-

-

July 10, 2020 at 1:52 pm

DanielLavayen

SubscriberHello everyone,

I am having some troubles analyzing the collapse of a hollow square tube in a 3 point bending test simulation. Even though I obtain a F-u curve quite close to the expected curve (theoretical and experimental). I have found some points that suffer from excesive plastic strain. Some of them have 1.1 and even -1.1 plastic strain in all directions. Those points are the ones in contact with the rigid force applicator. Also, the point where the collapse occurs, also suffers this large plastic deformations.

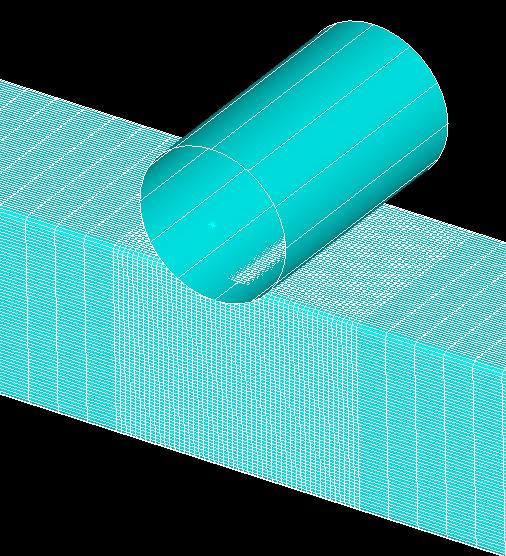

I used solid185 elements for the tube, with little fillets (if i dont use fillets, the problem is more severe) and conta174 elements for contacts and targe169 elements to model the supports and force applicator (as cylinders).

I tried the ERESX,NO option to avoid stress above the limit, I have also tried changing to enhanced strain formulation and simplified enhanced strain formulation (however this two last options have problems converging).

How can i decrease this extremely high plastic deformations? I tried several mesh sizes but have the same issues at the end. Below there are some screenshots of the problem at hand.

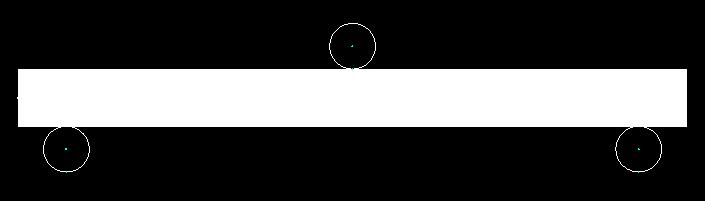

Here is the general scheme of the test

A detail of the mesh used

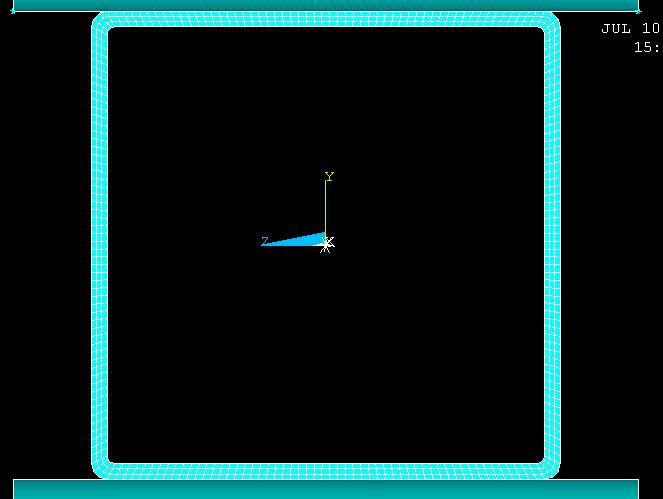

A cross section of the mesh

Plastic deformation in the x-direction. Notice the point with high plastic deformation

von Mises plastic deformation... excesive in one point in the middle

Thanks in advance for your help!

-

- The topic ‘Large plastic strain during collapse in 3 point bending simulation’ is closed to new replies.

-

4929

-

1623

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.