-

-

July 15, 2025 at 7:26 pm

rohansom

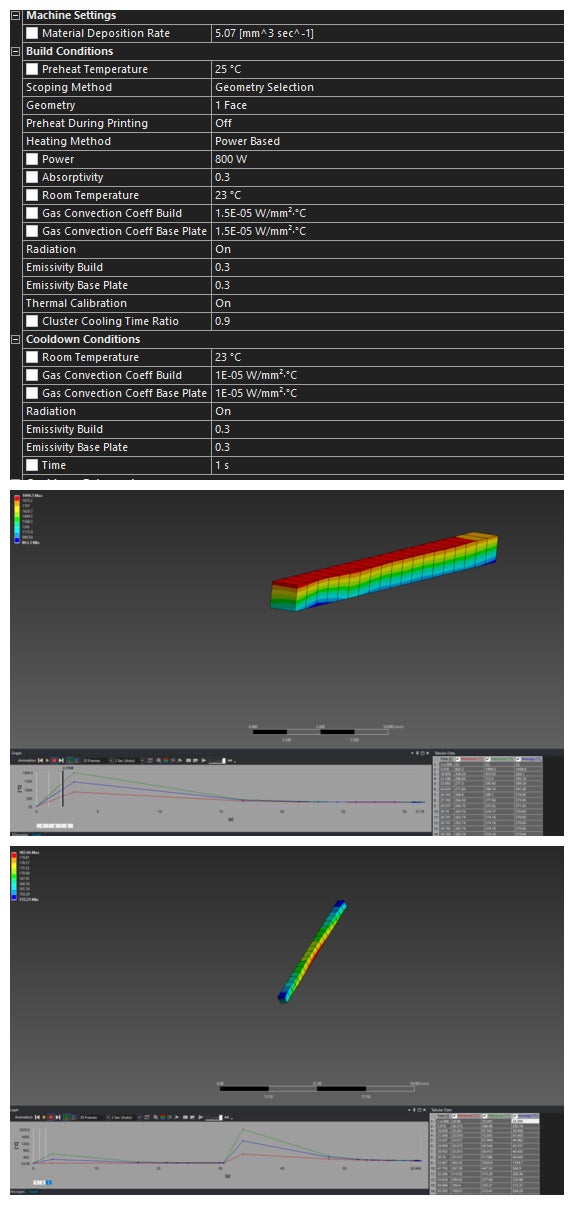

SubscriberI’m currently working on a project investigating how reheating affects the austenite percentage in L-DED (Direct Energy Deposition) of SS, and we are trying to extract accurate time–temperature curves from Ansys Additive DED. I had a doubt regarding the power mode in Ansys DED

