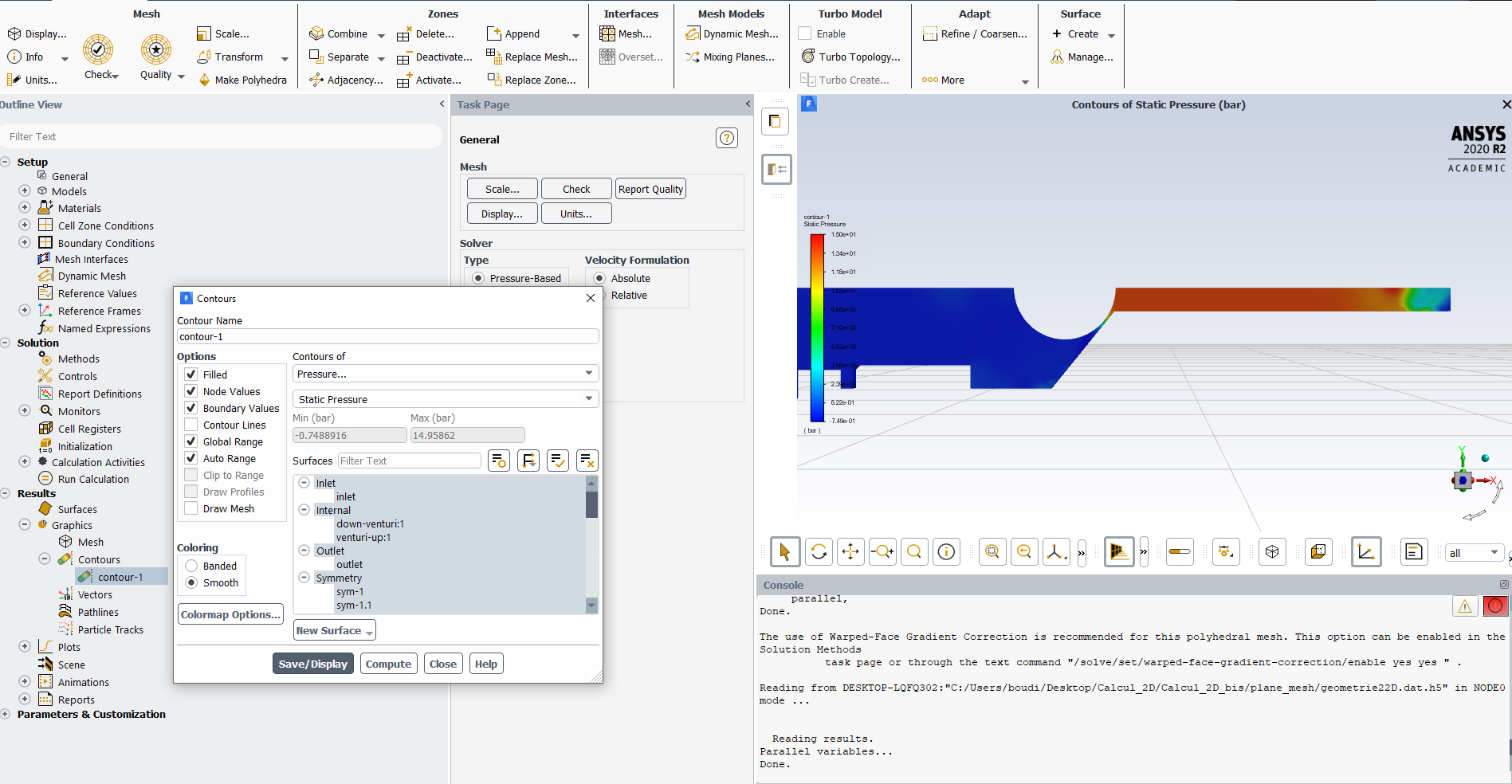

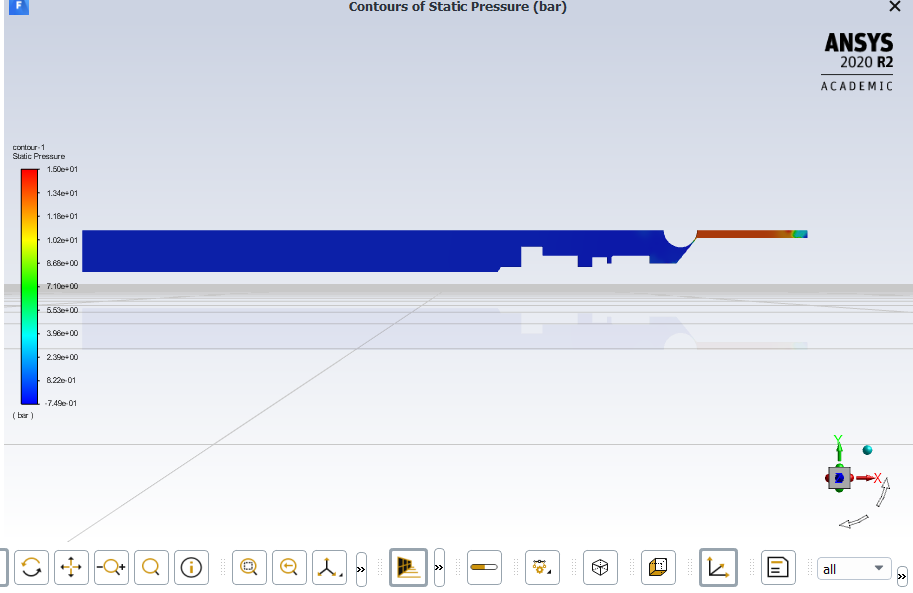

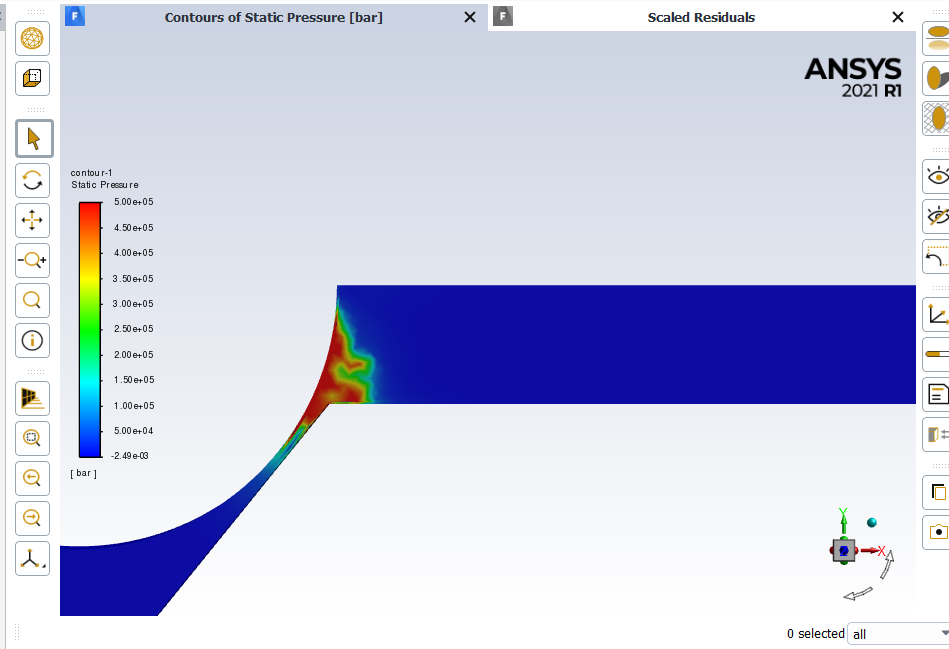

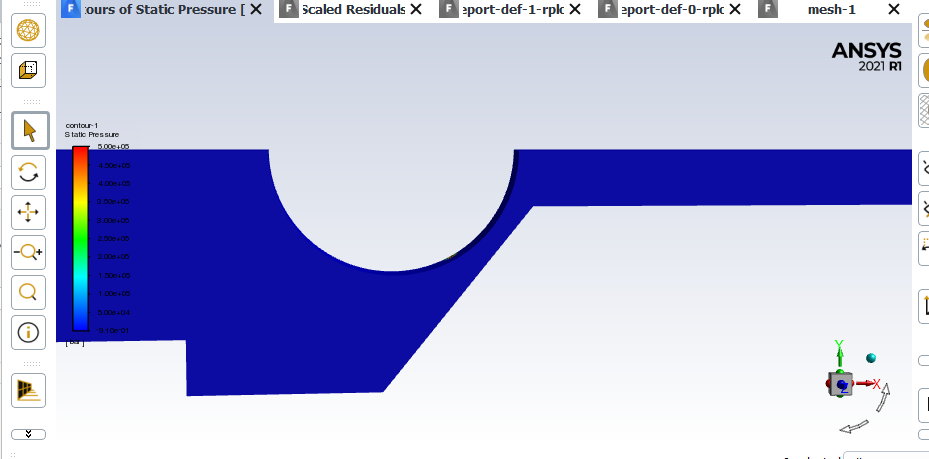

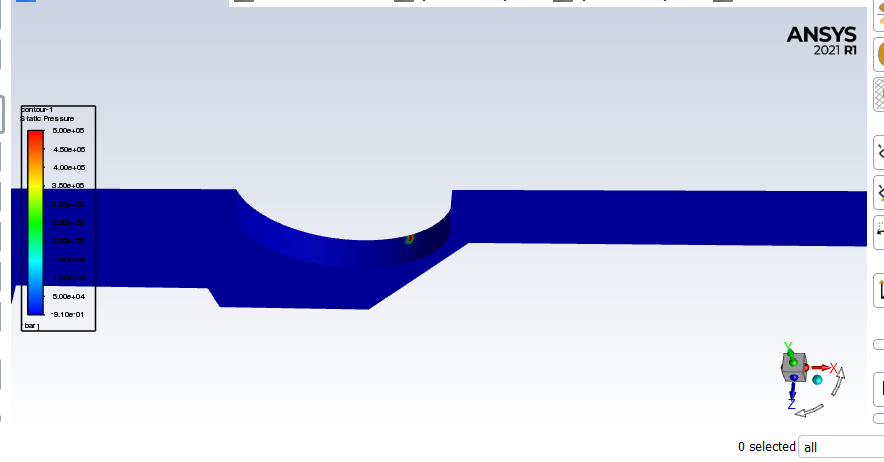

Forum ModeratorCheck the pressure field.

June 11, 2021 at 1:28 pmJune 11, 2021 at 2:23 pmRob

Forum ModeratorResiduals are only part of judging convergence. How did you initialise the problem?

June 11, 2021 at 2:28 pmEmperor

SubscriberI performed a standard initialization

June 11, 2021 at 3:44 pmRob

Forum ModeratorDid you then patch the upstream pressure? Using 2 pressure bc's and compressible flow makes the solution stiffer than for a fixed density and velocity bc.

June 14, 2021 at 7:05 amEmperor

SubscriberWhat do you mean by patched? I didn't do anything but set the input pressure value.

June 14, 2021 at 7:23 amaitor.amatriain

SubscriberIt makes no sense to have supersonic flow at the inlet. Have you checked the symmetries? Is the reference pressure equal to 1?

June 14, 2021 at 10:50 amJune 14, 2021 at 12:50 pmEmperor

SubscriberI checked the symmetries. I plotted the velocity vectors and I notice that there is a recirculation just after the inlet leading to a reverse flow at the inlet, so part of the fluid enters while the other leaves,June 14, 2021 at 12:52 pmRob

Forum ModeratorWhich is the solver trying to fill the region upstream of the valve following it potentially starting at atmospheric conditions.

June 14, 2021 at 1:02 pmEmperor

Subscriberthe type of solver is based on pressure. Are you talking about this or something else?

