TAGGED: Heat-solver, mechanical, mesh, meshing

-

-

March 7, 2024 at 10:37 pm

swu321

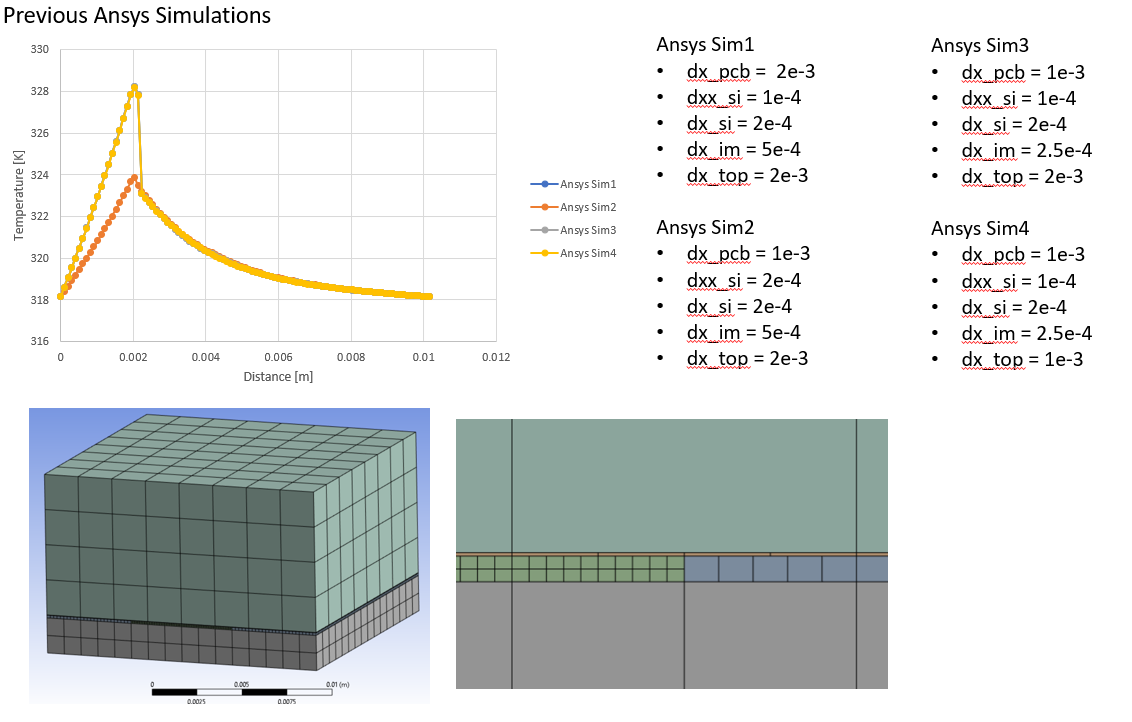

SubscriberI have this 4-layer structure and I did some simulations based on the different mesh sets. This structure contains a self-heat-generating part.

In the image below, the results from 1, 3, and 4 are overlapped while 2 has a weirdly low max point, while case 2 has a bigger mesh size for the heat-generating part. As I have reached the limit of my license, I am not able to get a smaller mesh size.

So, I am wondering if anyone has any idea of the proper way to set the mesh size in Mechanical?

I am kinda worried that my mesh size might be still not small enough and what I am seeing here is still not correct.

-

March 8, 2024 at 4:00 pm

Kaushal Vadnere

Ansys EmployeeHi,

Is your part symmetric in any direction? If yes, maybe you can use planar symmetry to reduce the model size. For your question regarding mesh size, the ideal mesh size depends on various factors such as the complexity of the geometry, the expected gradient of the field variable, and the computational resources available.

See if this post on forum helps: Element Size : What does that indicate ? (ansys.com)

Thanks!

-

- The topic ‘Mecanical solver bottleneck/limit’ is closed to new replies.

-

4618

-

1530

-

1386

-

1210

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.