TAGGED: #multiphase_models, cfd-combustion, dpm, gas-liquid-flow, species, supersonic-flow

-

-

January 16, 2024 at 3:04 am

hudson.pastuszko

SubscriberHi,

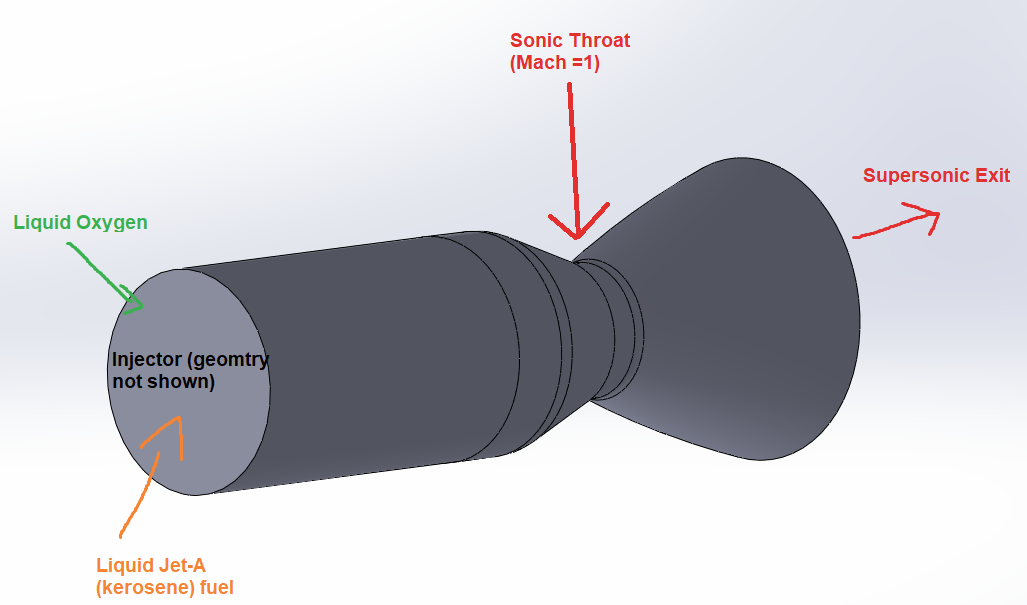

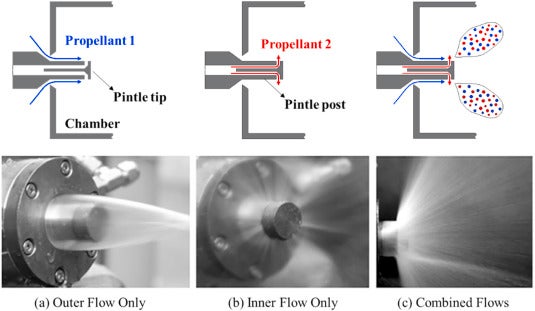

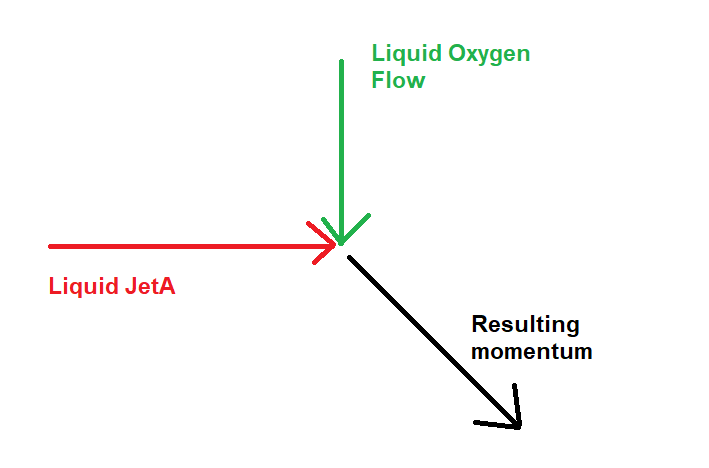

I am trying to model the combustion of a liquid rocket engine. This rocket engine has an impinging injector where liquid oxygen and liquid jet fuel collide at 90 degrees to each ofther mixing and combusting. Shown below is a simplified schematic of what the internal volume looks like.