June 14, 2021 at 3:22 pmRob

Forum ModeratorIf you initialise the domain at an average or outlet pressure you'll need to fill the zone upstream of the valve. As the inlet is at a high pressure you'll get non-physical velocities in that region. Hence patching the zones with roughly the right pressure.

June 17, 2021 at 1:42 pmEmperor

SubscriberI looked at the documentation on how to patch the zone, so I try to patch the pressure 170 on the input cell and zeo on the rest of the cells. Concerning the speeds should I patch them too? for example put speed 0 on the input cells

June 17, 2021 at 2:02 pmRob

Forum ModeratorIn theory patching the speeds would be good but it'll be hard to get them right given the jetting. Try with just pressure and see how it behaves.

June 17, 2021 at 2:05 pmaitor.amatriain

SubscriberWhy don't you consider hybrid initialization?

June 17, 2021 at 2:26 pmEmperor

Subscriberthe hybrid initialization gives me a recirculation at the inlet leading to a non uniformity of the pressure field as seen above.

Aitor, Rob thank you because thanks to you I'm learning a lot about CFD and it's getting more and more interesting!

So I patched the input zone to pressure (170b) and the rest of the zones to 0B. I only saw your answer later about the velocity patch, I had already patched the velocity on the output zones v=0.

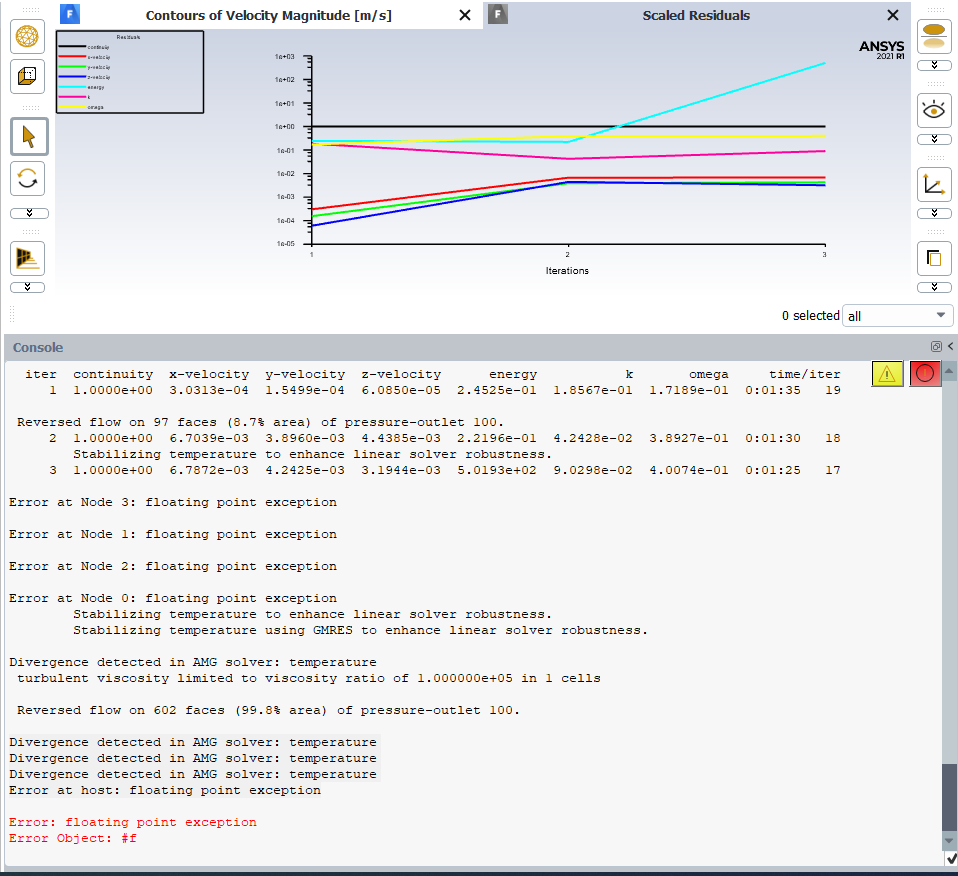

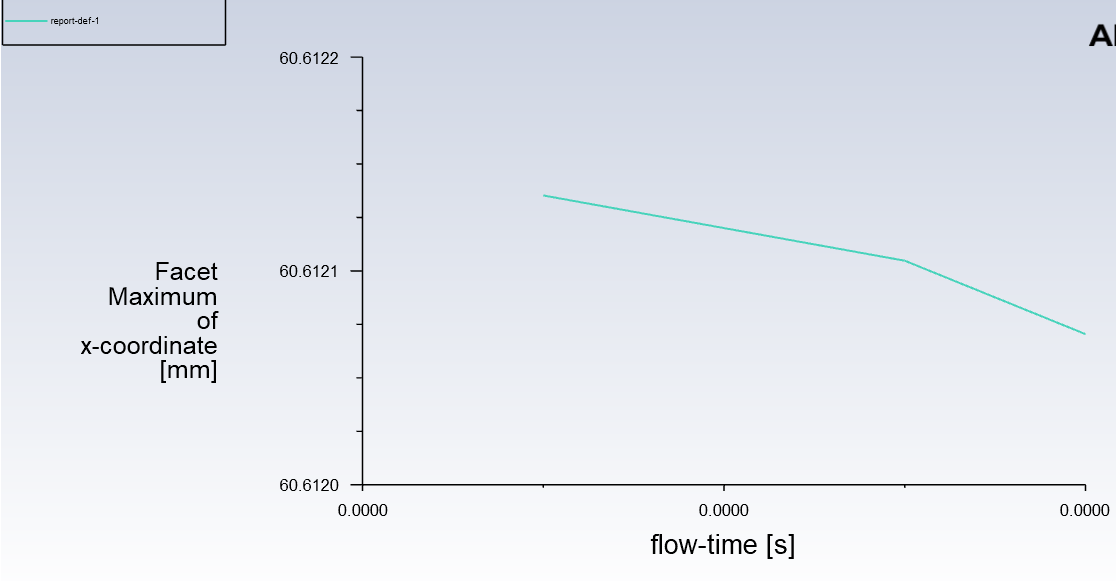

So I ran the calculation and I can start to appreciate the convergence of some residuals :

I stopped at 500iteration.

