-

-

March 17, 2021 at 8:59 am

youfoura

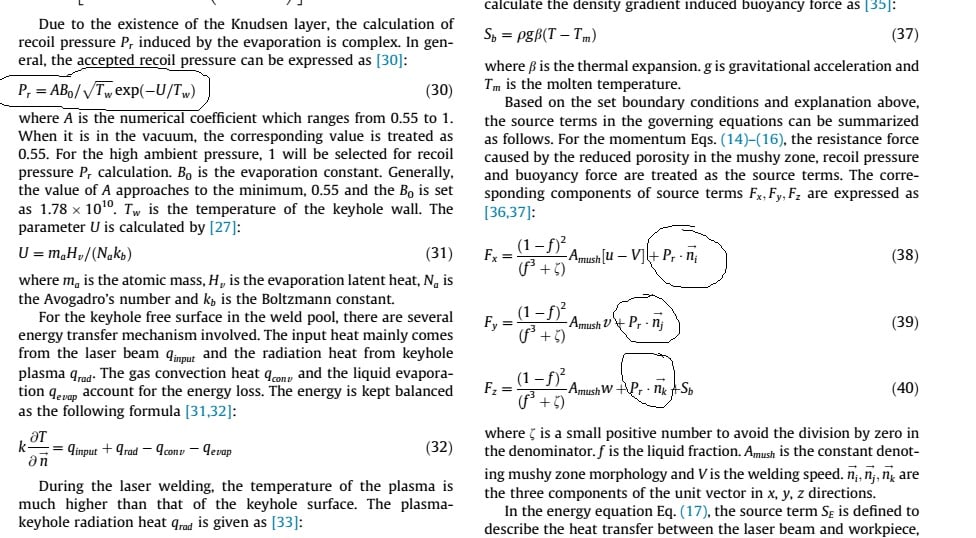

SubscriberThe laser will heat and melt the surface of steel with a temperature reaching above the evaporating temperature of the material (3000 K). Close to the evaporation temperature, the metal surface vaporizes and creates a small depression which is due to the effect of Recoil pressure (pressure acting against vaporization of steel). this recoil effect helps in Keyhole formation and aids in deeper penetration of laser weld. This effect is considered on the free surface.

During the simulation, the recoil effect is added as a momentum source in term as a volumetric force (dividing recoil pressure with gradients of volume fraction (N/m3) ) in the vapour cell when the temperature is above boiling point.

Phase considered are: steel liquid(ID 3), steel vapour(ID 4) and air(ID 2)

March 18, 2021 at 10:26 pmSurya Deb

Ansys EmployeeHello, nYou might need proper Multiphase thread looping structures in the UDF. This will allow to identify the primary vas secondary phases and then calculate the VOF gradients accordingly. nPlease check the link below. https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v211/en/flu_udf/flu_udf_UDFsForMultiphase.htmlnRegards,nSDnMarch 19, 2021 at 3:34 amYasserSelima

SubscriberThe input to define_adjust is the mixture domain ... you can't say domain = Get_domain and recall anther domain.nC_VOF(c,t) ... t must be phase thread as mentioned. You can't use C_VOF macro with mixture domain.nOne more thing, Define_adjust and Define_source are recalled every iteration ... how are you going to save data in UDMI between iterations using ON_DEMAND ??nMarch 19, 2021 at 9:42 amyoufoura

SubscriberHello, You might need proper Multiphase thread looping structures in the UDF. This will allow to identify the primary vas secondary phases and then calculate the VOF gradients accordingly. Please check the link below. https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v211/en/flu_udf/flu_udf_UDFsForMultiphase.htmlhttps://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v211/en/flu_udf/flu_udf_UDFsForMultiphase.htmlRegards,SD/forum/discussion/comment/111535#Comment_111535

thank you for your valuable suggestion. I will modify the structure as mentioned.nMarch 19, 2021 at 9:44 amyoufoura

SubscriberThe input to define_adjust is the mixture domain ... you can't say domain = Get_domain and recall anther domain.C_VOF(c,t) ... t must be phase thread as @sdeb mentioned. You can't use C_VOF macro with mixture domain.One more thing, Define_adjust and Define_source are recalled every iteration ... how are you going to save data in UDMI between iterations using ON_DEMAND ??/forum/discussion/comment/111552#Comment_111552

Thank you for the information. I will incorporate the changes as mentioned.nMarch 23, 2021 at 8:17 amyoufoura

