-

-

November 4, 2025 at 2:39 am

abdullahwaasi

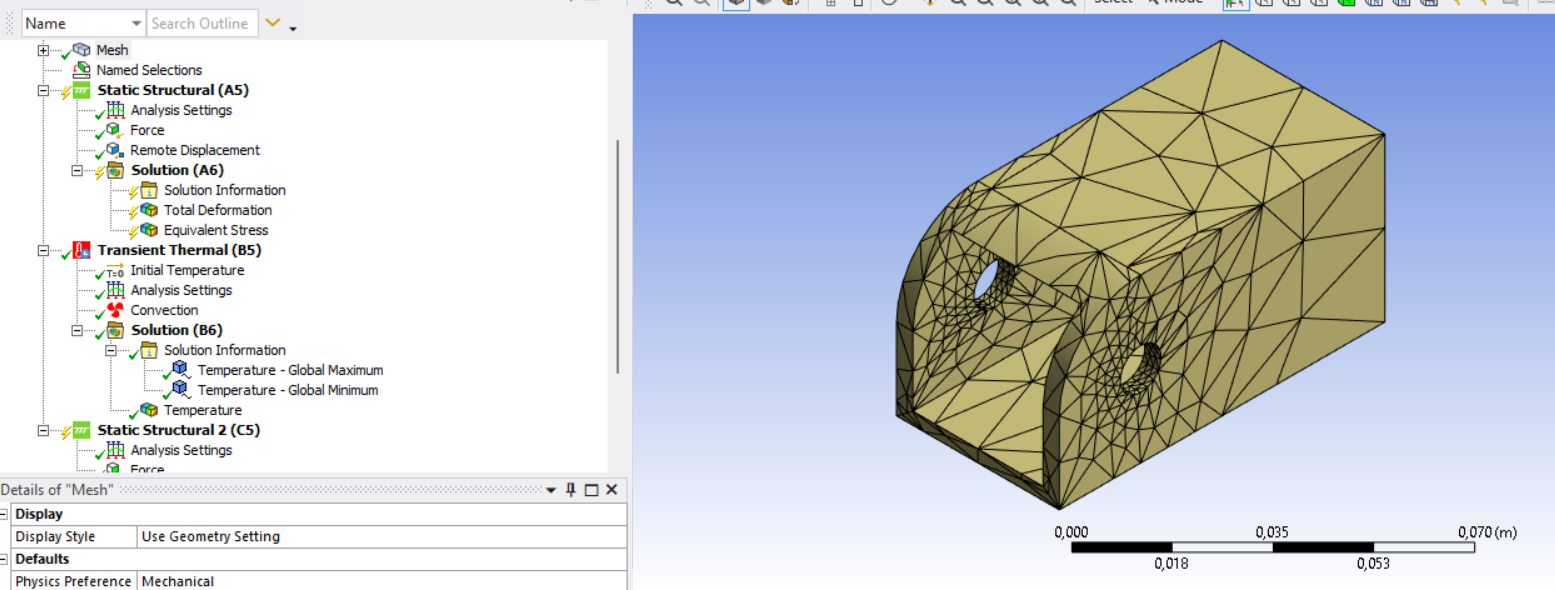

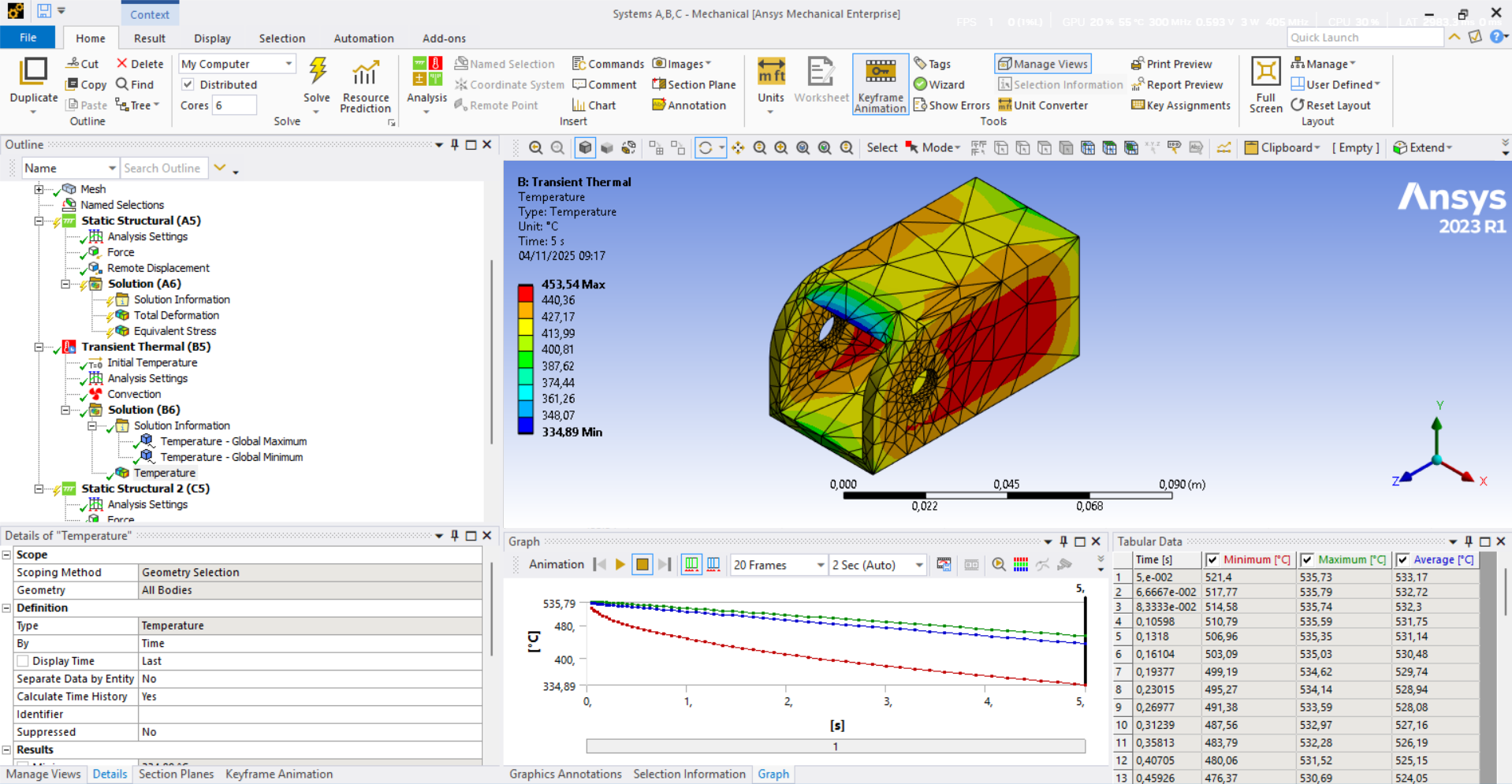

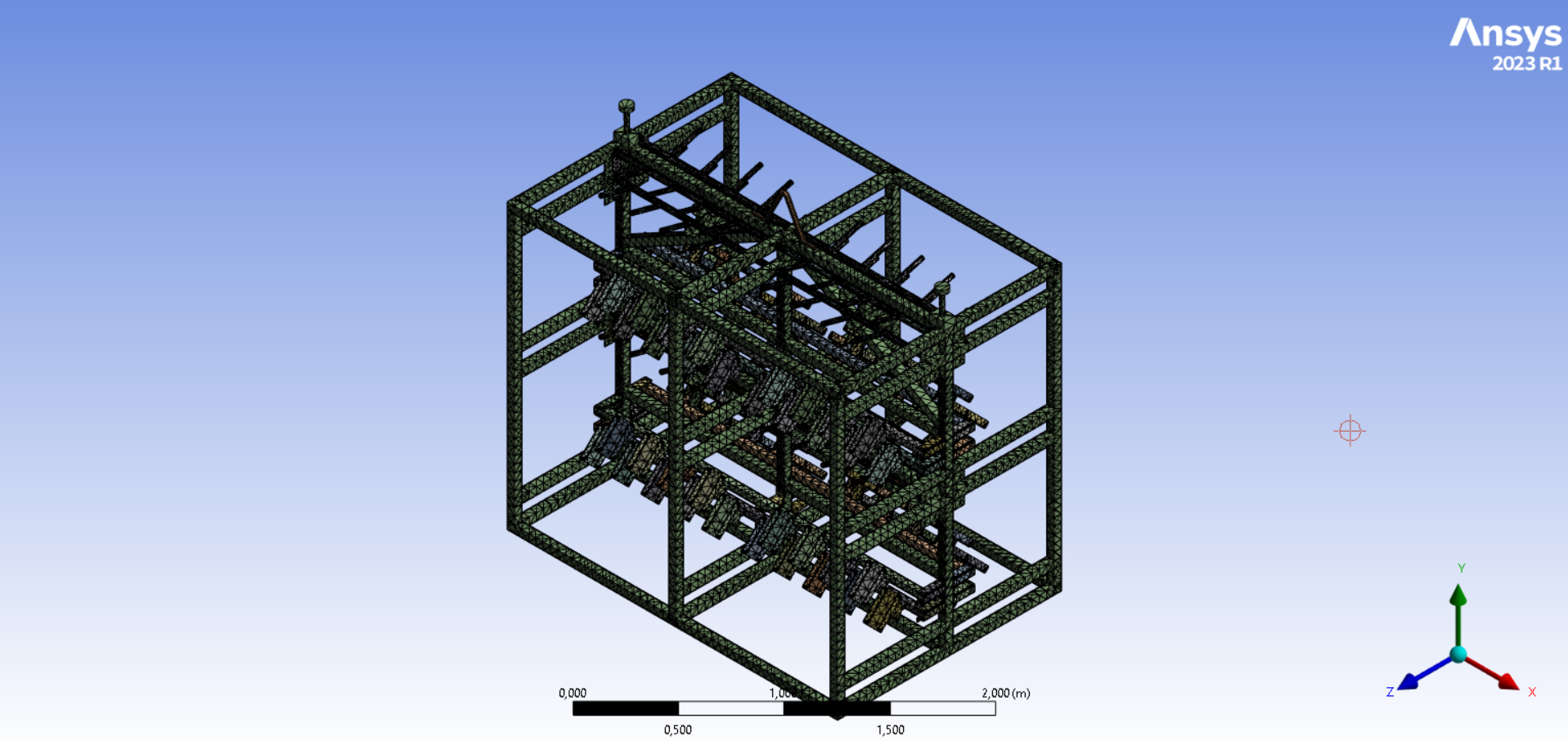

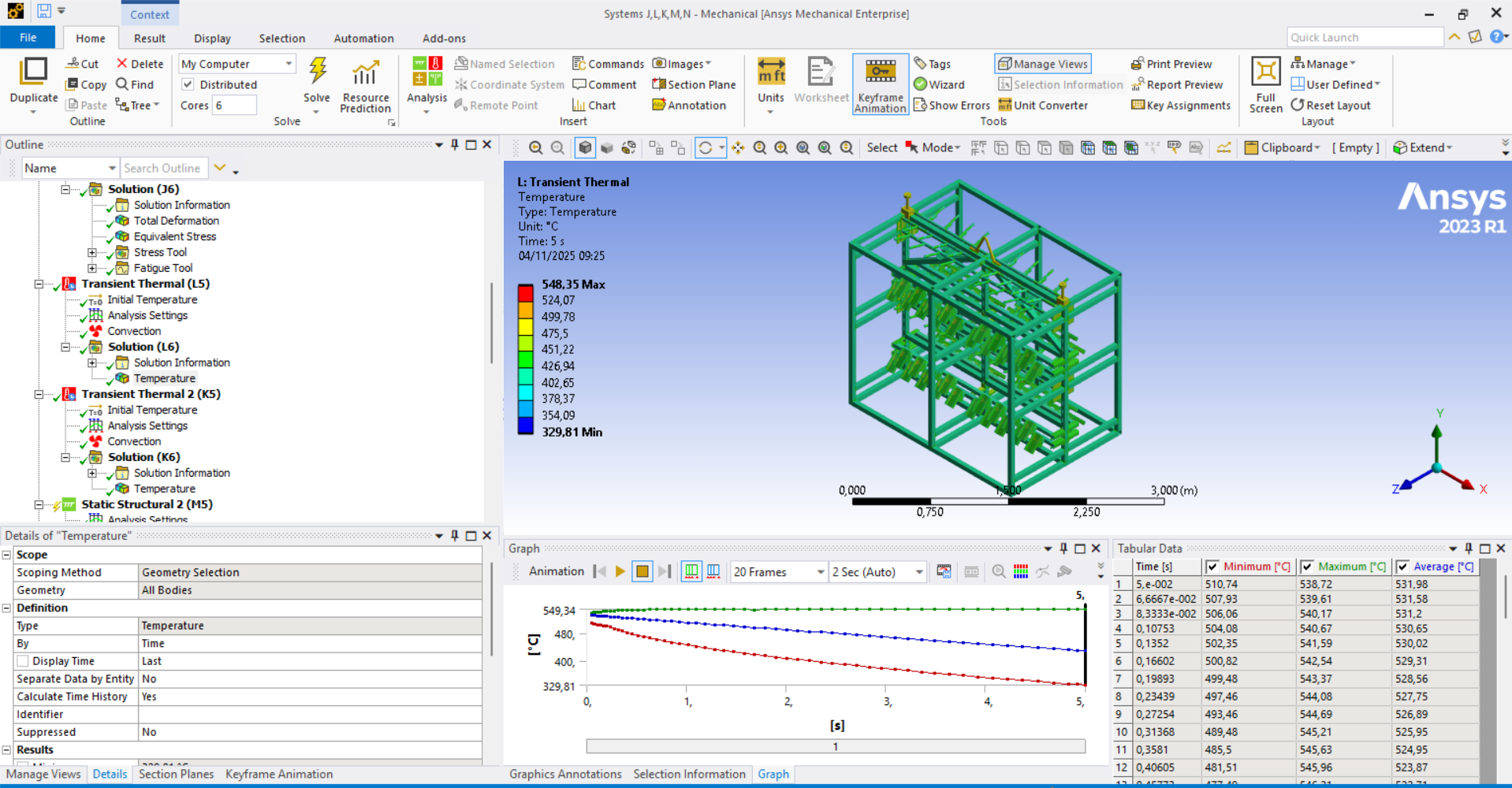

SubscriberI am a student who is currently interning at a bicycle factory. So, I had a project where i need to create new loading rack for T4 Solution Heat Treatment Furnace, the loading rack will be mounted with 72 bicycle frame, the parameter that used at the furnace is 535°C with 45 minute holding time, and after the heat treatment it will dipped on water tank with with 38°C temperature for 5s (quench). Actually the water itself is mixed with Aqua Quench 251 but since i had no basic knowledge about chemical, and from what i search so far i need to know the chemical formula of that solvent if i want to input it, so i think im gonna ignore the chemical from the analysis. So far i already use a simple structural