-

-

April 25, 2025 at 1:44 pm

2310209024

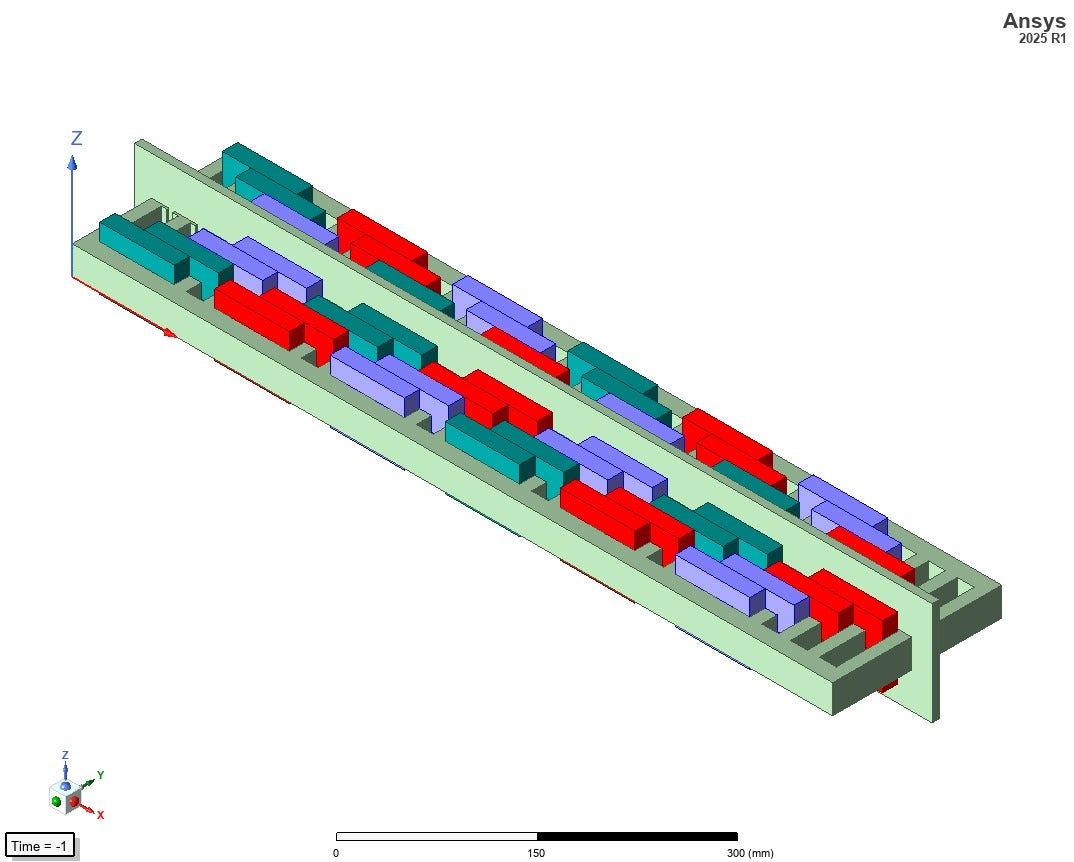

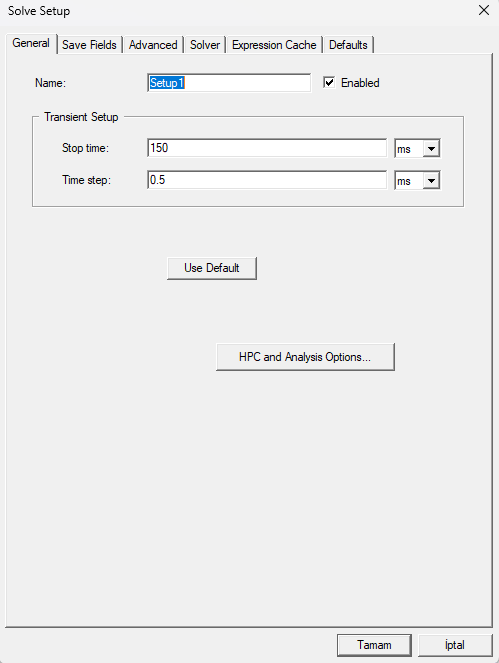

SubscriberI am doing double-sided linear induction motor analysis in Ansys electronics. I can do the analysis but I cannot get the values I want even though I try many different designs. I am requesting technical support on this issue. Can you please help me? I don't know if I am making a theoretical mistake.

