TAGGED: 3d-sampled-data, dpm, fluent, transient

-

-

January 31, 2024 at 9:55 pm

ll00023

SubscriberSince the inbuilt tool in FLUENT produced really confusing result of DPM (transient result), I tried to use Matlab to postprocess them.

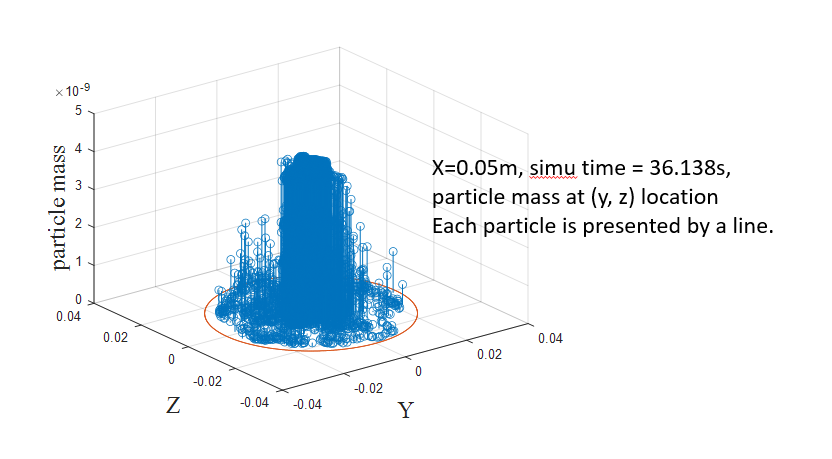

I have some preliminary results, shown below. I draw the single particle parcel mass in a 3D plot. it shows more particles appears in the center of the cylinder shape. see the reference line.

Then I want to add the mass at the same (y, z) coordinate. I didn't find a way in Matlab how to check whether the particle coordinates are the same. if there are different particles at the same location and time, then I need to add them up. so then it should be clearer.

or to draw them in a surface?

Do you have any suggestion about the tool to process this data?

Thank you.

-

February 2, 2024 at 6:13 am

Nilay Pedram

Forum ModeratorHello,

Feel free to reach out to Matlab support for any related inquiries. If you have questions about Ansys Fluent, we're here to assist you.

Thank you!-

February 2, 2024 at 2:32 pm

ll00023

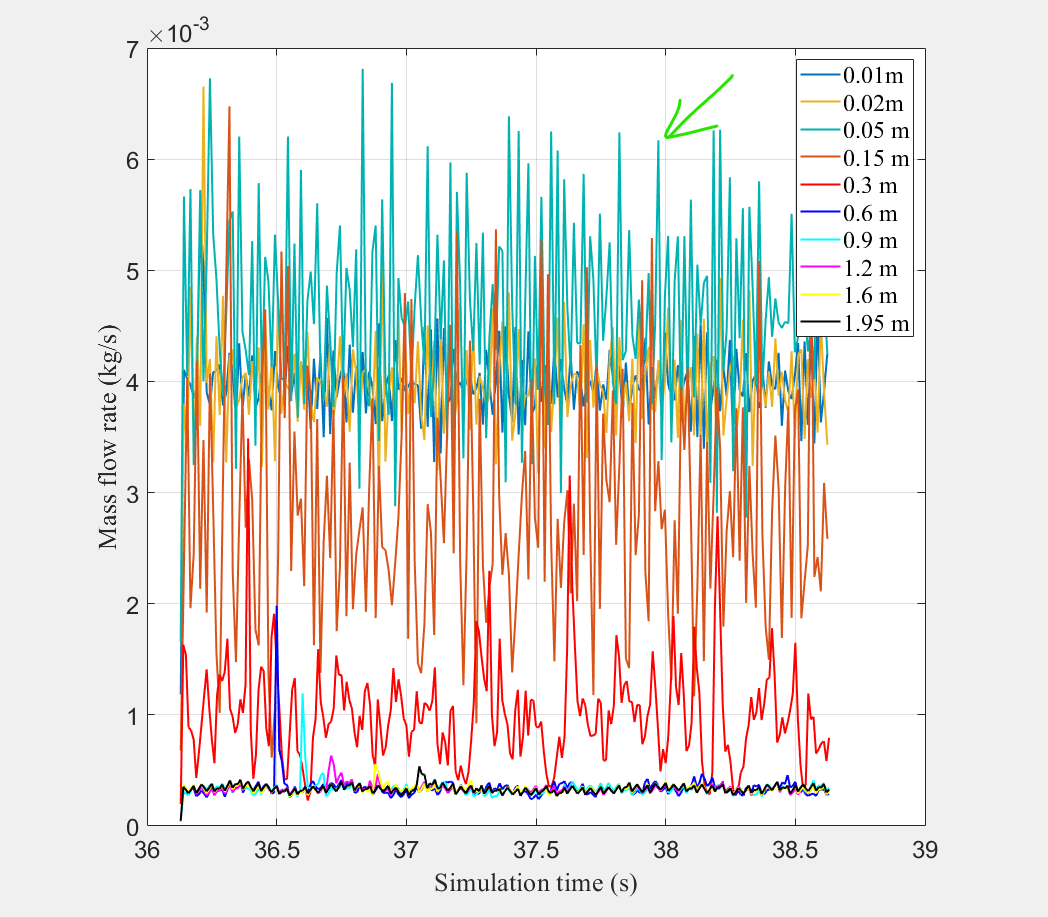

SubscriberWhat's the value of parcel mass meaning from the sampling?