analysis with thermal condition of 535°C to analyze the condition inside the furnace, and for analyze the quench proccess i use transient thermal analysis, i set the initial temperature at 535°C and i set the convection temperature at 38°C, and film coeffcient of 450 w/m^2°C, from what i know this film coefficient value is non liniear, so it should be tabular, but since i dont know where and how to get the number im gonna use this constant 450 that i get from yt videos, and after that im gonna insert the result as imported load for another structural analysis. and the problem is when i analyze the quench proccess with full model, the maximum temperature is increased, im pretty sure this gonna add another stress on the structural analysis but when i try to do the same analysis with the exact same parameter with one of component from loading rack, the maximum temperature is decreased. Is it normal? or there is something wrong with my settings? my objective is i just wanna know can my design withstand the weight of the bicycle frame, oven temperature, and cooling from the quenching process

i use AISI 1020 for the material and 100mm for the mesh size

-

November 6, 2025 at 6:31 am

peteroznewman

SubscriberFrom what you describe, the purpose of the analysis is the loading rack that holds the bike frames and not the bike frames themselves.

How is a bike frame supported by the loading rack? Is it just a cradle and gravity nests the bike frame into the loading rack on some contact surfaces or is the bike frame bolted to the loading rack?

How is the loading rack supported when it is in the furnace? Are there feet? How is the loading rack lifted out of the furnace? What feature is used to lift the loading rack? How does the lifting feature interface with the lift? These details will affect the stress in the loading rack as the temperature changes.

If the bike frames are just resting on the loading rack, only the mass of the bike frames applied to the contact surfaces on the lifting rack are important, no need to model the bike frames in detail.

The mesh you show for the one component is too coarse. There should be at least two elements through the thickness of the part.

Please show the material properties you have for AISI 1020 at 535 C and 38 C.

Here is the Technical Data Sheet for AQUA-QUENCH 251.

-

- You must be logged in to reply to this topic.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Convergence error in modal analysis

- APDL, memory, solid

- Meaning of the error

- How to model a bimodular material in Mechanical

- Simulate a fan on the end of shaft

- Nonlinear load cases combinations

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- Contact stiffness too big

-

4177

-

1487

-

1363

-

1194

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.