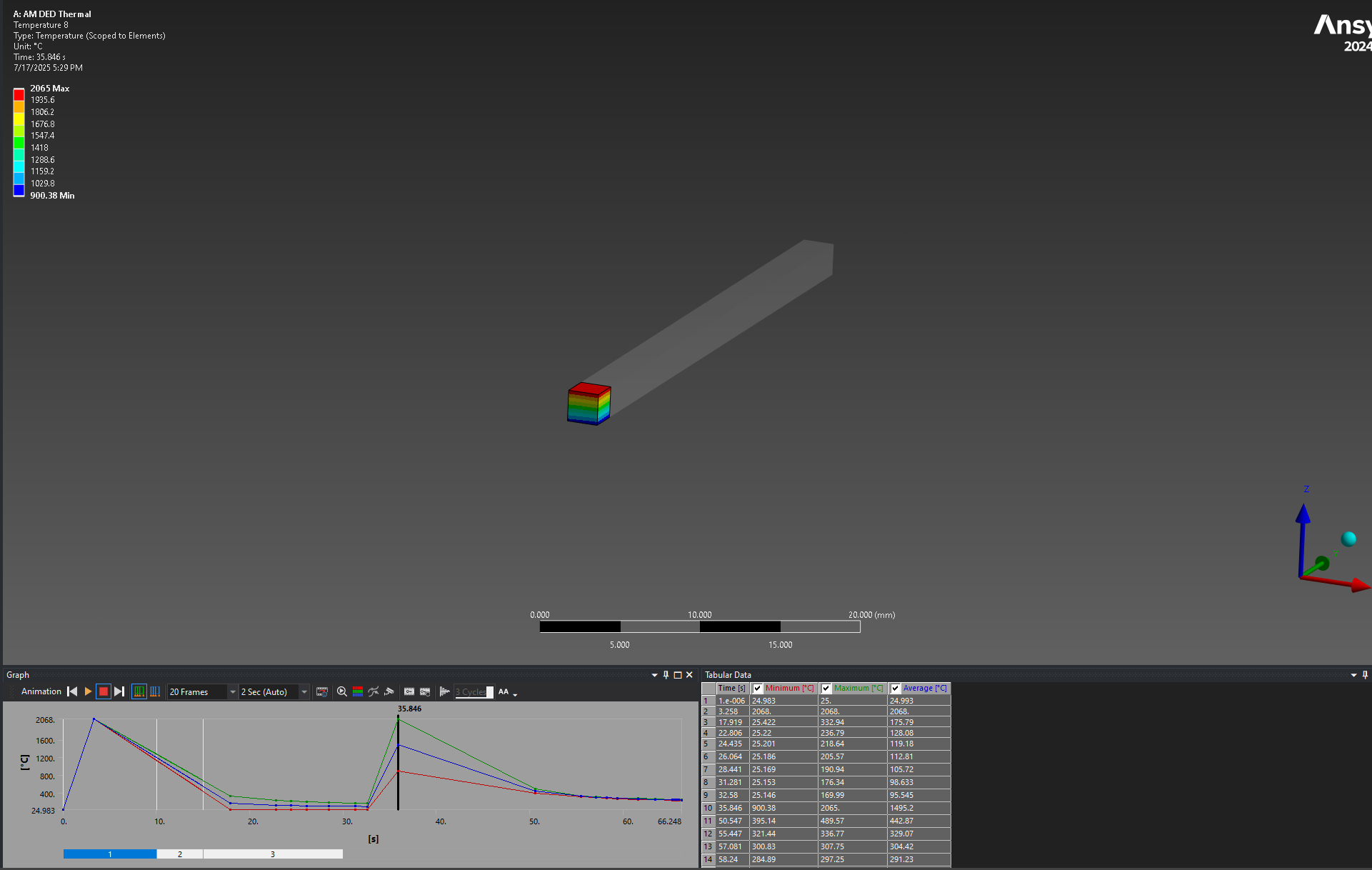

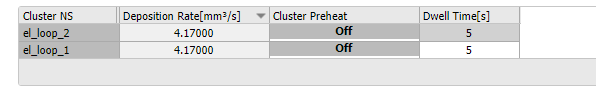

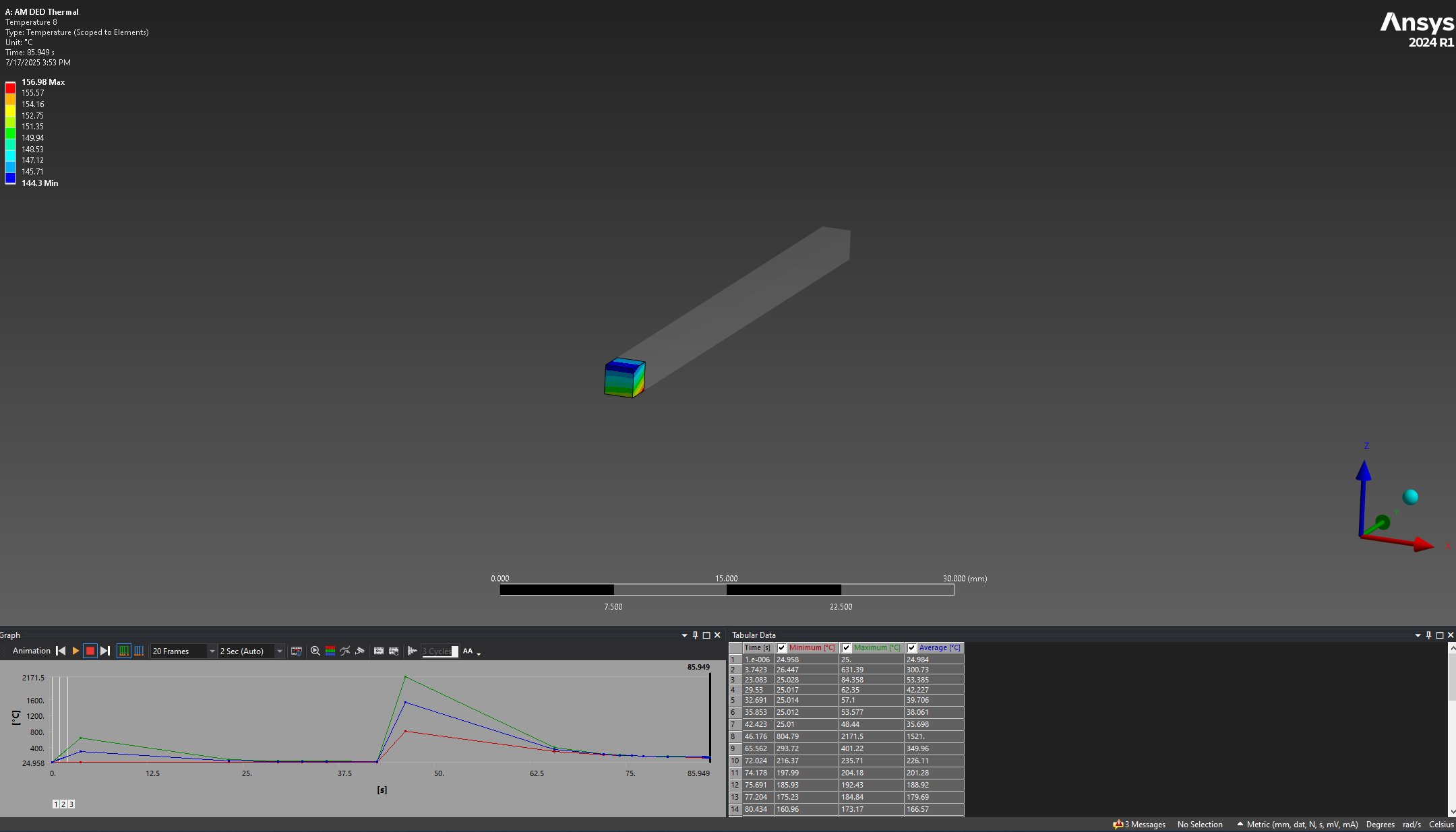

We're encountering issues specifically with the Power Mode. The simulations often produce unrealistically high temperatures. Increasing the cluster volume has helped to generate more reasonable results for single-layer cases. However, when simulating two layers with the same parameters, the first layer exhibits very low peak temperatures during its own deposition, but then receives significantly higher temperatures during the reheating stage from the second layer—a behavior that doesn't appear physically accurate.

Could anyone suggest how to address this issue? I’ve attached images of the single- and double-layer results for reference, and I’m happy to provide more details if needed.

-

July 17, 2025 at 7:05 pm

John Doyle

Ansys EmployeePerhaps you need to calibrate the dwell time to allow for a longer pause between the completion of this cluster and the beginning of the next, not including laser travel time.

-

July 17, 2025 at 8:00 pm

rohansom

SubscriberHi John, thanks for getting back.

I increased the dwell time and tried it for different dwell times. It doesn't make any difference. This was for the first layer of a two-layer print in power mode. I have chosen a single layer as a single cluster. Making it a smaller cluster will skyrocket the temperature.