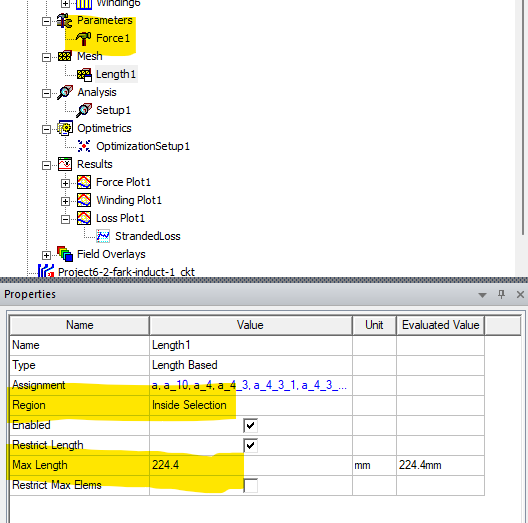

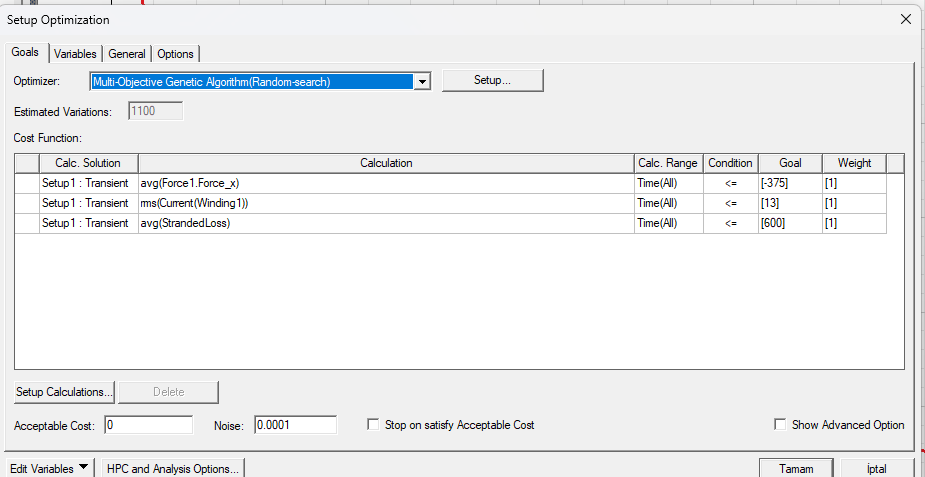

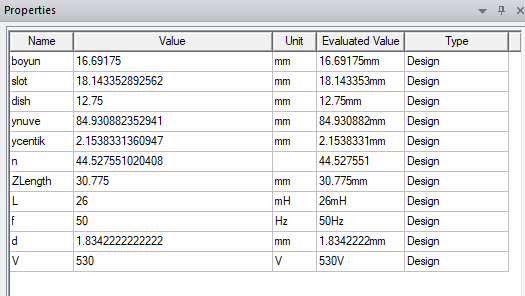

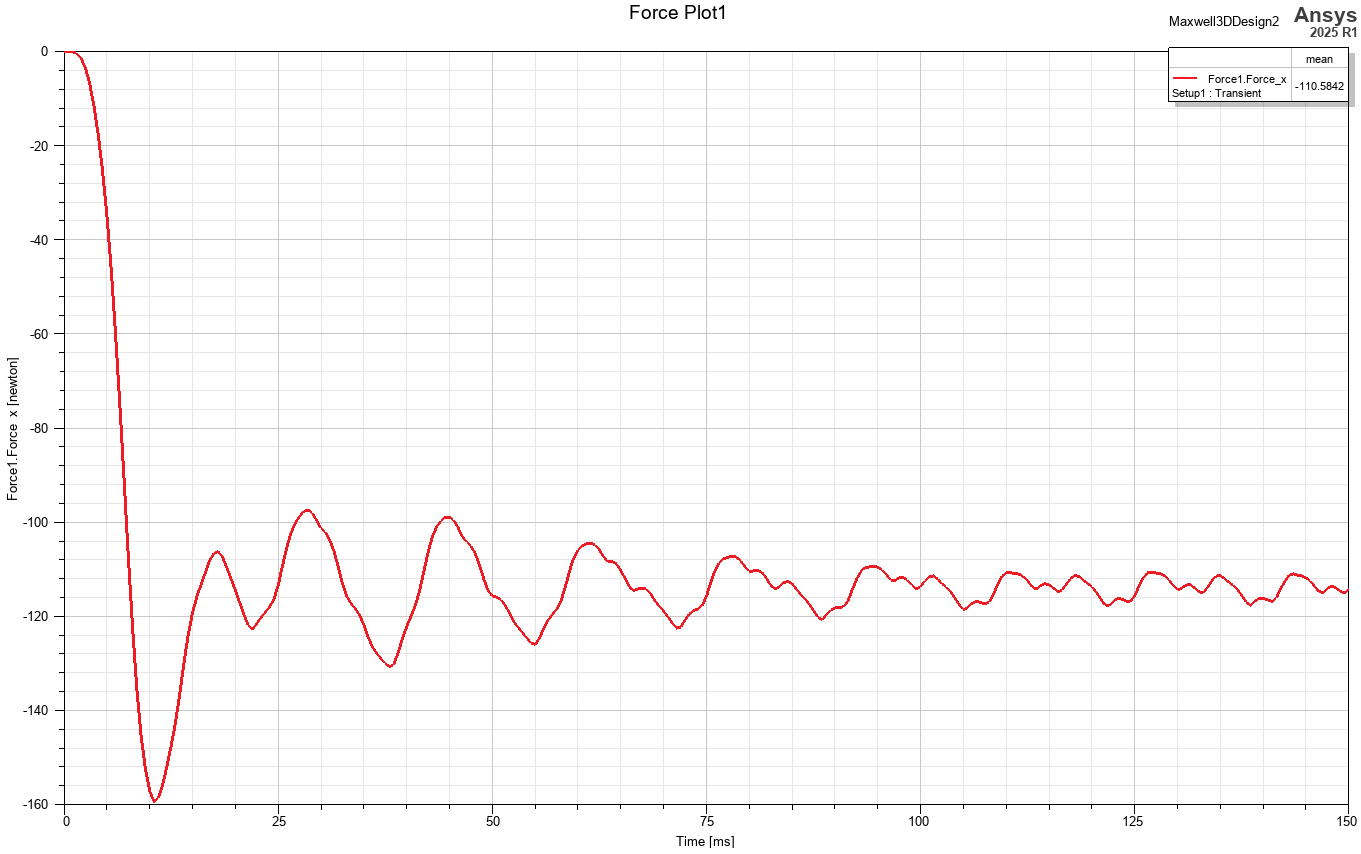

I tried hundreds of different designs. Finally, I assigned almost all the features of the motor (tooth width, slot width, slot length, motor thickness, yoke thickness, etc.) to variables. For example, as the slot width and tooth width increase or decrease, the motor length increases and decreases. In order to provide this and not to receive an error message in Ansys, all of them were assigned as interdependent variables. In this way, I can put the motor into structural analysis with the genetic algorithm. In addition, as a cost function in the genetic algorithm, I kept the force produced by the motor, the rms current (which will be important in real applications, because if I obtain the value of 100Arms and 375N at the same time, the motor windings will definitely coil burnout when I apply. For this reason, I think it is important to keep it in the range of 14-20Arms in real applications) and the winding loss in a certain range for the windings to heat up less.. Despite all this, I cannot get the results I want. Is there a technical error or deficiency? Can you please help?

I tried so hard that I went back to the beginning. Where should I start and what should I pay attention to when designing a double-sided linear induction motor with a power of 12 kW, a force of 375 N and a synchronous speed of 30 m/s?

-

April 25, 2025 at 1:48 pm

2310209024

SubscriberI could make the Max Length(mesh) value smaller to improve the solution, but I don't have enough RAM to do that. Also, there is not much difference between a smaller value and its current value.

-

- You must be logged in to reply to this topic.

-

3019

-

970

-

857

-

761

-

599

© 2025 Copyright ANSYS, Inc. All rights reserved.