I set the bin's flow time. Fluent provides the total mass of particle parcels passing through during the time interval.

you can see the max value is about 6e-3 kg/s while my particle injecting mass flow rate is 4e-6kg/s. Is it casued by flow recirculating?

-

-

February 2, 2024 at 3:06 pm

Prashanth

Ansys Employeeparcel mass is particle mass times the number of particles in a parcel

-

February 2, 2024 at 3:19 pm

ll00023

SubscriberI didn't make the question clear.

My question is: how sampling plane detects particle parcels?

in the dpm output file, particle location is listed. so the mass flow rate didn't consider the direction of particle. if recirculation, we didn't recognize it as negative flow rate, right?

-

-

February 2, 2024 at 3:43 pm

Prashanth

Ansys EmployeeI think it just logs the particle parcels when it crosses the plane. You might need to filter them using their IDs.

-

February 2, 2024 at 4:43 pm

ll00023

SubscriberDo you mean their ID could be the same if they are the same particle parcel?

I could test this by sorting up the ID number.

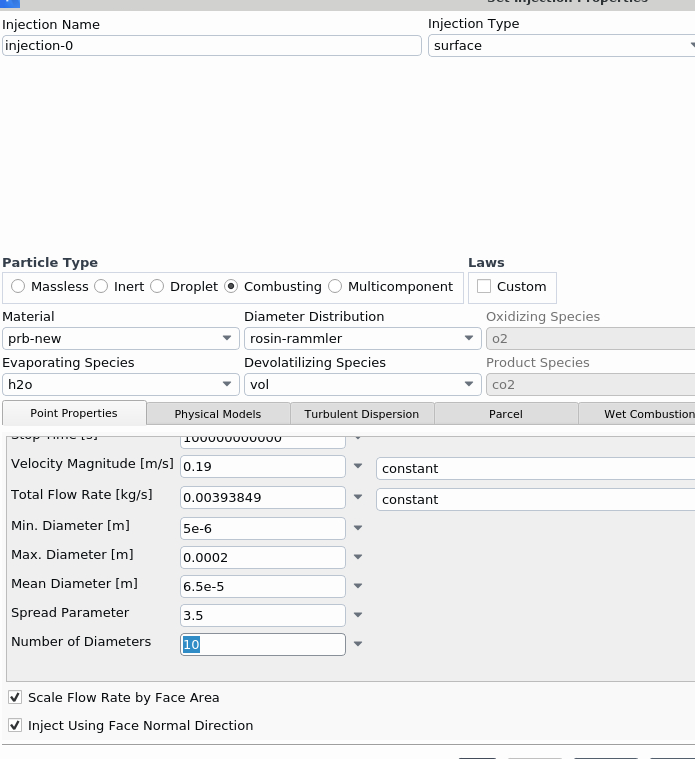

Another question: in transient simulation, number of particle parcel injected = number of mesh * number of diameter (refer to figure below)?

now I have 15120 particle parcel injected, so 10 particle parcel injected at each cell. particle parcel number density is uniform. does my assumption right?

-

-

February 2, 2024 at 6:07 pm

Prashanth

Ansys EmployeeYes, number of injections is number of diameter set for distribution times the number of facet cells. You can refer to the Fluent User manual for more such setup information.

-

February 2, 2024 at 10:23 pm

ll00023

SubscriberI found it by search Number of diameter in User guide manual

"Ansys Fluent will inject streams of particles from each face on the surface, with diameters defined

by the Rosin-Rammler distribution function. The total number of injection streams tracked for the

surface injection will be equal to the number of diameters in each distribution (Number of Diameters)

multiplied by the number of faces on the surface."I encountered a contradiction: I make a smaller surface by clip-surf, verified by its area compared with previous injection surface.

I generate the mesh in ICEM, by mapping. so the mesh structure of both surface should be the same. the clip surf should contain less mesh than previous surface, so the number of particle parcel should be less.

but the number of particle parcel at this clip surface is 15120, about 2 times of previous one 8820.

based on the definition above, I didn't change the number of diameters, it should be less.

-

- The topic ‘interrogating fluent dpm sampling output data’ is closed to new replies.

-

4838

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.