I stopped at 500iteration.

The velocity field is uniform and so is the pressure field:

can I appreciate some level of convergence with these elements?

can I appreciate some level of convergence with these elements?

The question I have now is about the y+. I should have a y+ =1 (roughly) but I have the max of y+ = 40 . I plotted the y+ and I noticed that the maximum value 40 is at the ball where there is the restriction of the passage (See image below). Should I reduce the height of the boundary layer in this area? Knowing that my orthogonal quality may decrease (here it is 0.09)?

June 17, 2021 at 2:38 pmRob

Forum ModeratorNot having a y+ of 1 will reduce the accuracy, but it depends on what you're wanting to model. I suspect the domain is axi-symmetric rather than an extruded shape so it may not matter. Adaption may be enough to give you the extra resolution but I'd run the model on first.

June 17, 2021 at 2:49 pmEmperor

Subscriberthe model is not axisymmetric, I make this model because I want to get all the information and techniques possible to make a transient 3D calculation containing the face of this extruded model. Working in this direction allows me to be faster and more efficient :). The most important thing in this modeling is that the right pressure arrives on the ball and that the ball undergoes the right loading.

June 17, 2021 at 4:01 pmRob

Forum ModeratorGood thinking: small models fail more quickly (or work) when you're learning.

If you want the pressure loading you'll need a y+ of as near 1 as possible. See where adaption gets you. Don't forget to increase the resolution over the shocks too as the wake has more of an effect on the flow than you may think.

June 18, 2021 at 8:32 amEmperor

SubscriberSo we can say that the solution for this discussion is to patch.

I will remember to do a mesh refinement study in this case. I saw that the value of y+ can be between 30 and 300 if we change the turbulence model, do you think this is an option to have a more accurate loading result?

June 18, 2021 at 1:59 pmRob

Forum ModeratorYes, patch. Otherwise the solver needs to pressurise the upstream section but also wants to have a shockwave there as the high pressure gas enters the domain. It'll eventually get to a stable solution but it may take a while.

Re-read the section on the wall functions. y+ = 1 means you're likely to be resolving the near wall gradients; y+ 30-300 or so means you're using a model which may have limitations.

