-

-

April 15, 2024 at 7:56 pm

Rowan Timoffee-Maberly

SubscriberHello!

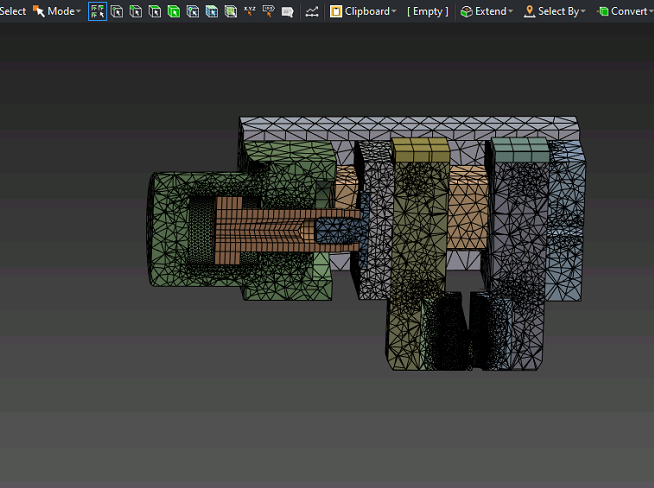

I am trying to determine how much my tools will deflect when pressed into each other with a set pressure.

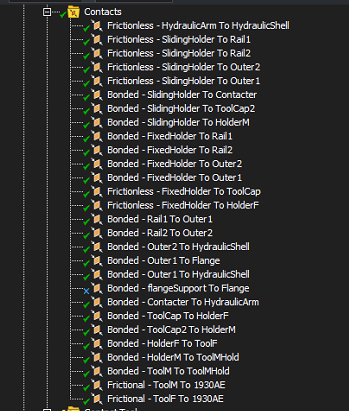

The left tool is able to slide along a rail into the other tool. I have created a model where the tools are almost already touching. I have appllied pressures to the back of the sliding tool. Unfortunately it just passes through the rails that it should be sliding along. The tools never end up influencing each other.

I have watched numerous tutorials at this point and am unsure as to why the left tool isnt being pressed into the right tool.

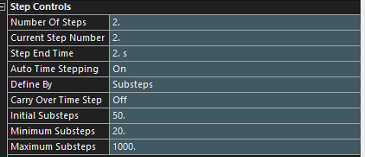

I have two steps, the first just tto try and get everything setteled in position. the second has a force applied.

The contacts that i would expect to move are all frictional or frictionless.

for example the "sliding holder" holds the left tool. it wraps around the "rail" and should be able to move.

As stated the parts just seem to pass through each other and fly into space even though the contacts have been defined.

Should I be doing this as a dynamic analysis instead? are there any suggestions to changes I could try implementing?

thanks. -

April 16, 2024 at 7:00 am

Akshay Maniyar

Ansys EmployeeHi Rowan,

Please check the below video for checking initial contact conditions. Make sure that the initial conditions look correct.

Checking Initial Contact Conditions Prior to Solving - Lesson 3 - ANSYS Innovation Courses

Are you using Large deflection as ON or OFF? Do you have weak springs in the model?

Thanks,

Akshay Maniyar

-

April 16, 2024 at 6:08 pm

Rowan Timoffee-Maberly

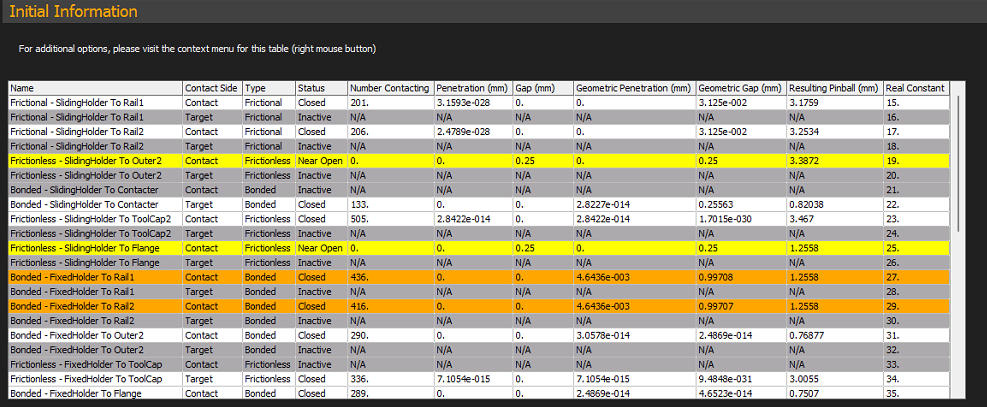

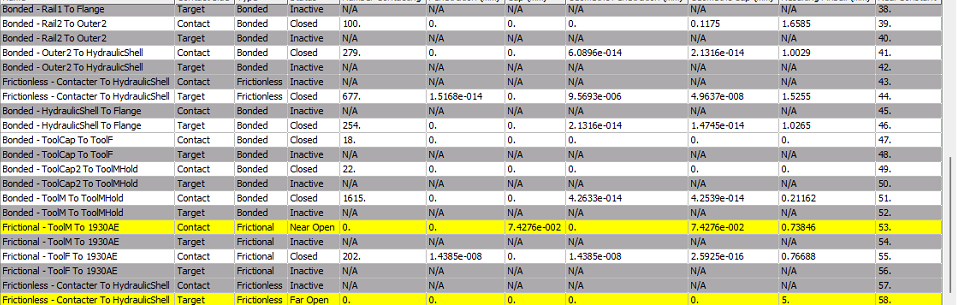

SubscriberThe intial conditions look correct from what I can see, but i am probably mistaken here. Is there a good way to diagnose which connections may be causing a model to be unsolvable?

Ive looked through a few times and have not gotten a convergence. I simplified my cad stucture a fair amount and am oging to run the solver again.

Large deflection and weak springs are both on.

Im wondering if it would be easier to add a displacment that pushes the tools together and get the force data from the reaction force graph.

The problem is i dont know how much dispalcement occurs, just how much pressure we are applying to the system. When split into two steps the first section converges where no forces have been applied. but the second step does not have any convergences. -

April 16, 2024 at 7:01 pm

Akshay Maniyar

Ansys EmployeeHi Rowan,

Can you check the initial information table and see if you have some orange or red-marked contacts? Also, can you try switching the weak spring OFF and see if your model is properly constrained?

It is better to use displacement constraint for the proper constrained model. You can apply displacement and check the reaction force for it.

Thanks,

Akshay Maniyar

-

April 16, 2024 at 7:32 pm

-

- The topic ‘Issues getting analysis to behave as I would expect.’ is closed to new replies.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- BackGround Color

- Contact stiffness too big

- Element Birth and Death

- Python-Script to Export all Children of a Solution Tree

- Which equations and in what form are valid for defining excitations?

-

4597

-

1495

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.