-

July 17, 2025 at 8:11 pm

John Doyle

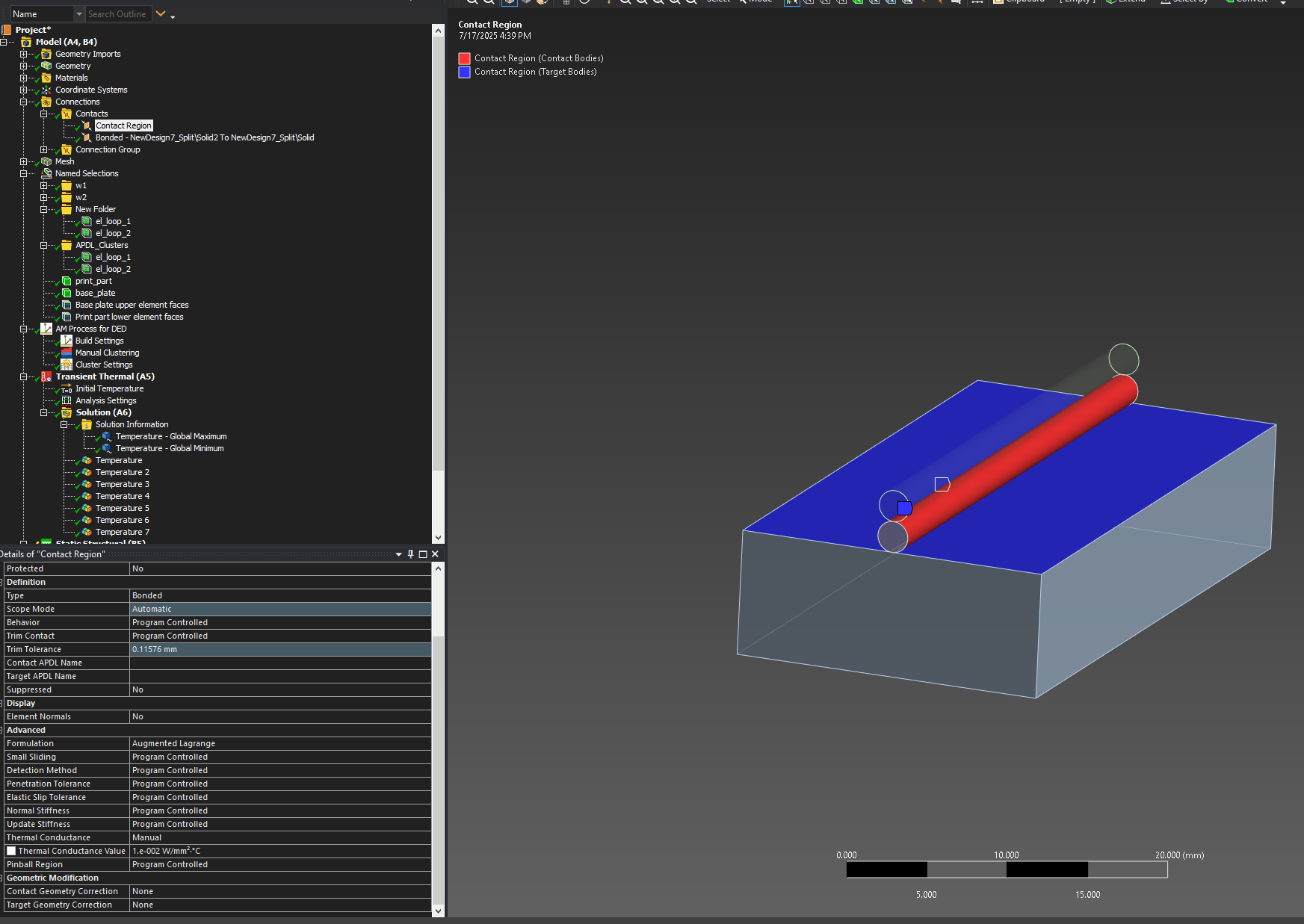

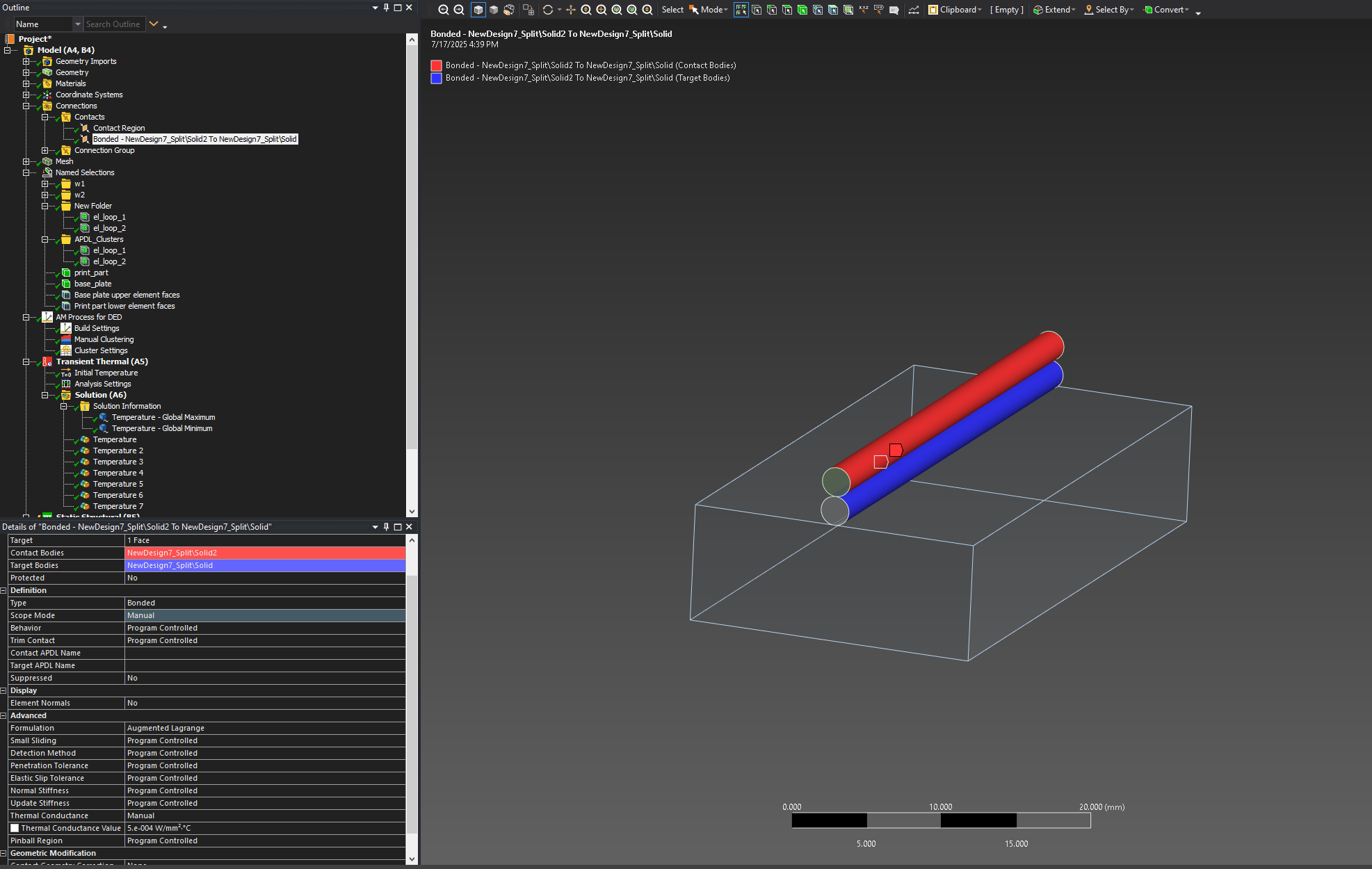

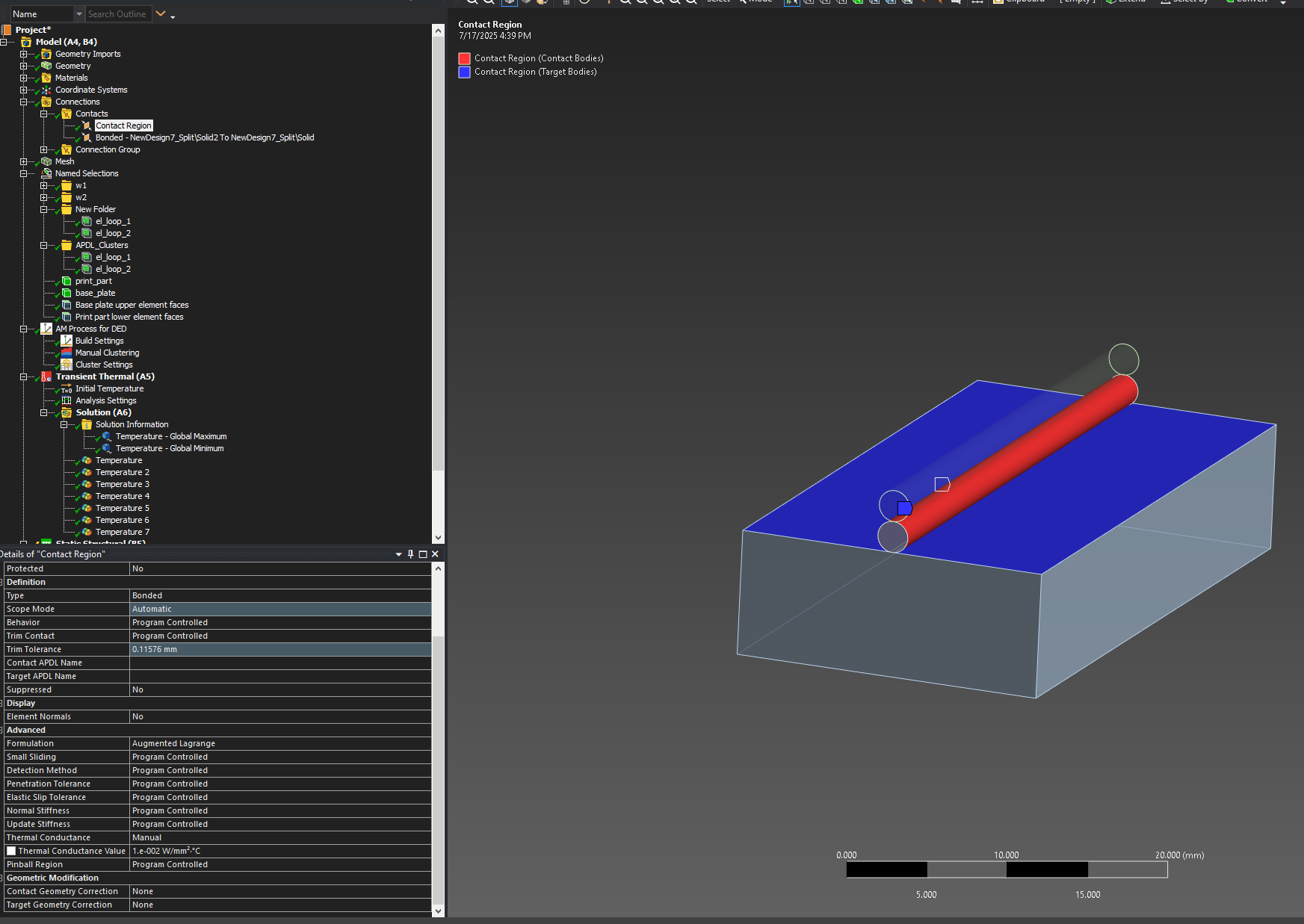

Ansys EmployeeCould material specific heat be too low? Also, I assume there is a bonded MPC contact between first layer and baseplate. Perhaps switch contact formulation to Augmented Lagrange and try calibrating the TCC (Thermal Contact Conductance) to a value that produces a reasonable heat transfer without over cooking the small cluster volume.

-

July 17, 2025 at 8:45 pm

-

July 17, 2025 at 9:01 pm

rohansom

Subscriberhttps://youtu.be/FG1fWrU53jU

This is the animation of a two-layer print; you can see it the first layer is not reaching the high temperature as expected. -

July 17, 2025 at 9:31 pm

-

- You must be logged in to reply to this topic.

-

3492

-

1057

-

1051

-

965

-

942

© 2025 Copyright ANSYS, Inc. All rights reserved.