June 22, 2021 at 9:56 amEmperor

Subscriberthank you for your answers and for these lessons,

Best regards

July 5, 2021 at 2:48 pmEmperor

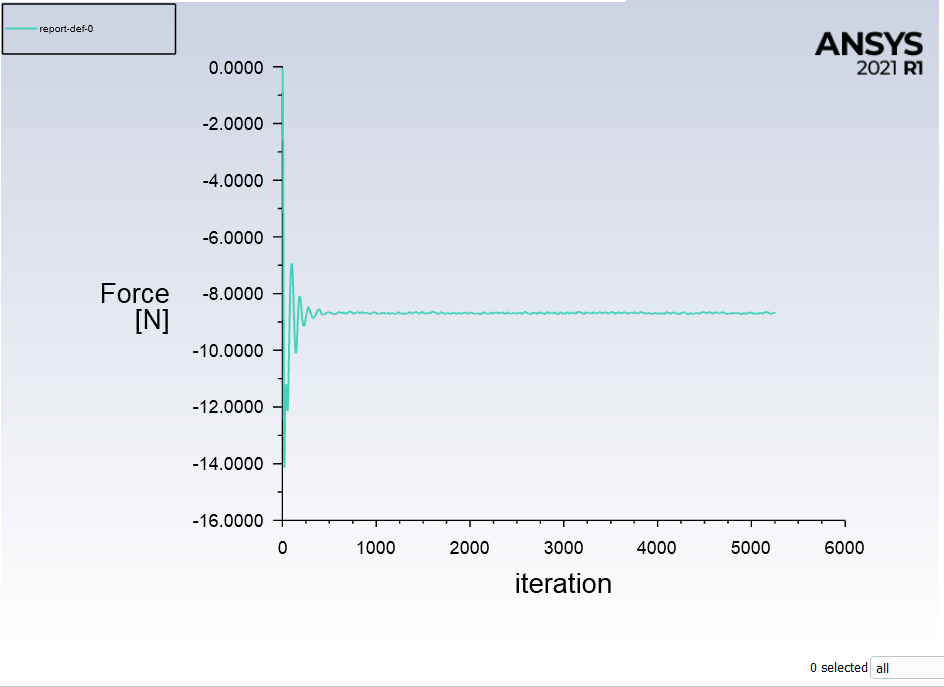

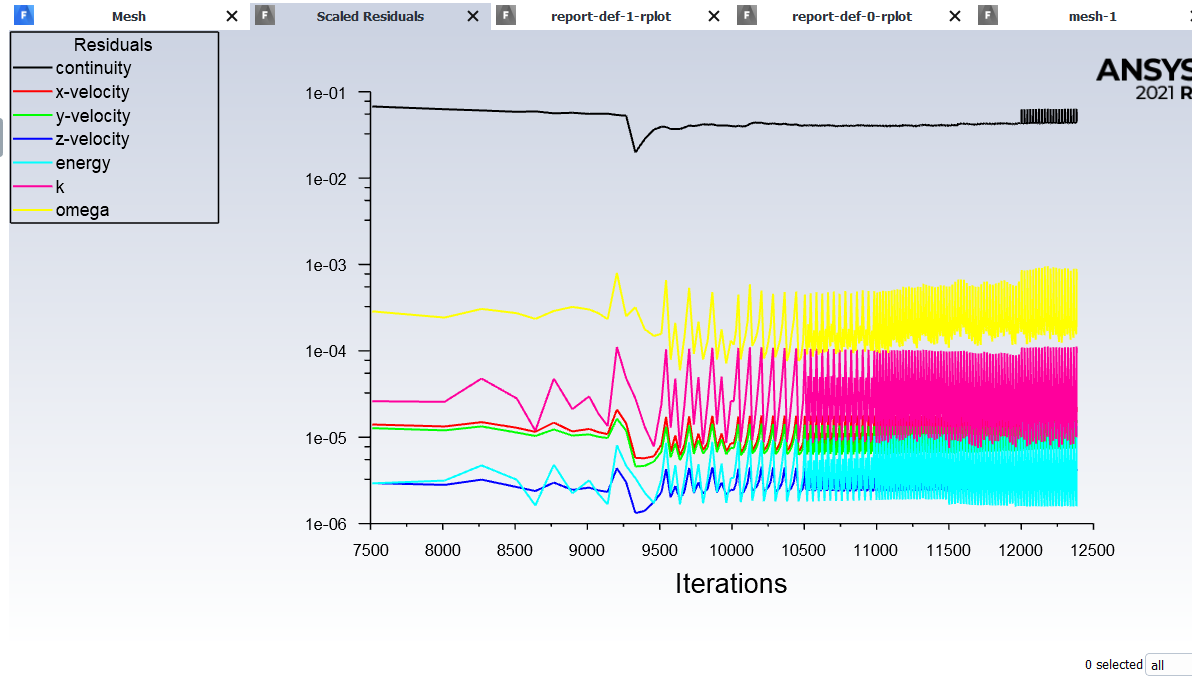

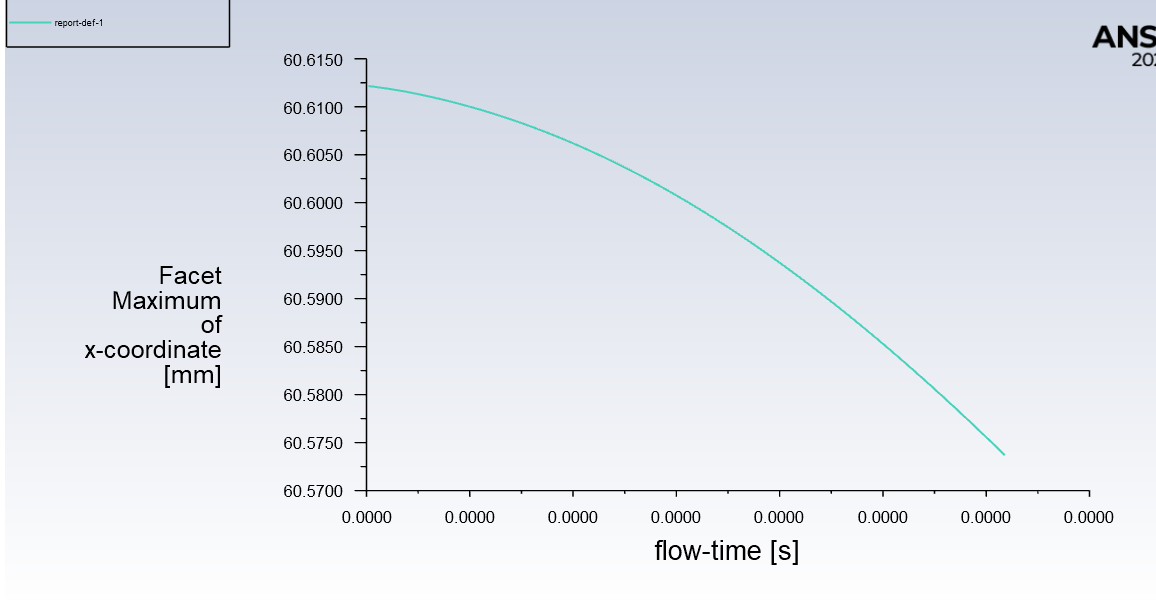

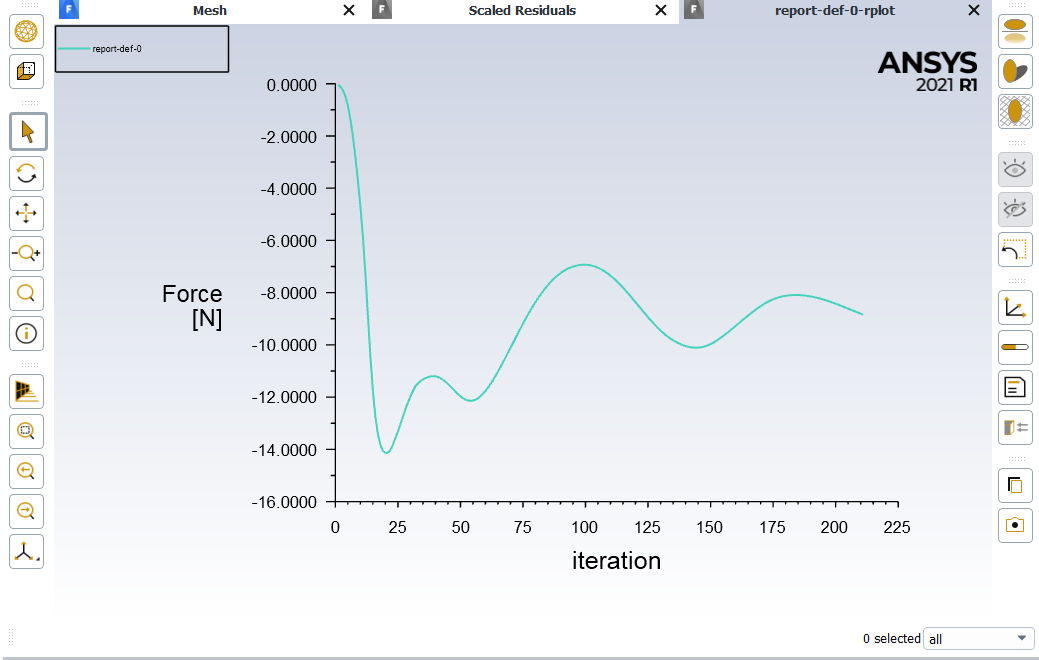

SubscriberI continue my calculation and I have a question about the same model. What is important for me in my calculation is to have the right effort (in newton) on the ball when the pressure is applied. The purpose of the calculation is a transient analysis. To help the solver to converge during the transient analysis I first made a static analysis. My calculation in progress I trace the force undergone by the ball, what I would like to know is: is this force supposed to stabilize once the calculation converged?

In the picture below the calculation is not yet converged but the force varies, should I expect a stable value?

July 6, 2021 at 6:40 amJuly 6, 2021 at 9:57 amRob

Forum ModeratorThat looks about right. If you look closely at the force report you'll see a fairly small oscillation in the value. Add that to the residuals and it suggests the flow is still changing as there's a transient in there. My guess is that the jet is moving a bit (plot a contour every 10 iterations and watch the movie later). However, I doubt the overall solution is changing by enough to matter.

July 6, 2021 at 10:11 amEmperor

Subscriberthank you for your answer.

