-

-

August 1, 2018 at 6:30 pm

Han-yu

SubscriberHi

Could you show me how to use Anasys Workbench to simulate the interacting between two different part?

For example, one part slide into another part.

-

August 1, 2018 at 6:56 pm

Sandeep Medikonda

Ansys Employee -

August 1, 2018 at 7:39 pm

-

August 1, 2018 at 8:05 pm

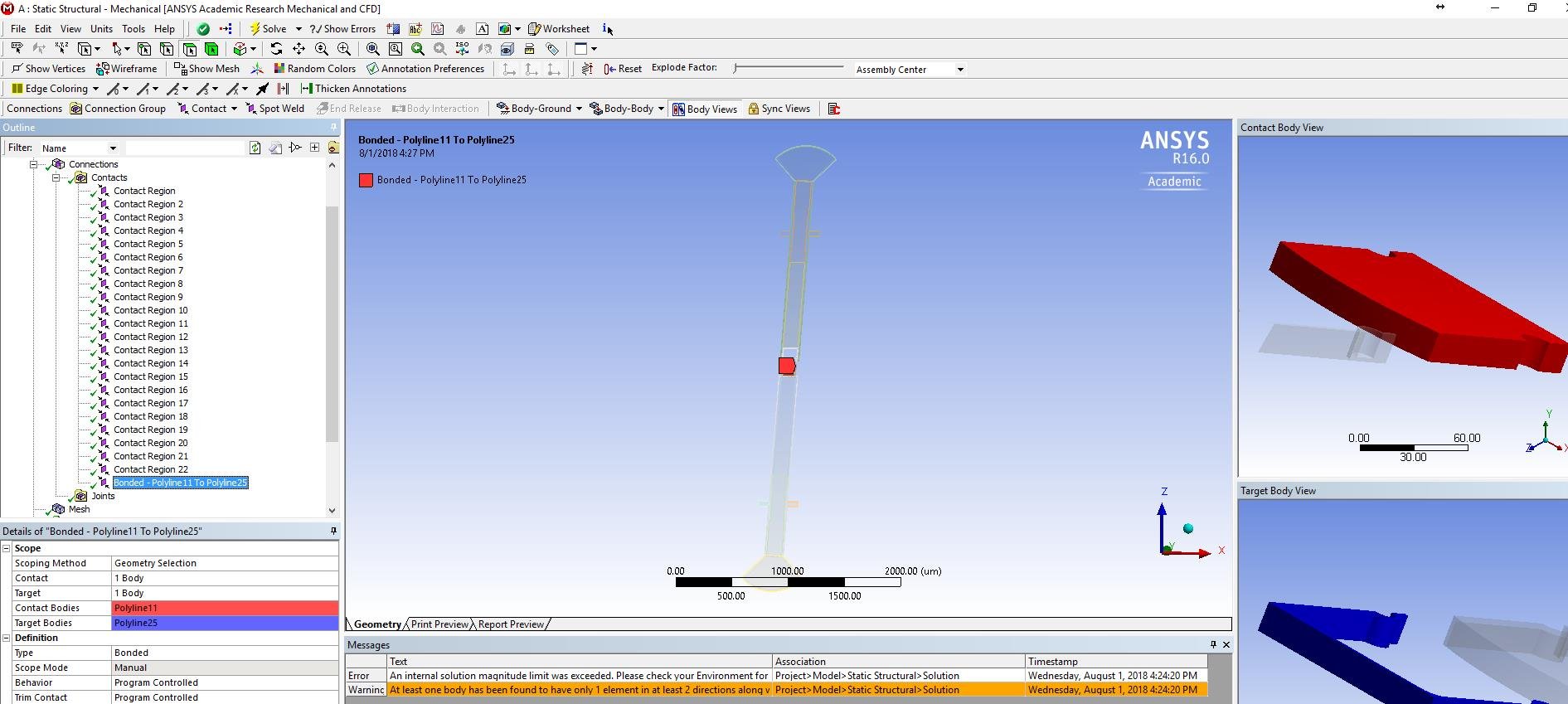

Sandeep Medikonda

Ansys EmployeeAre these solid bodies? It's hard to tell what your boundary conditions are? Can you post snapshots by clicking on the analysis (Static structural), this will give a nice summary of how you are loading the model. Also, please post snapshots of your tree and details in the connections? Typically you would just right click on connections, insert manual contact, select the contact and target surfaces and select the type of contact. i.e., Frictional in your case.

-

August 1, 2018 at 8:30 pm

-

August 1, 2018 at 8:49 pm

Sandeep Medikonda

Ansys EmployeeIf you are using bonded contact, I don't expect any sliding behavior. Please use frictional contact between the parts that are touching each other.

https://www.youtube.com/watch?v=ov7PAEwFZm8

Regards

-

August 1, 2018 at 9:00 pm

peteroznewman

SubscriberHi Virginia, yes, that is where you go, not your name, but it's a nicer name than ht5fy

I see you have a fixed support for first assembly, but the second assembly only has the two forces applied. That is not sufficient.

You want to add supports to the second assembly till there is only one degree of freedom left. There are several ways you could do that. One way is on the rectangular tube, you could apply a No Separation support to one flat face, and another No Separation support to the orthogonal face. That will leave just one degree of freedom for the tube to slide along its long axis. Another way is to add a Translational Joint under the Connections folder. That would be my choice.

I assume you want to push the blue metal spring form over the red solid block, and as Sandeep says, you what to select Frictional contact for that. Those two parts, and the part the spring clip fastens to are probably the only three parts needed to do the analysis. All the other parts don't do much except make the solution take longer. You can suppress all those other parts and move the supports nearer the action.

You would also be much better off creating a Displacement in the Z direction, and using many Substeps to gradually ramp that displacement from zero to its full amount. You can plot the Reaction Force that is needed to create this displacement.

Most important is that under Analysis Settings, you set Large Deflection to On.

If you want more help, it would be easier if you Attach a Workbench Project Archive .wbpz file to your reply after you post.

Regards,

Peter

-

August 2, 2018 at 3:37 pm

-

August 2, 2018 at 3:47 pm

peteroznewman

SubscriberThe contacts between the metal spring-form and the "plug" that is going into the spring-form should be Frictional Contacts.

You need Bonded Contacts between the spring-form and the arm it is attached to, and between the plug and the arm that is attached to.

Please show details of your Displacement. Which face(s) did you pick? Did you type in 0 instead of Free for the two sideway components to keep the arm aligned?

The metal spring-form must be meshed with a minimum of two elements through its thickness. There are mesh controls called Method Sweep that can do this. Please zoom in to the metal spring form and show the mesh.

It would be even better to go to DesignModeler or SpaceClaim and change the metal spring-form into a Midsurface representation, then the surface is assigned the thickness of the sheet metal and shell elements fill the surface.

Regards,

Peter

-

- The topic ‘Interaction between two different parts’ is closed to new replies.

- LPBF Simulation of dissimilar materials in ANSYS mechanical (Thermal Transient)

- Real Life Example of a non-symmetric eigenvalue problem

- How can the results of Pressures and Motions for all elements be obtained?

- BackGround Color

- Contact stiffness too big

- Element Birth and Death

- Python-Script to Export all Children of a Solution Tree

- Which equations and in what form are valid for defining excitations?

-

4592

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.