I am modeling liquid Kerosene (Jet-A entering the combustion chamber at 300K) and Liquid Oxygen (LOX entering the combustion chamber @ 85K) burning inside a combustion chamber of 21 bar. My general plan of attack here is to first compute a steady state solution and then transition to a transient SBES model.

Quick Mesh facts:

- Split into 60 degree rotational periodic domain

- ~9Million Poly-hexcore cells for 60 degrees

- largest cell size is 0.7mm

- Skewness max 0.82 (avg 0.0024)

- Non-Ortho min 0.17 (average 0.99)

For my Steady State Case:

- Steady State, Pressure Based Solver

- Energy On

- K-W SST model with Curvature correction

- Im currently using the species transport approach with a multi-step kerosene reaction mechanism (31 species). This is the only option as the non-premixed combustion model cannot handle oxidizer injection (mixture fraction is not tied to O2 concentration).

- Eddy Dissipation Model

- With relax to chemical equilibrium selected

- Diffusion energy source.

- Discrete Phase is on

- Continous Interaction On

- Update DPM Sources every flow iteration

- Dpm Iteration Interval Set to 1

- Unsteady particle tracking (required to model the colisions of the LOX/JetA Jets)

- Physical Models -> Stochastic collision

- Linearized Source terms + Coupled Heat-mass solution

- Injections are defined by surface injections with eddy random walk model

- Mixture set to ideal gas for density

- Liquid Oxygen Droplet and JetA Liquid Droplets

- Coupled Solver

- 1st Order Solution for everything

- Warped Face gradient Correction

- High order Term relaxation

- Controls

- Flow courant number 5

- All URF's are 0.5 except for discrete phase sources at 0.1

- Hybrid initialization

I am unable to get a stable solution with constant divergence. Im not sure if its the DPM solver settings or choosing DPM as opposed to Dense DPM or Eulerian. Any help or guidance here would be appreciated. I have tried following all of ANSYS' best practices under the combustion section of the Ansys Learning Hub. Have liquid rocket combustion problems ever been done before on FLUENT?

-

January 16, 2024 at 12:16 pm

Rob

Forum ModeratorCheck how the collision model works, I'm fairly sure it's only valid where the colliding droplets are the same material for DPM.

In general terms, for trouble shooting, turn off the combustion models. What happens? If divergence still occurs turn off DPM evaporation, and see how that behaves. Ie simplify the model until it works, which will help identify where the problem is coming from.

-

January 17, 2024 at 9:31 pm

Dwight Pienaar

SubscriberI just did a quick DPM droplet collision with unlike materials (diesel & water). So I'm pretty sure the collision between Jet A and LOx should be feasible. I had the breakup model enabled, but continuous phase interaction was off for a barebones model. Just posting this here for future reference to prove that colliding droplets of unlike materials is valid.

-

January 18, 2024 at 11:33 am

Rob

Forum ModeratorCoalesence need the same material, collision doesn't - it's been a long year....

-

January 18, 2024 at 12:50 pm

hudson.pastuszko

SubscriberDoes Ansys have a case study or best practices when it comes to liquid combustion? Would they recommend another multiphase model like VOF or Eulerian? Or is DPM the best method here?

-

January 18, 2024 at 2:26 pm

Rob

Forum ModeratorI'd not recommend VOF here, and VOF to DPM may not be what you want. DPM is often the model used in combustors.

There are some documents but if they're not in Learning, Courses or Knowledge they may be on the Customer Portal which you may not have access to.

-

January 28, 2024 at 3:44 pm

hudson.pastuszko

SubscriberIve been working out the details and Ive tested the both the combustion model seperatly (gas phase) and combined. The simulation works, however the collision seems to not be working very well. The intial breakup of the spray is not captured effectively by the DPM solver.