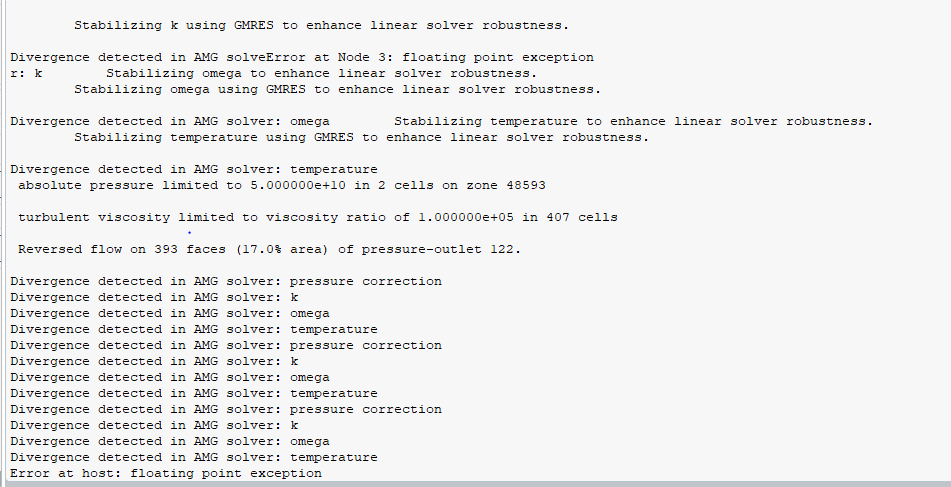

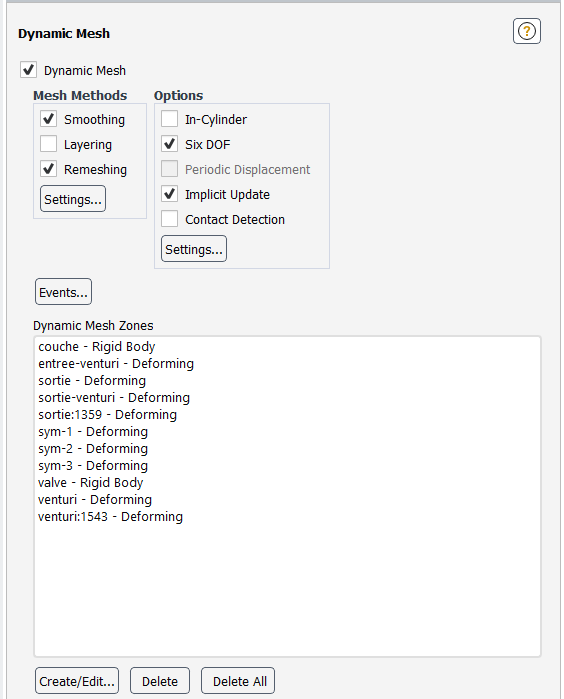

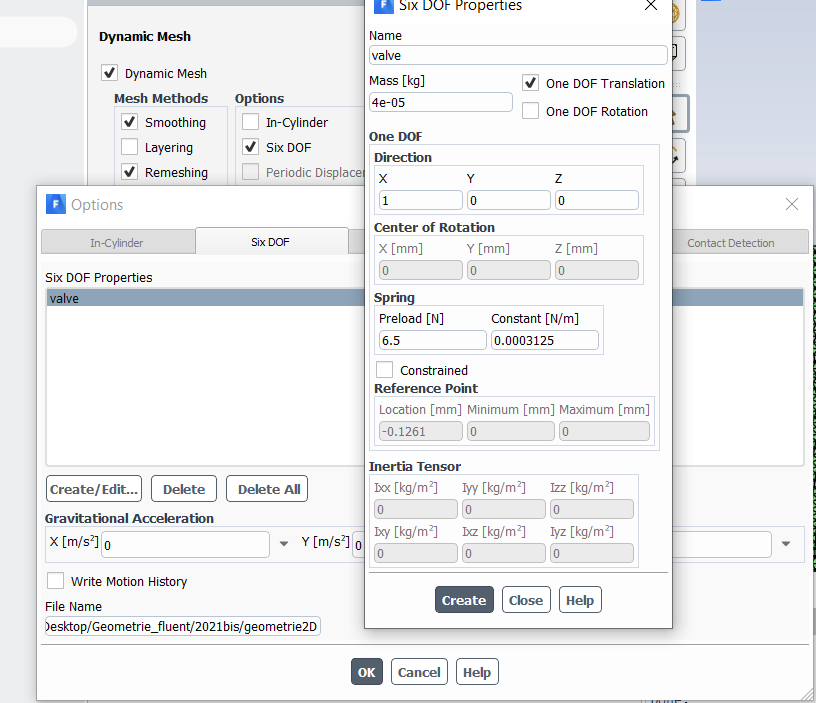

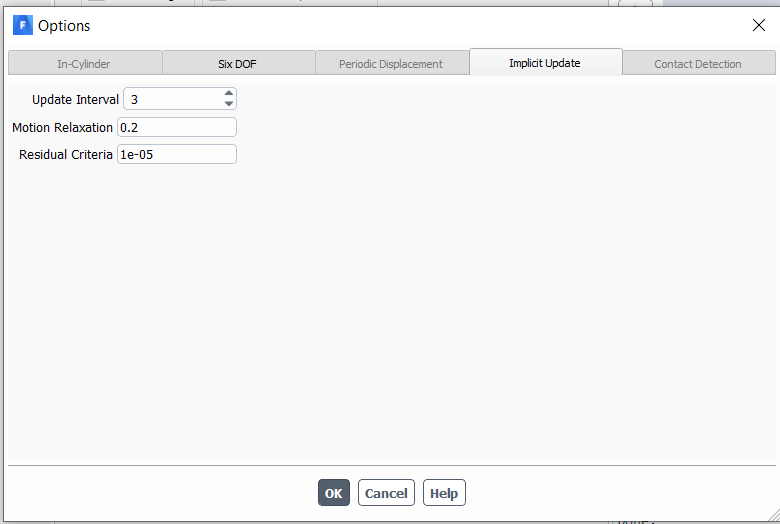

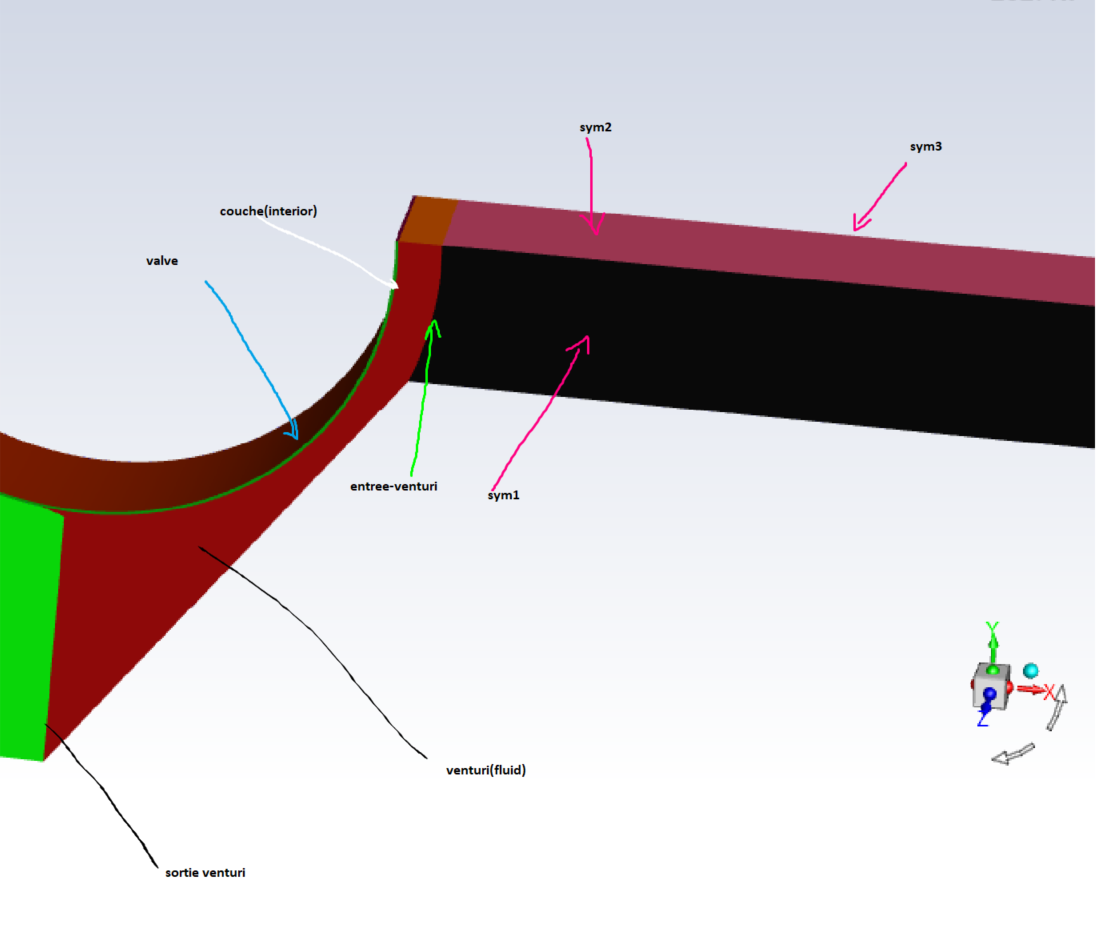

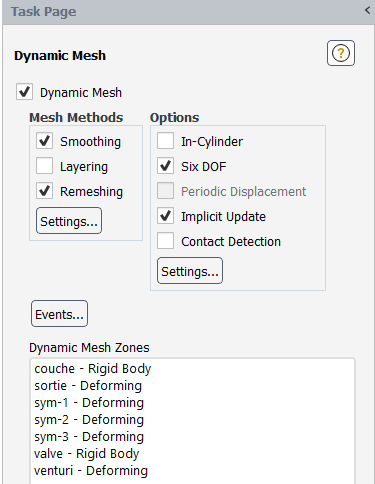

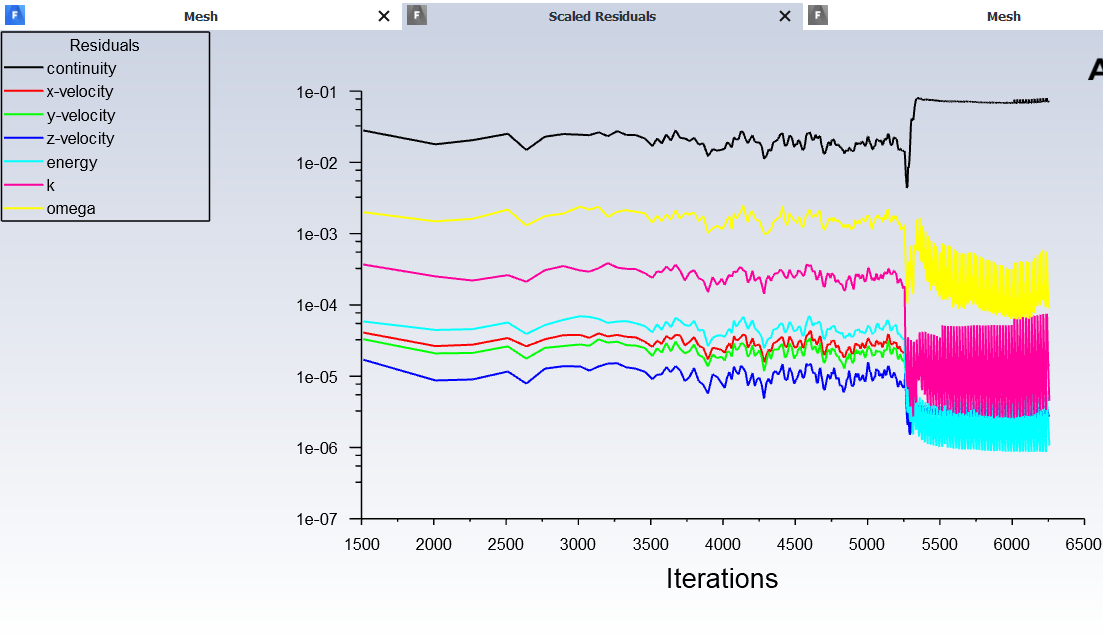

The first calculation I showed is static (pseudo-transient). I now want to run the transient calculation with the ball movement.