SubscriberThe laser will heat and melt the surface of steel with a temperature reaching above the evaporating temperature of the material (3000 K). Close to the evaporation temperature, the metal surface vaporizes and creates a small depression which is due to the effect of Recoil pressure (pressure acting against vaporization of steel). this recoil effect helps in Keyhole formation and aids in deeper penetration of laser weld. This effect is considered on the free surface.During the simulation, the recoil effect is added as a momentum source in term as a volumetric force (dividing recoil pressure with gradients of volume fraction (N/m3) ) in the vapour cell when the temperature is above boiling point.Phase considered are: steel liquid(ID 3), steel vapour(ID 4) and air(ID 2)https://us.v-cdn.net/6032193/uploads/XCT42FKS13C4/recoil-pressure.jpg I have written a UDF for the mixture but it is not compiling in the solver and maybe the CODE is incomplete. Can someone help or suggest, what all things have to be added while writing the CODE for considering the gradients of volume fraction?https://us.v-cdn.net/6032193/uploads/L3OSLX6V8MQ1/image.png#include "udf.h"#include "sg.h"#include "sg_mphase.h"#include "flow.h"#include "mem.h"#include "unsteady.h"# define domain_ID 4DEFINE_ADJUST(adjust_gradient, domain){ Thread *t;cell_t c;face_t f;domain = Get_Domain(domain_ID);/* Fill UDS with the variable. */thread_loop_c (t,domain){ ttbegin_c_loop (c,t)tt{ ttC_UDSI(c,t,0) = C_VOF_G(c,t)tt}tend_c_loop (c,t)}}DEFINE_ON_DEMAND(store_gradient){Domain *domain;cell_t c;Thread *t;domain=Get_Domain(domain_ID); /* Fill the UDM with magnitude of gradient. */thread_loop_c (t,domain){tbegin_c_loop (c,t)tt{ttC_UDMI(c,t,0) = NV_MAG(C_UDSI_G(c,t,0));tt}end_c_loop (c,t)}}DEFINE_SOURCE(y_recoil,c,t,dS,eqn){treal x[ND_ND]; treal source;treal time;treal temp;ttime=RP_Get_Real("flow-time"); //Acquire time from FLUENT solvertC_CENTROID(x,c,t);ttemp=C_T(c,t); t//Acquire the face centroid locationt if (C_T(c,t) > 3000.) { source = (54715.5*exp(13.14*(temp-(2600)/temp)))*C_UDMI(c,t,0);dS[eqn] = 0; }telse { source = 0;dS[eqn]=0.0; } return source;}/forum/discussion/25821/laser-welding-how-to-apply-recoil-pressure-in-the-momentum-equation

@YasserSelima, @sdeb, nThe Primary phase is assigned as air, secondary phase 1- steel liquid property and secondary phase 2- steel vapor property. I have modified the UDF. while interpreting the message shown is : line 18 (corresponding to if (FLUID_THREAD_P(t)) ..) structure reference not implemented. n#include 'udf.h'n#include 'sg.h'n#include 'sg_mphase.h'n#include 'flow.h'n#include 'mem.h'n#include 'unsteady.h'nDEFINE_ADJUST(adjust_gradient, domain)n{ntcell_t c;n Thread *t;ntThread **pt;ntint phase_domain_index = 2;ntDomain *pDomain = DOMAIN_SUB_DOMAIN(domain,phase_domain_index);ntmp_thread_loop_c (t,domain,pt)ntif (FLUID_THREAD_P(t))nt {nt Thread *tp = pt[phase_domain_index];ntbegin_c_loop (c,t)nt {n C_UDMI(c,t,0) = C_VOF_G(c,tp)[0];n C_UDMI(c,t,1) = C_VOF_G(c,tp)[1];n C_UDMI(c,t,2) = C_VOF_G(c,tp)[2];nC_UDMI(c,t,3) = sqrt(C_UDMI(c,t,0)*C_UDMI(c,t,0)+C_UDMI(c,t,1)*C_UDMI(c,t,1)+C_UDMI(c,t,2)*C_UDMI(c,t,2));nt }ntend_c_loop (c,t)n } n}nDEFINE_SOURCE(x_recoil,c,t,dS,eqn)n{ntreal x[ND_ND]; ntreal source;ntreal time;ntreal temp;nttime=RP_Get_Real('flow-time');ntC_CENTROID(x,c,t);nttemp=C_T(c,t); ntif (C_T(c,t) >= 3201.)n {ntsource = (54715.5*exp(13.14*(temp-(3201)/temp)))*(C_UDMI(c,t,0)/C_UDMI(c,t,3));n C_UDMI(c,t,4) = source;n }ntelsen {n source = 0.;n }n dS[eqn] = 0.n return source;n}nMarch 23, 2021 at 1:10 pmYasserSelima

SubscriberI am not sure what is wrong with this specific line ... but I can see later in your UDF you are requesting C_VOF with the mixture thread which will result in another errornnThere is an example in the manual, I believe DEFINE_INIT under Multiphase Looping Macros .. the example sets or initiate C_VOF ... follow the same loop structure to access C_VOFnI never used mp_thread_loop_c but I believe it requires { } as wellnMarch 24, 2021 at 9:10 amyoufoura

SubscriberOk.. Also, when I tried to remove that line the code was not compiling even though the code was intrepreting with out any error.nanyway I will check it again nViewing 7 reply threads- The topic ‘Laser welding- how to apply recoil pressure in the momentum equation’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3215

-

1031

-

968

-

859

-

798

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

Ansys Assistant

Welcome to Ansys Assistant!

An AI-based virtual assistant for active Ansys Academic Customers. Please login using your university issued email address.

Hey there, you are quite inquisitive! You have hit your hourly question limit. Please retry after '10' minutes. For questions, please reach out to ansyslearn@ansys.com.

RETRY