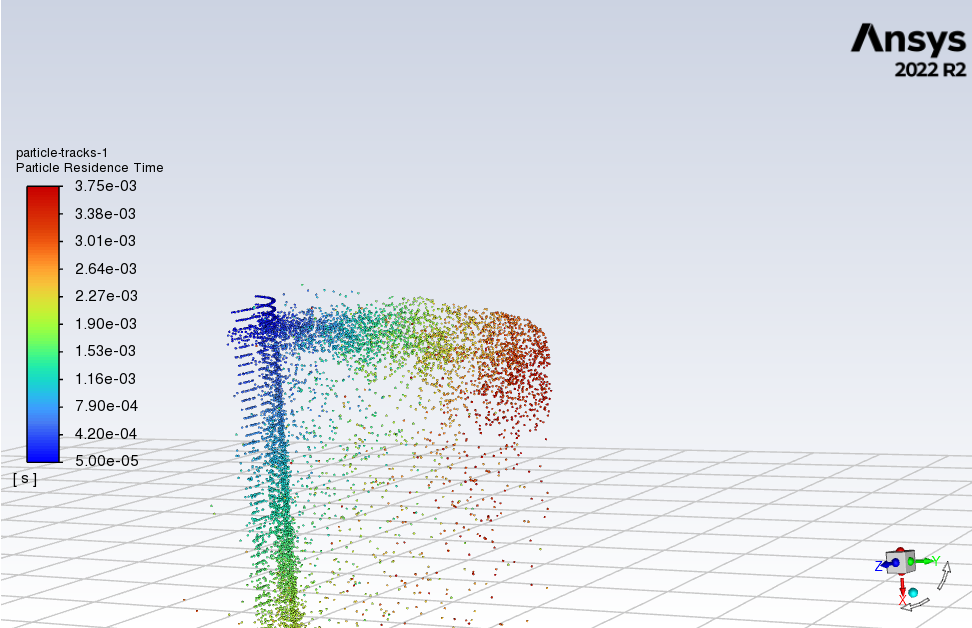

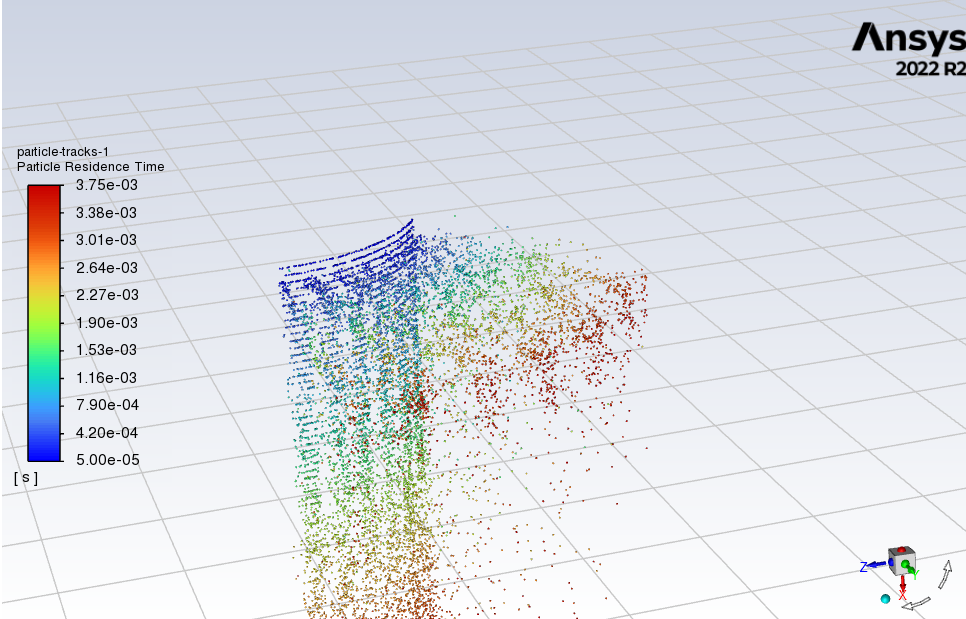

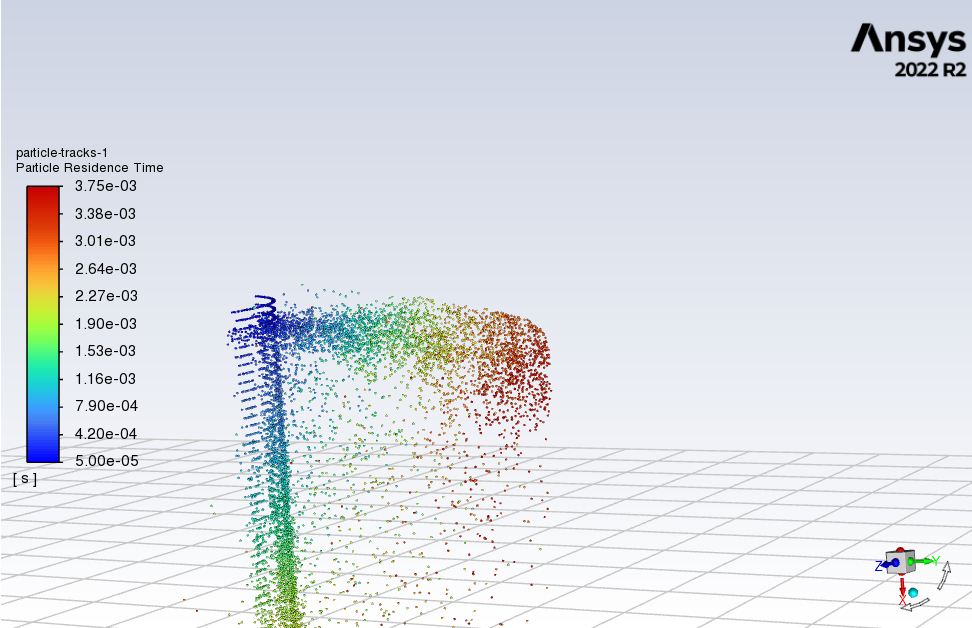

Here is what i am getting:

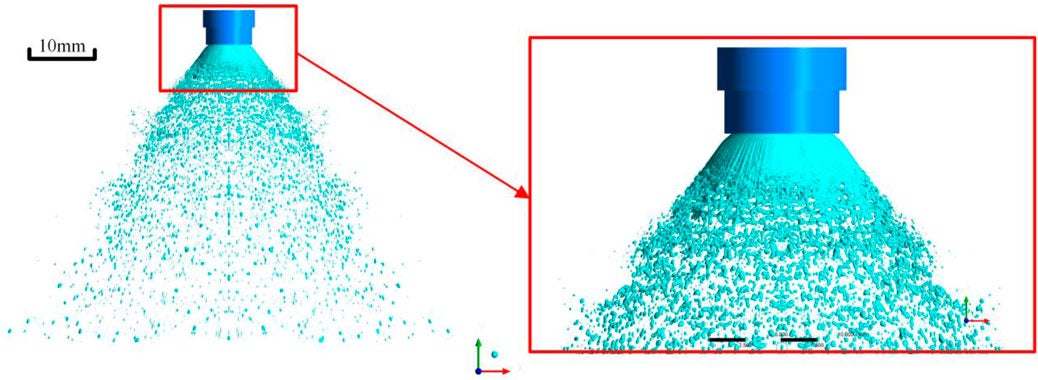

Where as I should be getting something that looks closer to this.

Do you know why these collisions are not accurate? I have attached my casefile here for the DPM injections only (40k coarse mesh).

https://drive.google.com/file/d/12G8_Vn6I3OT_oIfmLYdKUf42nFt3-GlB/view?usp=sharing

Thanks,

Hudson

-

January 28, 2024 at 5:38 pm

mehmetaliadiguzel04

SubscriberDid it get to work?

-

January 29, 2024 at 9:52 am

Rob

Forum ModeratorThat's a VOF sheet going to ligands and then secondary break up gets the droplets. Nothing to do with droplet collision.

-

January 30, 2024 at 6:53 am

-

-

January 30, 2024 at 11:38 am

Rob

Forum ModeratorOr two DPM streams taking note of my comments re droplet material for the coalesence model. It depends which bit you're interested in: primary break up or secondary break up & combustion.

-

January 30, 2024 at 8:04 pm

-

-

January 31, 2024 at 9:34 am

Rob

Forum ModeratorOK, so DPM. Look carefully at how the collision & coalesence model works. For the latter the two injections have to be the same material, nothing to say that material can't be "multicomponent", ie DPM species mixture.

-

January 31, 2024 at 2:28 pm

hudson.pastuszko

SubscriberHi Rob,

What do you mean by this? I have two different fluids, so I cannot have coalesence. How would you model two different fluids in the same injection?

-

January 31, 2024 at 2:28 pm

hudson.pastuszko

SubscriberHi Rob,

What do you mean by this? I have two different fluids, so I cannot have coalesence. How would you model two different fluids in the same injection?

Are you talking about something with Dense-Discrete Phase?

-

-

January 31, 2024 at 3:10 pm

Rob

Forum ModeratorNo, look at multicomponent droplets.

-

- The topic ‘Liquid Oxygen-JetA Multiphase Rocket Engine Combustion’ is closed to new replies.

-

4597

-

1500

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.