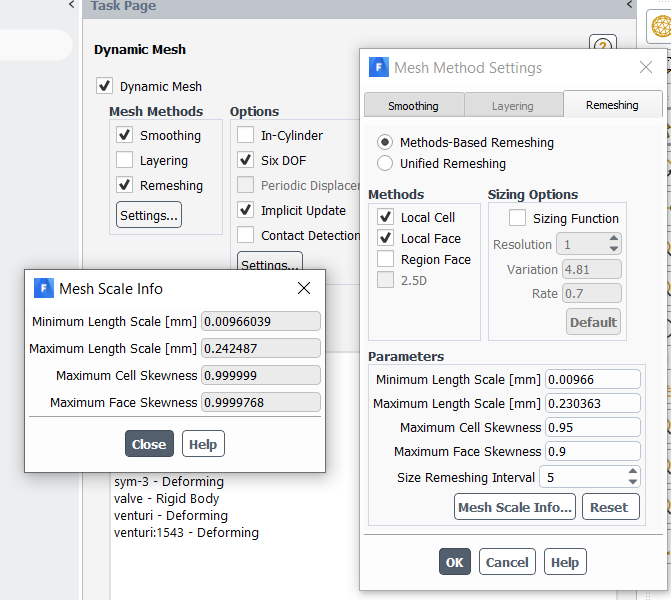

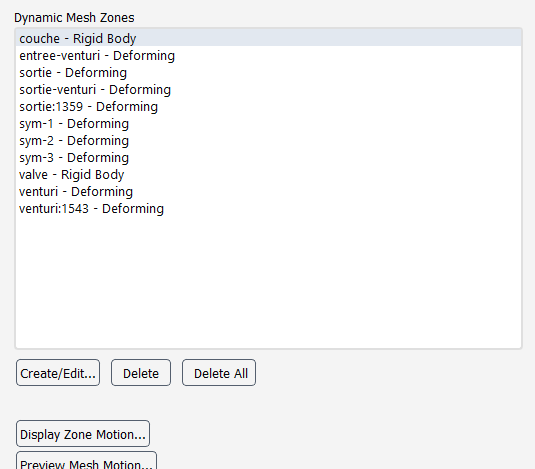

I have created a zone for the boundary layer of the ball to give it the same motion as the ball ( 6-dof off). The parameters for my 6-dof are :

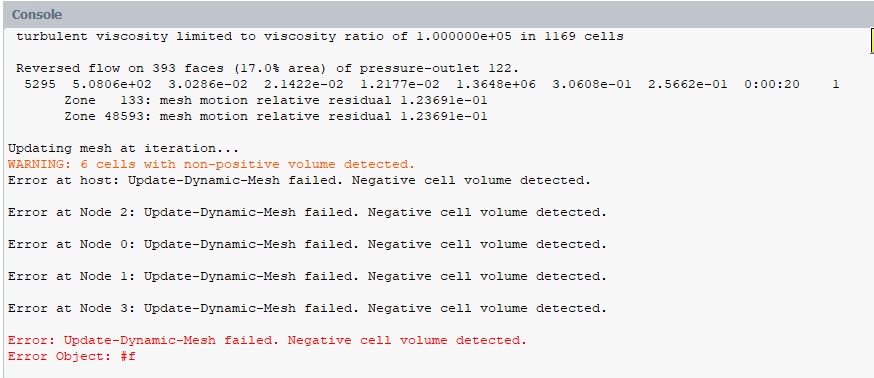

But the calculation does not converge and displays the error :

Divergence detected in AMG solver: temperature Divergence detected in AMG solver: temperature Divergence detected in AMG solver: temperature Error at host: floating point exception Error: floating point exception Error Object: #f

What could create the error in the remeshing and in the calculation pleaseJuly 6, 2021 at 10:17 amRob

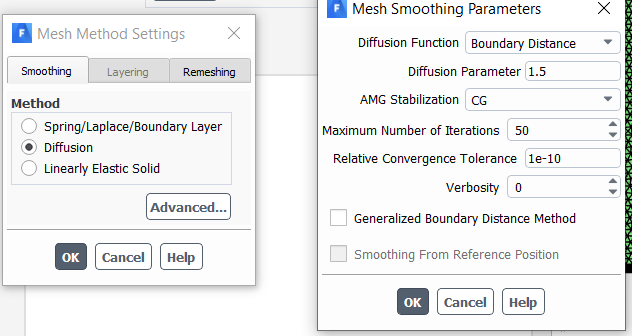

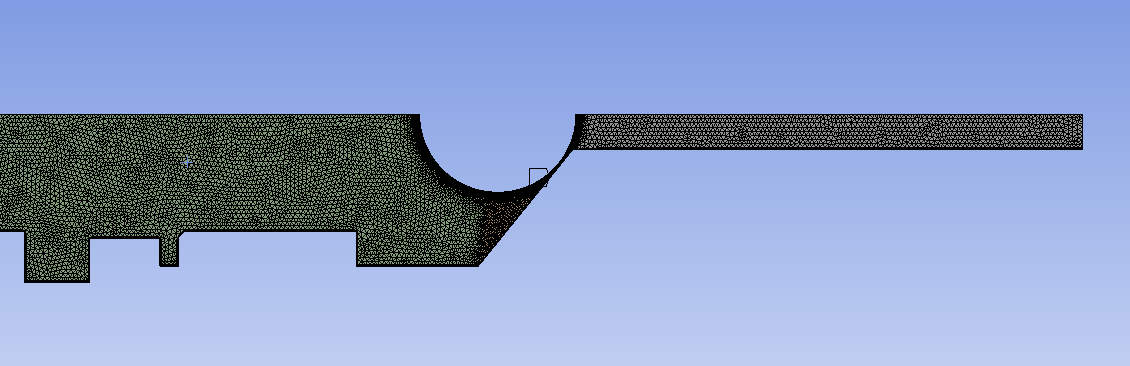

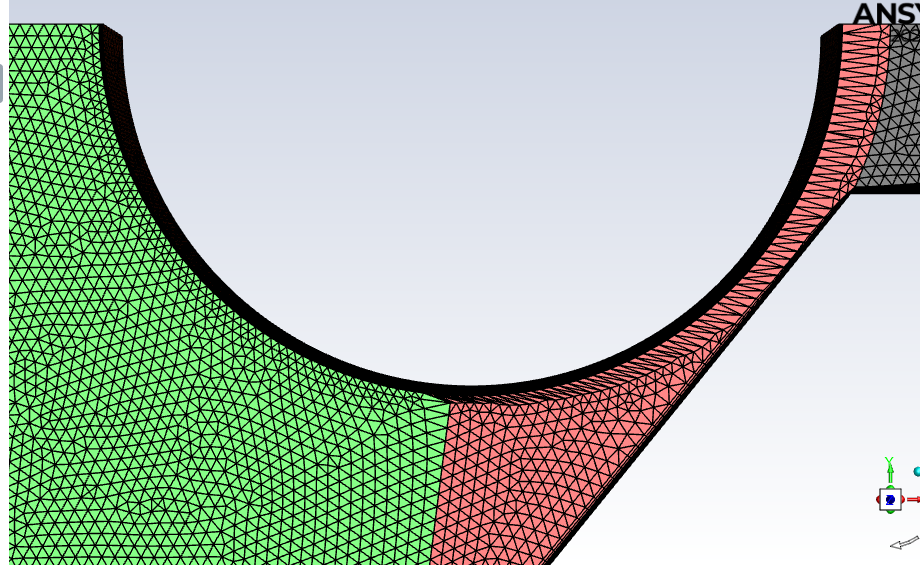

Forum ModeratorLook at the tet cell at the top of the boundary layer in the green cell zone. Now think what that's doing to the solver maths.

July 6, 2021 at 10:27 amEmperor

Subscriberis this tetra cell too distorted? How do you relate the solver math to this (how did you get this insight?)?I'm still developing my skills.. Does having this tet cell cause a problem in the interpolation? Can you please enlighten me more?

I made this part around the ball in order to have the boundary layer moving with the ball. Is it causing a problem? Do you think I should change the method?

