TAGGED: -quasi-static, convergence, error, mechanical, simulation, transient-structural

-

-

December 23, 2025 at 12:22 pm

nik_21000217

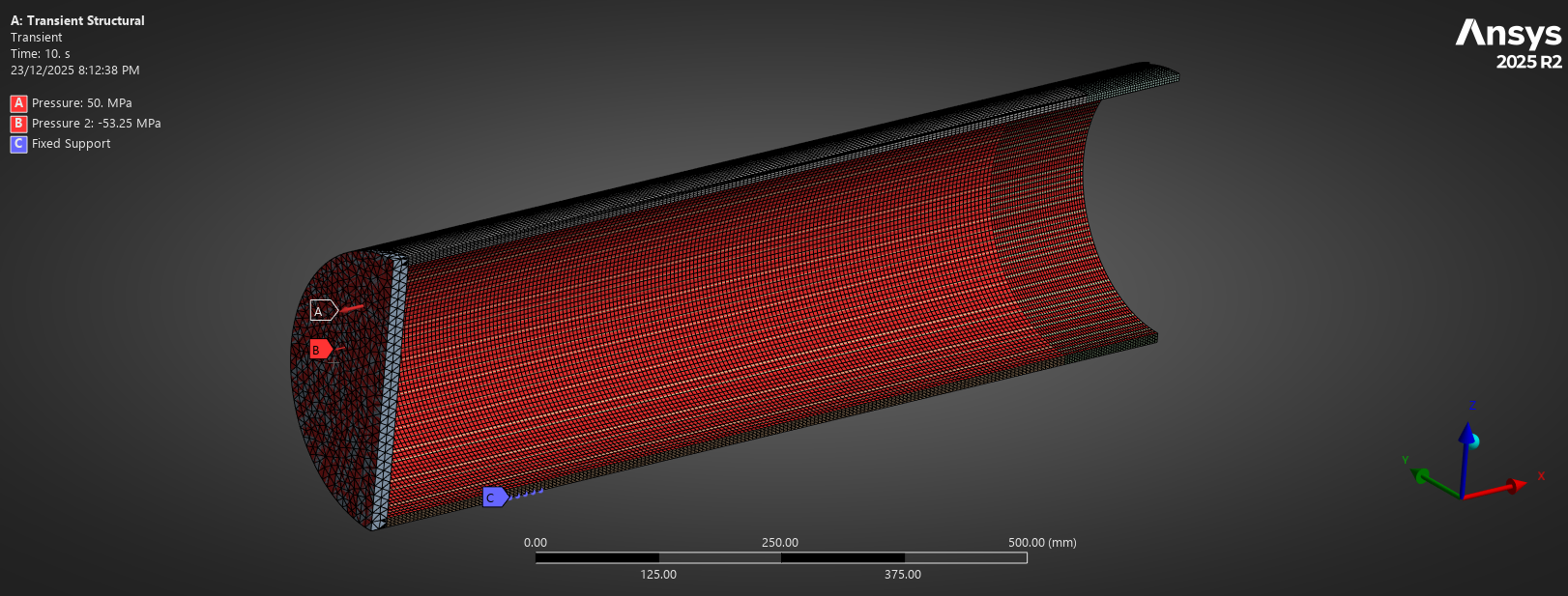

SubscriberHi there, I need help with the issues i have been struggling for the past few weeks. I am modelling a quarter model of a straight steel pipe with corrosion defects in ANSYS Mechanical (Transient Structural). Internal pressure and axial tensile loading are applied simultaneously (ramped over time).

To remove rigid body motion, I first fixed a small number of nodes at the outer pipe body, but this caused severe local element distortion (“element turning inside out”) and convergence failure before the von Mises stress reaches the pipe UTS at the corrosion defect region.

I then tried applying a Fixed Support at the centre of the end cap (the end cap is intended to act as a rigid region and should not deform). However, when I use this constraint, the axial tensile load does not seem to be properly transferred into the pipe body. During post-processing, the stress in the pipe body remains almost constant while the axial tensile load is ramping. I have attached images of the setup and loading history.

Question:

Since i want to analyse pipe failure pressure due to internal pressure and external axial tension, what is the recommended way to constrain a pressurised pipe model to prevent rigid body motion without suppressing axial load transfer or causing element distortion? -

December 23, 2025 at 1:47 pm

peteroznewman

SubscriberNik,

The way to support a pipe with a closed end is to use a Remote Displacement, Type = Deformable, on the cut face at the open end of the pipe. Set all six components of the Remote Displacement to zero to prevent rigid body motion. The deformable nature of the connection will allow the pipe to expand radially due to the internal pressure.

The reaction force on the Remote Displacement will be equal to Pin*Ain + Pout*Aout where Pin is the internal pressure, Ain is the cross-sectional area of the ID of the pipe, Pout is the external pressure and Aout is the area of the face that pressure was applied to.

I see you have a pressure applied to the external face of the end cap, but not on the side of the pipe. While that is easy to do in the FEM, how it physically possible to do in reality?

-

- You must be logged in to reply to this topic.

-

4683

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.