By decreasing the time step, I have the negative cell error but the valve has moved almost to the opening

I'm sorry to ask you so many questions but you are my only hope

I'm sorry to ask you so many questions but you are my only hope

July 6, 2021 at 11:27 amRob

Forum ModeratorYes, that tet cell is too flat - check the quality metrics - skew rather than orthoganal quality. Re the maths, as the cells get more skewed the gradient terms get messed up - if that's not in the solver theory it'll be in a text book somewhere. Because that cell layer is very much in a region of high gradients it'll very quickly become a problem.

July 6, 2021 at 1:00 pmEmperor

Subscriberto make this valve work do I need an udf or does the 6-dof allow it? What recommendation do you have?

July 6, 2021 at 1:51 pmRob

Forum ModeratorYou should just need to move the parts using rigid body, 6DOF is more for free moving parts. What you need to look at is how the mesh is built to allow remeshing and avoid flat tets.

July 6, 2021 at 1:56 pmEmperor

SubscriberOK, it works. The 2D model works very well, it's the 3D that causes all the problems. I'll try again and I'll put the results here for your guidance thanks a lot Rob

July 6, 2021 at 2:00 pmRob

Forum ModeratorIt's likely that near flat cell you've got - how did you model the 2d case?

July 6, 2021 at 2:06 pmEmperor

Subscriberthe 2D case was very simple with only one face. The same parameters for turbulence and 6-dof. The remeshing was obvious.Case 2D was a false case

In 3D, I don't know if I should just put the 6dof on the ball or I should also add it on the volume

July 6, 2021 at 2:30 pmJuly 6, 2021 at 3:14 pmRob

Forum ModeratorWhat was the initial condition?

July 7, 2021 at 7:09 amEmperor

Subscriberla condition initial est la m├¬me que celle de la discutions. 170bars ├á l'entr├®e et 0bar ├á la sortie. Pour remplir l'entr├®e de la vanne j'ai patch├® l'entr├®e ├á 170bar et 0bar sur la sortie,

July 7, 2021 at 10:31 amJuly 7, 2021 at 1:23 pmRob

Forum ModeratorThe mesher can't fill a section with just an inflation mesh, it must have at least one layer of the volume mesh. If you've broken the domain down like that you could see if you can sweep in that region with no inflation.

July 7, 2021 at 2:18 pmEmperor

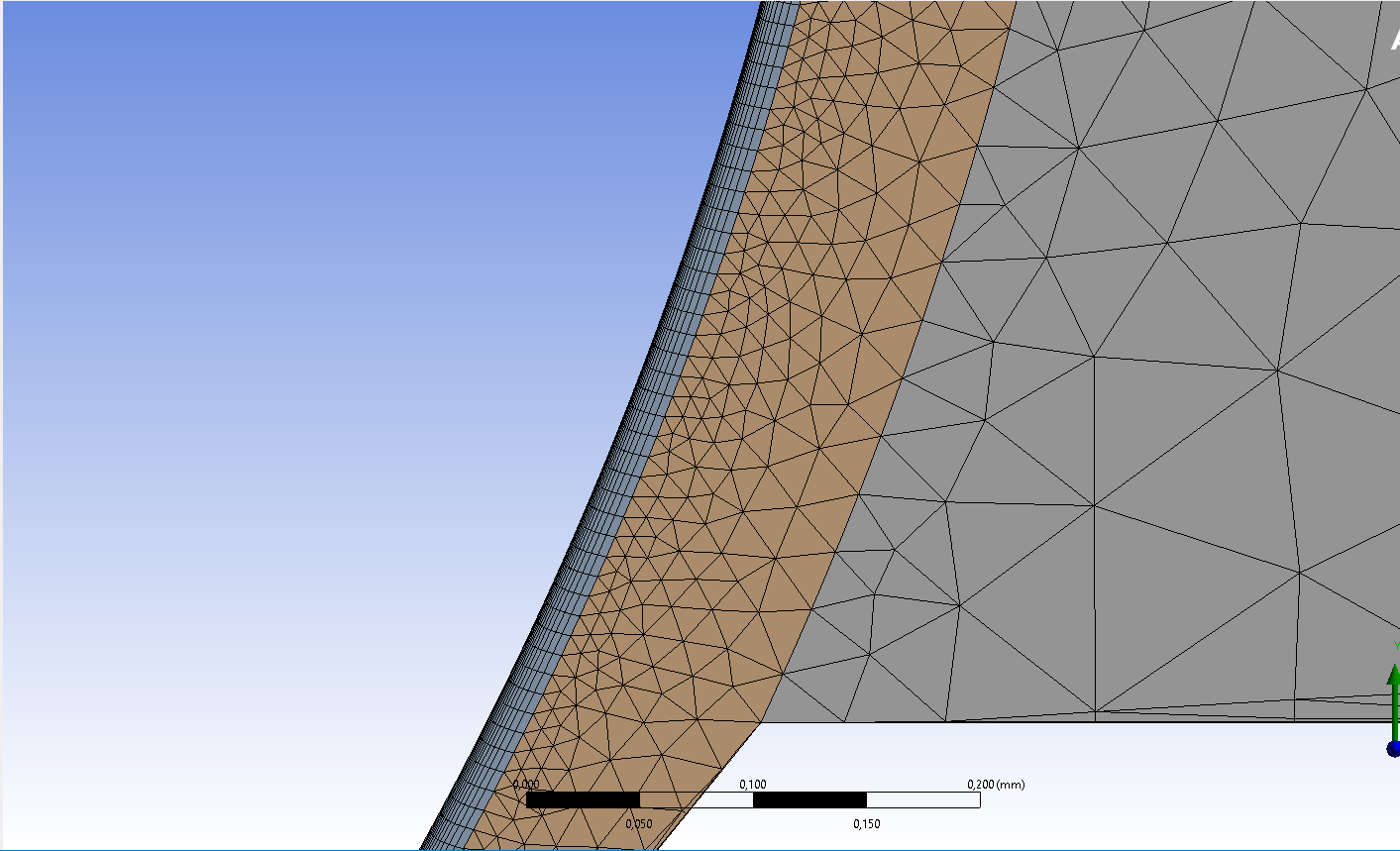

SubscriberI am trying the mechanical mesher where it is possible to put only elements representing the boundary layer without necessarily adding inflation, do you think it is better?

But it's hard to get good quality. As you said earlier, my mistake can be caused by the mesh, it can be that the skewness is too low, but even using both mesh, the good quality is still hard to get. Should I refine more and more knowing that I am already at :

For a station that has only 4 cores and 15GB of usable ram?

For a station that has only 4 cores and 15GB of usable ram?

July 8, 2021 at 10:51 amRob

Forum ModeratorThe cell count is OK, as you'll be using around 255k cells per core. I'd also try and get the inflation around the corner (so slightly adjust the decomposition) otherwise you should be OK. You may also want to refine near the corner to reduce the aspect ratio if the flow separates: y+ is only part of what makes a good mesh.

July 8, 2021 at 12:54 pmEmperor

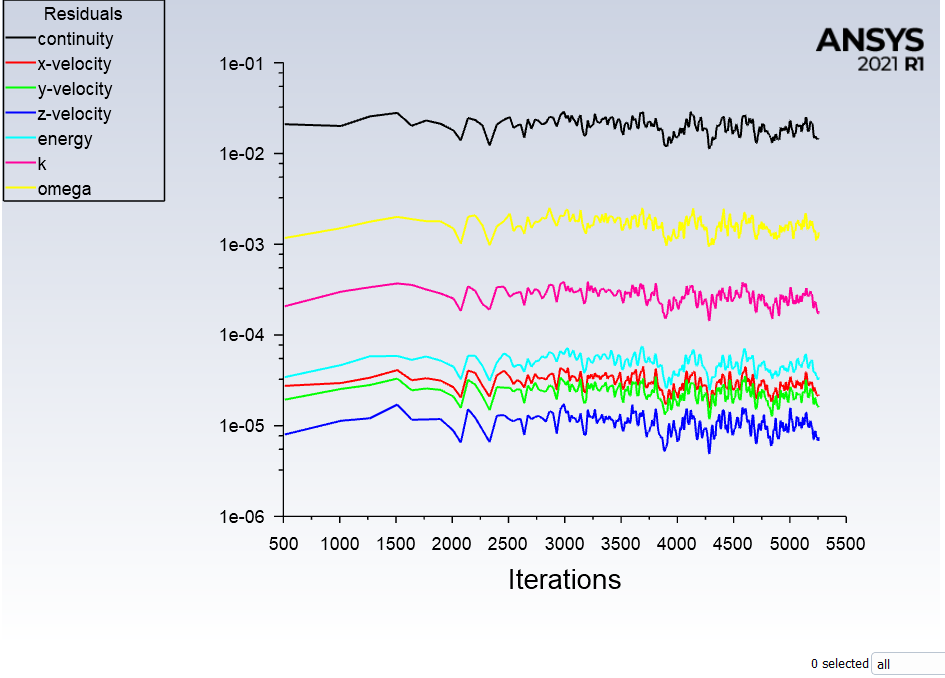

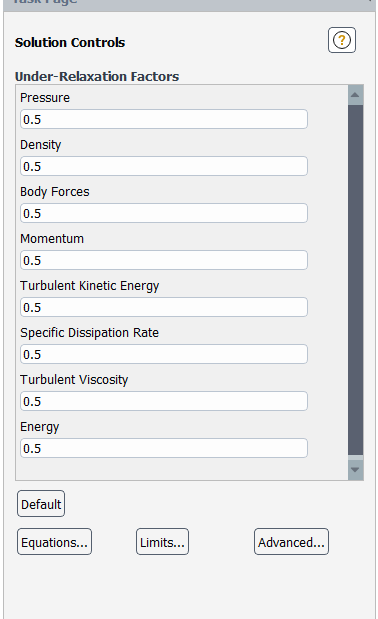

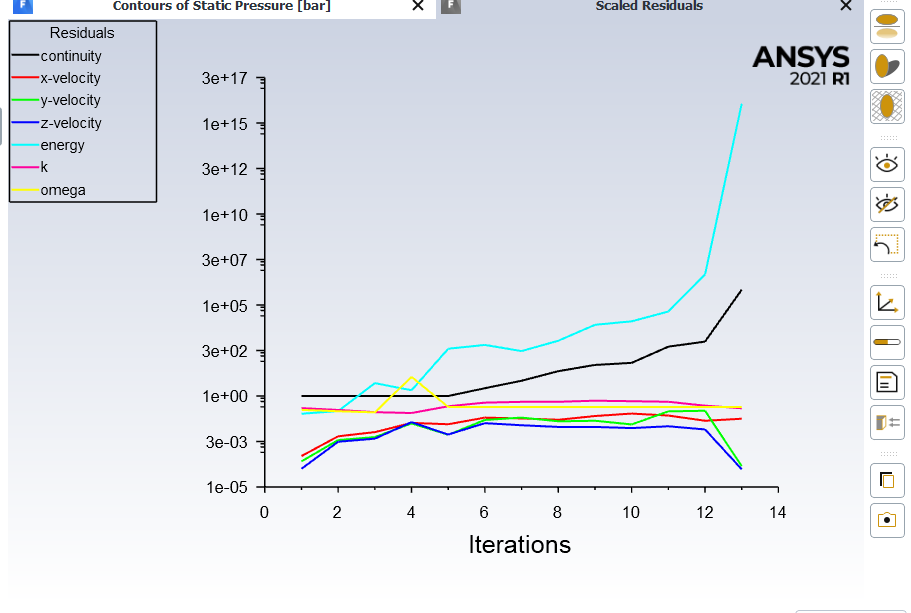

Subscriberthank you for the answer. Concerning the dynamic mesh I have the calculation in progress (I launched the transient calculation after the static calculation) and I have the residuals which are a little strange

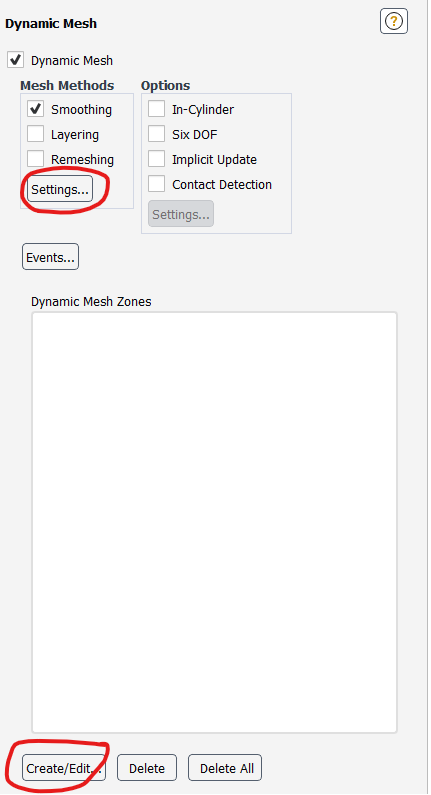

I defined the 6dof :

The valve and the boundary layer area around the valve are respectively in 6dof-on and 6dof-off. All other areas (internal and the rest) are in deforming. But it seems to me that the residues are not convergent enough and the calculation will crash in my opinion. What do you think about it rob?

The valve and the boundary layer area around the valve are respectively in 6dof-on and 6dof-off. All other areas (internal and the rest) are in deforming. But it seems to me that the residues are not convergent enough and the calculation will crash in my opinion. What do you think about it rob?

July 8, 2021 at 1:03 pmJuly 9, 2021 at 1:04 pmRob

Forum ModeratorGiven the elapsed time it's hard to give an opinion. How did it behave overnight?

July 9, 2021 at 1:18 pmJuly 15, 2021 at 7:05 amJuly 15, 2021 at 10:59 amRob

Forum ModeratorCheck the volume mesh, if that's also very skewed then it's a remeshing setting. If the volume is OK and it's the face then you need to force a face remesh. However I don't know what that will do with your inflation layer.

July 15, 2021 at 2:11 pmEmperor

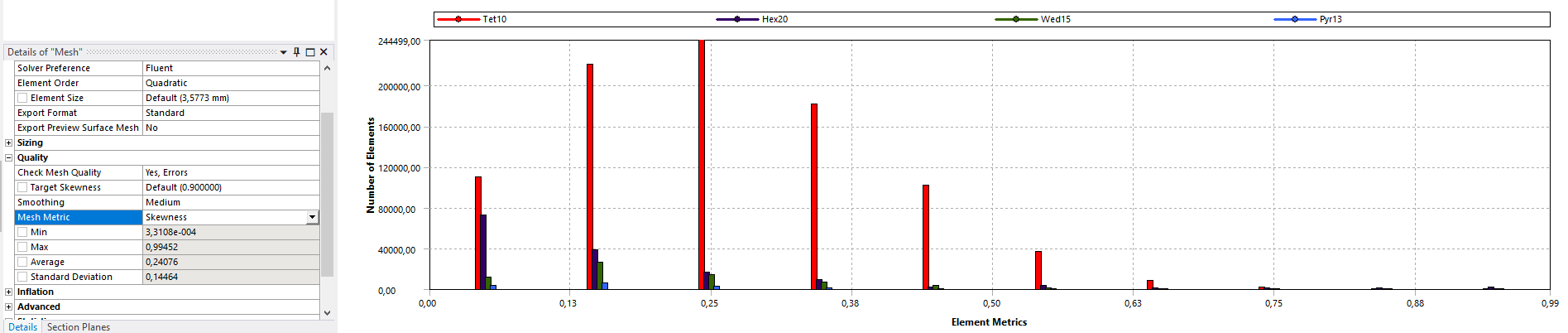

Subscriberit seems to be a problem in the remeshing.

If we look at the image below, we can notice that the interface between the green and the red area has difficulty to remesh, yet I defined them as deforming. Should I model all the structure in 1 body to not use the shared topology ? However I know that it is possible to divide the bodies for a better mesh, but is it a limitation for dynamic meshes?

If we look at the image below, we can notice that the interface between the green and the red area has difficulty to remesh, yet I defined them as deforming. Should I model all the structure in 1 body to not use the shared topology ? However I know that it is possible to divide the bodies for a better mesh, but is it a limitation for dynamic meshes?

July 15, 2021 at 3:17 pmRob

Forum ModeratorPossibly one for Removing the interior connections will help, but will also make inflation awkward. Moving mesh isn't one of the areas I'm overly expert: in most of what I cover if it moves/bends it breaks so we don't need to worry about it!

July 16, 2021 at 6:45 amEmperor

Subscriberthank you for your support, your time and your efforts I'm really grateful.

I hope very much that will share his knowledge :)

July 22, 2021 at 2:43 pmStephen Orlando

Ansys Employee

What are your Dynamic Mesh Settings? Please add a screenshot. Also add a screenshot showing the details of the Dynamic Mesh Zones you have.

You could also look into using the Boundary Layer Smoothing Method, described here: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v212/en/flu_ug/flu_ug_dynam_mesh_update.html%23flu_ug_boundary_layer_smooth_meth

Steve

July 23, 2021 at 7:16 amViewing 98 reply threads- The topic ‘mesher fluent’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

5159

-

1836

-

1387

-

1249

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.